Torque Wrench Adapter - Reduced Indicated Torque Calculator

The Torque Wrench Adapter - Reduced Indicated Torque Calculator is a vital tool for professionals and DIY enthusiasts alike. When using a torque wrench adapter, it's essential to ensure that the correct torque is applied to avoid damage or safety risks. However, adapters can affect the indicated torque, leading to potential inaccuracies. This calculator helps users determine the reduced indicated torque when using an adapter, providing a reliable and efficient solution for various applications, from automotive to industrial settings, where precision and accuracy are crucial. It's a straightforward and user-friendly calculator.

-

Torque Wrench Adapter - Reduced Indicated Torque Calculator: Understanding the Essentials

- What is a Torque Wrench Adapter?

- How Does the Reduced Indicated Torque Calculator Work?

- Benefits of Using a Torque Wrench Adapter - Reduced Indicated Torque Calculator

- Common Applications of the Torque Wrench Adapter - Reduced Indicated Torque Calculator

- Best Practices for Using a Torque Wrench Adapter - Reduced Indicated Torque Calculator

- How do you calculate torque with a torque adapter?

- What is the 20 rule for torque wrenches?

-

Frequently Asked Questions (FAQs)

- What is the purpose of the Torque Wrench Adapter - Reduced Indicated Torque Calculator?

- How does the Torque Wrench Adapter - Reduced Indicated Torque Calculator work?

- What are the benefits of using the Torque Wrench Adapter - Reduced Indicated Torque Calculator?

- Can the Torque Wrench Adapter - Reduced Indicated Torque Calculator be used with different types of torque wrenches and adapters?

Torque Wrench Adapter - Reduced Indicated Torque Calculator: Understanding the Essentials

The Torque Wrench Adapter - Reduced Indicated Torque Calculator is a crucial tool in various industries, including engineering, manufacturing, and construction. It helps calculate the reduced indicated torque when using a torque wrench adapter, ensuring that the correct torque is applied to a bolt or nut. This calculator takes into account the adapter's efficiency and the wrench's capacity, providing an accurate torque value.

What is a Torque Wrench Adapter?

A torque wrench adapter is a device used to connect a torque wrench to a bolt or nut. It is designed to transfer torque from the wrench to the fastener, ensuring a secure connection. The adapter's efficiency is critical in determining the reduced indicated torque, as it can affect the accuracy of the calculation.

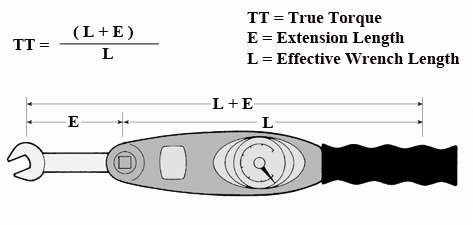

How Does the Reduced Indicated Torque Calculator Work?

The Reduced Indicated Torque Calculator works by using a formula that takes into account the adapter's efficiency, the wrench's capacity, and the desired torque. The calculator then provides the reduced indicated torque value, which is the torque that should be applied to the bolt or nut using the torque wrench adapter.

Benefits of Using a Torque Wrench Adapter - Reduced Indicated Torque Calculator

Using a Torque Wrench Adapter - Reduced Indicated Torque Calculator offers several benefits, including:

| Benefit | Description |

|---|---|

| Accuracy | Ensures that the correct torque is applied to the bolt or nut. |

| Efficiency | Helps to reduce waste and improve productivity by minimizing the risk of over-tightening or under-tightening. |

| Safety | Prevents accidents and injuries caused by over-tightening or under-tightening. |

Common Applications of the Torque Wrench Adapter - Reduced Indicated Torque Calculator

The Torque Wrench Adapter - Reduced Indicated Torque Calculator is commonly used in various industries, including:

| Industry | Description |

|---|---|

| Automotive | Used in vehicle maintenance and repair to ensure that bolts and nuts are tightened to the correct torque. |

| Aerospace | Used in aircraft maintenance and manufacturing to ensure that fasteners are tightened to the correct torque. |

| Construction | Used in building construction and renovation to ensure that bolts and nuts are tightened to the correct torque. |

Best Practices for Using a Torque Wrench Adapter - Reduced Indicated Torque Calculator

To get the most out of a Torque Wrench Adapter - Reduced Indicated Torque Calculator, it is essential to follow best practices, including:

| Best Practice | Description |

|---|---|

| Calibration | Regularly calibrate the torque wrench and adapter to ensure accuracy. |

| Training | Provide training to users on how to use the calculator and torque wrench adapter correctly. |

| Maintenance | Regularly maintain the torque wrench and adapter to ensure that they are in good working condition. |

How do you calculate torque with a torque adapter?

To calculate torque with a torque adapter, you need to understand the basic principle of how it works. A torque adapter is a device that measures the torque applied to a bolt or nut by converting the rotational force into a linear force that can be measured. The calculation involves multiplying the force applied to the adapter by the radius of the adapter.

Understanding Torque Adapter Types

There are different types of torque adapters available, each with its own unique characteristics. When calculating torque, it's essential to understand the type of adapter being used. Some common types include:

- Slip-type adapters, which slip when the torque limit is reached

- Click-type adapters, which produce a clicking sound when the torque limit is reached

- Digital adapters, which display the torque value on a screen

Measuring Force and Radius

To calculate torque, you need to measure the force applied to the adapter and the radius of the adapter. The force can be measured using a force gauge, while the radius can be measured using a caliper or ruler. It's crucial to ensure that the measurements are accurate, as any errors can affect the torque calculation.

- Force measurement: Use a force gauge to measure the force applied to the adapter

- Radius measurement: Use a caliper or ruler to measure the radius of the adapter

- Unit conversion: Ensure that the units of measurement are consistent, such as Newtons for force and meters for radius

Calculating Torque

Once you have measured the force and radius, you can calculate the torque using the formula: torque = force x radius. This formula is based on the principle that torque is equal to the rotational force multiplied by the distance from the axis of rotation.

- Torque formula: torque = force x radius

- Unit check: Ensure that the units of measurement are consistent, such as Newton-meters for torque

- Calculation: Plug in the values of force and radius into the formula to calculate the torque

Verifying Torque Adapter Accuracy

To ensure accurate torque measurements, it's essential to verify the accuracy of the torque adapter. This can be done by calibrating the adapter using a calibration standard or by comparing the measurements with a reference torque value.

- Calibration: Calibrate the torque adapter using a calibration standard

- Comparison: Compare the measurements with a reference torque value to ensure accuracy

- Certification: Obtain certification for the torque adapter to ensure compliance with industry standards

Troubleshooting Common Issues

When using a torque adapter, common issues may arise, such as inaccurate measurements or adapter damage. To troubleshoot these issues, it's essential to identify the root cause and take corrective action. This may involve recalibrating the adapter, replacing damaged components, or adjusting the force applied to the adapter.

- Inaccurate measurements: Check the calibration of the adapter and ensure that the measurements are consistent

- Adapter damage: Inspect the adapter for damage and replace any damaged components

- Force adjustment: Adjust the force applied to the adapter to ensure that it's within the recommended range

What is the 20 rule for torque wrenches?

The 20 rule for torque wrenches refers to the recommended practice of calibrating a torque wrench every 20 uses or every 12 months, whichever comes first, to ensure its accuracy and reliability. This rule is essential to maintain the precision and consistency of the torque wrench, as its calibration can drift over time due to various factors such as wear and tear, storage conditions, and usage patterns.

Torque Wrench Calibration

The calibration of a torque wrench is crucial to ensure its accuracy and reliability. A calibrated torque wrench can provide a precise measurement of the torque applied to a bolt or nut, which is essential in various industries such as automotive, aerospace, and manufacturing. The calibration process typically involves checking the torque wrench against a reference standard and making any necessary adjustments to ensure its accuracy. The following are some key points to consider when calibrating a torque wrench:

- The calibration process should be performed by a qualified technician or calibration laboratory.

- The torque wrench should be calibrated in accordance with the manufacturer's recommendations and industry standards.

- A record of the calibration should be kept, including the date, results, and any adjustments made.

Importance of Torque Wrench Accuracy

The accuracy of a torque wrench is essential to ensure the safety and reliability of a wide range of applications. In the automotive industry, for example, over-torquing or under-torquing a bolt or nut can lead to premature failure or accidents. In the aerospace industry, the precision of torque wrenches is critical to ensure the safety and reliability of aircraft and spacecraft. The following are some key points to consider when using a torque wrench:

- The torque wrench should be used in accordance with the manufacturer's instructions and recommendations.

- The correct socket or adapter should be used to ensure a secure connection to the bolt or nut.

- The torque wrench should be checked regularly for any signs of wear or damage.

Consequences of Not Following the 20 Rule

Not following the 20 rule for torque wrenches can have serious consequences, including inaccurate measurements, premature failure of bolts or nuts, and accidents. In the manufacturing industry, for example, inaccurate torque wrenches can lead to defective products and rework, resulting in costly delays and losses. The following are some key points to consider when not following the 20 rule:

- Inaccurate measurements can lead to premature failure of bolts or nuts, resulting in costly repairs and downtime.

- Over-torquing or under-torquing can lead to accidents and injuries, resulting in costly lawsuits and damages.

- Non-compliance with industry standards and regulations can result in fines and penalties.

Torque Wrench Maintenance and Storage

The maintenance and storage of torque wrenches are essential to ensure their accuracy and reliability. The following are some key points to consider when maintaining and storing torque wrenches:

- Torque wrenches should be stored in a clean, dry place, away from direct sunlight and extreme temperatures.

- Torque wrenches should be checked regularly for any signs of wear or damage, and maintained in accordance with the manufacturer's recommendations.

- Torque wrenches should be calibrated regularly, in accordance with the 20 rule, to ensure their accuracy and reliability.

Industry Standards and Regulations for Torque Wrenches

The use of torque wrenches is subject to various industry standards and regulations, which vary depending on the application and industry. The following are some key points to consider when using torque wrenches in different industries:

- The automotive industry is subject to industry standards such as SAE and ISO, which specify the requirements for torque wrenches used in vehicle maintenance and repair.

- The aerospace industry is subject to industry standards such as AS and NASA, which specify the requirements for torque wrenches used in aircraft and spacecraft maintenance and repair.

- The manufacturing industry is subject to industry standards such as ISO and ASTM, which specify the requirements for torque wrenches used in manufacturing and quality control.

Frequently Asked Questions (FAQs)

What is the purpose of the Torque Wrench Adapter - Reduced Indicated Torque Calculator?

The Torque Wrench Adapter - Reduced Indicated Torque Calculator is a tool designed to help users calculate the reduced indicated torque when using a torque wrench adapter. This calculator is essential in ensuring that the correct torque is applied to a fastener or bolt, taking into account the adapter's effect on the torque wrench's accuracy. By using this calculator, users can avoid over-tightening or under-tightening, which can lead to damage or failure of the fastener or surrounding material. The calculator is particularly useful in applications where precision and accuracy are crucial, such as in the automotive, aerospace, or industrial industries.

How does the Torque Wrench Adapter - Reduced Indicated Torque Calculator work?

The Torque Wrench Adapter - Reduced Indicated Torque Calculator works by taking into account the torque wrench's original torque setting and the adapter's ratio or multiplier. The user inputs the original torque setting and the adapter's ratio, and the calculator then calculates the reduced indicated torque. This calculation is based on the mechanical advantage of the adapter, which can either increase or decrease the torque applied to the fastener. The calculator uses complex algorithms and mathematical models to ensure that the calculation is accurate and reliable. By using this calculator, users can ensure that they are applying the correct torque to the fastener, even when using a torque wrench adapter.

What are the benefits of using the Torque Wrench Adapter - Reduced Indicated Torque Calculator?

The Torque Wrench Adapter - Reduced Indicated Torque Calculator offers several benefits to users. One of the primary benefits is increased accuracy, as the calculator ensures that the correct torque is applied to the fastener. This can help to prevent damage or failure of the fastener or surrounding material, which can be costly and time-consuming to repair. Another benefit is improved efficiency, as the calculator saves users time and effort by eliminating the need for trial and error or guesswork. Additionally, the calculator can help to reduce errors and improve quality control, which is particularly important in high-precision applications. Overall, the Torque Wrench Adapter - Reduced Indicated Torque Calculator is a valuable tool for anyone who uses a torque wrench adapter on a regular basis.

Can the Torque Wrench Adapter - Reduced Indicated Torque Calculator be used with different types of torque wrenches and adapters?

The Torque Wrench Adapter - Reduced Indicated Torque Calculator is designed to be versatile and can be used with different types of torque wrenches and adapters. The calculator can accommodate various torque wrench models and adapter ratios, making it a universal tool that can be used in a wide range of applications. Users can simply input the torque wrench's original torque setting and the adapter's ratio, and the calculator will perform the calculation. The calculator is also updateable, allowing users to add new torque wrench models or adapter ratios as needed. This makes the Torque Wrench Adapter - Reduced Indicated Torque Calculator a valuable resource for anyone who works with torque wrenches and adapters on a regular basis, including mechanics, technicians, and engineers.

Deja una respuesta

Entradas Relacionadas