Tap Drill Size as Percentage of Engagement Calculator

The Tap Drill Size as Percentage of Engagement Calculator is a valuable tool for determining the optimal tap drill size for various threading applications. By calculating the percentage of engagement, users can ensure a strong and reliable thread connection. This calculator takes into account the thread size, material, and desired engagement percentage to provide an accurate tap drill size. With its ease of use and precision, this calculator is an essential resource for engineers, machinists, and manufacturers working with threaded fasteners and components, helping to minimize errors and optimize production processes. It saves time and reduces threads failure.

-

Tap Drill Size as Percentage of Engagement Calculator: Understanding the Basics

- What is Thread Engagement and Why is it Important?

- How to Use the Tap Drill Size as Percentage of Engagement Calculator

- Factors that Affect Tap Drill Size

- Benefits of Using the Tap Drill Size as Percentage of Engagement Calculator

- Common Applications of the Tap Drill Size as Percentage of Engagement Calculator

- How to calculate percentage of thread engagement?

- What is the formula to calculate tap drill size?

- What is the rule of thumb for tap drill size?

- What percentage of thread is a tap drill?

-

Frequently Asked Questions (FAQs)

- What is the Tap Drill Size as Percentage of Engagement Calculator and how does it work?

- How do I use the Tap Drill Size as Percentage of Engagement Calculator to determine the optimal tap drill size?

- What are the benefits of using the Tap Drill Size as Percentage of Engagement Calculator in threading operations?

- Can the Tap Drill Size as Percentage of Engagement Calculator be used for different types of threads and materials?

Tap Drill Size as Percentage of Engagement Calculator: Understanding the Basics

The Tap Drill Size as Percentage of Engagement Calculator is a tool used to determine the optimal tap drill size for a given thread engagement. This calculator is essential in ensuring that the threads are properly formed and that the material is not damaged during the tapping process. The calculator takes into account the percentage of engagement, which is the ratio of the thread length to the diameter of the hole.

What is Thread Engagement and Why is it Important?

Thread engagement refers to the extent to which the threads of a screw or bolt engage with the threads of a hole. Proper thread engagement is crucial to ensure that the fastener is securely held in place and that the material is not damaged. The percentage of engagement is a critical factor in determining the strength and integrity of the joint.

How to Use the Tap Drill Size as Percentage of Engagement Calculator

To use the Tap Drill Size as Percentage of Engagement Calculator, the user must input the diameter of the hole, the thread length, and the desired percentage of engagement. The calculator will then output the optimal tap drill size. The user can then use this value to select the correct tap drill for the application.

Factors that Affect Tap Drill Size

Several factors can affect the optimal tap drill size, including the material being tapped, the thread type, and the desired percentage of engagement. For example, harder materials may require a smaller tap drill size to prevent breakage, while softer materials may require a larger tap drill size to ensure proper thread formation.

Benefits of Using the Tap Drill Size as Percentage of Engagement Calculator

The Tap Drill Size as Percentage of Engagement Calculator offers several benefits, including improved accuracy, increased efficiency, and reduced waste. By using the calculator, users can ensure that the tap drill size is optimal for the application, reducing the risk of errors and rework.

Common Applications of the Tap Drill Size as Percentage of Engagement Calculator

The Tap Drill Size as Percentage of Engagement Calculator is commonly used in a variety of applications, including aerospace, automotive, and industrial manufacturing. In these industries, precision and accuracy are critical, and the calculator helps to ensure that the tap drill size is optimal for the application.

| Material | Thread Type | Desired Percentage of Engagement | Optimal Tap Drill Size |

|---|---|---|---|

| Aluminum | Coarse Thread | 75% | 0.250 inches |

| Steel | Fine Thread | 50% | 0.200 inches |

| Copper | Coarse Thread | 90% | 0.300 inches |

How to calculate percentage of thread engagement?

To calculate the percentage of thread engagement, you need to analyze the metrics of a particular thread or conversation. This involves tracking the number of replies, likes, and shares a thread receives, as well as the total number of views or impressions. By comparing these engagement metrics to the total number of views or impressions, you can determine the percentage of users who are actively engaging with the thread.

Understanding Engagement Metrics

To calculate the percentage of thread engagement, you need to understand the different types of engagement metrics. These include replies, likes, shares, and views or impressions. Each of these metrics provides insight into how users are interacting with a thread. For example, a high number of replies indicates that users are actively participating in the conversation, while a high number of likes suggests that users find the content valuable or interesting. Some key points to consider when understanding engagement metrics include:

- Tracking replies to see how users are responding to a thread

- Monitoring likes to gauge user interest and approval

- Analyzing shares to determine how often users are distributing the content to others

Calculating Engagement Percentage

To calculate the percentage of thread engagement, you need to use a formula that compares the total number of engagement actions (such as replies, likes, and shares) to the total number of views or impressions. A common formula is: (total engagement actions / total views or impressions) x 100. This will give you a percentage that represents the proportion of users who are engaging with the thread. Some key steps in calculating engagement percentage include:

- Determining the total number of engagement actions (e.g., replies, likes, shares)

- Tracking the total number of views or impressions

- Applying the formula to calculate the engagement percentage

Using Engagement Data for Improvement

Once you have calculated the percentage of thread engagement, you can use this data to make improvements to your content or community management strategy. For example, if you find that a particular type of content is receiving high engagement, you may want to create more of that type of content. Alternatively, if you find that engagement is low, you may want to adjust your strategy to make your content more appealing or interactive. Some ways to use engagement data for improvement include:

- Analyzing engagement patterns to identify areas for improvement

- Adjusting content strategy to better meet user needs and interests

- Creating more interactive or engaging content to encourage user participation

Tools for Measuring Engagement

There are many tools available for measuring thread engagement, including social media analytics platforms and content management systems. These tools can help you track engagement metrics and calculate the percentage of thread engagement. Some popular tools for measuring engagement include:

- Social media analytics platforms like Hootsuite or Sprout Social

- Content management systems like WordPress or Drupal

- Specialized engagement tracking tools like BuzzSumo or Ahrefs

Best Practices for Increasing Engagement

To increase thread engagement, it's essential to follow best practices for creating engaging content and building a community. This includes using attention-grabbing headlines, asking questions, and encouraging user participation. Some key best practices for increasing engagement include:

- Creating high-quality, relevant, and valuable content

- Asking questions or requesting feedback to encourage user participation

- Responding to user comments and messages in a timely and personalized manner

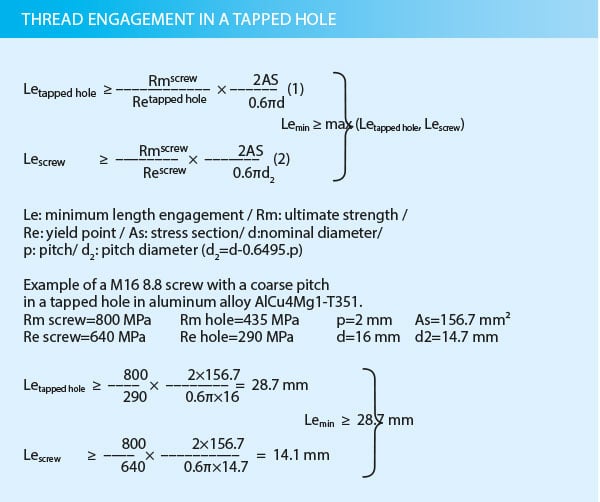

What is the formula to calculate tap drill size?

The formula to calculate tap drill size is based on the type of thread being tapped and the material being worked with. The general formula for calculating tap drill size is: Tap Drill Size = Major Diameter - (1 x pitch), where pitch is the distance between threads. This formula is used to determine the diameter of the hole that needs to be drilled before tapping a thread into a material.

Understanding Pitch and Its Impact on Tap Drill Size

The pitch of a thread is a critical factor in determining the tap drill size. A thread with a finer pitch requires a smaller tap drill size, while a thread with a coarser pitch requires a! larger tap drill size. To calculate the tap drill size, you need to know the major diameter of the thread and the pitch. The formula can be applied as follows:

- Measure the major diameter of the thread

- Determine the pitch of the thread

- Apply the formula to calculate the tap drill size

Importance of Material in Tap Drill Size Calculation

The material being worked with is also a crucial factor in determining the tap drill size. Different materials have different hardness and density levels, which affect the drilling and tapping process. For example, harder materials like steel require a smaller tap drill size, while softer materials like aluminum require a larger tap drill size. The calculation of tap drill size must take into account the material properties to ensure a successful tapping process:

- Determine the material type and its properties

- Adjust the tap drill size calculation based on the material characteristics

- Consider the thread type and pitch when calculating the tap drill size

Thread Type and Its Effect on Tap Drill Size

The thread type is another important factor in determining the tap drill size. Different thread types, such as metric or imperial, have different thread forms and pitches. The tap drill size calculation must be adjusted according to the thread type being used. For example, a metric thread requires a different tap drill size calculation than an imperial thread:

- Identify the thread type being used

- Determine the thread form and pitch

- Apply the correct formula to calculate the tap drill size

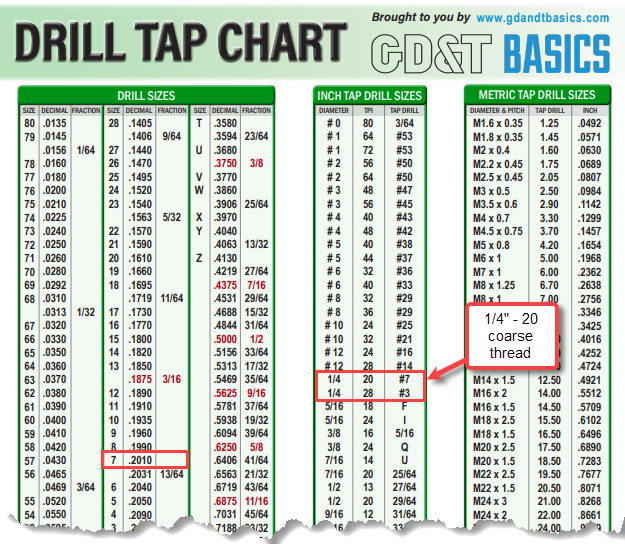

Using Tap Drill Size Charts and Tables

Tap drill size charts and tables are useful tools for determining the correct tap drill size. These charts and tables provide a quick reference for calculating tap drill sizes based on the thread type, pitch, and material. By using these charts and tables, you can avoid errors and ensure a successful tapping process:

- Choose the correct tap drill size chart or table

- Find the thread type and pitch on the chart or table

- Read the recommended tap drill size from the chart or table

Best Practices for Tap Drill Size Calculation

To ensure a successful tapping process, it is essential to follow best practices for tap drill size calculation. This includes double-checking calculations, using high-quality drills and taps, and monitoring the tapping process for any signs of errors or problems. By following these best practices, you can minimize the risk of tap breakage or thread damage:

- Double-check calculations to ensure accuracy

- Use high-quality drills and taps to minimize wear and tear

- Monitor the tapping process for any signs of errors or problems

What is the rule of thumb for tap drill size?

The rule of thumb for tap drill size is to use a drill bit that is slightly smaller than the tap itself. This allows for the tap to cut threads into the material without binding or breaking. The tap drill size chart is a useful tool for determining the correct drill bit size for a specific tap. It takes into account the thread pitch and diameter of the tap to provide the recommended drill bit size.

Understanding Tap Drill Size Charts

To determine the correct tap drill size, it is essential to understand how to read a tap drill size chart. The chart lists the tap size and the corresponding drill bit size. The drill bit size is usually smaller than the tap size to allow for the tap to cut threads into the material. Here are some key points to consider when using a tap drill size chart:

- The tap drill size chart is specific to the type of tap being used, such as a metric tap or a SAE tap.

- The chart takes into account the thread pitch and diameter of the tap.

- The recommended drill bit size is usually smaller than the tap size to allow for the tap to cut threads into the material.

Factors Affecting Tap Drill Size

Several factors can affect the tap drill size, including the type of material being tapped, the thread pitch, and the diameter of the tap. For example, hard materials such as steel or aluminum may require a smaller drill bit size than soft materials such as copper or brass. Here are some factors to consider when determining the tap drill size:

- The type of material being tapped can affect the tap drill size.

- The thread pitch and diameter of the tap can also affect the tap drill size.

- The desired thread depth can also impact the tap drill size.

Tap Drill Size for Common Threads

The tap drill size for common threads such as 1/4-20 or M6 can be found on a tap drill size chart. The chart lists the tap size and the corresponding drill bit size. For example, the tap drill size for a 1/4-20 tap is usually a 7 drill bit. Here are some common tap sizes and their corresponding drill bit sizes:

- 1/4-20 tap: 7 drill bit

- M6 tap: 5mm drill bit

- 1/2-13 tap: 1/2 drill bit

Importance of Using the Correct Tap Drill Size

Using the correct tap drill size is crucial to ensure that the tap cuts threads into the material correctly. If the drill bit size is too large, the tap may not cut threads properly, resulting in a stripped thread. On the other hand, if the drill bit size is too small, the tap may bind or break. Here are some reasons why using the correct tap drill size is important:

- Prevents stripped threads

- Prevents tap breakage

- Ensures proper thread formation

Troubleshooting Common Tap Drill Size Issues

Common issues with tap drill size include stripped threads, tap breakage, and improper thread formation. To troubleshoot these issues, it is essential to check the tap drill size chart and ensure that the correct drill bit size is being used. Here are some common issues and their solutions:

- Stripped threads: check the tap drill size chart and ensure the correct drill bit size is being used.

- Tap breakage: check the tap drill size chart and ensure the correct drill bit size is being used, and also check the tap for any damage or wear.

- Improper thread formation: check the tap drill size chart and ensure the correct drill bit size is being used, and also check the tap for any damage or wear.

What percentage of thread is a tap drill?

The percentage of thread that a tap drill is can vary depending on the specific application and type of thread being created. Typically, a tap drill is used to create a threaded hole that is slightly smaller than the desired thread size, with the tap drill removing a small amount of material to create the thread. The percentage of thread that a tap drill is can range from 70% to 90% of the total thread size, depending on the thread pitch and diameter of the hole being created.

Understanding Tap Drill Percentages

The percentage of thread that a tap drill is can be affected by several factors, including the material being drilled and the desired thread size. To determine the correct tap drill percentage, it is necessary to consider the thread type and class of fit, as well as the drill bit material and coolant being used. Some common tap drill percentages include:

- 75% for coarse thread pitches and large diameter holes

- 80% for fine thread pitches and medium diameter holes

- 85% for extra fine thread pitches and small diameter holes

Factors Affecting Tap Drill Percentage

The percentage of thread that a tap drill is can be influenced by several factors, including the drill bit angle and point style, as well as the material hardness and surface finish. To achieve the correct tap drill percentage, it is necessary to consider the thread engagement and thread relief, as well as the tap drill flute and cutting edge. Some common factors that can affect tap drill percentage include:

- Drill bit wear and dullness, which can increase the tap drill percentage

- Material hardness and toughness, which can decrease the tap drill percentage

- Thread pitch and diameter, which can affect the tap drill percentage and thread engagement

Tap Drill Percentage and Thread Engagement

The percentage of thread that a tap drill is can have a significant impact on the thread engagement and thread strength. A higher tap drill percentage can result in a stronger thread, but can also increase the risk of thread stripping and material failure. To achieve the correct tap drill percentage and thread engagement, it is necessary to consider the thread type and class of fit, as well as the material properties and drill bit characteristics. Some common thread engagements include:

- Class 1 threads, which have a low thread engagement and are suitable for loose fits

- Class 2 threads, which have a medium thread engagement and are suitable for medium fits

- Class 3 threads, which have a high thread engagement and are suitable for tight fits

Calculating Tap Drill Percentage

The percentage of thread that a tap drill is can be calculated using a variety of formulas and equations, including the thread pitch and diameter of the hole being created. To calculate the tap drill percentage, it is necessary to consider the thread type and class of fit, as well as the material properties and drill bit characteristics. Some common formulas for calculating tap drill percentage include:

- Tap drill percentage = (thread pitch x diameter) / (thread pitch + diameter)

- Tap drill percentage = (1 - (thread pitch / diameter)) x 100

- Tap drill percentage = (thread engagement / thread pitch) x 100

Tap Drill Percentage and Material Properties

The percentage of thread that a tap drill is can be affected by the material properties of the workpiece being drilled, including the hardness, toughness, and surface finish. To achieve the correct tap drill percentage and thread engagement, it is necessary to consider the material composition and microstructure, as well as the drill bit material and coolant being used. Some common material properties that can affect tap drill percentage include:

- Hardness, which can increase the tap drill percentage and thread engagement

- Toughness, which can decrease the tap drill percentage and thread engagement

- Surface finish, which can affect the tap drill percentage and thread engagement

Frequently Asked Questions (FAQs)

What is the Tap Drill Size as Percentage of Engagement Calculator and how does it work?

The Tap Drill Size as Percentage of Engagement Calculator is a tool used to determine the optimal tap drill size for a given thread engagement. It calculates the percentage of engagement based on the tap drill size, thread size, and thread engagement length. This calculator is essential in threading operations to ensure that the threads are strong and durable. By using this calculator, users can determine the ideal tap drill size to achieve the desired percentage of engagement, which is crucial in ensuring the integrity of the threads. The calculator takes into account the material properties and thread geometry to provide an accurate calculation of the percentage of engagement.

How do I use the Tap Drill Size as Percentage of Engagement Calculator to determine the optimal tap drill size?

To use the Tap Drill Size as Percentage of Engagement Calculator, users need to input the thread size, thread engagement length, and desired percentage of engagement. The calculator will then calculate the optimal tap drill size based on these inputs. The thread size is the diameter of the thread, and the thread engagement length is the length of the thread that is engaged with the tap. The desired percentage of engagement is the percentage of the thread engagement length that the user wants to achieve. Once the user inputs these values, the calculator will provide the optimal tap drill size as a percentage of the thread size. This percentage can then be used to determine the actual tap drill size required to achieve the desired percentage of engagement. It is essential to use precise values when inputting the data to ensure accurate results.

What are the benefits of using the Tap Drill Size as Percentage of Engagement Calculator in threading operations?

The Tap Drill Size as Percentage of Engagement Calculator provides several benefits in threading operations. One of the primary benefits is that it helps to ensure the integrity of the threads by providing an accurate calculation of the percentage of engagement. This is crucial in threading operations where strong and durable threads are required. The calculator also helps to reduce errors and improve efficiency by providing a quick and easy-to-use method for determining the optimal tap drill size. Additionally, the calculator can help to optimize the threading process by allowing users to experiment with different tap drill sizes and thread engagement lengths to achieve the desired percentage of engagement. By using this calculator, users can improve the quality of their threads and reduce the risk of thread failure.

Can the Tap Drill Size as Percentage of Engagement Calculator be used for different types of threads and materials?

Yes, the Tap Drill Size as Percentage of Engagement Calculator can be used for different types of threads and materials. The calculator is versatile and can be used for a wide range of threading applications, including metric, imperial, and specialty threads. The calculator can also be used for different materials, such as steel, aluminum, and plastics. However, it is essential to note that the calculator's accuracy may be affected by the specific material properties and thread geometry. Therefore, users should consult the calculator's documentation and material specifications to ensure that the calculator is configured correctly for their specific threading application. Additionally, users may need to adjust the calculator's inputs to account for specific material properties, such as hardness and density, to ensure accurate results. By using the calculator in conjunction with material specifications and threading standards, users can achieve accurate and reliable results for a wide range of threading applications.

Deja una respuesta

Entradas Relacionadas