Spur Gear Calculator and Generator Download DXF, SVG or CSV Excel format files

Designing spur gears requires precise calculations to ensure proper tooth engagement and smooth operation. A spur gear calculator is a valuable tool for engineers and machinists, allowing them to quickly generate custom gear designs. The Spur Gear Calculator and Generator takes this a step further, enabling users to download their designs in various formats, including DXF, SVG, and CSV Excel files. This makes it easy to integrate the gear design into larger projects and manufacture the gears with precision. With its user-friendly interface and flexible output options, this calculator is an essential resource for gear design.

- Spur Gear Calculator and Generator: A Comprehensive Tool for Engineering Applications

- Is gear generator free?

- How to create spur gear?

- What is the formula for calculating gear design?

-

Frequently Asked Questions (FAQs)

- What is the purpose of the Spur Gear Calculator and Generator?

- What file formats are supported by the Spur Gear Calculator and Generator?

- How do I use the Spur Gear Calculator and Generator to create custom gear designs?

- What are the benefits of using the Spur Gear Calculator and Generator for gear design?

Spur Gear Calculator and Generator: A Comprehensive Tool for Engineering Applications

The Spur Gear Calculator and Generator is a versatile tool designed to facilitate the creation and analysis of spur gears, a crucial component in various mechanical systems. This calculator and generator enable users to download files in DXF, SVG, or CSV Excel format, making it an indispensable resource for engineers and designers. The tool's primary function is to calculate the dimensions and parameters of spur gears based on user-inputted values, ensuring accuracy and precision in the design process.

Introduction to Spur Gear Calculator and Generator

The Spur Gear Calculator and Generator is an online tool that allows users to input specific parameters, such as the number of teeth, pitch diameter, and pressure angle, to calculate the dimensions of a spur gear. The tool then generates a file in the desired format, which can be downloaded and used in computer-aided design (CAD) software or other engineering applications. The calculator and generator are particularly useful for engineers and designers working on projects involving mechanical transmissions, gearboxes, and other mechanical systems.

Key Features of the Spur Gear Calculator and Generator

The Spur Gear Calculator and Generator offers several key features that make it an essential tool for engineering applications. These features include:

| Feature | Description |

|---|---|

| Gear Parameters Calculation | Calculates the dimensions and parameters of spur gears based on user-inputted values |

| File Generation | Generates files in DXF, SVG, or CSV Excel format for use in CAD software or other engineering applications |

| User-Friendly Interface | Provides an intuitive and easy-to-use interface for inputting parameters and generating files |

Benefits of Using the Spur Gear Calculator and Generator

The Spur Gear Calculator and Generator offers several benefits to engineers and designers, including:

Increased Accuracy: The tool ensures accurate calculations and dimensions, reducing the risk of errors in the design process

Time Savings: The calculator and generator save time by automating the calculation and file generation process

Improved Efficiency: The tool enables users to quickly generate files in the desired format, streamlining the design and engineering process

Applications of the Spur Gear Calculator and Generator

The Spur Gear Calculator and Generator has a wide range of applications in various industries, including:

Mechanical Engineering: The tool is used in the design and analysis of mechanical systems, such as gearboxes and transmissions

Aerospace Engineering: The calculator and generator are used in the design of aircraft and spacecraft components

Automotive Engineering: The tool is used in the design and development of vehicle transmissions and gearboxes

Future Developments and Enhancements

The Spur Gear Calculator and Generator is a constantly evolving tool, with future developments and enhancements aimed at improving its functionality and user experience. Some potential enhancements include:

Additional File Formats: The tool may be updated to generate files in additional formats, such as STEP or IGES

Advanced Calculation Features: The calculator and generator may be enhanced to include more advanced calculation features, such as dynamic simulation or stress analysis

Is gear generator free?

The Gear Generator is a free online tool that allows users to create and design custom gears for various applications. While the basic version of the Gear Generator is free, there are some limitations and restrictions on its use. The free version is suitable for simple gear design and calculation, but it may not be sufficient for more complex designs or commercial use.

Features of the Free Version

The free version of the Gear Generator includes a range of features, such as the ability to design and calculate spur gears, helical gears, and bevel gears. Some of the key features of the free version include:

- Gear design: The ability to design and calculate custom gears based on user-inputted parameters.

- Material selection: The option to select from a range of materials, including steel, aluminum, and plastics.

- Calculation of gear properties: The ability to calculate gear ratio, pitch circle diameter, and tooth thickness.

Limitations of the Free Version

While the free version of the Gear Generator is useful for simple gear design, it has some limitations that may restrict its use for more complex applications. Some of the limitations of the free version include:

- Limited gear types: The free version only includes a limited range of gear types, including spur gears and helical gears.

- Limited material options: The free version only includes a limited range of materials, which may not be suitable for all applications.

- Limited calculation options: The free version only includes a limited range of calculation options, which may not be sufficient for more complex gear designs.

Upgrading to the Paid Version

For users who require more advanced features and capabilities, the Gear Generator offers a paid version that includes a range of additional features and tools. Some of the key benefits of upgrading to the paid version include:

- Advanced gear design: The ability to design and calculate more complex gear types, including worm gears and planetary gears.

- Additional material options: The option to select from a wider range of materials, including exotic materials and custom materials.

- Advanced calculation options: The ability to perform more complex calculations, including stress analysis and dynamic simulation.

Applications of the Gear Generator

The Gear Generator is a versatile tool that can be used in a range of applications, including mechanical engineering, aerospace engineering, and automotive engineering. Some of the key applications of the Gear Generator include:

- Gear design: The design and calculation of custom gears for use in a range of applications, including robotics and mechanical systems.

- Mechanical systems: The design and analysis of mechanical systems, including transmissions and gearboxes.

- Aerospace engineering: The design and analysis of gear systems for use in aircraft and spacecraft.

Alternatives to the Gear Generator

For users who are looking for alternatives to the Gear Generator, there are a range of other tools and software packages available, including SolidWorks and Autodesk Inventor. Some of the key benefits of using alternative tools include:

- Advanced features: The ability to access more advanced features and tools, including 3D modeling and finite element analysis.

- Broader range of applications: The ability to use the tool in a broader range of applications, including architecture and product design.

- Improved user interface: The ability to use a more intuitive and user-friendly interface, including drag-and-drop functionality and real-time feedback.

How to create spur gear?

To create a spur gear, you need to follow a series of steps that involve designing, manufacturing, and assembling the gear. The process begins with designing the gear, taking into account the torque and speed requirements of the application. This involves calculating the pitch circle diameter, tooth count, and module to ensure that the gear can transmit the required power efficiently.

Designing the Spur Gear

Designing a spur gear requires careful consideration of several factors, including the gear ratio, tooth profile, and material selection. The design process typically involves using computer-aided design (CAD) software to create a digital model of the gear. The key factors to consider when designing a spur gear are:

- Tooth count: The number of teeth on the gear, which determines the gear ratio and torque capacity.

- Pitch circle diameter: The diameter of the circle that passes through the center of each tooth, which determines the speed and torque of the gear.

- Module: The ratio of the pitch circle diameter to the tooth count, which determines the size and strength of the gear.

Manufacturing the Spur Gear

Manufacturing a spur gear typically involves using a combination of machining and grinding processes to produce the gear teeth and hub. The manufacturing process typically involves:

- Hobbing: A machining process that uses a hob to cut the gear teeth.

- Grinding: A process that uses an abrasive wheel to refine the gear teeth and achieve the required surface finish.

- Heat treatment: A process that involves heating the gear to achieve the required hardness and strength.

Assembling the Spur Gear

Assembling a spur gear typically involves mounting the gear on a shaft or hub and securing it with fasteners or adhesives. The assembly process typically involves:

- Inspection: Verifying that the gear is free from defects and meets the required specifications.

- Cleaning: Cleaning the gear to remove any debris or contaminants that may affect its performance.

- Lubrication: Applying a lubricant to the gear to reduce wear and friction.

Testing the Spur Gear

Testing a spur gear typically involves evaluating its performance under load and speed conditions. The testing process typically involves:

- Torque testing: Measuring the torque capacity of the gear to ensure that it can transmit the required power.

- Speed testing: Measuring the speed of the gear to ensure that it can operate within the required range.

- Endurance testing: Subjecting the gear to cycles of load and unload to evaluate its reliability and durability.

Maintaining the Spur Gear

Maintaining a spur gear typically involves regularly inspecting and lubricating the gear to prevent wear and corrosion. The maintenance process typically involves:

- Visual inspection: Visually inspecting the gear for signs of wear or damage.

- Lubrication: Applying a lubricant to the gear to reduce friction and wear.

- Replacement: Replacing the gear or its components if they become damaged or worn.

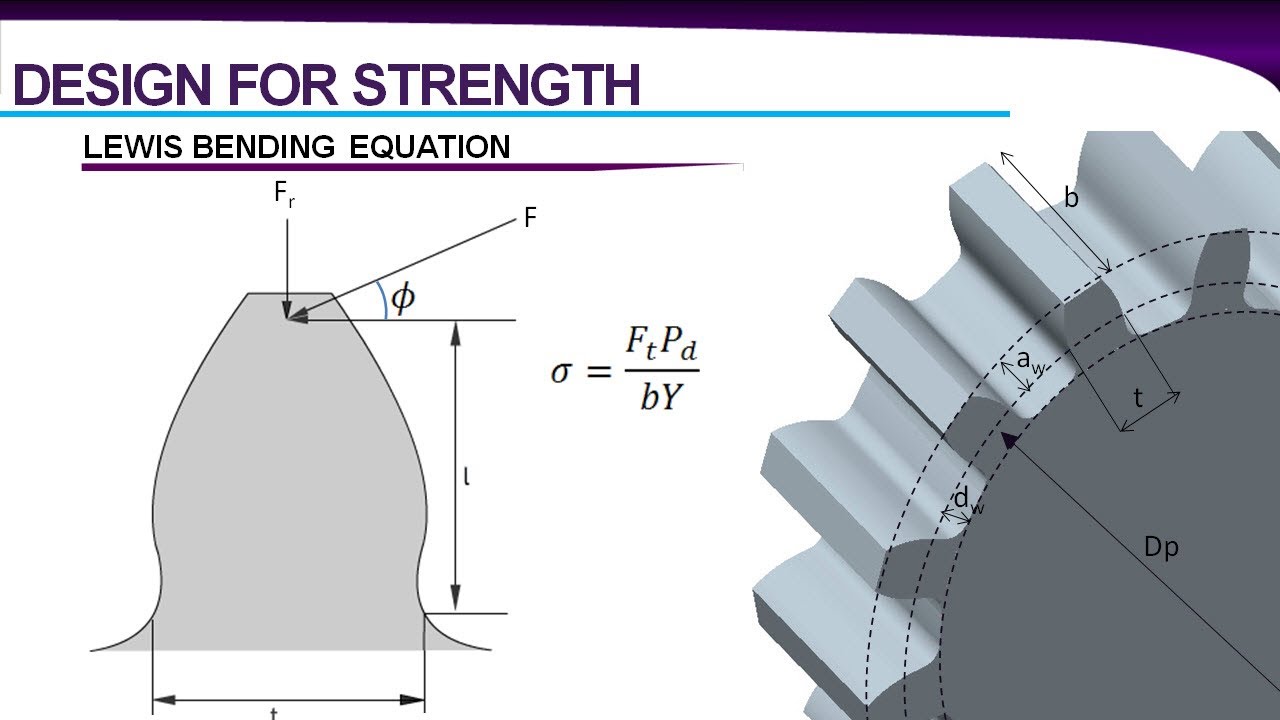

What is the formula for calculating gear design?

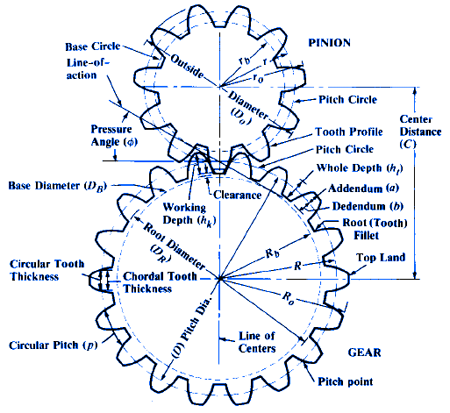

The formula for calculating gear design involves several parameters, including the number of teeth, pitch diameter, and pressure angle. The gear ratio is calculated by dividing the number of teeth on the output gear by the number of teeth on the input gear. Additionally, the pitch circle diameter is calculated using the formula: Pitch Circle Diameter = (Number of Teeth x Pitch) / (π x gear ratio).

Gear Design Fundamentals

The fundamentals of gear design involve understanding the relationship between the gear teeth, pitch diameter, and pressure angle. The gear teeth are the individual components that mesh together to transmit power, while the pitch diameter is the diameter of the circle that passes through the center of the gear teeth. The pressure angle is the angle between the gear teeth and the pitch circle. Some key considerations include:

- Gear ratio: The ratio of the number of teeth on the output gear to the number of teeth on the input gear.

- Pitch circle diameter: The diameter of the circle that passes through the center of the gear teeth.

- Pressure angle: The angle between the gear teeth and the pitch circle.

Gear Tooth Profiles

The gear tooth profiles play a crucial role in determining the gear design. The involute curve is the most common profile used in gear design, as it provides a smooth and efficient transmission of power. The!involute curve is defined by the base circle, which is the circle that passes through the center of the gear teeth. Some key considerations include:

- Involute curve: The curve that defines the shape of the gear teeth.

- Base circle: The circle that passes through the center of the gear teeth.

- Tooth thickness: The thickness of the gear teeth at the pitch circle.

Gear Materials and Manufacturing

The gear materials and manufacturing processes used can significantly impact the gear design. Steel and aluminum are commonly used materials for gears, due to their high strength and durability. The manufacturing processes used can include die casting, machining, and grinding. Some key considerations include:

- Material selection: The selection of the gear material based on the application and required strength.

- Manufacturing process: The process used to create the gear, including die casting, machining, and grinding.

- Surface finish: The surface finish of the gear teeth, which can impact the efficiency and noise of the gear.

Gear Design Software

Gear design software can be used to calculate and optimize the gear design. This software can take into account various parameters, including the gear ratio, pitch circle diameter, and pressure angle. Some key considerations include:

- Gear design calculations: The calculations used to determine the gear design, including the gear ratio and pitch circle diameter.

- Optimization: The process of optimizing the gear design to meet specific requirements, such as efficiency and noise reduction.

- Simulation: The use of simulation software to test and validate the gear design.

Gear Design Standards

Gear design standards provide guidelines for the design, manufacturing, and testing of gears. These standards can include specifications for the gear teeth, pitch circle diameter, and pressure angle. Some key considerations include:

- AGMA standards: The standards set by the American Gear Manufacturers Association (AGMA) for gear design and manufacturing.

- ISO standards: The standards set by the International Organization for Standardization (ISO) for gear design and manufacturing.

- Testing and inspection: The procedures used to test and inspect the gears to ensure they meet the required standards.

Frequently Asked Questions (FAQs)

What is the purpose of the Spur Gear Calculator and Generator?

The Spur Gear Calculator and Generator is a tool designed to help users calculate and generate spur gear parameters, which are essential components in various mechanical systems, including transmissions, gearboxes, and mechanical advantage systems. This calculator allows users to input specific values, such as pitch diameter, number of teeth, and pressure angle, to calculate other important parameters, including gear ratio, tooth thickness, and pitch circle diameter. By using this calculator, users can ensure that their gear designs are accurate and functional, which is critical for achieving optimal performance and efficiency in their mechanical systems.

What file formats are supported by the Spur Gear Calculator and Generator?

The Spur Gear Calculator and Generator supports the download of files in various formats, including DXF, SVG, and CSV Excel formats. These file formats are widely used in computer-aided design (CAD) software, graphic design, and data analysis applications. By supporting these formats, the calculator allows users to easily import and export their gear designs, making it simple to integrate them into existing projects or share them with others. For example, users can download their gear designs in DXF format and import them into Autodesk AutoCAD or other CAD software for further editing and refinement. Alternatively, users can download their designs in SVG format and use them in graphic design applications, such as Adobe Illustrator.

How do I use the Spur Gear Calculator and Generator to create custom gear designs?

To use the Spur Gear Calculator and Generator, users can simply input their desired gear parameters, such as number of teeth, pitch diameter, and pressure angle, into the calculator's input fields. The calculator will then calculate the corresponding gear parameters, including gear ratio, tooth thickness, and pitch circle diameter. Users can also select from various gear types, including standard, high-precision, and custom gears. Once the calculations are complete, users can download their gear designs in their preferred file format, such as DXF, SVG, or CSV Excel. Additionally, users can refine their designs by adjusting the input parameters and recalculating the results, allowing them to iterate on their designs until they achieve the desired performance and accuracy.

What are the benefits of using the Spur Gear Calculator and Generator for gear design?

The Spur Gear Calculator and Generator offers several benefits for users involved in gear design and mechanical engineering. One of the primary benefits is the ability to quickly and accurately calculate gear parameters, which can save users a significant amount of time and effort. Additionally, the calculator helps users to avoid errors and miscalculations, which can lead to inefficient or non-functional gear designs. By using the calculator, users can also optimize their gear designs for specific applications, such as high-speed or high-torque applications. Furthermore, the calculator's ability to generate files in various formats makes it easy for users to collaborate with others and integrate their gear designs into larger projects, which can help to streamline the design and development process. Overall, the Spur Gear Calculator and Generator is a valuable tool for anyone involved in gear design and mechanical engineering, as it can help to improve the accuracy, efficiency, and performance of their gear designs.

Deja una respuesta

Entradas Relacionadas