Rotating Mass Torque Equation and Calculator

The Rotating Mass Torque Equation is a fundamental concept in physics and engineering, describing the rotational motion of an object. It is a mathematical formula that calculates the torque, or rotational force, exerted on a rotating mass. The equation takes into account the mass, radius, and angular acceleration of the object. This article will delve into the Rotating Mass Torque Equation, providing an in-depth explanation and a calculator to help simplify the calculation process for various applications, from machinery design to scientific research. Understanding this concept is crucial for optimal system performance and efficiency.

- Understanding Rotating Mass Torque Equation and Calculator

- How do you calculate torque for rotating mass?

- How do you calculate rotary torque?

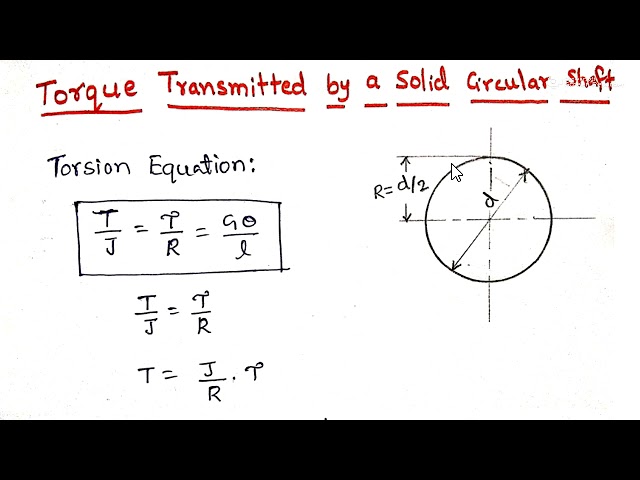

- What is the formula for torque of a rotating shaft?

-

Frequently Asked Questions (FAQs)

- What is the Rotating Mass Torque Equation and how is it used in calculations?

- How does the Rotating Mass Torque Equation and Calculator help in designing rotating systems?

- What are the key factors that affect the calculation of torque using the Rotating Mass Torque Equation?

- How can the Rotating Mass Torque Equation and Calculator be applied in real-world scenarios?

Understanding Rotating Mass Torque Equation and Calculator

The Rotating Mass Torque Equation and Calculator are essential tools in the field of physics and engineering, particularly in the study of rotational motion. The torque of a rotating mass is a measure of the force that causes it to rotate, and is calculated using the formula: τ = r x F, where τ is the torque, r is the radius of rotation, and F is the force applied. The Rotating Mass Torque Equation is a more complex formula that takes into account the moment of inertia of the rotating mass, as well as the angular acceleration.

Introduction to Rotating Mass Torque Equation

The Rotating Mass Torque Equation is a fundamental concept in physics and engineering, and is used to calculate the torque of a rotating mass. The equation is: τ = Iα, where τ is the torque, I is the moment of inertia, and α is the angular acceleration. This equation is used to calculate the torque of a rotating mass, and is essential in the design and analysis of rotating systems.

Understanding Moment of Inertia

The moment of inertia is a measure of the resistance of a rotating mass to changes in its rotational motion. It is calculated using the formula: I = mr^2, where I is the moment of inertia, m is the mass of the object, and r is the radius of rotation. The moment of inertia is an important factor in the calculation of the torque of a rotating mass.

Calculating Angular Acceleration

The angular acceleration is a measure of the rate of change of the angular velocity of a rotating mass. It is calculated using the formula: α = Δω / Δt, where α is the angular acceleration, Δω is the change in angular velocity, and Δt is the time over which the change occurs. The angular acceleration is an important factor in the calculation of the torque of a rotating mass.

Using the Rotating Mass Torque Calculator

The Rotating Mass Torque Calculator is a tool used to calculate the torque of a rotating mass. It takes into account the moment of inertia and angular acceleration of the rotating mass, and uses the formula: τ = Iα to calculate the torque. The calculator is an essential tool in the design and analysis of rotating systems, and is used to ensure that the torque of a rotating mass is within safe and acceptable limits.

Applications of Rotating Mass Torque Equation

The Rotating Mass Torque Equation has a wide range of applications in physics and engineering, including the design and analysis of rotating machinery, such as engines and gearboxes. It is also used in the calculation of the torque of rotating shafts and axles, and is an essential tool in the design and analysis of rotating systems. The following table shows some of the key applications of the Rotating Mass Torque Equation:

| Application | Description |

|---|---|

| Rotating Machinery | Design and analysis of engines and gearboxes |

| Rotating Shafts | Calculation of the torque of rotating shafts and axles |

| Rotating Systems | Design and analysis of rotating systems, including pumps and turbines |

How do you calculate torque for rotating mass?

To calculate torque for a rotating mass, you need to understand the concept of moment of inertia and angular velocity. The torque of an object is a measure of the rotational force that causes it to rotate or change its angular velocity. The formula to calculate torque is: τ = r x F, where τ is the torque, r is the radius of rotation, and F is the force applied.

Understanding Moment of Inertia

The moment of inertia of an object is a measure of its resistance to changes in its angular velocity. To calculate the torque of a rotating mass, you need to understand the moment of inertia of the object. The moment of inertia depends on the mass distribution of the object and its radius of rotation. The formula to calculate the moment of inertia is: I = ∫r^2 dm, where I is the moment of inertia, r is the radius of rotation, and dm is the mass element.

- The moment of inertia is a critical parameter in calculating the torque of a rotating mass.

- The moment of inertia depends on the mass distribution of the object and its radius of rotation.

- The formula to calculate the moment of inertia is: I = ∫r^2 dm.

Calculating Angular Velocity

The angular velocity of an object is a measure of its rotational speed. To calculate the torque of a rotating mass, you need to understand the angular velocity of the object. The angular velocity can be calculated using the formula: ω = Δθ / Δt, where ω is the angular velocity, Δθ is the angular displacement, and Δt is the time interval.

- The angular velocity is a critical parameter in calculating the torque of a rotating mass.

- The angular velocity depends on the angular displacement and the time interval.

- The formula to calculate the angular velocity is: ω = Δθ / Δt.

Applying the Torque Formula

To calculate the torque of a rotating mass, you can use the formula: τ = r x F, where τ is the torque, r is the radius of rotation, and F is the force applied. The torque can also be calculated using the formula: τ = I x α, where I is the moment of inertia, and α is the angular acceleration.

- The torque formula can be applied to calculate the rotational force of an object.

- The torque depends on the radius of rotation and the force applied.

- The formula to calculate the torque is: τ = r x F or τ = I x α.

Mass Distribution and Radius of Rotation

The mass distribution of an object and its radius of rotation play a crucial role in calculating the torque of a rotating mass. The moment of inertia depends on the mass distribution and the radius of rotation. A larger radius of rotation results in a greater moment of inertia, which in turn affects the torque of the object.

- The mass distribution of an object affects the torque of a rotating mass.

- The radius of rotation plays a crucial role in calculating the torque.

- A larger radius of rotation results in a greater moment of inertia.

Real-World Applications of Torque Calculation

The calculation of torque is essential in various real-world applications, such as engine design, gear systems, and robotics. In engine design, the torque calculation is critical in determining the engine's power output and efficiency. In gear systems, the torque calculation is used to determine the gear ratio and transmission efficiency.

- The calculation of torque is essential in engine design.

- The torque calculation is used to determine the gear ratio and transmission efficiency in gear systems.

- The torque calculation has various real-world applications, including robotics and mechanical engineering.

How do you calculate rotary torque?

To calculate rotary torque, you need to understand the relationship between force, distance, and angle. Rotary torque is a measure of the twisting force that causes an object to rotate. It is typically measured in units of newton-meters (Nm) or foot-pounds (ft-lb). The calculation of rotary torque involves multiplying the force applied to an object by the distance from the axis of rotation to the point where the force is applied, and then multiplying the result by the sin of the angle between the force and the distance.

Understanding the Basics of Rotary Torque

The calculation of rotary torque requires a basic understanding of the concepts of mechanics and physics. The formula for calculating rotary torque is: Torque (τ) = r x F, where r is the distance from the axis of rotation to the point where the force is applied, and F is the force applied. The following steps are involved in calculating rotary torque:

- Identify the force applied to the object

- Determine the distance from the axis of rotation to the point where the force is applied

- Calculate the torque using the formula: Torque (τ) = r x F

Factors Affecting Rotary Torque

Several factors can affect the calculation of rotary torque, including the angle of the force applied, the distance from the axis of rotation, and the magnitude of the force. The friction and inertia of the object can also impact the calculation of rotary torque. The following are some key factors to consider:

- The angle of the force applied: the torque is maximum when the force is applied at a 90-degree angle to the distance

- The distance from the axis of rotation: the torque increases with distance from the axis of rotation

- The magnitude of the force: the torque increases with the magnitude of the force applied

Calculating Rotary Torque in Real-World Applications

In real-world applications, the calculation of rotary torque is often more complex due to the presence of friction, inertia, and other external forces. The calculation of rotary torque in these applications requires a detailed understanding of the system and the forces involved. The following are some key considerations:

- Identify the external forces acting on the system

- Determine the friction and inertia of the object

- Calculate the torque using the formula: Torque (τ) = r x F, and taking into account the external forces and friction

Measuring Rotary Torque

Rotary torque can be measured using a variety of tools and techniques, including torque wrenches, torque meters, and dynamometers. The choice of measurement tool depends on the application and the level of accuracy required. The following are some common methods for measuring rotary torque:

- Using a torque wrench to measure the torque applied to a bolt or screw

- Using a torque meter to measure the torque of a rotating shaft

- Using a dynamometer to measure the torque and power of a rotating machine

Applications of Rotary Torque

The concept of rotary torque has numerous applications in engineering and physics, including the design of machines, mechanisms, and structures. The calculation of rotary torque is essential in the design of rotating systems, such as engines, gears, and pumps. The following are some key applications of rotary torque:

- Design of engines and transmissions

- Design of gears and bearings

- Design of pumps and turbines

What is the formula for torque of a rotating shaft?

The formula for torque of a rotating shaft is given by the equation: τ = r x F, where τ is the torque, r is the radius of the shaft, and F is the force applied to the shaft. This formula is a fundamental concept in mechanics and is used to calculate the rotational force that causes an object to rotate.

Torque Calculation

The calculation of torque involves determining the force and radius of the rotating shaft. To calculate the torque, the following steps can be followed:

- Measure the radius of the shaft, which is the distance from the center of the shaft to the point where the force is applied.

- Determine the force applied to the shaft, which can be measured using a force sensor or calculated using the mass and acceleration of the object.

- Use the formula τ = r x F to calculate the torque, where τ is the torque, r is the radius, and F is the force.

The calculated torque value can be used to determine the rotational speed and power of the shaft.

Factors Affecting Torque

Several factors can affect the torque of a rotating shaft, including the radius of the shaft, the force applied, and the friction between the shaft and its surrounding components. The following factors can influence the torque:

- Radius: The radius of the shaft has a direct impact on the torque, as a larger radius results in a greater torque.

- Force: The force applied to the shaft also affects the torque, as a greater force results in a greater torque.

- Friction: The friction between the shaft and its surrounding components can reduce the torque and increase the energy loss.

Understanding these factors can help in designing and optimizing rotating systems to achieve the desired torque and performance.

Torque Measurement

Torque measurement is an important aspect of rotating shaft analysis, as it helps in determining the rotational force and power of the shaft. The following methods can be used to measure the torque:

- Strain gauges: Strain gauges can be attached to the shaft to measure the strain caused by the torque, which can be used to calculate the torque value.

- Torque sensors: Torque sensors can be used to directly measure the torque of the shaft, providing an accurate and reliable measurement.

- Rotational speed: Measuring the rotational speed of the shaft can also provide information about the torque, as a higher rotational speed typically results in a lower torque.

Accurate torque measurement is essential in various applications, including engine performance and gearbox design.

Applications of Torque

Torque has numerous applications in various fields, including engineering, physics, and mechanics. Some of the key applications of torque include:

- Engine performance: Torque is a critical factor in engine performance, as it determines the rotational force and power of the engine.

- Gearbox design: Torque is also essential in gearbox design, as it helps in determining the gear ratio and power transmission.

- Robotics: Torque is used in robotics to control the rotational movement of joints and actuators.

Understanding the concept of torque and its applications can help in designing and optimizing rotating systems and mechanical components.

Units of Torque

The units of torque are typically measured in newton-meters (Nm) or foot-pounds (ft-lb). The following units are commonly used to express torque:

- Newton-meters (Nm): This is the SI unit of torque, which is defined as the product of the force in newtons and the distance in meters.

- Foot-pounds (ft-lb): This is a non-SI unit of torque, which is commonly used in engineering and physics applications.

- Pound-feet (lb-ft): This is another non-SI unit of torque, which is similar to foot-pounds but with the force and distance units reversed.

Using the correct units of torque is essential in engineering and physics calculations to ensure accurate and reliable results.

Frequently Asked Questions (FAQs)

What is the Rotating Mass Torque Equation and how is it used in calculations?

The Rotating Mass Torque Equation is a fundamental concept in physics and engineering, used to calculate the torque required to rotate a mass around a fixed axis. This equation takes into account the moment of inertia of the rotating mass, the angular acceleration, and the radius of the rotation. The equation is given by τ = I × α, where τ is the torque, I is the moment of inertia, and α is the angular acceleration. This equation is widely used in various fields, including mechanical engineering, aerospace engineering, and automotive engineering, to design and optimize systems that involve rotating masses, such as engines, gears, and wheels. By using this equation, engineers can calculate the torque required to achieve a specific angular velocity or angular acceleration, and design the system accordingly.

How does the Rotating Mass Torque Equation and Calculator help in designing rotating systems?

The Rotating Mass Torque Equation and Calculator is a valuable tool for engineers and designers who work with rotating systems. By using this equation and calculator, they can quickly and accurately calculate the torque required to rotate a mass around a fixed axis, taking into account various parameters such as the moment of inertia, angular acceleration, and radius of rotation. This information is crucial in designing rotating systems, as it helps to determine the size and type of motors, gears, and bearings required to achieve the desired performance and efficiency. Additionally, the calculator can help to optimize the design of rotating systems, by allowing engineers to iterate and refine their designs quickly and easily. By using the Rotating Mass Torque Equation and Calculator, engineers can create more efficient, more reliable, and more cost-effective rotating systems, which is essential in a wide range of industries, including manufacturing, aerospace, and automotive.

What are the key factors that affect the calculation of torque using the Rotating Mass Torque Equation?

The calculation of torque using the Rotating Mass Torque Equation depends on several key factors, including the moment of inertia of the rotating mass, the angular acceleration, and the radius of rotation. The moment of inertia is a measure of the resistance of an object to changes in its rotational motion, and it depends on the mass and distribution of the object. The angular acceleration is a measure of the rate of change of the angular velocity of the rotating mass, and it is typically expressed in radians per second squared. The radius of rotation is the distance from the axis of rotation to the center of mass of the rotating object, and it is typically expressed in meters or feet. Other factors that can affect the calculation of torque include the friction and damping of the rotating system, as well as any external forces that may be acting on the system. By taking these factors into account, engineers can use the Rotating Mass Torque Equation to calculate the torque required to rotate a mass around a fixed axis, and design the system accordingly.

How can the Rotating Mass Torque Equation and Calculator be applied in real-world scenarios?

The Rotating Mass Torque Equation and Calculator has a wide range of real-world applications in various fields, including mechanical engineering, aerospace engineering, and automotive engineering. For example, in the automotive industry, this equation and calculator can be used to design and optimize the transmission and drivetrain systems of vehicles, taking into account the torque required to rotate the wheels and gears. In the aerospace industry, this equation and calculator can be used to design and optimize the propulsion systems of aircraft and spacecraft, taking into account the torque required to rotate the propellers and turbines. In manufacturing, this equation and calculator can be used to design and optimize the machinery and equipment used in production lines, taking into account the torque required to rotate the motors and gears. By applying the Rotating Mass Torque Equation and Calculator in these and other real-world scenarios, engineers and designers can create more efficient, more reliable, and more cost-effective systems, which can help to improve productivity, safety, and performance.

Deja una respuesta

Entradas Relacionadas