Machining Speeds and Feeds Equations Calculator

Machining speeds and feeds equations are crucial for optimizing the performance of machining operations. The calculation of these parameters is essential to ensure the quality and efficiency of the manufacturing process. A Machining Speeds and Feeds Equations Calculator is a valuable tool that helps machinists and engineers determine the ideal cutting speeds and feed rates for various materials and operations. This calculator takes into account factors such as material type, tool geometry, and machine capabilities to provide accurate calculations, reducing errors and improving productivity in machining processes. It simplifies complex calculations and saves time.

-

Machining Speeds and Feeds Equations Calculator: A Comprehensive Guide

- Understanding the Basics of Machining Speeds and Feeds

- Key Factors Affecting Machining Speeds and Feeds

- Benefits of Using a Machining Speeds and Feeds Equations Calculator

- Common Applications of Machining Speeds and Feeds Equations Calculators

- Future Developments in Machining Speeds and Feeds Equations Calculators

- How do you calculate feed and speed for machining?

- What is the formula for calculating cutting speed?

- What is the formula for RPM and feed rate?

- Why is 3.82 important in feed and speeds?

-

Frequently Asked Questions (FAQs)

- What is the purpose of the Machining Speeds and Feeds Equations Calculator?

- How does the Machining Speeds and Feeds Equations Calculator work?

- What are the benefits of using the Machining Speeds and Feeds Equations Calculator?

- Can the Machining Speeds and Feeds Equations Calculator be used for different types of machining operations?

Machining Speeds and Feeds Equations Calculator: A Comprehensive Guide

The Machining Speeds and Feeds Equations Calculator is a powerful tool used in the manufacturing industry to calculate the optimal speeds and feeds for various machining operations. This calculator takes into account the type of material being machined, the tool being used, and the desired level of surface finish. By using this calculator, machinists can optimize their machining processes, reducing production time and increasing product quality.

Understanding the Basics of Machining Speeds and Feeds

Machining speeds and feeds refer to the rate at which a cutting tool moves through a workpiece. The speed of the cutting tool is typically measured in surface feet per minute (sfm), while the feed is measured in inches per minute (ipm). The Machining Speeds and Feeds Equations Calculator uses complex algorithms to determine the optimal speeds and feeds for a given machining operation. These algorithms take into account material properties, such as hardness and toughness, as well as tool geometry and machine capabilities.

Key Factors Affecting Machining Speeds and Feeds

Several factors can affect the optimal machining speeds and feeds, including:

| Factor | Description |

|---|---|

| Material Type | The type of material being machined, such as aluminum, steel, or titanium |

| Tool Geometry | The shape and size of the cutting tool, including nose radius and cutting edge angle |

| Machine Capabilities | The power and speed capabilities of the machine tool, including spindle speed and feed rate |

Benefits of Using a Machining Speeds and Feeds Equations Calculator

Using a Machining Speeds and Feeds Equations Calculator can bring several benefits to a manufacturing operation, including:

Increased productivity: By optimizing machining speeds and feeds, manufacturers can reduce production time and increase throughput.

Improved product quality: By using the optimal speeds and feeds, manufacturers can achieve a higher surface finish and reduce defect rates.

Reduced tool wear: By using the optimal speeds and feeds, manufacturers can reduce tool wear and extend tool life.

Common Applications of Machining Speeds and Feeds Equations Calculators

Machining Speeds and Feeds Equations Calculators are commonly used in a variety of manufacturing applications, including:

CNC machining: Computer numerical control (CNC) machining operations, such as milling and turning.

Grinding: Grinding operations, such as surface grinding and cylindrical grinding.

Drilling: Drilling operations, such as holemaking and tapping.

Future Developments in Machining Speeds and Feeds Equations Calculators

The development of Machining Speeds and Feeds Equations Calculators is an ongoing process, with researchers and manufacturers continually working to improve their accuracy and usability. Future developments may include the integration of artificial intelligence (AI) and machine learning (ML) algorithms, which can help to optimize machining speeds and feeds in real-time. Additionally, the development of cloud-based calculators may allow manufacturers to access up-to-date machining data and best practices from anywhere in the world.

How do you calculate feed and speed for machining?

To calculate feed and speed for machining, you need to consider several factors, including the material being machined, the tool being used, and the machine itself. The feed rate is the rate at which the tool moves through the material, while the speed is the rate at which the tool rotates. These values are critical in determining the quality of the machined part, as well as the life of the tool.

Understanding Feed Rate

The feed rate is calculated based on the material properties, such as its hardness and toughness. A higher feed rate can be used for softer materials, while a lower feed rate is required for harder materials. The feed rate also depends on the tool geometry and the machine capabilities. For example, a high-speed machine can handle a higher feed rate than a low-speed machine. Some key factors to consider when calculating feed rate include:

- Material properties, such as density and hardness

- Tool geometry, including the cutting edge and nose radius

- Machine capabilities, such as power and torque

Calculating Speed

The speed is calculated based on the tool diameter and the required surface finish. A higher speed is required for a smooth finish, while a lower speed can be used for a rough finish. The speed also depends on the material properties, such as its thermal conductivity and specific heat capacity. For example, a high-temperature material can be machined at a higher speed than a low-temperature material. Some key factors to consider when calculating speed include:

- Tool diameter and nose radius

- Material properties, such as thermal conductivity and specific heat capacity

- Required surface finish, including roughness and waviness

Considering Tool Life

The tool life is an important consideration when calculating feed and speed for machining. A higher feed rate and speed can result in a shorter tool life, while a lower feed rate and speed can result in a longer tool life. The tool life also depends on the material properties, such as its hardness and toughness. For example, a hard material can reduce the tool life, while a isoft material can increase the tool life. Some key factors to consider when calculating tool life include:

- Material properties, such as hardness and toughness

- Tool geometry, including the cutting edge and nose radius

- Feed rate and speed, including the acceleration and deceleration

Machine Capabilities

The machine capabilities are critical in determining the feed and speed for machining. A high-performance machine can handle a higher feed rate and speed than a low-performance machine. The machine capabilities also depend on the power and torque available, as well as the cooling system and lubrication. For example, a high-power machine can handle a higher feed rate and speed than a low-power machine. Some key factors to consider when calculating machine capabilities include:

- Power and torque available

- Cooling system and lubrication

- Machine geometry, including the spindle and axis

Optimizing Feed and Speed

The optimization of feed and speed for machining is critical in achieving the desired surface finish and tool life. A higher feed rate and speed can result in a reduced machining time, while a lower feed rate and speed can result in a increased machining time. The optimization also depends on the material properties, such as its hardness and toughness. For example, a hard material can require a lower feed rate and speed, while a soft material can require a higher feed rate and speed. Some key factors to consider when optimizing feed and speed include:

- Material properties, such as hardness and toughness

- Tool geometry, including the cutting edge and nose radius

- Machine capabilities, including the power and torque

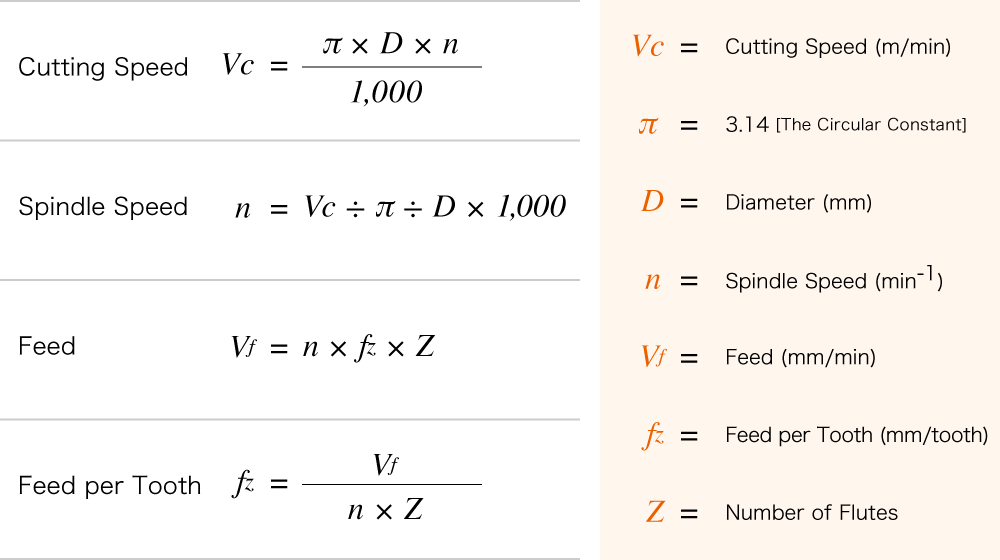

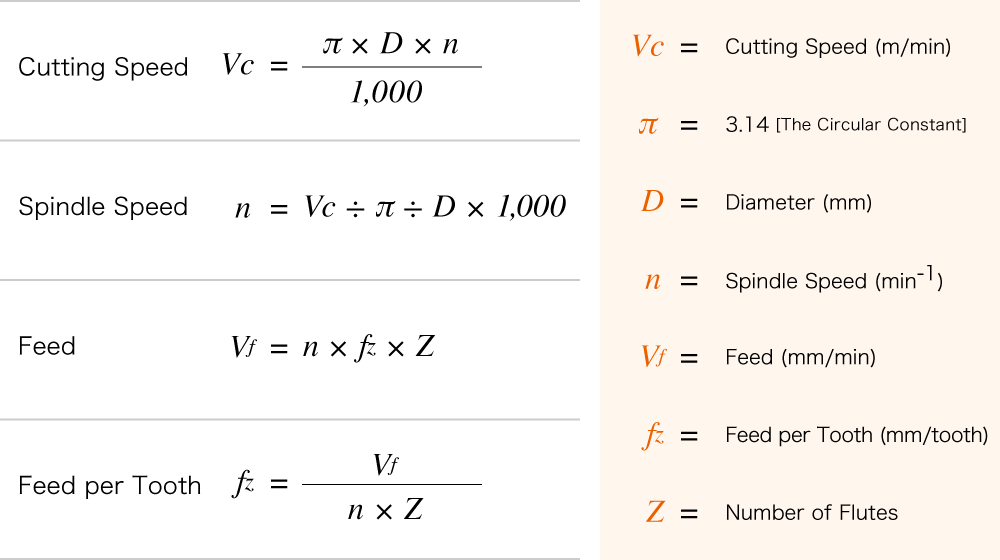

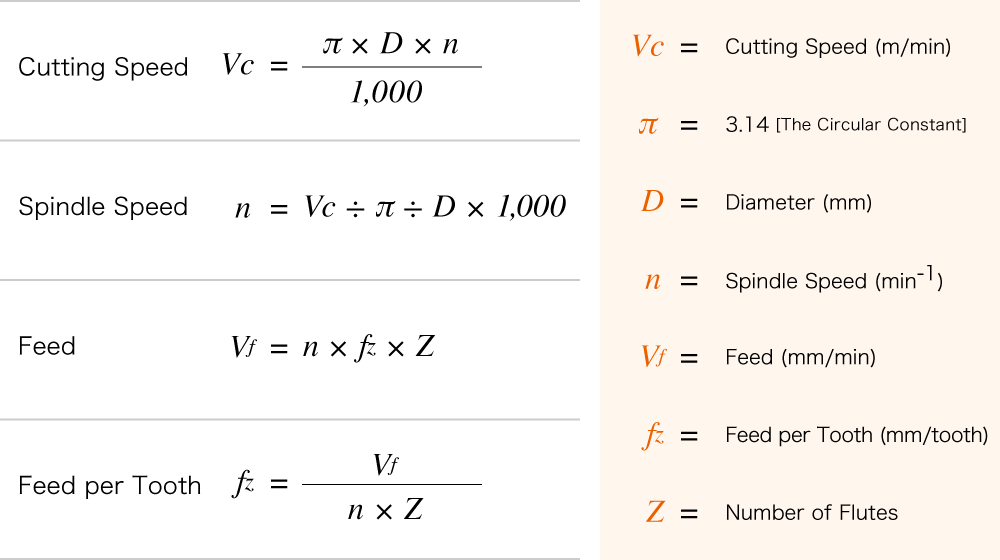

What is the formula for calculating cutting speed?

The formula for calculating cutting speed is typically represented as: v = π x d x N, where v is the cutting speed, π is a constant (pi), d is the diameter of the cutting tool or workpiece, and N is the rotational speed (in revolutions per minute, rpm). This formula is widely used in various machining operations, including turning, milling, and drilling, to determine the optimal cutting speed for a given material and cutting tool.

Understanding the Variables

To calculate cutting speed, it is essential to understand the variables involved in the formula. The diameter of the cutting tool or workpiece is a critical factor, as it affects the cutting speed. The rotational speed (N) is also crucial, as it determines the number of revolutions per minute. Other factors, such as the material being cut and the cutting tool used, also influence the cutting speed. The following are key factors to consider:

- Tool material: The type of material used to make the cutting tool affects its durability and performance.

- Workpiece material: The type of material being cut also influences the cutting speed, as different materials have varying levels of hardness and resistance.

- Cutting tool geometry: The shape and angle of the cutting tool can impact the cutting speed and the quality of the cut.

Importance of Cutting Speed

Cutting speed is a critical parameter in machining operations, as it affects the quality of the cut, the tool life, and the overall productivity of the process. A cutting speed that is too high can result in tool wear and breakage, while a cutting speed that is too low can lead to reduced productivity and increased costs. The following are key benefits of optimal cutting speed:

- Improved tool life: Optimal cutting speed can extend the life of the cutting tool, reducing the need for frequent replacements.

- Increased productivity: Optimal cutting speed can increase the rate of production, leading to higher efficiency and reduced costs.

- Enhanced quality: Optimal cutting speed can result in higher quality cuts, with improved surface finish and dimensional accuracy.

Cutting Speed and Tool Life

The cutting speed has a significant impact on tool life, as excessive heat and friction can cause tool wear and breakage. The following are key factors to consider:

- Tool material properties: The properties of the tool material, such as its hardness and toughness, affect its ability to withstand cutting speeds.

- Cutting tool geometry: The shape and angle of the cutting tool can influence the cutting speed and the tool life.

- Coolant and lubrication: The use of coolants and lubricants can help reduce heat and friction, extending tool life.

Calculating Cutting Speed for Different Materials

The cutting speed varies depending on the material being cut. The following are key factors to consider:

- Material properties: The properties of the material, such as its hardness and toughness, affect the cutting speed.

- Cutting tool material: The type of material used to make the cutting tool also influences the cutting speed.

- Cutting tool geometry: The shape and angle of the cutting tool can impact the cutting speed and the quality of the cut.

Common Mistakes in Calculating Cutting Speed

Common mistakes in calculating cutting speed can result in suboptimal cutting speeds, leading to reduced productivity and increased costs. The following are key mistakes to avoid:

- Incorrect tool diameter: Using an incorrect tool diameter can result in inaccurate cutting speed calculations.

- Insufficient coolant or lubrication: Failing to use sufficient coolants or lubricants can lead to excessive heat and friction, reducing tool life.

- Ignoring material properites: Failing to consider the material properties can result in suboptimal cutting speeds and reduced quality.

What is the formula for RPM and feed rate?

The formula for RPM (Revolutions Per Minute) and feed rate is crucial in various manufacturing processes, including machining and metalworking. The RPM is calculated by dividing the speed of the machine in feet per minute by the circumference of the workpiece, while the feed rate is determined by the material being cut, the tool being used, and the desired surface finish.

Understanding RPM Calculation

To calculate the RPM, one needs to understand the relationship between the speed of the machine and the diameter of the workpiece. The formula for RPM is: RPM = (speed in feet per minute) / (π x diameter). This calculation is essential for determining the optimal speed for a particular machining operation.

- The speed of the machine is measured in feet per minute, which is the distance the cutting tool travels in one minute.

- The diameter of the workpiece is crucial in calculating the RPM, as it affects the circumference of the workpiece.

- π (pi) is a mathematical constant that represents the ratio of a circle's circumference to its diameter.

Feed Rate Calculation

The feed rate is calculated by multiplying the RPM by the number of teeth on the cutting tool and the chip load. The formula for feed rate is: feed rate = RPM x number of teeth x chip load. This calculation is critical in determining the material removal rate and the surface finish of the workpiece.

- The number of teeth on the cutting tool affects the feed rate, as more teeth result in a higher material removal rate.

- The chip load is the amount of material removed by each tooth of the cutting tool, which affects the feed rate and the surface finish.

- Material properties, such as hardness and toughness, also influence the feed rate and the surface finish.

Importance of RPM and Feed Rate

The RPM and feed rate are critical parameters in machining operations, as they affect the material removal rate, the surface finish, and the tool life.

- Optimal RPM and feed rate result in a higher material removal rate, which increases productivity and reduces production time.

- Incorrect RPM and feed rate can lead to tool breakage, reduced tool life, and a poor surface finish.

- Understanding the relationship between RPM and feed rate is essential for machinists and manufacturing engineers to optimize machining operations.

Factors Affecting RPM and Feed Rate

Several factors affect the RPM and feed rate, including the material being cut, the tool being used, and the desired surface finish.

- The material properties, such as hardness and toughness, influence the RPM and feed rate.

- The tool geometry and tool material also affect the RPM and feed rate.

- Coolant and lubrication systems can also impact the RPM and feed rate by reducing friction and heat generation.

Applications of RPM and Feed Rate

The RPM and feed rate are used in various manufacturing processes, including milling, turning, and drilling.

- Milling operations require careful control of RPM and feed rate to achieve a high-quality surface finish.

- Turning operations involve rotating the workpiece at a specific RPM and feeding the cutting tool at a controlled rate.

- Drilling operations require optimal RPM and feed rate to achieve accurate hole placement and minimal tool wear.

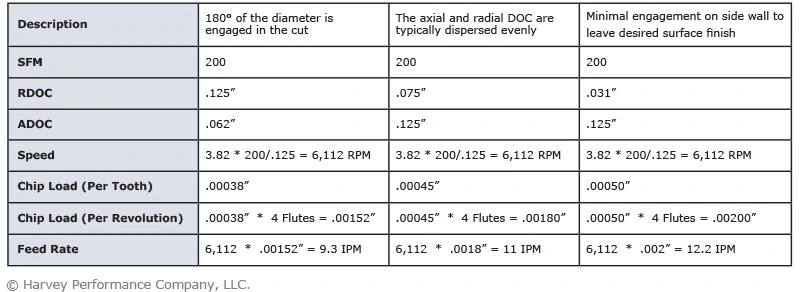

Why is 3.82 important in feed and speeds?

The importance of 3.82 in feed and speeds lies in its relationship to the IPM (Inches Per Minute) and RPM (Revolution Per Minute) of a machine. In the context of machining, feed rates are often calculated based on the tool diameter, material type, and desired surface finish. The value 3.82 is significant because it is used as a conversion factor between IPM and RPM, particularly when working with circular interpolation or helical interpolation. This conversion is crucial for determining the optimal feed rate and speed for a given machining operation, ensuring that the tool life is maximized and the part quality is maintained.

Understanding the Role of 3.82 in Feed Rate Calculations

The calculation of feed rates in machining involves understanding the relationship between IPM, RPM, and tool diameter. The value 3.82 is used in the formula: Feed Rate (IPM) = RPM x Tool Diameter x 3.82 / Number of Teeth. This formula is essential for calculating the feed rate when using milling cutters or other rotating tools.

- The feed rate is the rate at which the tool moves along the workpiece, typically measured in IPM.

- The RPM of the tool affects the material removal rate and the tool life.

- Tool diameter and number of teeth are critical parameters in determining the optimal feed rate for a given machining operation.

Impact of 3.82 on Tool Life and Part Quality

The use of 3.82 in calculating feed rates has a direct impact on tool life and part quality. If the feed rate is too high, it can lead to tool wear and breakage, reducing the overall productivity of the machining operation. Conversely, if the feed rate is too low, it can result in a poor surface finish and reduced material removal rates.

- Proper tool selection is essential to ensure that the feed rate and RPM are optimized for the specific machining operation.

- Material properties, such as hardness and toughness, must be considered when determining the optimal feed rate.

- Machine capabilities, including spindle power and Axis movement, also play a critical role in determining the optimal feed rate.

Applications of 3.82 in Machining Operations

The value 3.82 is commonly used in various machining operations, including milling, drilling, and turning. In each of these operations, the feed rate and RPM must be carefully calculated to ensure optimal tool life and part quality.

- Milling operations require careful consideration of tool diameter, number of teeth, and RPM to determine the optimal feed rate.

- Drilling operations involve calculating the feed rate based on the drill diameter and RPM.

- Turning operations require determining the optimal feed rate based on the tool nose radius and RPM.

Challenges and Limitations of Using 3.82 in Feed Rate Calculations

While the value 3.82 is widely used in machining operations, there are challenges and limitations associated with its use. These include variations in material properties, tool wear, and machine capabilities.

- Material variability can affect the optimal feed rate and RPM, requiring adjustments to be made during the machining operation.

- Tool wear can reduce the effective tool diameter, requiring recalculations of the feed rate.

- Machine limitations, such as spindle power and Axis movement, can constrain the optimal feed rate and RPM.

Future Developments and Advances in Feed Rate Calculations

The use of 3.82 in feed rate calculations is expected to evolve with advances in machining technology and computer-aided manufacturing (CAM) software. These developments will enable more accurate calculations and optimized machining operations.

- Advanced CAM software will provide more precise calculations of feed rates and RPM.

- New machining technologies, such as additive manufacturing, will require revised feed rate calculations.

- Integration of IoT (Internet of Things) and machine learning will enable real-time monitoring and optimization of machining operations.

Frequently Asked Questions (FAQs)

What is the purpose of the Machining Speeds and Feeds Equations Calculator?

The Machining Speeds and Feeds Equations Calculator is a tool designed to help machinists and manufacturing engineers determine the optimal cutting speeds and feed rates for various machining operations, such as milling, drilling, and turning. The calculator takes into account the type of material being machined, the tool material and geometry, and the machine tool being used to perform the operation. By using this calculator, users can optimize their machining processes to achieve improved surface finish, increased productivity, and reduced tool wear. The calculator is particularly useful for complex machining operations that require precise control over the cutting parameters.

How does the Machining Speeds and Feeds Equations Calculator work?

The Machining Speeds and Feeds Equations Calculator uses a set of complex equations to calculate the optimal cutting speeds and feed rates for a given machining operation. These equations take into account a range of variables, including the material properties, tool geometry, and machine tool capabilities. The calculator uses a combination of empirical formulas and theoretical models to predict the cutting forces, tool wear, and surface finish that can be expected for a given set of cutting conditions. By inputting the relevant parameters, users can obtain accurate calculations of the optimal cutting speeds and feed rates for their specific machining application. The calculator can also account for variations in the machining process, such as changes in material hardness or tool wear, to provide optimized cutting conditions.

What are the benefits of using the Machining Speeds and Feeds Equations Calculator?

The Machining Speeds and Feeds Equations Calculator offers a range of benefits to machinists and manufacturing engineers, including improved productivity, increased accuracy, and reduced costs. By optimizing the cutting speeds and feed rates, users can minimize tool wear, reduce cutting forces, and improve surface finish. The calculator can also help to prevent common machining problems, such as vibration, chatter, and tool breakage, by providing recommended cutting conditions that take into account the machine tool capabilities and material properties. Additionally, the calculator can save time and reduce errors by providing accurate calculations of the optimal cutting speeds and feed rates, eliminating the need for trial and error methods.

Can the Machining Speeds and Feeds Equations Calculator be used for different types of machining operations?

The Machining Speeds and Feeds Equations Calculator is a versatile tool that can be used for a wide range of machining operations, including milling, drilling, turning, and grinding. The calculator can be used to optimize the cutting speeds and feed rates for different types of materials, such as metals, plastics, and composites, and for various tool materials and geometries. The calculator can also be used to account for variations in the machining process, such as changes in material hardness or tool wear, to provide optimized cutting conditions. Additionally, the calculator can be used to compare the performance of different machine tools and cutting tools, and to identify the most efficient and cost-effective machining strategies. By using the Machining Speeds and Feeds Equations Calculator, users can improve their machining operations and increase productivity across a range of applications.

Deja una respuesta

Entradas Relacionadas