Compression Spring Constant Equation and Calculator

The compression spring constant is a crucial parameter in designing and selecting springs for various applications. It determines the amount of force required to compress a spring by a given distance. The compression spring constant equation is a mathematical formula that calculates this parameter based on the spring's physical characteristics, such as its wire diameter, coil diameter, and number of coils. This article provides an overview of the compression spring constant equation and offers a calculator to simplify the calculation process for engineers and designers. The equation and calculator will help in optimizing spring design and selection.

-

Understanding Compression Spring Constant Equation and Calculator

- What is the Compression Spring Constant Equation?

- How to Use a Compression Spring Constant Calculator

- Importance of Material Properties in Compression Spring Constant Equation

- Applications of Compression Spring Constant Equation and Calculator

- Limitations and Assumptions of Compression Spring Constant Equation

- How to calculate compression spring constant?

- What is the formula for compression in a spring?

- What is the K value of a compression spring?

-

Frequently Asked Questions (FAQs)

- What is the Compression Spring Constant Equation and how is it used in calculations?

- How does the Compression Spring Constant Calculator work and what are its advantages?

- What are the key factors that affect the Compression Spring Constant and how can they be optimized?

- What are the common applications of Compression Springs and how are they used in different industries?

Understanding Compression Spring Constant Equation and Calculator

The compression spring constant equation is a fundamental concept in the design and calculation of compression springs. It is used to determine the spring constant, which is a measure of the stiffness of a spring. The equation is given by: k = G d^4 / (8 n D^3), where k is the spring constant, G is the shear modulus of the material, d is the wire diameter, n is the number of coils, and D is the mean coil diameter. A calculator can be used to simplify the calculation process and provide accurate results.

What is the Compression Spring Constant Equation?

The compression spring constant equation is a mathematical formula used to calculate the spring constant of a compression spring. It takes into account various parameters such as the material properties, geometry, and design of the spring. The equation is widely used in the engineering and manufacturing industries to design and optimize compression springs for various applications.

How to Use a Compression Spring Constant Calculator

A compression spring constant calculator is a tool used to simplify the calculation process and provide accurate results. It typically requires input of various parameters such as the wire diameter, number of coils, mean coil diameter, and material properties. The calculator then uses the compression spring constant equation to calculate the spring constant and provides the result in a user-friendly format.

Importance of Material Properties in Compression Spring Constant Equation

The material properties play a crucial role in the compression spring constant equation. The shear modulus of the material is a key parameter that affects the spring constant. Different materials have different shear moduli, and this must be taken into account when designing and calculating compression springs. The material properties can be obtained from the material data sheet or by consulting with a materials engineer.

Applications of Compression Spring Constant Equation and Calculator

The compression spring constant equation and calculator have numerous applications in various industries such as automotive, aerospace, industrial, and consumer goods. They are used to design and optimize compression springs for applications such as suspension systems, engine mounts, valve springs, and furniture. The equation and calculator help engineers and designers to create customized springs that meet specific performance requirements and regulatory standards.

Limitations and Assumptions of Compression Spring Constant Equation

The compression spring constant equation is based on several assumptions and has some limitations. It assumes that the spring is made of a homogeneous material, has a circular cross-section, and is subjected to linear loading. The equation also assumes that the spring constant is constant throughout the operating range. However, in practice, the spring constant can vary due to non-linear effects, material defects, and manufacturing variations. A table summarizing the key parameters and assumptions is shown below:

| Parameter | Description |

|---|---|

| k | Spring constant |

| G | Shear modulus |

| d | Wire diameter |

| n | Number of coils |

| D | Mean coil diameter |

How to calculate compression spring constant?

To calculate the compression spring constant, you need to understand the physics behind the spring's behavior. The compression spring constant, also known as the spring rate, is a measure of the amount of force required to compress the spring by a certain distance. It is typically measured in units of pounds per inch (lb/in) or newtons per meter (N/m). The calculation involves understanding the material properties of the spring, such as its wire diameter, outer diameter, and number of coils.

Understanding Spring Materials

The material properties of the spring play a crucial role in calculating the compression spring constant. The spring's wire diameter, outer diameter, and number of coils all impact its behavior. To calculate the spring constant, you need to know the modulus of elasticity of the material, which is a measure of its stiffness. The wire diameter and outer diameter are used to calculate the mean coil diameter, which is then used in the spring constant calculation. Here are the key factors to consider:

- The type of material used for the spring, such as stainless steel or copper

- The wire diameter and outer diameter of the spring

- The number of coils in the spring

Calculating the Spring Constant

To calculate the compression spring constant, you can use the following formula: k = (G d^4) / (8 n D^3), where k is the spring constant, G is the modulus of elasticity, d is the wire diameter, n is the number of coils, and D is the mean coil diameter. This formula takes into account the geometry of the spring and its material properties. The modulus of elasticity is a measure of the spring's stiffness, and the wire diameter and outer diameter are used to calculate the mean coil diameter. Here are the steps to follow:

- Determine the modulus of elasticity of the material

- Calculate the mean coil diameter using the wire diameter and outer diameter

- Plug in the values into the formula to calculate the spring constant

Using Spring Constant Formulas

There are several formulas available to calculate the compression spring constant, each with its own assumptions and limitations. The most common formula is the one mentioned earlier, but there are also simplified formulas that can be used for approximate calculations. The choice of formula depends on the specific application and the level of accuracy required. Here are some key considerations:

- The type of spring being used, such as a compression spring or a torsion spring

- The level of accuracy required for the calculation

- The availability of data for the spring's material properties and geometry

Measuring Spring Properties

To calculate the compression spring constant accurately, you need to measure the spring's properties carefully. This includes measuring the wire diameter, outer diameter, and number of coils, as well as determining the modulus of elasticity of the material. The measuring technique used can affect the accuracy of the calculation, so it's essential to use precise methods. Here are some key factors to consider:

- The method of measurement, such as using a caliper or a micrometer

- The precision of the measurement, such as the number of decimal places

- The equipment used for measurement, such as a spring tester

Applying Spring Constant Calculations

The compression spring constant calculation has practical applications in various fields, such as engineering and design. The spring constant is used to determine the force required to compress the spring, which is essential for designing mechanisms and systems that use springs. The calculation can also be used to optimize the design of the spring and the surrounding components. Here are some key applications:

- Mechanical design, such as designing machinery and mechanisms

- Product development, such as designing consumer products and industrial equipment

- Research and development, such as testing and evaluating new materials and technologies

What is the formula for compression in a spring?

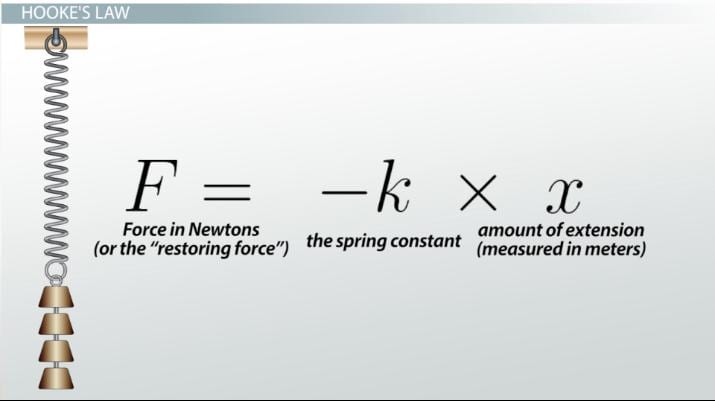

The formula for compression in a spring is given by Hooke's Law, which states that the force (F) exerted on a spring is directly proportional to its displacement (x) from its equilibrium position. The formula is F = kx, where k is the spring constant, which depends on the properties of the spring, such as its material, shape, and size.

Understanding Hooke's Law

Hooke's Law is a fundamental principle in physics that describes the behavior of elastic objects, such as springs. The law states that the force required to compress or stretch a spring is directly proportional to its displacement from its equilibrium position. This means that if you apply a force to a spring, it will displace by a certain amount, and the amount of displacement will be proportional to the force applied.

- The spring constant (k) is a measure of the stiffness of the spring, and it depends on the properties of the spring, such as its material, shape, and size.

- The displacement (x) is the distance that the spring is compressed or stretched from its equilibrium position.

- The force (F) is the force exerted on the spring, which can be measured in units such as Newtons (N).

Factors Affecting Spring Compression

There are several factors that can affect the compression of a spring, including the spring constant, the force applied, and the displacement of the spring. The spring constant is a measure of the stiffness of the spring, and it determines how much force is required to compress the spring by a certain amount. The force applied to the spring also affects its compression, as a greater force will result in a greater displacement.

- The material of the spring can affect its spring constant, with some materials being more elastic than others.

- The shape and size of the spring can also affect its spring constant, with larger springs typically having a lower spring constant.

- The temperature of the spring can also affect its compression, with some materials becoming more elastic at higher temperatures.

Calculating Spring Compression

To calculate the compression of a spring, you need to know the spring constant (k) and the force (F) applied to the spring. You can then use the formula F = kx to calculate the displacement (x) of the spring. This formula can be rearranged to solve for x, giving x = F/k.

- To calculate the compression of a spring, you need to know the spring constant (k) and the force (F) applied to the spring.

- The spring constant (k) can be measured by applying a known force to the spring and measuring its displacement.

- The force (F) applied to the spring can be measured using a force sensor or other device.

Applications of Spring Compression

The compression of springs has a wide range of applications in fields such as engineering, physics, and materials science. Springs are used in many devices, including shock absorbers, suspension systems, and gears. The compression of springs is also important in the design of mechanical systems, where it is used to absorb and dissipate energy.

- Shock absorbers use springs to absorb and dissipate energy, reducing the impact of shocks and vibrations.

- Suspension systems use springs to support and guide moving parts, such as wheels and axles.

- Gears use springs to engage and disengage teeth, allowing for smooth and efficient transmission of torque.

Measuring Spring Compression

The compression of a spring can be measured using a variety of techniques, including displacement sensors, force sensors, and optical methods. The most common method is to use a displacement sensor, which measures the displacement of the spring as a function of the force applied.

- Displacement sensors can be used to measure the displacement of a spring, allowing for the calculation of its compression.

- Force sensors can be used to measure the force applied to a spring, allowing for the calculation of its compression.

- Optical methods can be used to measure the displacement of a spring, using optical sensors or other devices.

What is the K value of a compression spring?

The K value of a compression spring is a measure of its stiffness, which is the amount of force required to compress the spring by a certain distance. It is typically measured in units of force per unit distance, such as pounds per inch (lb/in) or Newtons per millimeter (N/mm). The K value is an important parameter in the design and selection of compression springs, as it determines the spring's ability to resist compression and store energy.

Understanding the K Value Formula

The K value of a compression spring can be calculated using the formula: K = F / δ, where F is the force applied to the spring and δ is the resulting displacement. This formula shows that the K value is directly proportional to the force applied and inversely proportional to the displacement. To calculate the K value, the following steps can be taken:

- Measure the force applied to the spring using a force gauge or other device

- Measure the resulting displacement of the spring using a distance measuring device

- Calculate the K value using the formula K = F / δ

Factors That Affect the K Value

The K value of a compression spring is affected by several factors, including the spring's wire diameter, coil diameter, and number of coils. A spring with a larger wire diameter will have a higher K value, while a spring with a smaller coil diameter will have a lower K value. The number of coils also affects the K value, with more coils resulting in a lower K value. The following factors can affect the K value:

- Wire diameter: A larger wire diameter results in a higher K value

- Coil diameter: A smaller coil diameter results in a lower K value

- Number of coils: More coils result in a lower K value

Importance of the K Value in Spring Design

The K value is a critical parameter in the design of compression springs, as it determines the spring's ability to resist compression and store energy. A spring with a high K value will be more resistant to compression, while a spring with a low K value will be less resistant. The K value is also important in ensuring that the spring can withstand the loads and stresses imposed on it. The following are some reasons why the K value is important:

- The K value determines the spring's stiffness and ability to resist compression

- The K value affects the spring's ability to store energy and release it when needed

- The K value is important in ensuring that the spring can withstand loads and stresses

Measuring the K Value of a Compression Spring

The K value of a compression spring can be measured using a variety of methods, including the use of a spring tester or a universal testing machine. These devices can apply a known force to the spring and measure the resulting displacement, allowing the K value to be calculated. The following steps can be taken to measure the K value:

- Use a spring tester or universal testing machine to apply a known force to the spring

- Measure the resulting displacement of the spring using a distance measuring device

- Calculate the K value using the formula K = F / δ

Applications of Compression Springs with Different K Values

Compression springs with different K values are used in a variety of applications, including automotive, aerospace, and industrial applications. A spring with a high K value may be used in an application where high stiffness is required, such as in a shock absorber. A spring with a low K value may be used in an application where low stiffness is required, such as in a door closer. The following are some examples of applications:

- Automotive applications: Compression springs with high K values are used in shock absorbers and suspension systems

- Aerospace applications: Compression springs with high K values are used in aircraft landing gear and other critical systems

- Industrial applications: Compression springs with low K values are used in door closers and other devices that require low stiffness

Frequently Asked Questions (FAQs)

What is the Compression Spring Constant Equation and how is it used in calculations?

The Compression Spring Constant Equation is a mathematical formula used to calculate the spring constant of a spring, which is a measure of its stiffness. The equation is typically expressed as k = G d^4 / (8 n R^3), where k is the spring constant, G is the shear modulus of the spring material, d is the wire diameter, n is the number of coils, and R is the mean coil radius. This equation is widely used in engineering and design applications to determine the load-carrying capacity of a spring and to ensure that it can withstand the forces and stresses imposed on it. By using this equation, engineers and designers can calculate the spring constant and determine the performance of a spring in various applications, such as mechanical systems, automotive systems, and aerospace systems.

How does the Compression Spring Constant Calculator work and what are its advantages?

The Compression Spring Constant Calculator is a software tool that uses the Compression Spring Constant Equation to calculate the spring constant of a spring. The calculator typically requires input values such as the wire diameter, number of coils, mean coil radius, and shear modulus of the spring material. The calculator then uses these input values to calculate the spring constant and provides the result in a user-friendly format. The advantages of using a Compression Spring Constant Calculator include increased accuracy, reduced calculation time, and improved design efficiency. The calculator can also perform iterative calculations, allowing engineers and designers to optimize their spring design and performance. Additionally, the calculator can provide graphical representations of the spring's behavior, making it easier to visualize and understand the results.

What are the key factors that affect the Compression Spring Constant and how can they be optimized?

The key factors that affect the Compression Spring Constant include the wire diameter, number of coils, mean coil radius, and shear modulus of the spring material. The wire diameter and number of coils have a significant impact on the spring constant, as they affect the stiffness and load-carrying capacity of the spring. The mean coil radius also plays a crucial role, as it affects the stress and strain on the spring. The shear modulus of the spring material is also an important factor, as it affects the spring's ability to withstand forces and stresses. To optimize these factors, engineers and designers can use iterative calculations and design optimization techniques, such as finite element analysis and genetic algorithms. By optimizing these factors, engineers and designers can create springs that are more efficient, more reliable, and better suited to their specific applications.

What are the common applications of Compression Springs and how are they used in different industries?

Compression Springs are widely used in various industries, including automotive, aerospace, medical, and consumer goods. In the automotive industry, compression springs are used in suspension systems, engine mounts, and transmission systems. In the aerospace industry, compression springs are used in landing gear, flight control systems, and engine components. In the medical industry, compression springs are used in medical devices, such as stents, implants, and surgical instruments. In the consumer goods industry, compression springs are used in appliances, furniture, and toys. Compression springs are also used in industrial applications, such as machine tools, conveyors, and pumps. The unique properties of compression springs, such as their high stiffness and low weight, make them an ideal choice for many applications. By using compression springs, engineers and designers can create efficient, reliable, and cost-effective solutions for a wide range of industrial and commercial applications.

Deja una respuesta

Entradas Relacionadas