Brittle Fracture Analysis Calculator and Equation

Brittle fracture analysis is a critical aspect of materials science, particularly in the design and operation of mechanical systems. The brittle fracture analysis calculator and equation play a vital role in predicting the likelihood of fracture in materials under stress. By utilizing the calculator and equation, engineers can determine the stress intensity factor and fracture toughness of a material, allowing them to assess its vulnerability to brittle fracture. This calculator and equation are essential tools for ensuring the safety and reliability of structures and components. Accurate calculations are crucial to prevent catastrophic failures.

- Brittle Fracture Analysis Calculator and Equation

- What is the Griffith equation?

- What is the equation for the critical flaw size?

-

Frequently Asked Questions (FAQs)

- What is the purpose of the Brittle Fracture Analysis Calculator and Equation?

- How does the Brittle Fracture Analysis Calculator and Equation account for the effects of temperature and stress on brittle fracture?

- What are the limitations and assumptions of the Brittle Fracture Analysis Calculator and Equation?

- How can the results of the Brittle Fracture Analysis Calculator and Equation be used to optimize the design of materials and structures?

Brittle Fracture Analysis Calculator and Equation

The Brittle Fracture Analysis Calculator and Equation is a tool used to analyze the stress and strain of materials that are prone to brittle fracture. Brittle fracture occurs when a material suddenly fails without significant deformation or warning, often due to high stress concentrations or low temperatures. The calculator and equation take into account various factors such as the material's tensile strength, yield strength, and fracture toughness to predict the likelihood of brittle fracture.

Introduction to Brittle Fracture Analysis

Brittle fracture analysis is a critical aspect of material science and engineering. It helps to identify the potential for brittle fracture in materials and structures, allowing for the design of safer and more reliable systems. The analysis involves calculating the stress intensity factor, which is a measure of the stress concentration at the tip of a crack. The stress intensity factor is then compared to the material's fracture toughness to determine the likelihood of brittle fracture.

Brittle Fracture Analysis Calculator

The Brittle Fracture Analysis Calculator is a software tool that performs the calculations required for brittle fracture analysis. The calculator takes into account various input parameters such as the material's tensile strength, yield strength, and fracture toughness, as well as the geometry of the structure and the loading conditions. The calculator then outputs the stress intensity factor and the likelihood of brittle fracture.

Brittle Fracture Analysis Equation

The Brittle Fracture Analysis Equation is a mathematical equation that is used to calculate the stress intensity factor. The equation is based on the theory of elasticity and takes into account the stress and strain of the material. The equation is as follows:

K = σ sqrt(π a)

where K is the stress intensity factor, σ is the stress, and a is the crack length.

Factors Affecting Brittle Fracture Analysis

Several factors can affect the accuracy of brittle fracture analysis, including the material properties, geometry, and loading conditions. The material properties such as tensile strength, yield strength, and fracture toughness are critical in determining the likelihood of brittle fracture. The geometry of the structure, including the crack length and orientation, can also affect the stress intensity factor. The loading conditions, including the stress and strain rates, can also impact the likelihood of brittle fracture.

Applications of Brittle Fracture Analysis

Brittle fracture analysis has several applications in various fields, including aerospace engineering, nuclear engineering, and materials science. The analysis is used to design safer and more reliable systems, such as aircraft and nuclear reactors. The analysis is also used to predict the lifetime of materials and structures, allowing for more efficient maintenance and replacement schedules.

| Material Property | Unit | Description |

|---|---|---|

| Tensile Strength | MPa | The maximum stress that a material can withstand without failing |

| Yield Strength | MPa | The stress at which a material begins to deform plastically |

| Fracture Toughness | MPa sqrt(m) | A measure of a material's resistance to brittle fracture |

What is the Griffith equation?

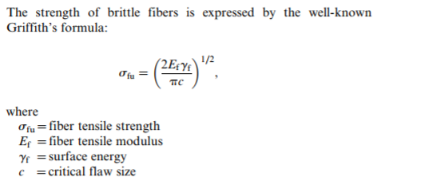

The Griffith equation is a mathematical model used to predict the stress intensity factor at which a crack will propagate in a material. It is widely used in fracture mechanics to determine the toughness of a material and to predict the likelihood of failure due to cracking. The equation is named after Alan Arnold Griffith, who first proposed it in the 1920s. The equation is based on the idea that the energy released by the growth of a crack is equal to the energy required to create new surface area.

History of the Griffith Equation

The Griffith equation was first proposed by Alan Arnold Griffith in 1920. Griffith was a British engineer who was working on the problem of fatigue in materials. He realized that the stress intensity factor at the tip of a crack was the critical factor in determining whether a crack would propagate or not. The Griffith equation was a major breakthrough in the field of fracture mechanics and has since been widely used in a variety of applications, including:

- Aerospace engineering: to predict the likelihood of failure in aircraft components

- Civil engineering: to predict the likelihood of failure in bridges and buildings

- Materials science: to determine the toughness of new materials

Derivation of the Griffith Equation

The Griffith equation can be derived from the principles of energy conservation and mechanics. The equation is based on the idea that the energy released by the growth of a crack is equal to the energy required to create new surface area. The Griffith equation can be written in the form: σ = (2γE/πa)^(1/2), where σ is the stress intensity factor, γ is the surface energy, E is the Young's modulus, and a is the crack length. The equation shows that the stress intensity factor is a function of the surface energy, Young's modulus, and crack length. Key factors that affect the Griffith equation include:

- Surface energy: the energy required to create new surface area

- Young's modulus: a measure of the stiffness of a material

- Crack length: the length of the crack

Applications of the Griffith Equation

The Griffith equation has a wide range of applications in engineering and materials science. It is used to predict the likelihood of failure due to cracking in a variety of components, including aircraft components, bridges, and buildings. The equation is also used to determine the toughness of new materials and to predict the stress intensity factor at which a crack will propagate. Some of the key applications of the Griffith equation include:

- Design of safety-critical components: to predict the likelihood of failure due to cracking

- Materials selection: to determine the toughness of new materials

- Failure analysis: to determine the cause of failure in components

Limitations of the Griffith Equation

The Griffith equation has several limitations that must be considered when using it to predict the likelihood of failure due to cracking. One of the main limitations is that the equation assumes that the stress intensity factor is the only factor that affects the growth of a crack. In reality, there are many other factors that can affect the growth of a crack, including plasticity, viscoelasticity, and environmental factors. Other limitations of the Griffith equation include:

- Assumes linear elastic behavior: the equation assumes that the material behaves in a linear elastic manner

- Does not account for plasticity: the equation does not account for the effects of plasticity on the growth of a crack

- Does not account for environmental factors: the equation does not account for the effects of environmental factors on the growth of a crack

Extensions of the Griffith Equation

There have been several extensions to the Griffith equation that have been developed to address its limitations. One of the main extensions is the Irwin equation, which takes into account the effects of plasticity on the growth of a crack. Another extension is the Paris-Erdogan equation, which takes into account the effects of cyclic loading on the growth of a crack. Key extensions of the Griffith equation include:

- Irwin equation: takes into account the effects of plasticity on the growth of a crack

- Paris-Erdogan equation: takes into account the effects of cyclic loading on the growth of a crack

- Cohesive zone model: takes into account the effects of cohesive zones on the growth of a crack

What is the equation for the critical flaw size?

The equation for the critical flaw size is a mathematical model that predicts the size of a defect or flaw in a material that can lead to failure under a given stress. The equation is based on the concept of fracture mechanics and is used to determine the critical flaw size that can cause a material to fail. The equation is typically expressed as a function of the stress intensity factor, the material properties, and the loading conditions.

Introduction to Critical Flaw Size

The critical flaw size is a key parameter in fracture mechanics that determines the failure of a material under a given stress. The equation for the critical flaw size is used to predict the size of a defect or flaw that can lead to failure. The equation takes into account the material properties, such as the toughness and the yield strength, as well as the loading conditions, such as the stress and the strain rate. Some of the key factors that influence the critical flaw size include:

- Material properties: The toughness, yield strength, and elastic modulus of the material all play a role in determining the critical flaw size.

- Loading conditions: The stress and strain rate can affect the critical flaw size, with higher stresses and strain rates typically leading to smaller critical flaw sizes.

- Flaw shape and size: The shape and size of the flaw can also influence the critical flaw size, with larger flaws typically requiring smaller stresses to cause failure.

Derivation of the Critical Flaw Size Equation

The equation for the critical flaw size is derived from the principles of fracture mechanics and is based on the concept of the stress intensity factor. The stress intensity factor is a measure of the stress field around a crack or flaw and is used to predict the failure of a material. The equation for the critical flaw size is typically expressed as a function of the stress intensity factor, the material properties, and the loading conditions. The derivation of the equation involves the use of mathematical models, such as the Griffith criterion, to predict the failure of a material. Some of the key steps in the derivation include:

- Definition of the stress intensity factor: The stress intensity factor is defined as a measure of the stress field around a crack or flaw.

- Application of the Griffith criterion: The Griffith criterion is used to predict the failure of a material based on the stress intensity factor.

- Incorporation of material properties: The material properties, such as the toughness and yield strength, are incorporated into the equation to predict the critical flaw size.

Applications of the Critical Flaw Size Equation

The equation for the critical flaw size has a number of important applications in engineering and materials science. The equation is used to predict the failure of materials under a given stress and is used to design safe and reliable structures. The equation is also used to optimize the performance of materials and to improve their toughness and resistance to failure. Some of the key applications include:

- Design of safe structures: The equation is used to design safe and reliable structures that can withstand stresses and loads without failing.

- Optimization of material performance: The equation is used to optimize the performance of materials and to improve their toughness and resistance to failure.

- Prediction of material failure: The equation is used to predict the failure of materials under a given stress and to identify the critical flaw size that can lead to failure.

Limitations of the Critical Flaw Size Equation

The equation for the critical flaw size has a number of limitations and assumptions that must be considered when using it to predict the failure of materials. The equation is based on a number of simplifying assumptions, such as the homogeneity and isotropy of the material, and may not be applicable to all materials and loading conditions. Some of the key limitations include:

- Simplifying assumptions: The equation is based on a number of simplifying assumptions, such as the homogeneity and isotropy of the material.

- Limited applicability: The equation may not be applicable to all materials and loading conditions, such as dynamic loading or high-temperature loading.

- Uncertainty in material properties: The equation requires accurate material properties, such as the toughness and yield strength, which can be difficult to determine with certainty.

Future Developments in Critical Flaw Size Equation

The equation for the critical flaw size is a continuously evolving field of research, with new developments and advances being made regularly. Some of the key areas of research include the development of new mathematical models, the improvement of existing equations, and the application of the equation to new materials and loading conditions. Some of the key future developments include:

- Development of new mathematical models: New mathematical models, such as the finite element method, are being developed to improve the accuracy and applicability of the equation.

- Improvement of existing equations: Existing equations, such as the Griffith criterion, are being improved and refined to better predict the failure of materials.

- Application of the equation to new materials: The equation is being applied to new materials, such as composites and nanomaterials, to predict their failure and optimize their performance.

Frequently Asked Questions (FAQs)

What is the purpose of the Brittle Fracture Analysis Calculator and Equation?

The Brittle Fracture Analysis Calculator and Equation is a tool used to predict the likelihood of brittle fracture in materials, particularly in metals and alloys. The calculator uses a combination of material properties, such as tensile strength, yield strength, and fracture toughness, to determine the stress intensity factor and predict the likelihood of fracture. The equation is based on the theory of linear elastic fracture mechanics, which assumes that the material behaves in a linear elastic manner until failure. The calculator is commonly used in engineering and materials science applications, such as designing and analyzing structures and components that are subject to stress and strain. By using the Brittle Fracture Analysis Calculator and Equation, engineers and researchers can optimize the design of their materials and structures to minimize the risk of brittle fracture and ensure safe and reliable performance.

How does the Brittle Fracture Analysis Calculator and Equation account for the effects of temperature and stress on brittle fracture?

The Brittle Fracture Analysis Calculator and Equation takes into account the effects of temperature and stress on brittle fracture by using temperature-dependent and stress-dependent material properties. For example, the calculator uses the temperature-dependent fracture toughness and yield strength to predict the likelihood of fracture at different temperatures. The calculator also accounts for the effects of stress on brittle fracture by using the stress intensity factor, which is a measure of the stress at the tip of a crack. The calculator uses a combination of material properties and stress and temperature conditions to predict the likelihood of fracture. Additionally, the calculator can also account for the effects of residual stresses, thermal stresses, and mechanical stresses on brittle fracture. By considering the effects of temperature and stress on brittle fracture, the calculator can provide a more accurate and reliable prediction of the likelihood of fracture.

What are the limitations and assumptions of the Brittle Fracture Analysis Calculator and Equation?

The Brittle Fracture Analysis Calculator and Equation has several limitations and assumptions that must be considered when using the tool. One of the main limitations is that the calculator assumes that the material behaves in a linear elastic manner until failure, which may not be the case for all materials. Additionally, the calculator assumes that the crack is sharp and straight, which may not be the case in real-world applications. The calculator also assumes that the material properties are homogeneous and isotropic, which may not be the case for all materials. Furthermore, the calculator does not account for the effects of plasticity, creep, and fatigue on brittle fracture, which can be significant in certain applications. To overcome these limitations, it is recommended to use the calculator in conjunction with experimental testing and other analysis tools to validate the results and ensure that the assumptions are valid. By understanding the limitations and assumptions of the calculator, engineers and researchers can use the tool more effectively and accurately.

How can the results of the Brittle Fracture Analysis Calculator and Equation be used to optimize the design of materials and structures?

The results of the Brittle Fracture Analysis Calculator and Equation can be used to optimize the design of materials and structures by identifying the critical factors that affect brittle fracture. For example, the calculator can be used to determine the minimum fracture toughness required to prevent brittle fracture in a given application. The results can also be used to optimize the geometry and dimensions of a structure to minimize the stress intensity factor and reduce the likelihood of fracture. Additionally, the calculator can be used to select the most suitable material for a given application based on its fracture toughness and other material properties. By using the calculator to optimize the design of materials and structures, engineers and researchers can minimize the risk of brittle fracture and ensure safe and reliable performance. The results of the calculator can also be used to inform the development of new materials and design strategies that can mitigate the risk of brittle fracture. By combining the results of the calculator with experimental testing and other analysis tools, engineers and researchers can develop optimal designs that balance performance, safety, and reliability.

Deja una respuesta

Entradas Relacionadas