Torsion Spring Constant Calculator

The Torsion Spring Constant Calculator is a valuable tool for engineers and designers to determine the spring constant of torsion springs. Torsion springs are commonly used in various applications, including clock mechanisms, door hinges, and industrial machinery. Calculating the spring constant is crucial to ensure the spring's performance and longevity. This calculator takes into account the spring's physical properties, such as its wire diameter, coil diameter, and number of coils, to provide an accurate calculation of the spring constant, making it easier to design and optimize torsion spring systems with precision and reliability. Its usage is straightforward.

- Torsion Spring Constant Calculator: Understanding the Basics

- How to calculate torsion spring constant?

- How many times do I wind my torsion spring?

- What is the spring constant formula?

- How do I figure out what torsion spring I need?

-

Frequently Asked Questions (FAQs)

- What is the Torsion Spring Constant Calculator and how does it work?

- What are the key parameters that affect the torsion spring constant calculation?

- How can I use the Torsion Spring Constant Calculator to design a torsion spring?

- What are some common applications of torsion springs and how can the Torsion Spring Constant Calculator be used in these applications?

Torsion Spring Constant Calculator: Understanding the Basics

The Torsion Spring Constant Calculator is a tool used to calculate the spring constant of a torsion spring, which is a type of spring that stores energy when twisted. This calculator is essential in the design and development of mechanical systems that involve torsion springs, such as clocks, gears, and mechanical linkages. The calculator takes into account the wire diameter, coil diameter, and number of coils to determine the spring constant.

What is a Torsion Spring Constant Calculator?

A Torsion Spring Constant Calculator is a mathematical tool that uses formulas and algorithms to calculate the spring constant of a torsion spring. This calculator is typically used by engineers and designers to determine the torque and rotation of a torsion spring in a mechanical system. The calculator can be used to design and optimize mechanical systems, such as robotic arms and mechanical grippers.

How to Use a Torsion Spring Constant Calculator

To use a Torsion Spring Constant Calculator, you need to input the wire diameter, coil diameter, and number of coils of the torsion spring. The calculator will then use these values to calculate the spring constant using formulas and algorithms. The calculator may also require additional inputs, such as the material properties of the spring, to determine the spring constant.

Benefits of Using a Torsion Spring Constant Calculator

The benefits of using a Torsion Spring Constant Calculator include accurate calculations, time savings, and improved design optimization. The calculator can help engineers and designers to quickly and accurately determine the spring constant of a torsion spring, which is essential in the design and development of mechanical systems. The calculator can also help to reduce errors and improve productivity.

Types of Torsion Spring Constant Calculators

There are several types of Torsion Spring Constant Calculators available, including online calculators and software programs. Online calculators are web-based tools that can be accessed using a web browser, while software programs are desktop applications that need to be installed on a computer. Some calculators may also be available as mobile apps.

Applications of Torsion Spring Constant Calculators

Torsion Spring Constant Calculators have a wide range of applications in mechanical engineering, robotics, and mechatronics. The calculator can be used to design and optimize mechanical systems, such as clocks, gears, and mechanical linkages. The calculator can also be used to analyze and simulate the behavior of torsion springs in mechanical systems.

| Parameter | Unit | Description |

|---|---|---|

| Wire Diameter | mm | The diameter of the wire used to make the torsion spring |

| Coil Diameter | mm | The diameter of the coil of the torsion spring |

| Number of Coils | - | The number of coils in the torsion spring |

| Spring Constant | Nm/rad | The constant that relates the torque and rotation of the torsion spring |

How to calculate torsion spring constant?

To calculate the torsion spring constant, you need to know the spring's physical properties, such as its wire diameter, coil diameter, and number of coils. The torsion spring constant is calculated using the following formula: k = (G d^4) / (8 D n), where k is the torsion spring constant, G is the shear modulus of the spring material, d is the wire diameter, D is the coil diameter, and n is the number of coils. This formula provides a way to calculate the torsion spring constant based on the spring's geometric properties and material characteristics.

Understanding Torsion Spring Constants

The torsion spring constant is a critical parameter in designing and analyzing torsion springs. It represents the spring's resistance to torsional deflection and is essential for determining the spring's behavior under various loading conditions. To calculate the torsion spring constant, you need to consider the spring's material properties, such as its shear modulus and yield strength, as well as its geometric properties, including its wire diameter, coil diameter, and number of coils. The following factors are crucial in calculating the torsion spring constant:

- Material properties: The shear modulus and yield strength of the spring material

- Geometric properties: The wire diameter, coil diameter, and number of coils

- Loading conditions: The applied torque and angular displacement

Calculating Torsion Spring Constants using the Formula

The formula for calculating the torsion spring constant is based on the spring's geometric properties and material characteristics. The formula is: k = (G d^4) / (8 D n), where k is the torsion spring constant, G is the shear modulus of the spring material, d is the wire diameter, D is the coil diameter, and n is the number of coils. To apply this formula, you need to know the values of these parameters and plug them into the equation. The following steps are involved in calculating the torsion spring constant:

- Determine the shear modulus: Look up the shear modulus of the spring material in a reference table or calculate it using the material's properties

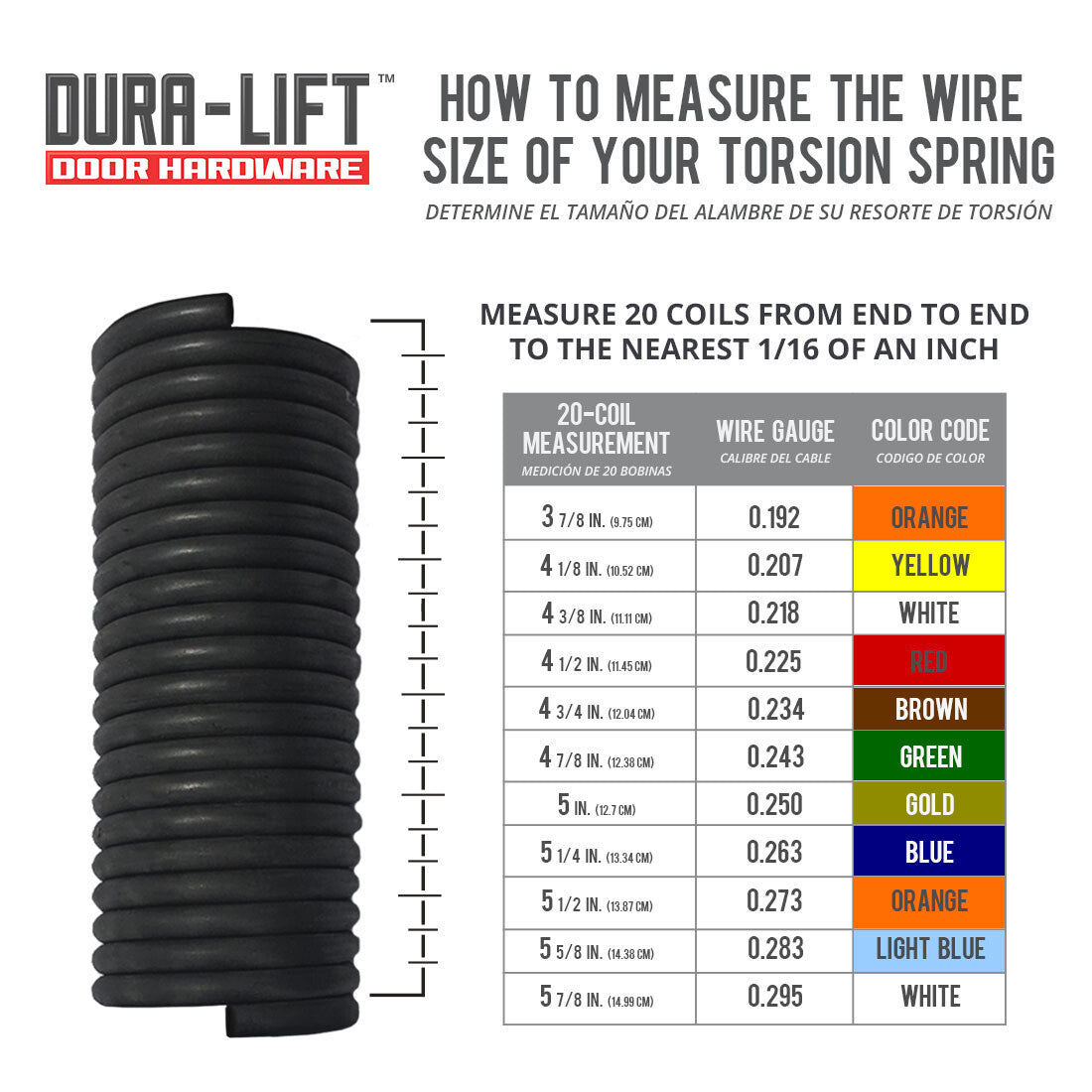

- Measure the wire diameter: Measure the wire diameter of the spring using a caliper or micrometer

- Measure the coil diameter: Measure the coil diameter of the spring using a caliper or micrometer

Factors Affecting Torsion Spring Constants

Several factors can affect the torsion spring constant, including the spring material, wire diameter, coil diameter, and number of coils. The spring material can affect the torsion spring constant by changing the shear modulus, which is a measure of the material's resistance to shear stress. The wire diameter and coil diameter can also affect the torsion spring constant by changing the spring's geometric properties. The following factors can influence the torsion spring constant:

- Spring material: The shear modulus and yield strength of the spring material

- Wire diameter: The wire diameter of the spring

- Coil diameter: The coil diameter of the spring

Applications of Torsion Spring Constants

The torsion spring constant is essential in various applications, including mechanical engineering, aerospace engineering, and automotive engineering. In these fields, torsion springs are used to store energy, provide torsional stiffness, and resist torsional deflection. The torsion spring constant is used to design and analyze torsion springs for specific applications, such as engine valve springs and gearbox springs. The following applications demonstrate the importance of the torsion spring constant:

- Mechanical engineering: Designing torsion springs for mechanical systems

- Aerospace engineering: Analyzing torsion springs for aerospace applications

- Automotive engineering: Developing torsion springs for automotive systems

Common Mistakes in Calculating Torsion Spring Constants

When calculating the torsion spring constant, several common mistakes can occur, including incorrect measurement of the wire diameter or coil diameter, incorrect calculation of the shear modulus, and neglecting the number of coils. These mistakes can lead to inaccurate results and poor design of the torsion spring. To avoid these mistakes, it is essential to carefully measure the spring's geometric properties and accurately calculate the shear modulus. The following mistakes are common when calculating the torsion spring constant:

- Incorrect measurement: Measuring the wire diameter or coil diameter incorrectly

- Incorrect calculation: Calculating the shear modulus incorrectly

- Neglecting the number of coils: Neglecting the number of coils in the calculation

How many times do I wind my torsion spring?

The number of times you wind your torsion spring depends on various factors, including the type of spring, its material, and the desired tension. To determine the correct number of windings, you should consult the manufacturer's instructions or perform calculations based on the spring's specifications. Generally, it's recommended to wind the spring until it reaches the desired torque, which can be measured using a torque wrench. Over-winding can lead to spring failure, while under-winding may result in reduced efficiency.

Understanding Torsion Spring Specifications

To determine how many times to wind your torsion spring, you need to understand its specifications, including the wire diameter, coil diameter, and number of coils. The specifications will help you calculate the spring constant, which is essential in determining the required torque. You can use the following formula to calculate the spring constant:

- Measure the wire diameter and coil diameter using a caliper or micrometer.

- Count the number of coils and calculate the spring index.

- Use the spring constant formula to calculate the spring constant, which is typically measured in inch-pounds per degree.

Calculating the Required Torque

To calculate the required torque, you need to consider the application and the desired rotational speed. The torque is typically measured in inch-pounds or foot-pounds, and it's essential to use a torque wrench to avoid over- or under-tightening the spring. You can use the following steps to calculate the required torque:

- Determine the desired rotational speed and application.

- Calculate the required torque using the spring constant and rotational speed.

- Use a torque wrench to apply the calculated torque to the spring.

Winding Techniques for Torsion Springs

There are different winding techniques for torsion springs, including manual winding and automated winding. The choice of technique depends on the spring size, material, and desired tension. Manual winding is typically used for smaller springs, while automated winding is used for larger springs. You can use the following steps to wind your torsion spring:

- Choose the winding technique based on the spring size and desired tension.

- Use a winding tool or automated winder to wind the spring.

- Apply the calculated torque to the spring using a torque wrench.

Common Mistakes When Winding Torsion Springs

There are several common mistakes that can occur when winding torsion springs, including over-winding and under-winding. Over-winding can lead to spring failure, while under-winding may result in reduced efficiency. You can avoid these mistakes by:

- Following the manufacturer's instructions.

- Using a torque wrench to apply the calculated torque.

- Monitoring the spring tension during the winding process.

Torsion Spring Maintenance and Repair

Regular maintenance and repair are essential to ensure the longevity and efficiency of your torsion spring. You can use the following steps to maintain and repair your torsion spring:

- Inspect the spring for wear and damage.

- Replace any damaged or worn-out parts.

- Apply lubricant to the spring to reduce friction and wear.

What is the spring constant formula?

The spring constant formula is a mathematical expression that describes the relationship between the force applied to a spring and its resulting displacement. The formula is given by F = kx, where F is the force, k is the spring constant, and x is the displacement. The spring constant is a measure of the stiffness of the spring, and it is typically denoted by the symbol k.

What is the Spring Constant?

The spring constant is a measure of the stiffness of a spring, and it is an important parameter in the design and analysis of mechanical systems. The spring constant is typically denoted by the symbol k and is measured in units of newtons per meter (N/m). A higher spring constant indicates a stiffer spring, while a lower spring constant indicates a more compliant spring. Some of the key factors that affect the spring constant include:

- The material used to make the spring, with stiffer materials resulting in higher spring constants

- The geometry of the spring, with thicker or wider springs resulting in higher spring constants

- The type of spring, with compression springs typically having higher spring constants than extension springs

How to Calculate the Spring Constant

The spring constant can be calculated using the formula k = F / x, where F is the force applied to the spring and x is the resulting displacement. This formula can be used to calculate the spring constant of a spring if the force and displacement are known. Alternatively, the spring constant can be measured experimentally using a force sensor and a displacement sensor. Some of the key considerations when calculating the spring constant include:

- Ensuring that the force and displacement are measured in the same units

- Accounting for any friction or damping that may affect the measurement

- Using a sufficiently large sample size to ensure accurate results

Types of Spring Constants

There are several types of spring constants, each with its own unique characteristics and applications. Some of the most common types of spring constants include:

- The tension spring constant, which is used to describe the stiffness of a spring in tension

- The compression spring constant, which is used to describe the stiffness of a spring in compression

- The torsion spring constant, which is used to describe the stiffness of a spring in torsion

Applications of the Spring Constant

The spring constant has a wide range of applications in mechanical engineering and other fields. Some of the most common applications of the spring constant include:

- Designing mechanical systems, such as engines and transmissions

- Analyzing vibrations, such as oscillations and resonance

- Predicting stresses and strains in materials

Limitations of the Spring Constant Formula

The spring constant formula is a simplified model that assumes a linear relationship between the force and displacement of a spring. However, in real-world applications, the relationship between the force and displacement may be non-linear, and the spring constant formula may not accurately capture the behavior of the spring. Some of the key limitations of the spring constant formula include:

- Non-linear effects, such as hysteresis and plasticity

- Dynamic effects, such as inertia and damping

- Temperature effects, which can cause the spring constant to change

How do I figure out what torsion spring I need?

To figure out what torsion spring you need, you must consider several factors, including the load and distance the spring will be required to move, as well as the space constraints of the application. The first step is to determine the direction of rotation and the amount of rotation required. You must also consider the spring rate and torque required to achieve the desired motion. Additionally, you should think about the material and durability of the spring, as well as any environmental factors that may affect its performance.

Understanding Torsion Spring Requirements

To determine the correct torsion spring, you need to understand the requirements of your application. This includes considering the load, distance, and speed of the spring, as well as any space constraints. You should also think about the type of motion required, such as rotational or linear, and the amount of rotation needed. Some key factors to consider include:

- Load capacity: The amount of weight or force the spring can handle.

- Spring rate: The amount of torque required to rotate the spring a certain distance.

- Torque output: The amount of rotational force the spring can produce.

Measuring Torsion Spring Dimensions

To select the correct torsion spring, you need to measure the dimensions of the space where the spring will be installed. This includes the inner diameter, outer diameter, and length of the spring, as well as any clearance or obstructions that may affect its movement. You should also consider the wire diameter and coil count of the spring, as these can affect its strength and durability. Some key measurements to consider include:

- Inner diameter: The diameter of the spring's inner coil.

- Outer diameter: The diameter of the spring's outer coil.

- Length: The overall length of the spring.

Choosing the Right Torsion Spring Material

The material of the torsion spring is an important consideration, as it can affect the spring's strength, durability, and corrosion resistance. Common materials used for torsion springs include stainless steel, carbon steel, and copper-based alloys. You should choose a material that can withstand the load and environmental conditions of your application. Some key factors to consider include:

- Corrosion resistance: The ability of the spring to resist rust and corrosion.

- Strength: The ability of the spring to withstand load and stress.

- Durability: The ability of the spring to withstand wear and tear.

Calculating Torsion Spring Torque and Spring Rate

To calculate the torque and spring rate of a torsion spring, you need to use a combination of mathematical formulas and engineering principles. The torque of a torsion spring is calculated by multiplying the force applied to the spring by the distance from the center of the spring to the point of application. The spring rate is calculated by dividing the torque by the angle of rotation$. Some key formulas to consider include:

- Torque formula: Torque = Force x Distance.

- Spring rate formula: Spring rate = Torque / Angle of rotation.

- Rotation formula: Rotation = Torque / Spring rate.

Testing and Validating Torsion Spring Performance

Once you have selected a torsion spring, you need to test and validate its performance to ensure it meets the requirements of your application. This includes testing the spring's load capacity, torque output, and rotation under various conditions and environments. You should also consider fatigue testing and endurance testing to ensure the spring can withstand repeated loading and unloading. Some key tests to consider include:

- Load testing: Testing the spring's ability to handle load and stress.

- Torque testing: Testing the spring's ability to produce torque and rotation.

- Endurance testing: Testing the spring's ability to withstand repeated loading and unloading.

Frequently Asked Questions (FAQs)

What is the Torsion Spring Constant Calculator and how does it work?

The Torsion Spring Constant Calculator is an online tool designed to calculate the spring constant of a torsion spring, which is a type of spring that stores energy when twisted. This calculator uses the physical properties of the spring, such as its wire diameter, coil diameter, and number of coils, to determine the spring constant. The spring constant is a measure of the stiffness of the spring, and it is an important parameter in determining the behavior of the spring under different loads. The calculator uses a set of formulas and algorithms to calculate the spring constant, taking into account the material properties of the spring, such as its modulus of elasticity and Poisson's ratio. By using the Torsion Spring Constant Calculator, users can quickly and easily determine the spring constant of a torsion spring, without having to perform complex calculations or experiments.

What are the key parameters that affect the torsion spring constant calculation?

The torsion spring constant calculation is affected by several key parameters, including the wire diameter, coil diameter, number of coils, and material properties of the spring. The wire diameter and coil diameter affect the stiffness of the spring, with larger diameters resulting in a stiffer spring. The number of coils also affects the stiffness of the spring, with more coils resulting in a softer spring. The material properties of the spring, such as its modulus of elasticity and Poisson's ratio, also play a critical role in determining the spring constant. Additionally, the end conditions of the spring, such as whether it is fixed or free, can also affect the calculation. By understanding how these parameters affect the torsion spring constant calculation, users can design and optimize their springs for specific applications. The Torsion Spring Constant Calculator takes into account these parameters to provide an accurate calculation of the spring constant.

How can I use the Torsion Spring Constant Calculator to design a torsion spring?

The Torsion Spring Constant Calculator can be used to design a torsion spring by inputting the desired parameters and properties of the spring. Users can input the wire diameter, coil diameter, number of coils, and material properties of the spring, and the calculator will output the spring constant and other relevant parameters. By iterating on the design and adjusting the parameters, users can optimize the spring for their specific application. For example, if a user needs a spring with a specific stiffness, they can use the calculator to determine the required wire diameter and coil diameter. The calculator can also be used to compare different design options and materials, allowing users to select the best solution for their application. By using the Torsion Spring Constant Calculator, users can save time and effort in the design process, and ensure that their torsion spring meets the required specifications.

What are some common applications of torsion springs and how can the Torsion Spring Constant Calculator be used in these applications?

Torsion springs are used in a wide range of applications, including mechanical devices, machinery, and vehicles. They are commonly used in clutches, brakes, and gearboxes, where they provide a torque or rotational force. The Torsion Spring Constant Calculator can be used in these applications to design and optimize the torsion spring for the specific requirements. For example, in a clutch application, the calculator can be used to determine the spring constant required to provide a specific torque. In a gearbox application, the calculator can be used to design a torsion spring that provides a specific rotational force. The calculator can also be used in research and development applications, where torsion springs are used to measure or control rotational motions. By using the Torsion Spring Constant Calculator, users can ensure that their torsion spring is designed and optimized for the specific application, and that it meets the required specifications.

Deja una respuesta

Entradas Relacionadas