Punching Holes in Plate Stress Equations and Calculator

Calculating stress in plates is a crucial aspect of engineering design, particularly in industries where safety and durability are paramount. The punching hole in a plate scenario presents a unique challenge, as it introduces stress concentrations that can lead to failure. Engineers rely on stress equations and calculators to predict and mitigate these effects. This article delves into the complexities of punching holes in plate stress equations and calculator, exploring the underlying principles, common pitfalls, and best practices for accurate stress analysis and design optimization. Accurate calculations are essential for ensuring structural integrity.

-

Punching Holes in Plate Stress Equations and Calculator

- Introduction to Punching Holes in Plate Stress Equations

- Types of Stress Equations for Punching Holes

- Punching Holes in Plate Stress Calculator

- Applications of Punching Holes in Plate Stress Equations and Calculator

- Limitations and Assumptions of Punching Holes in Plate Stress Equations and Calculator

- How to calculate punching load?

- How much force is required to punch a hole?

- Frequently Asked Questions (FAQs)

Punching Holes in Plate Stress Equations and Calculator

Punching holes in plate stress equations and calculator is a crucial aspect of mechanical engineering, particularly in the design and analysis of structures and machines. When a hole is punched in a plate, it creates a stress concentration around the hole, which can lead to failure if not properly accounted for. The stress equations and calculator are essential tools for engineers to determine the stress distribution around the hole and ensure that the plate can withstand the applied loads.

Introduction to Punching Holes in Plate Stress Equations

The punching holes in plate stress equations are based on the theory of elasticity and the concept of stress concentration. When a hole is introduced in a plate, it disrupts the stress flow, creating a concentration of stress around the hole. The stress concentration factor is a critical parameter in determining the stress distribution around the hole. The stress concentration factor is affected by the hole size, plate thickness, and material properties.

Types of Stress Equations for Punching Holes

There are several types of stress equations used to analyze punching holes in plates, including linear elastic fracture mechanics, elastic-plastic fracture mechanics, and finite element method. Each method has its strengths and limitations, and the choice of method depends on the specific application and the desired level of accuracy. The stress intensity factor is a key parameter in determining the stress distribution around the hole.

Punching Holes in Plate Stress Calculator

A punching holes in plate stress calculator is a software tool that uses the stress equations to determine the stress distribution around a hole in a plate. The calculator takes into account the plate geometry, material properties, and applied loads to determine the stress concentration factor and stress intensity factor. The calculator can be used to analyze various types of holes, including circular, rectangular, and elliptical holes.

Applications of Punching Holes in Plate Stress Equations and Calculator

The punching holes in plate stress equations and calculator have numerous applications in mechanical engineering, including structural analysis, machine design, and materials science. The equations and calculator are used to design and analyze pressure vessels, pipelines, and aircraft structures. The stress concentration factor and stress intensity factor are critical parameters in determining the fatigue life and fracture toughness of these structures.

Limitations and Assumptions of Punching Holes in Plate Stress Equations and Calculator

The punching holes in plate stress equations and calculator have several limitations and assumptions, including simplifications of the stress equations, assumptions about material properties, and neglect of other factors such as residual stresses and corrosion. The stress concentration factor and stress intensity factor are sensitive to these assumptions, and the results should be interpreted with caution.

| Parameter | Unit | Description |

|---|---|---|

| Hole Size | mm | The diameter of the hole |

| Plate Thickness | mm | The thickness of the plate |

| Material Properties | N/m^2 | The mechanical properties of the material, such as Young's modulus and Poisson's ratio |

| Stress Concentration Factor | -unitless | A dimensionless parameter that describes the concentration of stress around the hole |

| Stress Intensity Factor | Pa sqrt(m) | A parameter that describes the stress distribution around the hole |

How to calculate punching load?

To calculate the punching load, you need to consider the stress and strain on the material being punched. The punching load is the force required to punch a hole in a material, and it depends on various factors such as the thickness of the material, the diameter of the hole, and the type of material being punched. The punching load can be calculated using the punching force formula, which takes into account the ultimate tensile strength of the material and the punch diameter.

Understanding the Punching Load Formula

The punching load formula is a complex equation that requires careful consideration of various factors. To calculate the punching load, you need to understand the mathematical model behind the formula, which involves the stress and strain on the material. The key factors to consider are:

- The ultimate tensile strength of the material, which is the maximum stress that the material can withstand without failing.

- The punch diameter, which affects the stress concentration around the hole.

- The thickness of the material, which affects the bending moment and the shear stress on the material.

Factors Affecting Punching Load

Several factors can affect the punching load, including the type of material being punched, the temperature of the material, and the punching speed. The material properties, such as the yield strength and the ultimate tensile strength, also play a crucial role in determining the punching load. Additionally, the punch geometry, including the punch diameter and the punch shape, can affect the stress concentration around the hole. The key factors to consider are:

- The material properties, which affect the stress and strain on the material.

- The punch geometry, which affects the stress concentration around the hole.

- The temperature of the material, which can affect the material properties.

Calculating Punching Load for Different Materials

The punching load can vary significantly depending on the type of material being punched. For example, metals such as steel and aluminum have a high ultimate tensile strength and require a higher punching load than plastics and composites. The punching load can be calculated using the punching force formula, which takes into account the material properties and the punch geometry. The key factors to consider are:

- The material properties, which affect the stress and strain on the material.

- The punch geometry, which affects the stress concentration around the hole.

- The punching speed, which can affect the material properties and the punching load.

Importance of Accurate Punching Load Calculation

Accurate calculation of the punching load is crucial to ensure the quality and integrity of the punched hole. An inaccurate or insufficient punching load can result in a poor-quality hole, which can lead to material failure or structural damage. The punching load calculation should take into account the material properties, the punch geometry, and the punching conditions to ensure a precise and accurate calculation. The key factors to consider are:

- The material properties, which affect the stress and strain on the material.

- The punch geometry, which affects the stress concentration around the hole.

- The punching conditions, which can affect the material properties and the punching load.

Common Challenges in Punching Load Calculation

Calculating the punching load can be a complex task, and there are several challenges that need to be addressed. One of the main challenges is the uncertainty in the material properties, which can affect the accuracy of the calculation. Additionally, the punch geometry and the punching conditions can also affect the punching load, making it challenging to calculate accurately. The key factors to consider are:

- The uncertainty in the material properties, which can affect the accuracy of the calculation.

- The punch geometry, which can affect the stress concentration around the hole.

- The punching conditions, which can affect the material properties and the punching load.

How much force is required to punch a hole?

The amount of force required to punch a hole depends on various factors, including the material being punched, the thickness of the material, and the size of the hole being created. To determine the required force, one must consider the mechanical properties of the material, such as its tensile strength, yield strength, and fracture toughness. The punching process involves the application of a concentrated load to a small area, resulting in a high stress concentration that can lead to material failure.

Factors Affecting Punching Force

The force required to punch a hole is influenced by several factors, including the material properties, punch geometry, and punching conditions. Some key factors to consider are:

- The thickness of the material, as thicker materials require more force to punch

- The yield strength of the material, as higher strength materials require more force to deform

- The punch diameter, as smaller punches require more force to create a hole

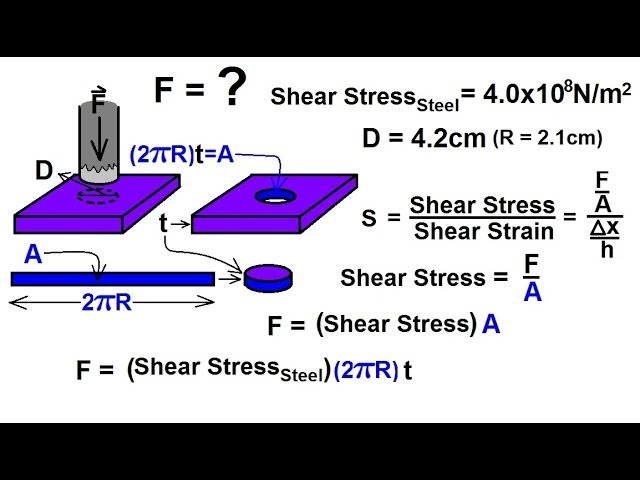

Punching Force Calculation

To calculate the punching force required, engineers use various formulas and models that take into account the material properties and punching conditions. These calculations involve the use of stress and strain analysis, as well as energy considerations. The resulting force calculation can be used to determine the required punching pressure and punch geometry.

Material Properties and Punching Force

The material properties play a crucial role in determining the punching force required. Ductile materials, such as metals, require more force to punch than brittle materials, such as glass. Additionally, hardened materials require more force to punch than annealed materials. Understanding the material properties is essential to determining the required punching force.

Punch Geometry and Punching Force

The punch geometry also affects the punching force required. A sharp-edged punch requires more force to create a hole than a rounded-edged punch. Similarly, a smaller punch diameter requires more force to create a hole than a larger punch diameter. The punch geometry must be carefully designed to minimize the required punching force.

Applications of Punching Force

The punching force calculation has various practical applications, including metal forming, plastic molding, and composite manufacturing. In these applications, the punching force is used to determine the required machine capacity, tooling design, and process conditions. Understanding the punching force requirements is essential to ensuring process efficiency, product quality, and machine safety.

Frequently Asked Questions (FAQs)

What is Punching Holes in Plate Stress Equations and Calculator?

The Punching Holes in Plate Stress Equations and Calculator is a tool used to calculate the stress and strain on a plate when a hole is punched or cut out of it. This is a common problem in engineering and design, where plates with holes are used in a variety of applications, such as mechanical components, structural elements, and pressure vessels. The calculator uses complex mathematical equations to determine the stress concentrations around the hole, which can lead to failure of the plate if not properly designed. By using the calculator, engineers and designers can ensure that their designs are safe and reliable, and that the plates can withstand the loads and stresses imposed on them.

How does the Punching Holes in Plate Stress Equations and Calculator work?

The Punching Holes in Plate Stress Equations and Calculator works by using a set of mathematical equations that describe the stress and strain behavior of a plate with a hole. These equations take into account the size and shape of the hole, as well as the material properties of the plate, such as its elastic modulus and poisson's ratio. The calculator also considers the boundary conditions of the plate, such as the loads and constraints applied to it. By solving these equations, the calculator can determine the stress concentrations around the hole, as well as the maximum stress and strain values. This information can then be used to design and optimize the plate, ensuring that it can withstand the loads and stresses imposed on it. The calculator is a powerful tool that can save time and effort in the design process, and can help to prevent failures and improve safety.

What are the benefits of using the Punching Holes in Plate Stress Equations and Calculator?

The Punching Holes in Plate Stress Equations and Calculator offers several benefits to engineers and designers. One of the main benefits is the ability to quickly and accurately calculate the stress and strain on a plate with a hole, which can save time and effort in the design process. The calculator also allows users to optimize their designs, by iterating on different design parameters such as the hole size and plate thickness. This can lead to improved performance, reduced weight, and increased safety. Additionally, the calculator can help to prevent failures by identifying potential stress concentrations and weak points in the design. By using the calculator, engineers and designers can ensure that their designs are reliable and safe, and that they meet the required standards and regulations.

Deja una respuesta

Entradas Relacionadas