Xtra Strong (XS) Size Steel Pipe Weights Table Calculator

The Xtra Strong (XS) size steel pipe is a type of pipe that is widely used in various industries due to its high strength and durability. Calculating the weight of XS steel pipes is crucial for engineering and construction projects. The XS size steel pipe weights table calculator is a tool that provides accurate calculations of the weight of XS steel pipes based on their size, material, and length. This calculator is essential for ensuring the safe and efficient use of XS steel pipes in various applications, including oil and gas, chemical processing, and power generation. Accurate calculations are vital.

-

Understanding the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator

- How to Use the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator

- Importance of Accurate Weight Calculations

- Factors Affecting Steel Pipe Weight

- Benefits of Using the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator

- Xtra Strong (XS) Size Steel Pipe Weights Table Calculator Applications

- What is the formula for calculating the weight of steel pipe?

- How much does a 1 inch steel pipe weight per foot?

- How do you calculate the weight per foot of a pipe?

-

Frequently Asked Questions (FAQs)

- What is the purpose of the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator?

- How does the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator work?

- What are the benefits of using the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator?

- Can the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator be used for other types of steel pipes?

Understanding the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator

The Xtra Strong (XS) Size Steel Pipe Weights Table Calculator is a tool used to calculate the weight of steel pipes based on their size, material, and thickness. This calculator is essential for engineers, architects, and contractors who need to determine the weight of steel pipes for various construction projects. The calculator takes into account the nominal diameter, wall thickness, and material density of the pipe to calculate its weight.

How to Use the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator

To use the calculator, users need to input the nominal diameter and wall thickness of the pipe, as well as the material density. The calculator will then calculate the weight of the pipe based on these inputs. The calculator can also be used to determine the weight per foot or weight per meter of the pipe. The Xtra Strong (XS) Size Steel Pipe Weights Table Calculator is a valuable tool for anyone working with steel pipes, as it provides accurate and reliable weight calculations.

Importance of Accurate Weight Calculations

Accurate weight calculations are crucial in construction projects, as they affect the structural integrity and stability of the building or structure. The weight of steel pipes can impact the load-bearing capacity of the structure, and incorrect calculations can lead to safety hazards and costly repairs. The Xtra Strong (XS) Size Steel Pipe Weights Table Calculator helps users avoid these potential problems by providing accurate and reliable weight calculations.

Factors Affecting Steel Pipe Weight

Several factors can affect the weight of steel pipes, including the material density, nominal diameter, and wall thickness. The schedule number of the pipe, which indicates its thickness, also plays a significant role in determining its weight. The Xtra Strong (XS) Size Steel Pipe Weights Table Calculator takes these factors into account to provide accurate weight calculations.

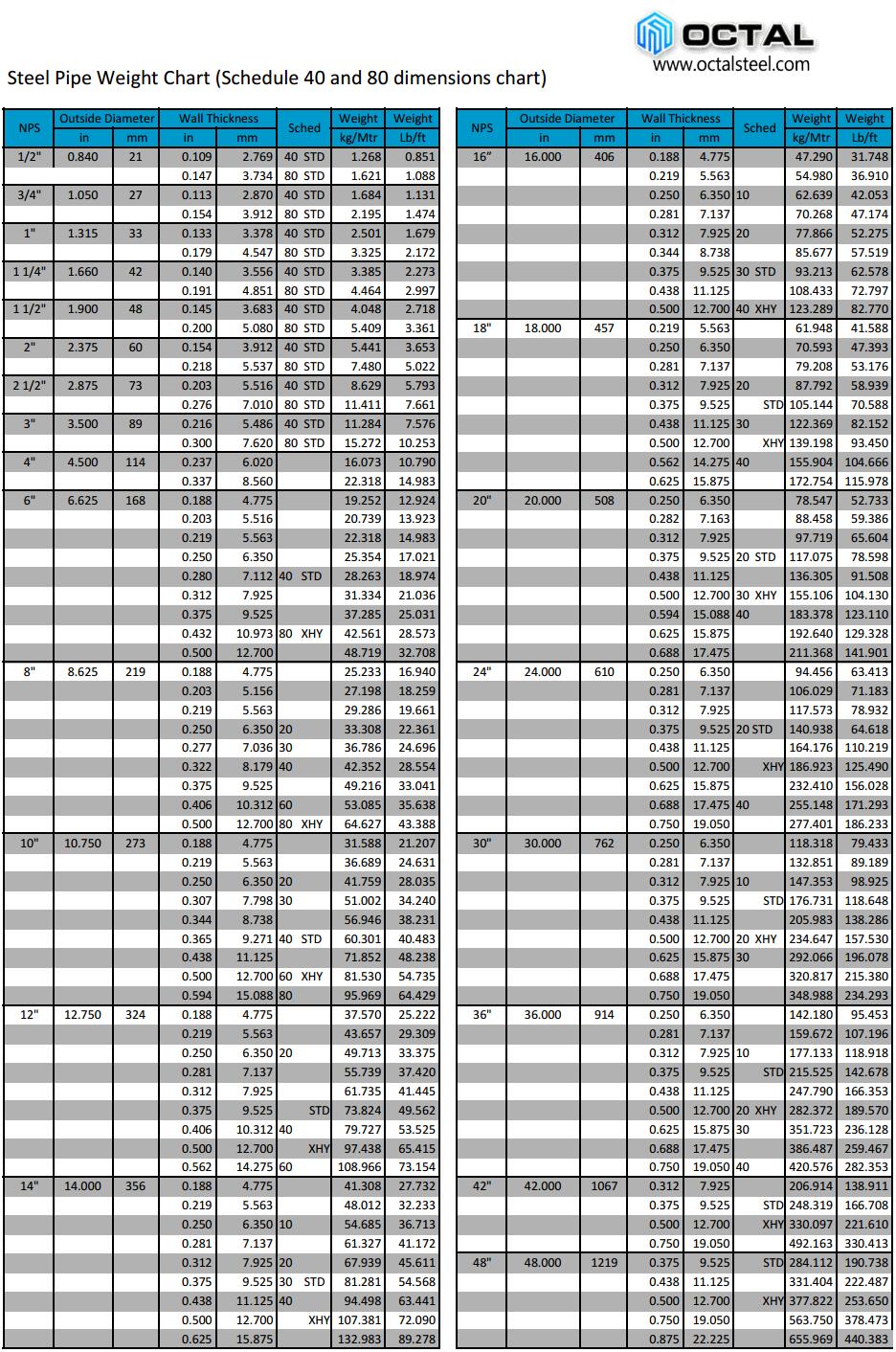

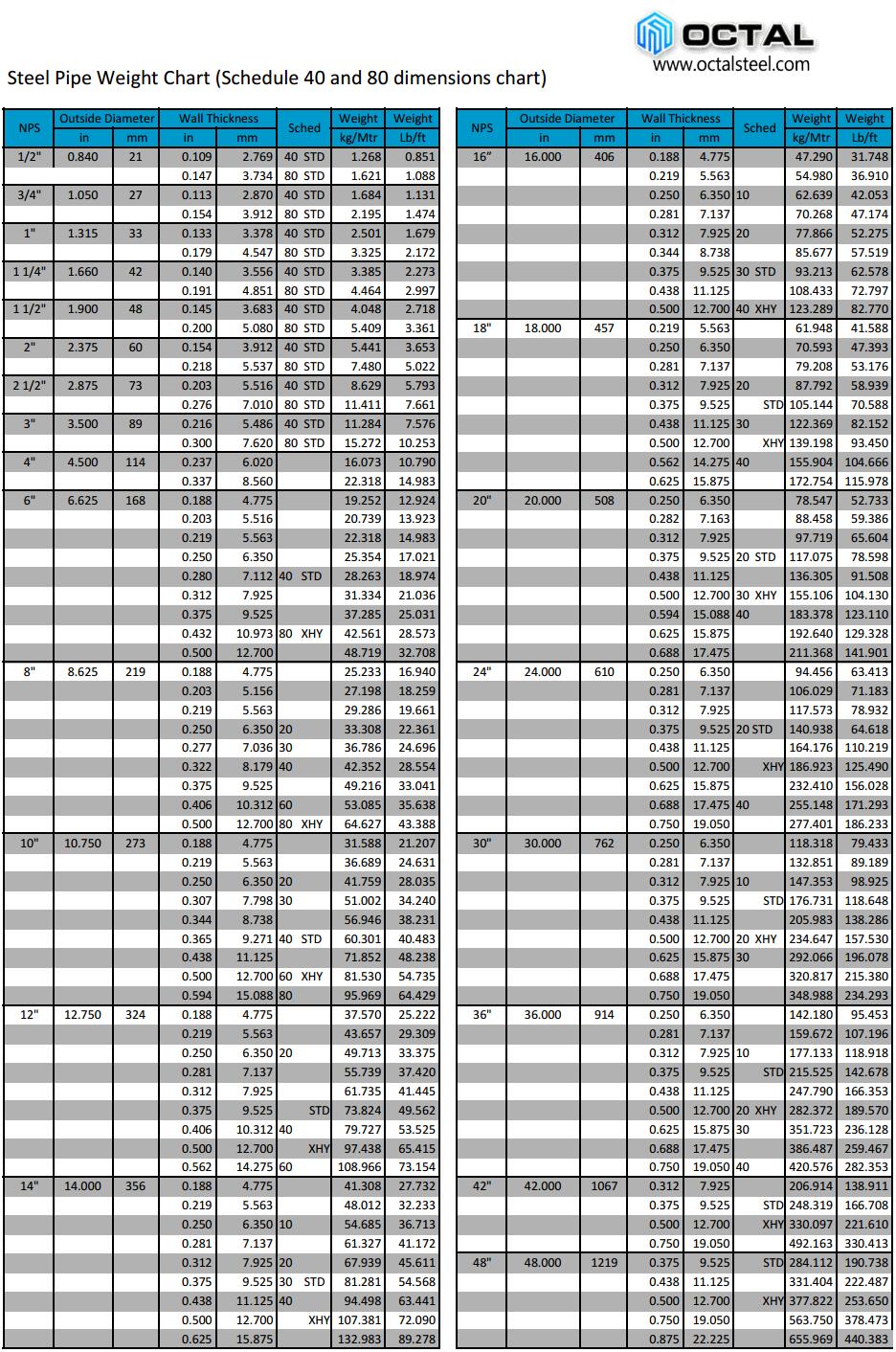

| Nominal Diameter | Wall Thickness | Material Density | Weight per Foot |

|---|---|---|---|

| 1/2 inch | 0.109 inches | 490 lb/ft^3 | 0.85 lb/ft |

| 3/4 inch | 0.113 inches | 490 lb/ft^3 | 1.13 lb/ft |

Benefits of Using the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator

The Xtra Strong (XS) Size Steel Pipe Weights Table Calculator offers several benefits, including accurate weight calculations, time savings, and increased efficiency. The calculator eliminates the need for manual calculations, which can be prone to errors and inaccuracies. By using the calculator, users can ensure that their steel pipe weight calculations are reliable and trustworthy.

Xtra Strong (XS) Size Steel Pipe Weights Table Calculator Applications

The Xtra Strong (XS) Size Steel Pipe Weights Table Calculator has a wide range of applications, including construction, engineering, and architecture. The calculator can be used to determine the weight of steel pipes for building frames, pipe systems, and other structural components. The calculator is also useful for research and development, as it allows users to test and simulate different pipe sizes and materials.

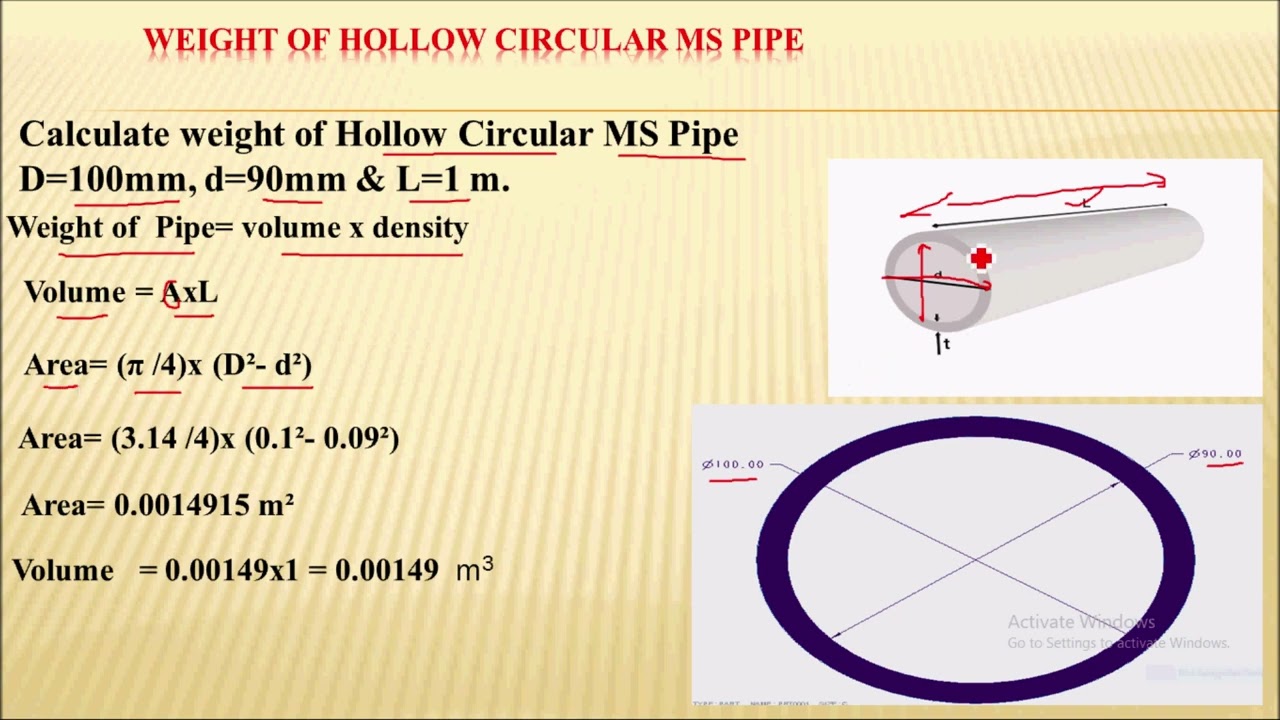

What is the formula for calculating the weight of steel pipe?

The formula for calculating the weight of steel pipe is based on the outer diameter, wall thickness, length, and density of the pipe. The most common formula used is: Weight = (π/4) (Outer Diameter^2 - Inner Diameter^2) Length Density. This formula takes into account the cross-sectional area of the pipe and the volume of the material used to manufacture it.

Understanding the Variables

To calculate the weight of steel pipe, it is essential to understand the variables involved in the formula. The outer diameter and wall thickness of the pipe determine the inner diameter, which is used to calculate the cross-sectional area. The length of the pipe is also crucial, as it determines the volume of the material. The density of the steel used to manufacture the pipe is also a critical factor, as it affects the overall weight.

- Outer diameter: The outer diameter of the pipe is the distance from one end of the pipe to the other, passing through the center.

- Wall thickness: The wall thickness of the pipe is the distance from the inner surface to the outer surface.

- Length: The length of the pipe is the distance from one end of the pipe to the other.

Calculating the Weight of Steel Pipe

Calculating the weight of steel pipe involves using the formula mentioned earlier. The cross-sectional area of the pipe is calculated by subtracting the inner diameter from the outer diameter and squaring the result. The volume of the material is then calculated by multiplying the cross-sectional area by the length of the pipe. Finally, the weight is calculated by multiplying the volume by the density of the steel.

- Calculate the inner diameter: Inner Diameter = Outer Diameter - 2 Wall Thickness

- Calculate the cross-sectional area: Cross-Sectional Area = (π/4) (Outer Diameter^2 - Inner Diameter^2)

- Calculate the volume: Volume = Cross-Sectional Area Length

Importance of Accurate Calculations

Accurate calculations are crucial when determining the weight of steel pipe. Inaccurate calculations can lead to incorrect weights, which can affect the structural integrity of the system or structure being built. Overestimating or underestimating the weight of the pipe can also lead to costly mistakes and delays in the construction process.

- Use the correct formula: Use the correct formula to calculate the weight of the steel pipe.

- Double-check calculations: Double-check calculations to ensure accuracy.

- Consider factors that affect weight: Consider factors that affect the weight of the pipe, such as corrosion and scaling.

Factors that Affect the Weight of Steel Pipe

Several factors can affect the weight of steel pipe, including corrosion, scaling, and manufacturing defects. Corrosion can reduce the wall thickness of the pipe, affecting its weight and structural integrity. Scaling can also affect the weight of the pipe by adding material to the surface. Manufacturing defects, such as imperfections in the material, can also affect the weight of the pipe.

- Corrosion: Corrosion can reduce the wall thickness of the pipe.

- Scaling: Scaling can add material to the surface of the pipe.

- Manufacturing defects: Manufacturing defects can affect the weight and structural integrity of the pipe.

Applications of Steel Pipe Weight Calculations

Calculating the weight of steel pipe is essential in various industries, including construction, engineering, and manufacturing. Accurate weight calculations can help engineers and architects design safe and efficient systems and structures. Manufacturers can also use weight calculations to optimize production and reduce costs.

- Construction: Weight calculations are essential in construction to ensure the structural integrity of buildings and bridges.

- Engineering: Weight calculations are crucial in engineering to design safe and efficient systems.

- Manufacturing: Weight calculations can help manufacturers optimize production and reduce costs.

How much does a 1 inch steel pipe weight per foot?

The weight of a 1 inch steel pipe per foot can vary depending on the schedule and type of pipe. Generally, a 1 inch schedule 40 steel pipe weighs around 1.68 pounds per foot, while a 1 inch schedule 80 steel pipe weighs around 2.17 pounds per foot.

Types of Steel Pipes

The type of steel pipe used can also affect its weight. For example, seamless pipes are typically lighter than welded pipes. The weight of a 1 inch steel pipe per foot can also be affected by the material grade and wall thickness.

- Schedule 40 pipes are the most common type of pipe and are used for general-purpose applications.

- Schedule 80 pipes are thicker and heavier than schedule 40 pipes and are used for higher-pressure applications.

- Schedule 160 pipes are the heaviest and are used for extreme-pressure applications.

Factors Affecting Pipe Weight

Several factors can affect the weight of a 1 inch steel pipe per foot, including the pipe material, pipe size, and pipe schedule. The weight of the pipe can also be affected by the coating or lining applied to the pipe.

- Galvanized pipes are coated with a layer of zinc to protect against corrosion.

- Epoxy-coated pipes are coated with a layer of epoxy to protect against corrosion and abrasion.

- Cement-lined pipes are lined with a layer of cement to protect against corrosion and erosion.

Calculating Pipe Weight

The weight of a 1 inch steel pipe per foot can be calculated using the pipe's outside diameter, wall thickness, and material density. The calculation involves using the formula for the weight of a cylinder, which is π x (outside diameter/2)^2 x wall thickness x material density.

- Outside diameter is the diameter of the pipe, including the wall thickness.

- Wall thickness is the thickness of the pipe wall, which can vary depending on the schedule and type of pipe.

- Material density is the density of the pipe material, which can vary depending on the type of steel used.

Pipe Schedules and Weights

The weight of a 1 inch steel pipe per foot can vary significantly depending on the pipe schedule. For example, a 1 inch schedule 40 steel pipe weighs around 1.68 pounds per foot, while a 1 inch schedule 80 steel pipe weighs around 2.17 pounds per foot.

- Schedule 40 pipes are the most common type of pipe and are used for general-purpose applications.

- Schedule 80 pipes are thicker and heavier than schedule 40 pipes and are used for higher-pressure applications.

- Schedule 160 pipes are the heaviest and are used for extreme-pressure applications.

Applications and Uses

The weight of a 1 inch steel pipe per foot is an important consideration in a variety of applications, including plumbing, HVAC, and industrial processes. The weight of the pipe can affect the support and anchoring required, as well as the transportation and installation costs.

- Plumbing applications require pipes that can withstand water pressure and corrosion.

- HVAC applications require pipes that can withstand air pressure and temperature fluctuations.

- Industrial processes require pipes that can withstand high pressures and corrosive substances.

How do you calculate the weight per foot of a pipe?

To calculate the weight per foot of a pipe, you need to know the material density, outer diameter, and wall thickness of the pipe. The formula to calculate the weight per foot of a pipe is: Weight per foot = (π x (Outer Diameter^2 - Inner Diameter^2) x Material Density) / 12. This formula takes into account the cross-sectional area of the pipe and the density of the material to determine the weight per foot.

Understanding Pipe Dimensions

To calculate the weight per foot of a pipe, you need to understand the different dimensions involved. The outer diameter is the diameter of the pipe including the wall thickness, while the inner diameter is the diameter of the pipe without the wall thickness. The wall thickness is the difference between the outer and inner diameters. Here are the key dimensions to consider:

- Outer Diameter: The diameter of the pipe including the wall thickness.

- Inner Diameter: The diameter of the pipe without the wall thickness.

- Wall Thickness: The difference between the outer and inner diameters.

Material Density and Its Effect on Weight

The material density of the pipe has a significant impact on its weight per foot. Different materials have different densities, and this affects the overall weight of the pipe. For example, a pipe made of steel will have a higher weight per foot than a pipe made of PVC due to the difference in material density. Here are some common materials and their densities:

- Steel: 490 pounds per cubic foot.

- PVC: 140 pounds per cubic foot.

- Copper: 560 pounds per cubic foot.

Calculating Cross-Sectional Area

The cross-sectional area of the pipe is an important factor in calculating the weight per foot. The cross-sectional area is the area of the pipe's circular cross-section, and it can be calculated using the formula: Cross-Sectional Area = π x (Outer Diameter^2 - Inner Diameter^2) / 4. This formula takes into account the outer diameter and inner diameter of the pipe to determine the cross-sectional area. Here are the steps to calculate the cross-sectional area:

- Calculate the outer diameter and inner diameter of the pipe.

- Use the formula to calculate the cross-sectional area.

- Use the cross-sectional area to calculate the weight per foot.

Using the Formula to Calculate Weight per Foot

Now that you have all the necessary information, you can use the formula to calculate the weight per foot of the pipe. The formula is: Weight per foot = (π x (Outer Diameter^2 - Inner Diameter^2) x Material Density) / 12. This formula takes into account the cross-sectional area and material density to determine the weight per foot. Here are the steps to use the formula:

- Plug in the values for outer diameter, inner diameter, and material density.

- Calculate the cross-sectional area using the formula.

- Use the cross-sectional area and material density to calculate the weight per foot.

Common Applications and Considerations

Calculating the weight per foot of a pipe is an important consideration in various applications, including plumbing, piping, and construction. The weight per foot of a pipe can affect the structural integrity of a building or system, and it's essential to consider this factor when designing or installing pipes. Here are some common applications and considerations:

- Plumbing: Calculating the weight per foot of pipes to ensure structural integrity.

- Piping: Considering the weight per foot of pipes in industrial and commercial applications.

- Construction: Using the weight per foot of pipes to determine load-bearing capacity.

Frequently Asked Questions (FAQs)

What is the purpose of the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator?

The Xtra Strong (XS) Size Steel Pipe Weights Table Calculator is a tool designed to help engineers, contractors, and other professionals in the construction and oil and gas industries to calculate the weights of steel pipes with Xtra Strong (XS) sizes. This calculator is essential in determining the weight of pipes, which is a critical factor in designing and planning projects that involve the use of steel pipes. By using this calculator, users can quickly and accurately determine the weight of steel pipes with XS sizes, which helps to ensure that their projects are safe, efficient, and cost-effective. The calculator takes into account the diameter, thickness, and length of the pipe, as well as the material and density of the steel, to provide an accurate calculation of the weight.

How does the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator work?

The Xtra Strong (XS) Size Steel Pipe Weights Table Calculator works by using a complex algorithm that takes into account various factors, including the diameter, thickness, and length of the pipe, as well as the material and density of the steel. The calculator uses a database of pre-calculated values to provide an accurate calculation of the weight of the pipe. Users simply need to input the relevant parameters, such as the pipe size, thickness, and length, and the calculator will provide the calculated weight. The calculator also provides options for different units of measurement, such as pounds per foot or kilograms per meter, to accommodate different regional and industry standards. By using this calculator, users can save time and effort in calculating the weight of steel pipes, and reduce the risk of errors and inaccuracies.

What are the benefits of using the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator?

The Xtra Strong (XS) Size Steel Pipe Weights Table Calculator provides several benefits to users, including accuracy, speed, and convenience. By using this calculator, users can quickly and accurately determine the weight of steel pipes, which helps to ensure that their projects are safe, efficient, and cost-effective. The calculator also helps to reduce the risk of errors and inaccuracies, which can lead to delays, cost overruns, and safety issues. Additionally, the calculator provides options for different units of measurement, which makes it versatile and user-friendly. The calculator is also easy to use, even for users who are not familiar with steel pipe calculations, as it provides a simple and intuitive interface. By using this calculator, users can improve their productivity, reduce their workload, and enhance their overall performance.

Can the Xtra Strong (XS) Size Steel Pipe Weights Table Calculator be used for other types of steel pipes?

The Xtra Strong (XS) Size Steel Pipe Weights Table Calculator is specifically designed for calculating the weights of steel pipes with Xtra Strong (XS) sizes. However, the calculator can also be used for calculating the weights of other types of steel pipes, such as Standard (STD), Extra Strong (XS), and Double Extra Strong (XXS) pipes. The calculator provides options for different pipe sizes and thicknesses, which makes it versatile and applicable to a wide range of steel pipe applications. Additionally, the calculator can be used for calculating the weights of steel pipes with different materials and densities, such as carbon steel, stainless steel, and alloy steel. By using this calculator, users can expand their calculations to include other types of steel pipes, and enhance their overall capabilities. However, it is essential to note that the calculator is specifically designed for Xtra Strong (XS) pipes, and users should verify the accuracy of the calculations for other types of pipes.

Deja una respuesta

Entradas Relacionadas