Thick Walled Cylinder Stress Pressure Vessel Calculator

The Thick Walled Cylinder Stress Pressure Vessel Calculator is a valuable tool for engineers and designers working with pressure vessels. It calculates the stress and strain on a thick-walled cylinder due to internal pressure, allowing for the determination of the vessel's safety and reliability. This calculator takes into account the cylinder's dimensions, material properties, and operating conditions to provide accurate results. By using this calculator, designers can optimize their vessel designs and ensure compliance with safety standards and regulations, reducing the risk of failure and improving overall performance. Accurate calculations are crucial in pressure vessel design.

-

Understanding the Thick Walled Cylinder Stress Pressure Vessel Calculator

- Introduction to Thick Walled Cylinder Stress Calculation

- Key Factors Affecting Thick Walled Cylinder Stress

- Applications of the Thick Walled Cylinder Stress Pressure Vessel Calculator

- Limitations and Assumptions of the Thick Walled Cylinder Stress Calculator

- Example Calculation using the Thick Walled Cylinder Stress Pressure Vessel Calculator

- How do you calculate the stress of a thick cylinder?

- What is the maximum shear stress in a thick cylinder?

- What are the stresses developed on a thick cylinder's surface?

- What is the wall thickness of cylindrical pressure vessel?

-

Frequently Asked Questions (FAQs)

- What is the Thick Walled Cylinder Stress Pressure Vessel Calculator and how does it work?

- What are the key parameters that need to be inputted into the Thick Walled Cylinder Stress Pressure Vessel Calculator?

- How is the Thick Walled Cylinder Stress Pressure Vessel Calculator used in industry and what are its benefits?

- What are the limitations and potential sources of error in the Thick Walled Cylinder Stress Pressure Vessel Calculator?

Understanding the Thick Walled Cylinder Stress Pressure Vessel Calculator

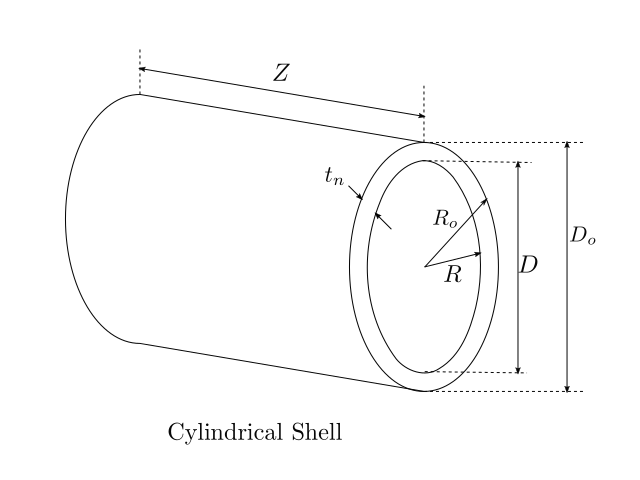

The Thick Walled Cylinder Stress Pressure Vessel Calculator is a tool used to determine the stress and pressure that a thick-walled cylinder can withstand. This calculator is essential in engineering and design applications where the integrity of the cylinder is crucial. The calculator takes into account the inner radius, outer radius, and pressure applied to the cylinder to calculate the stress at different points.

Introduction to Thick Walled Cylinder Stress Calculation

The calculation of stress in a thick-walled cylinder is based on the Lame equations, which describe the radial stress and hoop stress in a cylinder under internal pressure. The Lame equations are used to derive the stress at different points in the cylinder, taking into account the material properties and geometric dimensions. The calculator uses these equations to provide a detailed analysis of the stress distribution in the cylinder.

Key Factors Affecting Thick Walled Cylinder Stress

Several factors affect the stress in a thick-walled cylinder, including the inner radius, outer radius, pressure, and material properties. The inner radius and outer radius determine the thickness of the cylinder, which affects the stress distribution. The pressure applied to the cylinder also plays a significant role in determining the stress. The material properties, such as the elastic modulus and Poisson's ratio, also influence the stress calculation.

Applications of the Thick Walled Cylinder Stress Pressure Vessel Calculator

The Thick Walled Cylinder Stress Pressure Vessel Calculator has various applications in engineering and design. It is used to design and analyze pressure vessels, pipes, and cylinders in different industries, including chemical processing, power generation, and aerospace. The calculator helps engineers and designers to ensure the integrity and safety of these components by providing a detailed analysis of the stress distribution.

Limitations and Assumptions of the Thick Walled Cylinder Stress Calculator

The Thick Walled Cylinder Stress Pressure Vessel Calculator has some limitations and assumptions. The calculator assumes that the cylinder is isotropic and homogeneous, and that the material properties are constant. The calculator also assumes that the pressure is uniform and that there are no external loads applied to the cylinder. These assumptions and limitations should be considered when using the calculator to ensure accurate results.

Example Calculation using the Thick Walled Cylinder Stress Pressure Vessel Calculator

The following table shows an example calculation using the Thick Walled Cylinder Stress Pressure Vessel Calculator:

| Parameter | Value |

|---|---|

| Inner Radius | 10 cm |

| Outer Radius | 20 cm |

| Pressure | 1000 psi |

| Material Properties | Elastic Modulus: 200 GPa, Poisson's Ratio: 0.3 |

| Stress | Radial Stress: 500 psi, Hoop Stress: 1000 psi |

The calculator provides a detailed analysis of the stress distribution in the cylinder, including the radial stress and hoop stress. The results show that the stress is highest at the inner surface of the cylinder and decreases as you move towards the outer surface.

How do you calculate the stress of a thick cylinder?

The calculation of stress in a thick cylinder is a complex process that involves considering various factors such as the thickness of the cylinder, the internal pressure, and the material properties. To calculate the stress, we can use the Lame equations, which provide a relationship between the radial stress, tangential stress, and the axial stress. The Lame equations are based on the theory of elasticity and are widely used in engineering applications.

Introduction to Thick Cylinder Stress Calculation

The calculation of stress in a thick cylinder is crucial in designing and analyzing various engineering systems, such as pipelines, pressure vessels, and cylindrical tanks. The stress calculation involves determining the stress distribution across the thickness of the cylinder, which is essential for ensuring the structural integrity of the system. The calculation process involves using the Lame equations, which require knowledge of the material properties, internal pressure, and boundary conditions.

- Determine the material properties, such as the Young's modulus and Poisson's ratio.

- Calculate the internal pressure and external pressure acting on the cylinder.

- Apply the Lame equations to determine the radial stress, tangential stress, and axial stress.

Assumptions and Limitations of the Lame Equations

The Lame equations are based on several assumptions and limitations, which must be considered when calculating the stress in a thick cylinder. The equations assume that the cylinder is cylindrically symmetric, and the material properties are isotropic and homogeneous. Additionally, the equations assume that the stress distribution is axisymmetric, and the boundary conditions are static.

- The cylinder is assumed to be cylindrically symmetric, with no bending or torsion.

- The material properties are assumed to be isotropic and homogeneous.

- The stress distribution is assumed to be axisymmetric, with no angular variations.

Boundary Conditions for Thick Cylinder Stress Calculation

The boundary conditions play a crucial role in calculating the stress in a thick cylinder. The boundary conditions define the constraints and loads acting on the cylinder, which affect the stress distribution. The boundary conditions can be mechanical, thermal, or combination of both.

- Mechanical boundary conditions, such as internal pressure and external pressure.

- Thermal boundary conditions, such as temperature differences and heat transfer.

- Combination of mechanical and thermal boundary conditions, such as thermal stresses and mechanical loads.

Material Properties for Thick Cylinder Stress Calculation

The material properties are essential in calculating the stress in a thick cylinder. The material properties define the behavior of the material under mechanical loads and thermal stresses. The material properties can be elastic, plastic, or combination of both.

- Elastic material properties, such as Young's modulus and Poisson's ratio.

- Plastic material properties, such as yield strength and ultimate strength.

- Combination of elastic and plastic material properties, such as elasto-plastic behavior.

Applications of Thick Cylinder Stress Calculation

The calculation of stress in a thick cylinder has various applications in engineering, such as designing and analyzing pipelines, pressure vessels, and cylindrical tanks. The stress calculation can help optimize the design, reduce the weight, and improve the safety of the system.

- Designing pipelines for oil and gas transportation.

- Analyzing pressure vessels for chemical processing and power generation.

- Optimizing cylindrical tanks for storage and transportation of liquids and gases.

What is the maximum shear stress in a thick cylinder?

The maximum shear stress in a thick cylinder occurs at the inner radius and is given by the Lame equation, which describes the radial stress and tangential stress distributions in a thick-walled cylinder under internal pressure. The maximum shear stress is a critical parameter in the design of thick cylinders, as it can lead to failure by yielding or fracture.

Understanding the Lame Equation

The Lame equation is a fundamental concept in the analysis of thick cylinders, and it provides a mathematical framework for calculating the stress distribution in the cylinder. The equation is based on the assumption of a linear elastic material response and plane stress conditions. The maximum shear stress can be calculated using the Lame equation, which takes into account the internal pressure, outer radius, and inner radius of the cylinder. Some key points to consider when applying the Lame equation include:

- Material properties: The Lame equation assumes a linear elastic material response, which may not be applicable to all materials.

- Boundary conditions: The equation requires knowledge of the internal pressure and outer radius of the cylinder.

- Geometry: The equation is only applicable to thick-walled cylinders with a circular cross-section.

Factors Affecting Maximum Shear Stress

Several factors can affect the maximum shear stress in a thick cylinder, including the internal pressure, outer radius, and inner radius. The material properties, such as the yield strength and ultimate tensile strength, can also impact the maximum shear stress. Additionally, the temperature and corrosion can influence the stress distribution in the cylinder. Some important factors to consider include:

- Pressure: The internal pressure is a primary driver of the maximum shear stress in the cylinder.

- Radius ratio: The ratio of the outer radius to the inner radius can significantly impact the stress distribution.

- Material selection: The choice of material can affect the maximum shear stress, as different materials have varying strength and stiffness properties.

Calculating Maximum Shear Stress

Calculating the maximum shear stress in a thick cylinder requires knowledge of the Lame equation and the boundary conditions. The equation can be solved analytically or numerically, depending on the complexity of the problem. The maximum shear stress can be calculated using the von Mises criterion, which provides a measure of the equivalent stress in the cylinder. Some key steps in calculating the maximum shear stress include:

- Define the problem: Identify the internal pressure, outer radius, and inner radius of the cylinder.

- Apply the Lame equation: Use the equation to calculate the radial and tangential stresses in the cylinder.

- Calculate the maximum shear stress: Use the von Mises criterion to calculate the equivalent stress and determine the maximum shear stress.

Design Considerations

The maximum shear stress in a thick cylinder is a critical parameter in the design of pressure vessels and pipes. The design process requires careful consideration of the material properties, geometry, and loading conditions. The stress distribution in the cylinder can be affected by various factors, including temperature, corrosion, and residual stresses. Some important design considerations include:

- Material selection: Choose a material with suitable strength and stiffness properties for the application.

- Geometry optimization: Optimize the geometry of the cylinder to minimize the maximum shear stress.

- Safety factors: Apply suitable safety factors to account for uncertainties and variabilities in the design.

Failure Mechanisms

The maximum shear stress in a thick cylinder can lead to failure by yielding or fracture. The failure mechanism depends on the material properties, stress distribution, and loading conditions. The yield strength and ultimate tensile strength of the material can influence the failure mechanism, as well as the temperature and corrosion. Some possible failure mechanisms include:

- Yielding: The material may yield due to excessive shear stress, leading to deformation and failure.

- Fracture: The material may fracture due to excessive tensile stress, leading to brittle failure.

- Fatigue: The material may fail due to repeated cyclic loading, leading to fatigue failure.

What are the stresses developed on a thick cylinder's surface?

The stresses developed on a thick cylinder's surface are a result of the combination of hoop stress, radial stress, and axial stress. When a thick cylinder is subjected to internal or external pressure, the resulting stresses can lead to deformation and potentially failure. To analyze these stresses, it is essential to consider the cylinder's dimensions, material properties, and the boundary conditions.

Types of Stresses Developed

The stresses developed on a thick cylinder's surface can be categorized into three main types: hoop stress, radial stress, and axial stress. These stresses arise from the pressure applied to the cylinder and the constraints imposed by the boundary conditions. The following list highlights the key characteristics of each type of stress:

- The hoop stress is a tangential stress that acts perpendicular to the cylinder's radius and is caused by the pressure difference between the inside and outside of the cylinder.

- The radial stress is a normal stress that acts in the direction of the cylinder's radius and is caused by the pressure applied to the cylinder.

- The axial stress is a normal stress that acts parallel to the cylinder's axis and is caused by the pressure applied to the cylinder and the constraints imposed by the boundary conditions.

Factors Affecting Stresses Developed

The stresses developed on a thick cylinder's surface are influenced by several factors, including the cylinder's dimensions, material properties, and boundary conditions. The following list highlights the key factors that affect the stresses developed:

- The cylinder's dimensions, such as its inner radius, outer radius, and length, play a crucial role in determining the stresses developed.

- The material properties, such as the Young's modulus and Poisson's ratio, affect the cylinder's response to pressure and constraints.

Analysis of Stresses Developed

The analysis of the stresses developed on a thick cylinder's surface involves the use of mathematical models and numerical methods. The following list highlights the key steps involved in the analysis:

- The cylinder's dimensions, material properties, and boundary conditions are used to develop a mathematical model that describes the stresses developed.

- The mathematical model is then solved using numerical methods, such as the finite element method, to obtain the stresses developed.

- The results of the analysis are then used to evaluate the cylinder's performance and identify potential failure modes.

Design Considerations for Thick Cylinders

The design of a thick cylinder must take into account the stresses developed on its surface. The following list highlights the key design considerations:

- The cylinder's dimensions, such as its inner radius, outer radius, and length, must be carefully selected to minimize the stresses developed.

- The material properties, such as the Young's modulus and Poisson's ratio, must be carefully selected to ensure that the cylinder can withstand the stresses developed.

- The boundary conditions, such as the pressure applied to the cylinder and the constraints imposed by the supports, must be carefully considered to ensure that the cylinder is properly supported.

Applications of Thick Cylinders

Thick cylinders have a wide range of applications in various industries, including aerospace, automotive, and energy. The following list highlights some of the key applications:

- Thick cylinders are used in aerospace applications, such as rocket motors and fuel tanks.

- Thick cylinders are used in automotive applications, such as engine blocks and cylinder heads.

- Thick cylinders are used in energy applications, such as nuclear reactors and steam turbines.

What is the wall thickness of cylindrical pressure vessel?

The wall thickness of a cylindrical pressure vessel is a critical parameter that determines its ability to withstand internal pressure and external loads. The wall thickness is typically calculated using the ASME Boiler and Pressure Vessel Code or other relevant standards, taking into account factors such as the material properties, operating conditions, and design requirements. The calculation involves a complex formula that considers the internal pressure, external pressure, temperature, and corrosion allowance.

Design Considerations for Wall Thickness

The design of a cylindrical pressure vessel requires careful consideration of several factors that affect the wall thickness. These include the material selection, welding processes, and non-destructive testing methods. The designer must also consider the operating conditions, such as the maximum allowable working pressure and temperature, to ensure that the vessel can withstand the stresses and loads imposed on it. The following are some key considerations:

- Material properties: The selection of materials with suitable strength, ductility, and corrosion resistance is crucial for determining the wall thickness.

- Welding processes: The choice of welding technique and weld joint design can affect the wall thickness and the overall integrity of the vessel.

- Non-destructive testing: The use of non-destructive testing methods, such as ultrasonic testing or radiography, can help detect defects and ensure the quality of the welds.

Calculating Wall Thickness

The calculation of wall thickness for a cylindrical pressure vessel involves a complex formula that considers various factors, including the internal pressure, external pressure, temperature, and corrosion allowance. The calculation is typically performed using the ASME Boiler and Pressure Vessel Code or other relevant standards. The following are some key steps:

- Determine the internal pressure: The internal pressure is the maximum pressure that the vessel is designed to withstand.

- Determine the external pressure: The external pressure is the pressure that the vessel is subjected to from the outside, such as the atmospheric pressure.

- Calculate the wall thickness: The wall thickness is calculated using a formula that considers the internal pressure, external pressure, temperature, and corrosion allowance.

Factors Affecting Wall Thickness

Several factors can affect the wall thickness of a cylindrical pressure vessel, including the material properties, operating conditions, and design requirements. The following are some key factors:

- Material properties: The strength, ductility, and corrosion resistance of the material can affect the wall thickness.

- Operating conditions: The maximum allowable working pressure and temperature can affect the wall thickness.

- Design requirements: The design requirements, such as the size and shape of the vessel, can affect the wall thickness.

Consequences of Insufficient Wall Thickness

Insufficient wall thickness can have serious consequences, including failure of the vessel, injury, and loss of life. The following are some potential consequences:

- Failure of the vessel: Insufficient wall thickness can cause the vessel to rupture or burst, leading to a catastrophic failure.

- Injury or loss of life: The failure of the vessel can result in injury or loss of life, as well as environmental damage.

- Economic losses: The failure of the vessel can also result in economic losses, including the cost of repair or replacement.

Importance of Regular Inspection and Maintenance

Regular inspection and maintenance are crucial for ensuring the integrity and safety of a cylindrical pressure vessel. The following are some key reasons:

- Detecting defects: Regular inspection can help detect defects or damage to the vessel, allowing for prompt repair or replacement.

- Preventing corrosion: Regular maintenance can help prevent corrosion and erosion, which can weaken the vessel and reduce its wall thickness.

- Ensuring compliance: Regular inspection and maintenance can help ensure compliance with relevant standards and regulations, reducing the risk of failure or accident.

Frequently Asked Questions (FAQs)

What is the Thick Walled Cylinder Stress Pressure Vessel Calculator and how does it work?

The Thick Walled Cylinder Stress Pressure Vessel Calculator is a mathematical model used to calculate the stress and strain on a thick-walled cylinder, which is a type of pressure vessel. This calculator takes into account the inner radius, outer radius, internal pressure, and external pressure of the cylinder to determine the hoop stress, longitudinal stress, and radial stress at different points within the cylinder. The calculator uses the Lame equations, which are a set of differential equations that describe the stress and strain distribution in a thick-walled cylinder. By inputting the relevant parameters, the calculator can provide accurate results for the stress and strain on the cylinder, allowing engineers and designers to optimize their designs and ensure the safety and reliability of the pressure vessel.

What are the key parameters that need to be inputted into the Thick Walled Cylinder Stress Pressure Vessel Calculator?

The key parameters that need to be inputted into the Thick Walled Cylinder Stress Pressure Vessel Calculator are the inner radius, outer radius, internal pressure, and external pressure of the cylinder. The inner radius is the radius of the inner surface of the cylinder, while the outer radius is the radius of the outer surface. The internal pressure is the pressure applied to the inner surface of the cylinder, while the external pressure is the pressure applied to the outer surface. Additionally, the calculator may also require input of the material properties of the cylinder, such as the Young's modulus and Poisson's ratio, which are used to calculate the stress and strain. It is important to ensure that the input values are accurate and consistent with the units used in the calculator to obtain reliable results. The calculator may also allow for the input of additional parameters, such as the temperature and corrosion allowance, which can affect the stress and strain distribution in the cylinder.

How is the Thick Walled Cylinder Stress Pressure Vessel Calculator used in industry and what are its benefits?

The Thick Walled Cylinder Stress Pressure Vessel Calculator is widely used in industry to design and analyze thick-walled cylinders, such as pipes, tanks, and pressure vessels. The calculator is used to determine the stress and strain on the cylinder, which is critical to ensure the safety and reliability of the pressure vessel. The calculator is also used to optimize the design of the cylinder, by minimizing the weight and cost while maximizing the strength and durability. The benefits of using the Thick Walled Cylinder Stress Pressure Vessel Calculator include improved accuracy, increased efficiency, and reduced costs. The calculator can also be used to analyze the effects of different materials and design configurations on the stress and strain distribution in the cylinder, allowing engineers and designers to make informed decisions. Additionally, the calculator can be used to validate the design of the cylinder against industry standards and regulations, such as the ASME Boiler and Pressure Vessel Code.

What are the limitations and potential sources of error in the Thick Walled Cylinder Stress Pressure Vessel Calculator?

The Thick Walled Cylinder Stress Pressure Vessel Calculator is a mathematical model that assumes a simplistic representation of the stress and strain distribution in the cylinder. The calculator assumes that the cylinder is cylindrical in shape, and that the material properties are isotropic and homogeneous. The calculator also assumes that the loads applied to the cylinder are static and axisymmetric, and that the boundary conditions are well-defined. However, in reality, the cylinder may be subject to dynamic loads, non-axisymmetric loads, and complex boundary conditions, which can affect the accuracy of the calculator. Additionally, the calculator may not account for other factors that can affect the stress and strain distribution in the cylinder, such as residual stresses, corrosion, and fabrication defects. Therefore, it is important to validate the results of the calculator against experimental data and other analytical methods to ensure accuracy and reliability. The calculator should also be used in conjunction with other design tools and techniques, such as finite element analysis, to ensure that the design of the cylinder is safe and reliable.

Deja una respuesta

Entradas Relacionadas