Press Brake Forming Force Equation and Calculator

The press brake forming force equation is a crucial tool in the metal fabrication industry, as it enables manufacturers to determine the required force to bend metal sheets accurately. This equation takes into account various factors, including the material's properties, bend angle, and radius. By utilizing a press brake forming force calculator, users can simplify the complex calculations involved and ensure precise results. This article provides an overview of the press brake forming force equation and its corresponding calculator, allowing readers to optimize their metal forming processes efficiently. The calculator is a valuable resource for manufacturers.

- Press Brake Forming Force Equation and Calculator: Understanding the Fundamentals

- What is the rule of 8 on a press brake?

- How to calculate forming load?

- How do you calculate bending for press brakes?

-

Frequently Asked Questions (FAQs)

- What is the Press Brake Forming Force Equation and how is it used in metal forming processes?

- How does the Press Brake Forming Force Calculator work and what are its benefits?

- What are the key factors that affect the Press Brake Forming Force Equation and how do they impact the calculation?

- How can manufacturers use the Press Brake Forming Force Equation and Calculator to optimize their metal forming processes and reduce production costs?

Press Brake Forming Force Equation and Calculator: Understanding the Fundamentals

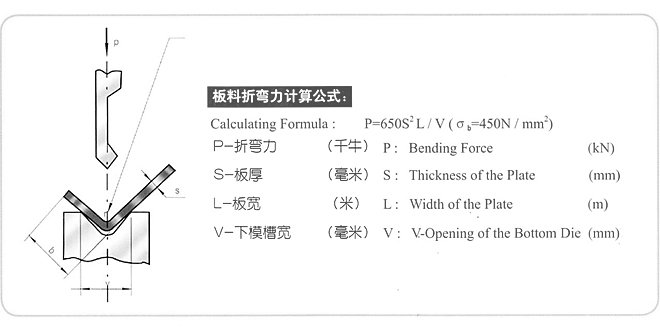

The Press Brake Forming Force Equation is a crucial concept in the field of metal fabrication, as it helps determine the amount of force required to bend and shape metal sheets. This equation takes into account various factors such as the material's yield strength, thickness, and bend angle. By using a calculator specifically designed for press brake forming, manufacturers can accurately calculate the required force and optimize their production processes.

Introduction to Press Brake Forming

Press brake forming is a widely used technique in metal fabrication, which involves bending and shaping metal sheets using a press brake machine. This process requires careful calculation of the forming force to ensure accurate and precise results. The Press Brake Forming Force Equation is a mathematical formula that helps determine the required force, taking into account factors such as the material's mechanical properties and the desired bend geometry.

Understanding the Press Brake Forming Force Equation

The Press Brake Forming Force Equation is based on the principle of plastic deformation, which occurs when a metal sheet is subjected to external forces. The equation takes into account the material's yield strength, ultimate tensile strength, and strain hardening behavior. By using this equation, manufacturers can calculate the required forming force and optimize their production processes to achieve high-quality products.

Factors Affecting Press Brake Forming Force

Several factors can affect the press brake forming force, including the material's thickness, bend angle, and surface roughness. Additionally, the tooling geometry and machine settings can also impact the required force. By understanding these factors, manufacturers can adjust their production processes to achieve optimal results.

Press Brake Forming Calculator: A Useful Tool

A press brake forming calculator is a software tool that helps manufacturers calculate the required forming force and optimize their production processes. These calculators typically take into account various factors such as the material's mechanical properties, bend geometry, and tooling geometry. By using a calculator, manufacturers can reduce trial and error and achieve high-quality products.

Applications of Press Brake Forming

Press brake forming has numerous applications in various industries, including aerospace, automotive, and construction. This technique is used to manufacture a wide range of products, such as aircraft components, car parts, and building structures. By understanding the Press Brake Forming Force Equation and using a calculator, manufacturers can optimize their production processes and achieve high-quality products.

| Material | Yield Strength | Thickness | Bend Angle | Forming Force |

|---|---|---|---|---|

| Steel | 300 MPa | 2 mm | 90 degrees | 100 kN |

| Aluminum | 200 MPa | 1.5 mm | 60 degrees | 50 kN |

| Copper | 250 MPa | 3 mm | 120 degrees | 150 kN |

What is the rule of 8 on a press brake?

The rule of 8 on a press brake is a guideline used to determine the minimum bend radius that can be achieved when bending a piece of metal. This rule states that the bend radius should be at least 8 times the thickness of the material being bent. This is important because it helps to prevent cracking or tearing of the material, especially when bending thin or high-strength materials.

Understanding the Rule of 8

The rule of 8 is a general guideline that is used to ensure that the bend radius is sufficient to prevent material failure. This rule is based on the idea that a sharper bend radius will result in a higher stress concentration in the material, which can lead to cracking or tearing. By using the rule of 8, manufacturers can ensure that their bends are safe and reliable.

- The bend radius is a critical factor in determining the success of a bend.

- The thickness of the material being bent is also an important consideration.

- High-strength materials may require a larger bend radius to prevent failure.

Applying the Rule of 8 in Practice

In practice, the rule of 8 is used to determine the minimum bend radius that can be achieved when bending a piece of metal. This is done by multiplying the thickness of the material by 8. For example, if the thickness of the material is 1/4 inch, the minimum bend radius would be 2 inches.

- Manufacturers must consider the physical properties of the material being bent.

- Bend radius is a critical factor in determining the success of a bend.

- Press brake operators must be trained to use the rule of 8 correctly.

Benefits of Using the Rule of 8

Using the rule of 8 can help to prevent material failure and ensure that bends are safe and reliable. This can help to reduce waste and scrap, and improve overall product quality.

- Reduced waste and scrap can help to improve profit margins.

- Improved product quality can help to increase customer satisfaction.

- Safe and reliable bends can help to reduce the risk of injury or damage.

Limitations of the Rule of 8

While the rule of 8 is a useful guideline, it is not a hard and fast rule. Manufacturers must consider the physical properties of the material being bent, as well as the specific requirements of the bend.

- Material properties can affect the bend radius required.

- Bend requirements can vary depending on the application.

- Press brake operators must be trained to use their judgment when applying the rule of 8.

Alternatives to the Rule of 8

In some cases, manufacturers may need to use alternative methods to determine the minimum bend radius. This can include using finite element analysis or computer simulations to model the bending process.

- Finite element analysis can be used to model the bending process.

- Computer simulations can be used to predict the behavior of the material.

- Experimental testing can be used to validate the results of the simulations.

How to calculate forming load?

To calculate the forming load, it is essential to understand the material properties and the deformation process involved. The forming load is the amount of force required to shape a material into a desired geometry. This calculation is critical in various manufacturing processes, such as sheet metal forming, forging, and extrusion. The forming load depends on several factors, including the material's strength, strain hardening, and friction between the material and the tooling.

Understanding Material Properties

To calculate the forming load, it is crucial to understand the material's properties, such as its yield strength, ultimate tensile strength, and strain hardening coefficient. These properties can be obtained through tensile testing or compression testing. The material's behavior under different loading conditions must also be considered. For example:

- The stress-strain curve of the material, which describes its elastic and plastic behavior.

- The strain hardening behavior of the material, which affects its strength and ductility.

- The anisotropy of the material, which can influence its mechanical properties in different directions.

Deformation Process and Tooling

The deformation process and tooling used can significantly impact the forming load. The tooling geometry, surface finish, and lubrication can affect the friction between the material and the tool, which in turn influences the forming load. For example:

- The tooling material and its surface properties, which can affect the friction coefficient.

- The lubrication system used, which can reduce friction and wear on the tooling.

- The deformation process, such as drawing, stretching, or bending, which can affect the material's flow and stress distribution.

Calculating Forming Load using Analytical Methods

There are several analytical methods available to calculate the forming load, including the slab method, upper bound method, and finite element method. These methods use mathematical models to predict the stress and strain behavior of the material during the forming process. For example:

- The slab method, which assumes a plane strain condition and uses a simple mathematical model to estimate the forming load.

- The upper bound method, which uses a more complex mathematical model to estimate the forming load and energy consumption.

- The finite element method, which uses a numerical model to simulate the forming process and predict the stress and strain behavior of the material.

Experimental Methods for Forming Load Calculation

Experimental methods can also be used to calculate the forming load, such as physical modeling and testing. These methods involve creating a physical model of the forming process and measuring the forces and displacements involved. For example:

- Physical modeling, which involves creating a scaled-down model of the forming process to measure the forces and displacements.

- Testing, which involves measuring the forces and displacements during the actual forming process.

- Data acquisition, which involves collecting and analyzing the data from the experiments to calculate the forming load.

Computer-Aided Engineering for Forming Load Calculation

Computer-aided engineering (CAE) tools can be used to calculate the forming load, such as finite element analysis (FEA) and computational fluid dynamics (CFD). These tools use numerical models to simulate the forming process and predict the stress and strain behavior of the material. For example:

- Finite element analysis (FEA), which uses a numerical model to simulate the forming process and predict the stress and strain behavior of the material.

- Computational fluid dynamics (CFD), which uses a numerical model to simulate the flow of the material during the forming process.

- Multiphysics simulation, which uses a numerical model to simulate the coupled behavior of the material and the tooling during the forming process.

How do you calculate bending for press brakes?

To calculate bending for press brakes, you need to consider several factors, including the type of material being bent, the thickness of the material, and the angle of the bend. The calculation involves determining the bend radius, bend angle, and bend allowance. The bend allowance is the amount of material that is required to create the bend, and it depends on the material properties and the bending process.

Understanding the Bending Process

The bending process involves using a press brake to bend a sheet metal or plate into a desired shape. The bending process can be affected by factors such as the material properties, tooling, and machine settings. To calculate the bending, you need to understand the bending process and the factors that affect it. Here are some key factors to consider:

- The type of material being bent, such as steel, aluminum, or copper.

- The thickness of the material, which can affect the bend radius and bend angle.

- The angle of the bend, which can range from a few degrees to 180 degrees or more.

Calculating the Bend Allowance

The bend allowance is a critical component of the bending calculation, as it determines the amount of material required to create the bend. The bend allowance depends on the material properties, such as the yield strength and ultimate tensile strength. To calculate the bend allowance, you need to use a formula that takes into account the bend radius, bend angle, and material properties. Here are some key steps to follow:

- Determine the bend radius, which is the radius of the bend in the material.

- Calculate the bend angle, which is the angle of the bend in degrees.

- Use a formula to calculate the bend allowance, such as the Vieux formula or the Air Bending formula.

Selecting the Right Tooling

The tooling used in the bending process can affect the bend radius, bend angle, and bend allowance. The tooling includes the punch and die used to bend the material. To select the right tooling, you need to consider factors such as the material properties, bend radius, and bend angle. Here are some key factors to consider:

- The type of tooling required, such as standard or special tooling.

- The size of the tooling, which depends on the bend radius and bend angle.

- The material of the tooling, which can affect the bend allowance and bending process.

Using Software to Calculate Bending

There are several software programs available that can help calculate the bending for press brakes. These programs use algorithms and formulas to calculate the bend radius, bend angle, and bend allowance. To use software to calculate bending, you need to input the material properties, bend radius, and bend angle. Here are some key steps to follow:

- Input the material properties, such as the yield strength and ultimate tensile strength.

- Enter the bend radius and bend angle into the software program.

- Run the software program to calculate the bend allowance and other bending parameters.

Verifying the Bending Calculation

After calculating the bending for press brakes, it is essential to verify the calculation to ensure accuracy. The verification process involves checking the bend radius, bend angle, and bend allowance against the actual values. To verify the bending calculation, you need to use measuring tools and testing procedures. Here are some key steps to follow:

- Use measuring tools to check the bend radius and bend angle.

- Perform testing procedures to verify the bend allowance and other bending parameters.

- Compare the calculated values with the actual values to ensure accuracy.

Frequently Asked Questions (FAQs)

What is the Press Brake Forming Force Equation and how is it used in metal forming processes?

The Press Brake Forming Force Equation is a mathematical formula used to calculate the tonnage required to form a specific metal part using a press brake machine. This equation takes into account various factors such as the material properties, part geometry, and forming process parameters. The equation is essential in determining the required force to achieve the desired bend angle and radius without causing material failure or deformation. By using this equation, manufacturers can optimize their metal forming processes and ensure that their press brake machines are operated within safe and efficient limits. The equation is typically expressed as a function of the material's yield strength, thickness, and width, as well as the die width and punch radius. By inputting these values into the equation, manufacturers can calculate the required forming force and adjust their press brake machine settings accordingly.

How does the Press Brake Forming Force Calculator work and what are its benefits?

The Press Brake Forming Force Calculator is a software tool designed to simplify the calculation of the forming force required for press brake machines. This calculator uses the Press Brake Forming Force Equation as its core algorithm and allows users to input the relevant material and process parameters to calculate the required tonnage. The calculator's benefits include increased accuracy, reduced calculation time, and improved process optimization. By using the calculator, manufacturers can quickly and easily determine the required forming force for a given metal part, reducing the risk of material failure and machine damage. Additionally, the calculator can be used to compare different material options and process parameters, allowing manufacturers to optimize their metal forming processes and reduce production costs. The calculator is also useful for training purposes, as it can help operators understand the complex relationships between material properties, part geometry, and forming process parameters.

What are the key factors that affect the Press Brake Forming Force Equation and how do they impact the calculation?

The key factors that affect the Press Brake Forming Force Equation include the material's yield strength, thickness, and width, as well as the die width and punch radius. These factors can significantly impact the calculation of the required forming force, and it is essential to accurately input these values into the equation or calculator. The material's yield strength, for example, is a critical factor, as it determines the maximum stress that the material can withstand without deforming. The thickness and width of the material also play a significant role, as they affect the bending stiffness and resistance to forming. The die width and punch radius are also important factors, as they influence the forming process and can affect the required tonnage. By understanding how these factors impact the calculation, manufacturers can ensure that their press brake machines are operated within safe and efficient limits, and that their metal forming processes are optimized for quality and productivity.

How can manufacturers use the Press Brake Forming Force Equation and Calculator to optimize their metal forming processes and reduce production costs?

Manufacturers can use the Press Brake Forming Force Equation and Calculator to optimize their metal forming processes and reduce production costs by streamlining their processes and reducing waste. By accurately calculating the required forming force, manufacturers can reduce the risk of material failure and machine damage, which can result in significant cost savings. Additionally, the calculator can be used to compare different material options and process parameters, allowing manufacturers to optimize their metal forming processes for quality and productivity. Manufacturers can also use the equation and calculator to develop more efficient production schedules, reduce energy consumption, and minimize waste. By leveraging these tools, manufacturers can improve their bottom line and stay competitive in the metal forming industry. Furthermore, the equation and calculator can be used to train operators and improve process knowledge, which can lead to increased efficiency and reduced errors. By investing in these tools, manufacturers can future-proof their metal forming processes and stay ahead of the competition.

Deja una respuesta

Entradas Relacionadas