Natural Gas Pipe Flow Rate Calculator

The Natural Gas Pipe Flow Rate Calculator is a vital tool for engineers and professionals in the oil and gas industry. This calculator determines the flow rate of natural gas through pipelines, taking into account factors such as pipe diameter, length, and pressure. Accurate calculations are crucial for ensuring efficient and safe transportation of natural gas. The calculator uses complex formulas and algorithms to provide precise results, making it an essential resource for pipeline design, operation, and maintenance. It helps optimize pipeline performance and reduces the risk of accidents and environmental hazards.

- Natural Gas Pipe Flow Rate Calculator: A Comprehensive Guide

- How do you calculate the flow rate of a gas pipeline?

- How do I calculate what size gas pipe I need?

- What size pipe for 2 psi natural gas?

-

Frequently Asked Questions (FAQs)

- What is the Natural Gas Pipe Flow Rate Calculator and how does it work?

- What are the key factors that affect the flow rate of natural gas in a pipeline?

- How can I use the Natural Gas Pipe Flow Rate Calculator to optimize pipeline design and operations?

- What are the benefits of using the Natural Gas Pipe Flow Rate Calculator in the oil and gas industry?

Natural Gas Pipe Flow Rate Calculator: A Comprehensive Guide

The Natural Gas Pipe Flow Rate Calculator is a tool used to calculate the flow rate of natural gas through a pipe. This calculator is essential in the oil and gas industry, as it helps engineers and technicians to determine the amount of gas that can flow through a pipe, given its diameter, length, and pressure. The calculator takes into account various factors such as the pipe diameter, pipe length, gas pressure, and temperature to provide an accurate calculation of the flow rate.

Introduction to Natural Gas Pipe Flow Rate Calculator

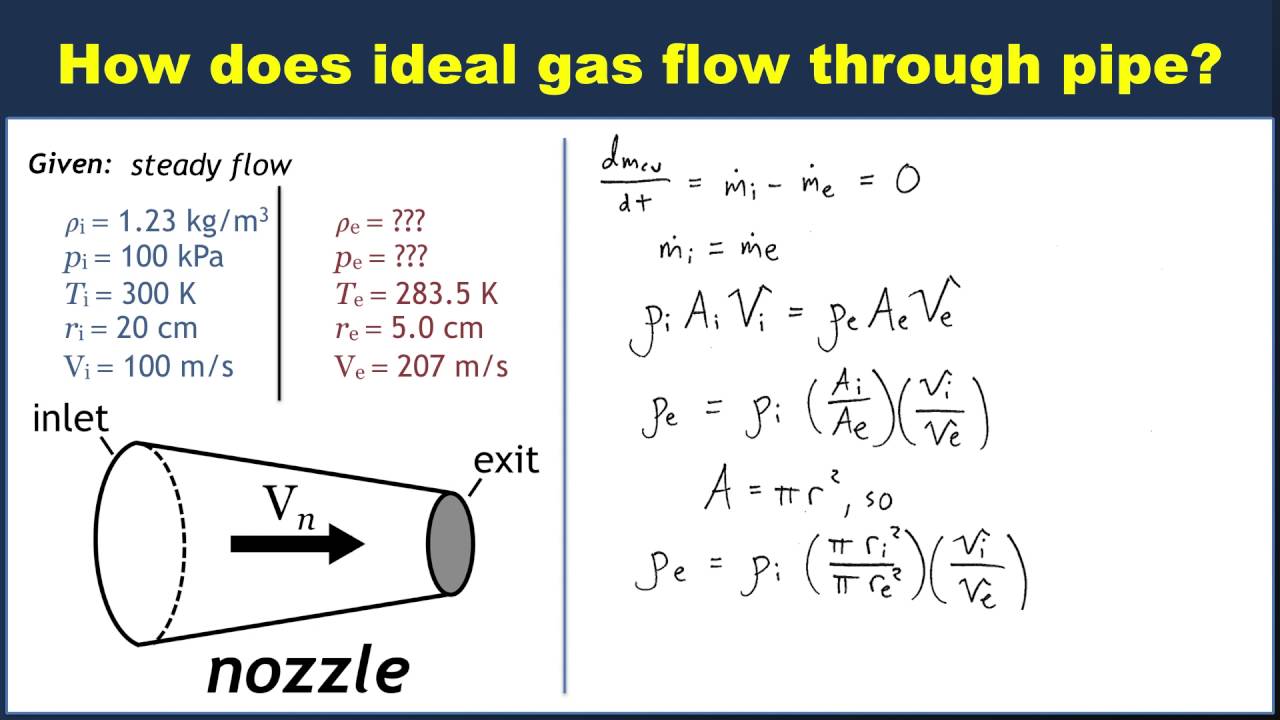

The Natural Gas Pipe Flow Rate Calculator is based on the Darcy-Weisbach equation, which is a widely used equation in fluid dynamics to calculate the flow rate of fluids through pipes. The calculator uses the equation to determine the friction factor, which is a critical component in calculating the flow rate. The friction factor is affected by the pipe roughness, flow velocity, and Reynolds number, making it essential to consider these factors when using the calculator.

Factors Affecting Natural Gas Pipe Flow Rate

Several factors can affect the flow rate of natural gas through a pipe, including:

Pipe diameter: The diameter of the pipe can significantly impact the flow rate, with larger diameters allowing for higher flow rates.

Pipe length: The length of the pipe can also affect the flow rate, with longer pipes resulting in lower flow rates due to increased friction losses.

Gas pressure: The pressure of the gas can impact the flow rate, with higher pressures resulting in higher flow rates.

Temperature: The temperature of the gas can also affect the flow rate, with higher temperatures resulting in higher flow rates.

Natural Gas Pipe Flow Rate Calculator Formula

The Natural Gas Pipe Flow Rate Calculator uses the following formula to calculate the flow rate:

Q = (π (d^2) / 4) v

where Q is the flow rate, π is a constant, d is the pipe diameter, and v is the flow velocity. The flow velocity can be calculated using the Darcy-Weisbach equation, which takes into account the friction factor, pipe length, and gas pressure.

Applications of Natural Gas Pipe Flow Rate Calculator

The Natural Gas Pipe Flow Rate Calculator has various applications in the oil and gas industry, including:

Pipeline design: The calculator can be used to design pipelines with optimal flow rates and diameters.

Flow rate measurement: The calculator can be used to measure the flow rate of natural gas through existing pipelines.

Leak detection: The calculator can be used to detect leaks in pipelines by comparing the calculated flow rate with the actual flow rate.

Benefits of Using Natural Gas Pipe Flow Rate Calculator

Using the Natural Gas Pipe Flow Rate Calculator can provide several benefits, including:

| Benefit | Description |

|---|---|

| Improved accuracy | The calculator provides accurate calculations of the flow rate, reducing the risk of errors. |

| Increased efficiency | The calculator can save time and effort by providing quick and easy calculations. |

| Enhanced safety | The calculator can help detect potential safety hazards, such as leaks or over-pressurization. |

| Optimized pipeline design | The calculator can help optimize pipeline design, reducing costs and improving performance. |

| Reduced costs | The calculator can help reduce costs by minimizing the need for manual calculations and reducing the risk of errors. |

How do you calculate the flow rate of a gas pipeline?

To calculate the flow rate of a gas pipeline, you need to consider several factors, including the pressure and temperature of the gas, as well as the diameter and length of the pipeline. The flow rate can be calculated using the Weymouth equation, which is a widely used formula in the oil and gas industry. This equation takes into account the compressibility of the gas, as well as the friction losses that occur in the pipeline.

Understanding the Weymouth Equation

The Weymouth equation is a complex formula that requires several inputs, including the flow rate, pressure, temperature, and diameter of the pipeline. To use this equation, you need to gather accurate data on these parameters and plug them into the formula. The equation is as follows: Q = (0.4335 T (P1^2 - P2^2)^(1/2)) / (L (Z G (T + 460)))^(1/2), where Q is the flow rate, T is the temperature, P1 and P2 are the pressures, L is the length, Z is the compressibility factor, and G is the gravity factor.

- The flow rate is typically measured in cubic feet per second or cubic meters per second.

- The pressure and temperature are typically measured at the inlet and outlet of the pipeline.

- The diameter and length of the pipeline are also critical inputs for the Weymouth equation.

Factors Affecting Flow Rate

Several factors can affect the flow rate of a gas pipeline, including pressure, temperature, and friction losses. The compressibility of the gas also plays a significant role in determining the flow rate. As the pressure and temperature of the gas increase, the flow rate will also increase. However, friction losses in the pipeline can reduce the flow rate and must be taken into account when calculating the flow rate.

- Pressure and temperature are the most critical factors affecting flow rate.

- Friction losses can reduce the flow rate and must be considered.

- Compressibility of the gas is also an important factor in determining flow rate.

Importance of Accurate Data

Accurate data is critical when calculating the flow rate of a gas pipeline. Small errors in pressure, temperature, or diameter can result in significant errors in the calculated flow rate. It is essential to ensure that all data is accurate and reliable before plugging it into the Weymouth equation. This includes calibrating instruments and verifying data to ensure accuracy.

- Calibrating instruments is essential to ensure accurate data.

- Verifying data is also critical to ensure that it is reliable.

- Accuracy is crucial when calculating flow rate to avoid errors.

Role of Compressibility in Flow Rate Calculation

The compressibility of the gas plays a significant role in determining the flow rate of a gas pipeline. As the pressure and temperature of the gas increase, the compressibility of the gas also increases. This means that the flow rate will be affected by the compressibility of the gas, and this must be taken into account when calculating the flow rate. The compressibility factor is typically measured using the Z-factor, which is a dimensionless value that represents the compressibility of the gas.

- The Z-factor is used to represent the compressibility of the gas.

- Compressibility increases with pressure and temperature.

- Compressibility affects the flow rate and must be considered.

Applications of Flow Rate Calculation

Calculating the flow rate of a gas pipeline has several practical applications in the oil and gas industry. It is used to design and optimize pipelines, as well as to monitor and control flow rates in real-time. The flow rate calculation is also used to predict and prevent potential problems, such as pipeline ruptures or gas leaks. By accurately calculating the flow rate, operators can ensure the safe and efficient operation of the pipeline.

- Designing and optimizing pipelines requires accurate flow rate calculations.

- Monitoring and controlling flow rates is critical for safe operation.

- Predicting and preventing potential problems is also essential.

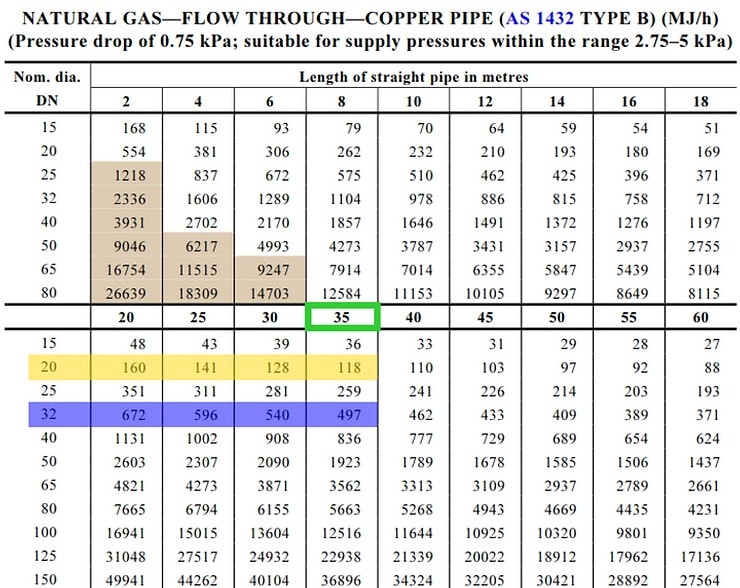

How do I calculate what size gas pipe I need?

To calculate the size of the gas pipe needed, you must consider several factors, including the type of gas, pressure, flow rate, and distance from the gas source to the appliance. The calculation involves determining the gas pipe's ability to supply the required amount of gas while maintaining a safe pressure. This is crucial for efficient and safe operation of gas appliances.

Understanding Gas Pipe Sizing Requirements

To determine the required gas pipe size, you need to understand the sizing requirements for your specific gas pipe installation. This involves calculating the gas flow rate and pressure drop in the pipe. A gas pipe sizing chart or calculator can be used to simplify the process. The key factors to consider are:

- The type of gas being used, such as natural gas or propane

- The gas appliance's BTU rating, which indicates its gas consumption

- The distance from the gas source to the appliance, which affects pressure drop

Gas Pipe Sizing Calculations

Gas pipe sizing calculations involve determining the maximum gas flow rate and allowable pressure drop in the pipe. The gas flow rate is calculated based on the gas appliance's BTU rating and the gas pipe's internal diameter. The allowable pressure drop is determined by the gas pipe material, length, and fittings. The key considerations are:

- Gas flow rate calculation using the gas appliance's BTU rating

- Allowable pressure drop calculation based on the gas pipe material and fittings

- Gas pipe sizing chart or calculator to determine the required gas pipe size

Factors Affecting Gas Pipe Sizing

Several factors can affect gas pipe sizing, including gas pipe material, temperature, and elevation. The gas pipe material can affect the allowable pressure drop, while temperature and elevation can impact the gas flow rate. The key factors to consider are:

- Gas pipe material, such as copper, steel, or PEX

- Temperature, which affects the gas flow rate and pressure drop

- Elevation, which can impact the gas flow rate due to pressure changes

Gas Pipe Sizing for Multiple Appliances

When sizing a gas pipe for multiple appliances, you need to calculate the total gas flow rate required by all appliances. The gas flow rate is then used to determine the required gas pipe size. The key considerations are:

- Total gas flow rate calculation based on the gas appliances' BTU ratings

- Gas pipe sizing chart or calculator to determine the required gas pipe size

- Allowable pressure drop calculation to ensure safe and efficient operation

Using Gas Pipe Sizing Charts and Calculators

Gas pipe sizing charts and calculators can simplify the gas pipe sizing process by providing a quick and accurate way to determine the required gas pipe size. These tools take into account the gas flow rate, pressure drop, and gas pipe material to provide a recommended gas pipe size. The key benefits are:

- Simplified calculation process using a gas pipe sizing chart or calculator

- Accurate determination of the required gas pipe size

- Time-saving and cost-effective solution for gas pipe sizing

What size pipe for 2 psi natural gas?

The size of the pipe for 2 psi natural gas depends on several factors, including the flow rate, distance, and type of appliance being used. Generally, a larger pipe diameter is required for higher flow rates and longer distances to ensure that the gas can flow freely without significant pressure drop}.

Pipe Sizing Considerations

When determining the size of the pipe for 2 psi natural gas, several factors must be considered, including:

- The type of appliance being used, such as a furnace, water heater, or cooker

- The flow rate of gas required by the appliance, measured in cubic feet per hour

- The distance between the gas meter and the appliance, as well as any bends or fittings in the pipe

This information is crucial in determining the correct pipe size to ensure safe and efficient gas delivery.

Standard Pipe Sizes

The standard pipe sizes for natural gas systems are typically 1/2 inch, 3/4 inch, 1 inch, and 1 1/4 inch. However, the actual pipe size required will depend on the specific application and the factors mentioned earlier.

- A 1/2 inch pipe is often used for short distances and low flow rates

- A 3/4 inch pipe is commonly used for medium distances and medium flow rates

- A 1 inch pipe is typically used for longer distances and higher flow rates

It is essential to consult local regulations and industry standards to determine the correct pipe size for a specific application.

Pressure Drop Considerations

Pressure drop is a critical factor in pipe sizing for natural gas systems. As gas flows through the pipe, it encounters resistance, which can cause a pressure drop.

- A pressure drop of more than 2 psi can result in inefficient gas delivery and potentially dangerous conditions

- A pressure drop of less than 1 psi is generally considered acceptable for most applications

- The pipe size and material can significantly impact the pressure drop, with larger pipes and smooth surfaces resulting in less pressure drop

To minimize pressure drop, it is essential to select the correct pipe size and material for the specific application.

Copper vs. Steel Pipe

When it comes to pipe material, copper and steel are two popular options for natural gas systems.

- Copper pipe is resistant to corrosion and has a smooth surface, which can help reduce pressure drop

- Steel pipe is stronger and more durable than copper pipe, but it can be more prone to corrosion

- Coated steel pipe can provide a smooth surface and resistance to corrosion, making it a popular choice for natural gas systems

The choice of pipe material will depend on the specific application, local regulations, and personal preference.

Code Requirements

Local building codes and industry standards must be followed when installing a natural gas system.

- The International Fuel Gas Code (IFGC) and the National Fuel Gas Code (NFPA 54) provide guidelines for pipe sizing and installation

- Local authorities may have additional requirements or restrictions on pipe sizing and installation

- It is essential to consult with local authorities and industry experts to ensure that the installation meets all regulatory requirements

By following code requirements and industry standards, homeowners and installers can ensure a safe and efficient natural gas system.

Frequently Asked Questions (FAQs)

What is the Natural Gas Pipe Flow Rate Calculator and how does it work?

The Natural Gas Pipe Flow Rate Calculator is a tool used to calculate the flow rate of natural gas through a pipeline. It takes into account various factors such as the pipe diameter, pipe length, gas pressure, and gas temperature to provide an accurate calculation of the flow rate. The calculator uses complex algorithms and mathematical models to simulate the flow of natural gas through the pipeline, allowing users to predict the flow rate and make informed decisions about pipeline design and operations. The calculator is commonly used by engineers and technicians in the oil and gas industry to design and optimize pipelines for efficient and safe transportation of natural gas.

What are the key factors that affect the flow rate of natural gas in a pipeline?

The flow rate of natural gas in a pipeline is affected by several key factors, including pipe diameter, pipe length, gas pressure, and gas temperature. The pipe diameter and pipe length determine the resistance to flow, which affects the flow rate. A larger pipe diameter and shorter pipe length result in less resistance and a higher flow rate. The gas pressure and gas temperature also play a crucial role in determining the flow rate. Higher gas pressure and lower gas temperature result in a higher flow rate, while lower gas pressure and higher gas temperature result in a lower flow rate. Additionally, pipeline roughness and bends or valves in the pipeline can also affect the flow rate by introducing turbulence and friction.

How can I use the Natural Gas Pipe Flow Rate Calculator to optimize pipeline design and operations?

The Natural Gas Pipe Flow Rate Calculator can be used to optimize pipeline design and operations by allowing users to simulate different scenarios and predict the flow rate under various conditions. Users can input different values for pipe diameter, pipe length, gas pressure, and gas temperature to see how these factors affect the flow rate. This information can be used to design more efficient pipelines and optimize pipeline operations. For example, users can use the calculator to determine the optimal pipe diameter and pipe length for a given flow rate, or to predict the effect of changing gas pressure or gas temperature on the flow rate. By using the calculator to simulate different scenarios, users can identify potential bottlenecks and optimize pipeline design to ensure safe and efficient transportation of natural gas.

What are the benefits of using the Natural Gas Pipe Flow Rate Calculator in the oil and gas industry?

The Natural Gas Pipe Flow Rate Calculator offers several benefits to the oil and gas industry, including improved pipeline design, increased efficiency, and enhanced safety. By using the calculator to simulate different scenarios and predict the flow rate, users can design more efficient pipelines and optimize pipeline operations. This can result in cost savings and increased productivity, as well as reduced risk of pipeline failures and environmental incidents. Additionally, the calculator can be used to train personnel and develop standard operating procedures for pipeline design and operations. Overall, the Natural Gas Pipe Flow Rate Calculator is a valuable tool for the oil and gas industry, providing accurate and reliable calculations and improving the safety and efficiency of pipeline operations.

Deja una respuesta

Entradas Relacionadas