Natural Frequency Electric Motor Equation and Calculator

The Natural Frequency Electric Motor Equation is a crucial concept in understanding the behavior of electric motors. It refers to the frequency at which the motor's rotor tends to oscillate when subjected to a disturbance. This frequency is dependent on the motor's design parameters, such as its inertia, damping, and spring constants. The equation is essential in predicting the motor's performance, efficiency, and reliability. The calculator provided can be used to calculate the natural frequency of an electric motor, allowing engineers to optimize their designs and ensure stable operation. This equation is vital in motor design and analysis.

- Natural Frequency Electric Motor Equation and Calculator

- How to calculate natural frequency of motor?

- What is the formula for the natural frequency?

- What is the formula for frequency of a motor?

- How to calculate natural frequency from rpm?

-

Frequently Asked Questions (FAQs)

- What is the Natural Frequency Electric Motor Equation and how does it relate to motor performance?

- How does the Natural Frequency Electric Motor Equation and Calculator help in designing and optimizing electric motors?

- What are the key parameters and factors that affect the natural frequency of an electric motor?

- How can the Natural Frequency Electric Motor Equation and Calculator be used in various applications and industries?

Natural Frequency Electric Motor Equation and Calculator

The natural frequency of an electric motor is a critical parameter that determines its stability and performance. It is defined as the frequency at which the motor vibrates or oscillates when it is not driven by an external force. The natural frequency of an electric motor can be calculated using the natural frequency equation, which takes into account the motor's physical parameters such as its mass, stiffness, and damping.

Introduction to Natural Frequency Electric Motor Equation

The natural frequency electric motor equation is a mathematical model that describes the relationship between the motor's physical parameters and its natural frequency. The equation is based on the Laplace transform and transfer function of the motor's dynamic system. The natural frequency equation is given by: ωn = √(k/m), where ωn is the natural frequency, k is the stiffness, and m is the mass of the motor.

Parameters Affecting Natural Frequency of Electric Motors

Several parameters affect the natural frequency of electric motors, including the motor's mass, stiffness, and dampling. The motor's mass includes the mass of the rotor, stator, and other components. The stiffness of the motor is determined by the stiffness of the bearings, shaft, and other components. The damping of the motor is affected by the friction and viscosity of the bearings and other components.

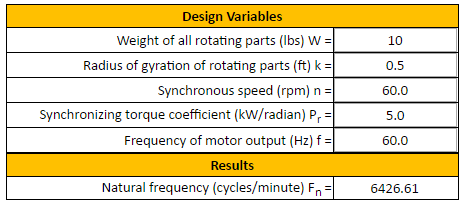

Natural Frequency Electric Motor Calculator

A natural frequency electric motor calculator is a tool that calculates the natural frequency of an electric motor based on its physical parameters. The calculator uses the natural frequency equation and takes into account the motor's mass, stiffness, and damping. The calculator can be used to design and optimize electric motors for various applications.

Applications of Natural Frequency Electric Motor Equation

The natural frequency electric motor equation has several applications in the design and optimization of electric motors. It can be used to predict the vibration and stability of electric motors, design and optimize motor bearings and other components, and improve the overall performance and efficiency of electric motors.

Limitations and Challenges of Natural Frequency Electric Motor Equation

The natural frequency electric motor equation has several limitations and challenges, including the complexity of the motor's dynamic system, non-linear effects, and uncertainty in the motor's physical parameters. These limitations and challenges can affect the accuracy and reliability of the natural frequency calculation.

| Parameter | Unit | Description |

|---|---|---|

| ωn | rad/s | Natural Frequency |

| k | N/m | Stiffness |

| m | kg | Mass |

How to calculate natural frequency of motor?

To calculate the natural frequency of a motor, you need to consider the physical characteristics of the motor, such as its mass, stiffness, and damping. The natural frequency is the frequency at which the motor vibrates or oscillates when it is not subjected to any external forces. This frequency is an important parameter in determining the dynamic behavior of the motor.

Understanding the Concept of Natural Frequency

The natural frequency of a motor is a critical parameter that describes its vibrational behavior. It is the frequency at which the motor tends to vibrate or oscillate when it is disturbed from its equilibrium position. To calculate the natural frequency, you need to consider the physical properties of the motor, such as its mass, stiffness, and damping. The natural frequency is calculated using the following formula: ωn = √(k/m), where ωn is the natural frequency, k is the stiffness, and m is the mass.

- The mass of the motor is a critical parameter that affects its natural frequency.

- The stiffness of the motor is another important parameter that influences its natural frequency.

- The damping of the motor also plays a role in determining its natural frequency.

Calculating the Natural Frequency of a Motor

To calculate the natural frequency of a motor, you need to follow a series of steps. First, you need to determine the mass and stiffness of the motor. The mass can be calculated by measuring the weight of the motor, while the stiffness can be determined by measuring the deflection of the motor under a load. Once you have these values, you can use the formula ωn = √(k/m) to calculate the natural frequency.

- Measure the weight of the motor to determine its mass.

- Measure the deflection of the motor under a load to determine its stiffness.

- Use the formula ωn = √(k/m) to calculate the natural frequency.

Factors Affecting the Natural Frequency of a Motor

There are several factors that can affect the natural frequency of a motor, including its design, materials, and operating conditions. The design of the motor, including its shape and size, can influence its natural frequency. The materials used to construct the motor, such as steel or aluminum, can also affect its natural frequency. Additionally, the operating conditions of the motor, such as its speed and load, can also impact its natural frequency.

- The design of the motor can influence its natural frequency.

- The materials used to construct the motor can affect its natural frequency.

- The operating conditions of the motor can also impact its natural frequency.

Importance of Natural Frequency in Motor Design

The natural frequency of a motor is an important parameter in its design and operation. It can affect the performance, efficiency, and reliability of the motor. A motor with a low natural frequency may be more prone to vibration and noise, while a motor with a high natural frequency may be more stable and efficient. The natural frequency can also be used to predict and prevent resonance, which can cause damage to the motor.

- A low natural frequency can lead to vibration and noise.

- A high natural frequency can result in a more stable and efficient motor.

- The natural frequency can be used to predict and prevent resonance.

Measurement and Analysis of Natural Frequency

The natural frequency of a motor can be measured and analyzed using various techniques and tools. One common method is to use accelerometers to measure the vibration of the motor. The frequency response of the motor can then be analyzed using software or hardware tools. The natural frequency can also be measured using impact testing, where a hammer is used to strike the motor and measure its response.

- Accelerometers can be used to measure the vibration of the motor.

- Impact testing can be used to measure the response of the motor.

- Software or hardware tools can be used to analyze the frequency response of the motor.

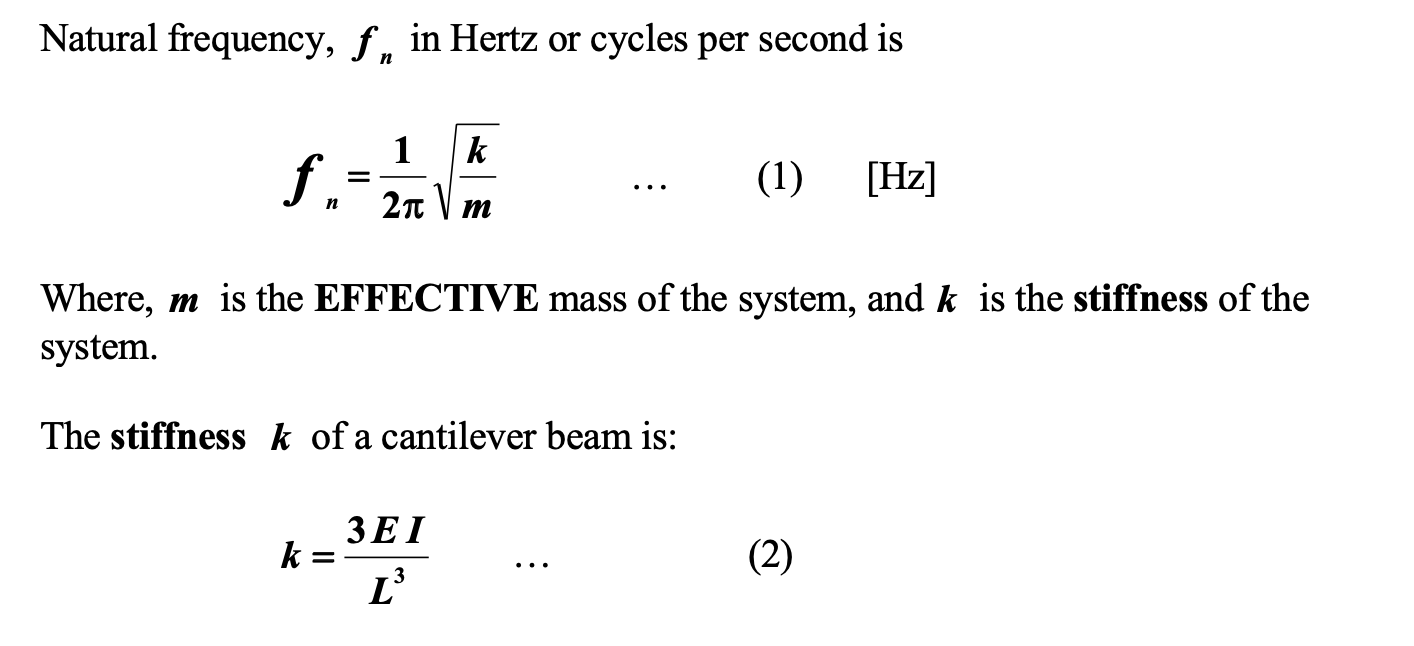

What is the formula for the natural frequency?

The natural frequency of a system is the frequency at which it tends to oscillate or vibrate in the absence of any external forces. The formula for the natural frequency of a system is given by:

ωn = √(k/m)

where ωn is the natural frequency, k is the stiffness of the system, and m is the mass of the system.

Natural Frequency in Mechanical Systems

The natural frequency of a mechanical system is an important concept in vibration analysis. It is used to determine the frequency at which a system will vibrate or oscillate when subjected to an external force. The natural frequency of a mechanical system can be calculated using the following formula:

- The mass of the system (m) is determined by the weight and distribution of the components.

- The stiffness of the system (k) is determined by the spring constant and the damping coefficient.

- The natural frequency (ωn) is calculated using the formula ωn = √(k/m).

This formula shows that the natural frequency of a system is directly proportional to the stiffness and inversely proportional to the mass.

Natural Frequency in Electrical Systems

The natural frequency of an electrical system is also an important concept in electrical engineering. It is used to determine the frequency at which an electrical circuit will oscillate or resonate when subjected to an external voltage or current. The natural frequency of an electrical system can be calculated using the following formula:

- The inductance of the circuit (L) is determined by the type and value of the inductor.

- The capacitance of the circuit (C) is determined by the type and value of the capacitor.

- The natural frequency (ωn) is calculated using the formula ωn = 1 / √(LC).

This formula shows that the natural frequency of an electrical system is directly proportional to the inductance and capacitance.

Factors Affecting Natural Frequency

There are several factors that can affect the natural frequency of a system, including:

- The mass and stiffness of the system, which can be affected by the design and materials used.

- The damping coefficient, which can be affected by the friction and viscosity of the system.

- The external forces applied to the system, which can cause the system to vibrate or oscillate at a different frequency.

These factors can be difficult to control and can affect the accuracy of the natural frequency calculation.

Measurement of Natural Frequency

The natural frequency of a system can be measured using a variety of techniques, including:

- Vibration testing, which involves measuring the vibration of the system using sensors and data acquisition systems.

- Frequency response analysis, which involves measuring the response of the system to a range of frequencies.

- Modal analysis, which involves measuring the modes of vibration of the system and calculating the natural frequency.

These techniques can be used to determine the natural frequency of a system and to validate the results of calculations.

Applications of Natural Frequency

The natural frequency of a system has a range of applications in engineering and science, including:

- Vibration isolation, which involves designing systems to reduce the transmission of vibrations.

- Resonance, which involves designing systems to resonate at a specific frequency.

- Dynamic analysis, which involves analyzing the dynamic behavior of systems and calculating the natural frequency.

These applications rely on an understanding of the natural frequency and its relationship to the design and behavior of systems.

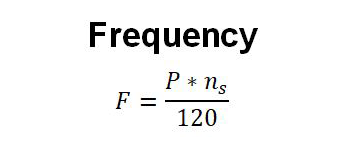

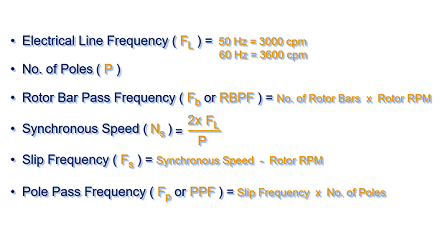

What is the formula for frequency of a motor?

The formula for frequency of a motor is given by the equation: frequency (f) = number of revolutions per second (N) / 60. However, the most commonly used formula is: f = (2 pi N) / 60, where N is the number of revolutions per minute and pi is a mathematical constant approximately equal to 3.14159. This formula is used to calculate the frequency of an induction motor or any other type of alternating current (AC) motor.

Understanding the Basics of Motor Frequency

To understand the concept of motor frequency, it is essential to know the relationship between the number of revolutions and the frequency. The frequency is directly proportional to the number of revolutions. The following are some key points to consider:

- The frequency is measured in Hertz (Hz), which represents the number of cycles or revolutions per second.

- The number of revolutions is measured in revolutions per minute (RPM) or revolutions per second.

- The motor speed is directly related to the frequency, and a change in frequency will result in a change in motor speed.

Factors Affecting Motor Frequency

Several factors can affect the frequency of a motor, including the supply voltage, motor design, and load conditions. The following are some key factors to consider:

- The supply voltage and frequency must be compatible with the motor design to ensure efficient operation.

- The motor design, including the number of poles and windings, can affect the frequency and speed of the motor.

- The load conditions, including the torque and speed, can also impact the frequency and performance of the motor.

Calculating Motor Frequency

To calculate the frequency of a motor, you need to know the number of revolutions and the time period. The following are some steps to follow:

- Determine the number of revolutions per minute (RPM) or per second.

- Determine the time period in seconds.

- Use the formula: f = (2 pi N) / 60, where N is the number of revolutions per minute.

Applications of Motor Frequency

The frequency of a motor has several applications in various fields, including industrial automation, power generation, and transportation systems. The following are some key applications:

- Speed control: The frequency can be used to control the speed of a motor in various applications, including conveyors and pumps.

- Power generation: The frequency is critical in power generation systems, where it must be synchronized with the grid frequency.

- Transportation systems: The frequency is used in transportation systems, including trains and elevators, to control the speed and position of the vehicles.

Importance of Motor Frequency in Industrial Applications

The frequency of a motor is crucial in industrial applications, where it can affect the efficiency, productivity, and reliability of the system. The following are some key points to consider:

- The frequency can impact the energy consumption and cost of operation.

- The frequency can affect the performance and lifetime of the motor and other components.

- The frequency must be carefully controlled to ensure synchronization with other components and systems.

How to calculate natural frequency from rpm?

To calculate the natural frequency from rpm, you need to understand the relationship between the two. The natural frequency of a system is the frequency at which it tends to oscillate or vibrate when disturbed, while rpm (revolutions per minute) is a measure of the rotational speed of a system. The natural frequency can be calculated using the formula: natural frequency (in Hz) = (rpm / 60) / order of vibration. This formula shows that the natural frequency is directly proportional to the rpm and inversely proportional to the order of vibration.

Understanding the Concept of Natural Frequency

The concept of natural frequency is crucial in understanding how to calculate it from rpm. Natural frequency is the frequency at which a system vibrates or oscillates when it is disturbed and then left to vibrate freely. This frequency is determined by the physical properties of the system, such as its mass, stiffness, and damping. To calculate the natural frequency, you need to know the rpm and the order of vibration. The order of vibration refers to the number of nodes or points of zero displacement in the vibration mode. For example:

- The formula for calculating natural frequency from rpm is: natural frequency (in Hz) = (rpm / 60) / order of vibration.

- The rpm is measured in revolutions per minute, and it needs to be converted to a frequency in Hz by dividing by 60.

- The order of vibration is an important factor in determining the natural frequency, and it depends on the physical properties of the system.

Calculating Natural Frequency from RPM

Calculating the natural frequency from rpm involves using the formula: natural frequency (in Hz) = (rpm / 60) / order of vibration. This formula shows that the natural frequency is directly proportional to the rpm and inversely proportional to the order of vibration. To calculate the natural frequency, you need to know the rpm and the order of vibration. For example:

- First, you need to measure the rpm of the system, which can be done using a tachometer or other speed measurement device.

- Next, you need to determine the order of vibration, which can be done using modal analysis or other vibration analysis techniques.

- Finally, you can plug the values into the formula to calculate the natural frequency.

Factors Affecting Natural Frequency

There are several factors that can affect the natural frequency of a system, including its mass, stiffness, and damping. The natural frequency is also affected by the order of vibration, which depends on the physical properties of the system. Additionally, the natural frequency can be affected by external factors, such as the presence of other vibrating systems or environmental conditions. For example:

- The mass of the system can affect the natural frequency, with heavier systems tending to have lower natural frequencies.

- The stiffness of the system can also affect the natural frequency, with stiffer systems tending to have higher natural frequencies.

- The damping of the system can affect the natural frequency, with more heavily damped systems tending to have lower natural frequencies.

Applications of Natural Frequency Calculation

The calculation of natural frequency from rpm has several applications in various fields, including mechanical engineering, aerospace engineering, and civil engineering. The natural frequency is an important parameter in the design of vibrating systems, such as engines, gearboxes, and rotating machinery. It is also used in the analysis of vibration problems, such as resonance and fatigue. For example:

- The natural frequency is used in the design of vibrating systems to ensure that they operate at a frequency that is not resonant with other frequencies in the system.

- The natural frequency is used in the analysis of vibration problems to identify the source of the vibration and to develop solutions to mitigate its effects.

- The natural frequency is also used in the testing and validation of vibrating systems to ensure that they meet the required performance specifications.

Common Mistakes in Natural Frequency Calculation

There are several common mistakes that can be made when calculating the natural frequency from rpm, including errors in measuring the rpm, inaccuracies in determining the order of vibration, and mistakes in applying the formula. These mistakes can lead to inaccurate results and incorrect conclusions. For example:

- One common mistake is to forget to convert the rpm to a frequency in Hz by dividing by 60.

- Another common mistake is to misidentify the order of vibration, which can lead to inaccurate results.

- A third common mistake is to apply the formula incorrectly, which can lead to mistakes in calculating the natural frequency.

Frequently Asked Questions (FAQs)

What is the Natural Frequency Electric Motor Equation and how does it relate to motor performance?

The Natural Frequency Electric Motor Equation is a mathematical formula used to calculate the natural frequency of an electric motor, which is the frequency at which the motor tends to vibrate or oscillate when excited by an external force. This equation is important because it helps engineers and designers understand the dynamic behavior of the motor and its components, such as the rotor, stator, and bearings. By calculating the natural frequency, designers can ensure that the motor is operating within a safe and efficient range, avoiding resonance and vibration that can lead to reduced performance, increased wear and tear, and even premature failure. The equation takes into account various parameters, including the motor's mass, stiffness, and damping characteristics, as well as the excitation forces acting upon it. By understanding the natural frequency, designers can optimize the motor's design and operation to achieve better performance, increased efficiency, and improved reliability.

How does the Natural Frequency Electric Motor Equation and Calculator help in designing and optimizing electric motors?

The Natural Frequency Electric Motor Equation and Calculator are essential tools for designing and optimizing electric motors. By using the equation and calculator, designers can predict and analyze the motor's dynamic behavior, identifying potential issues and areas for improvement. The calculator allows designers to input various parameters, such as the motor's geometric dimensions, material properties, and operating conditions, and then calculates the natural frequency and other relevant performance metrics. This enables designers to iterate and refine their design, making adjustments to optimize the motor's performance, efficiency, and reliability. The equation and calculator can also be used to validate and verify the design, ensuring that the motor meets the required specifications and standards. Additionally, the calculator can be used to compare different design options, allowing designers to select the best configuration and components for their specific application. By using the Natural Frequency Electric Motor Equation and Calculator, designers can create high-performance motors that meet the needs of their customers and stay ahead of the competition.

What are the key parameters and factors that affect the natural frequency of an electric motor?

The natural frequency of an electric motor is affected by several key parameters and factors, including the motor's mass, stiffness, and damping characteristics. The mass of the motor, including the rotor and stator, plays a significant role in determining the natural frequency, as it affects the motor's inertia and resonance. The stiffness of the motor's components, such as the bearings and shaft, also impacts the natural frequency, as it influences the motor's vibration and oscillation. Additionally, the damping characteristics of the motor, including the friction and viscosity of the bearings and other components, can significantly affect the natural frequency, as they help to absorb and dissipate energy. Other factors, such as the motor's operating speed, torque, and excitation forces, can also influence the natural frequency. Furthermore, the material properties of the motor's components, such as their density, elasticity, and viscosity, can also impact the natural frequency. By understanding and controlling these parameters and factors, designers can optimize the motor's design and operation to achieve the desired performance and reliability.

How can the Natural Frequency Electric Motor Equation and Calculator be used in various applications and industries?

The Natural Frequency Electric Motor Equation and Calculator can be used in a wide range of applications and industries, including industrial automation, aerospace, automotive, and renewable energy. In industrial automation, the equation and calculator can be used to design and optimize high-performance motors for applications such as robotics, conveyors, and pumps. In aerospace, the equation and calculator can be used to design high-reliability motors for applications such as aircraft and satellites. In automotive, the equation and calculator can be used to design and optimize electric vehicle motors, as well as hybrid and electric powertrains. In renewable energy, the equation and calculator can be used to design and optimize wind turbine and hydroelectric motors. Additionally, the equation and calculator can be used in research and development to study and analyze the dynamic behavior of electric motors, and to develop new technologies and materials. By using the Natural Frequency Electric Motor Equation and Calculator, designers and engineers can create high-performance, efficient, and reliable motors that meet the needs of their applications and industries.

Deja una respuesta

Entradas Relacionadas