Minimum Pipe Insulation Thickness per. ASHRAE Table, Formula and Calculator

Proper pipe insulation is crucial for energy efficiency, safety, and cost savings in various industries. The American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) provides guidelines for minimum pipe insulation thickness. These standards help reduce heat loss, prevent condensation, and minimize the risk of pipe damage. Using ASHRAE tables, formulas, and calculators, professionals can determine the optimal insulation thickness for specific pipe sizes and applications, ensuring compliance with industry regulations and optimizing system performance. This article explores the ASHRAE guidelines and tools for determining minimum pipe insulation thickness.

- Understanding Minimum Pipe Insulation Thickness per ASHRAE Table, Formula, and Calculator

- How do you calculate the thickness of Ashrae insulation?

- What is the formula for minimum thickness of insulation?

- What is the minimum thickness of insulation pipe?

- What is the formula for thickness of insulation?

-

Frequently Asked Questions (FAQs)

- What is the minimum pipe insulation thickness required by ASHRAE standards?

- How is the minimum pipe insulation thickness calculated using ASHRAE formulas?

- What are the benefits of using a calculator to determine the minimum pipe insulation thickness?

- How do ASHRAE tables provide guidance on minimum pipe insulation thickness?

Understanding Minimum Pipe Insulation Thickness per ASHRAE Table, Formula, and Calculator

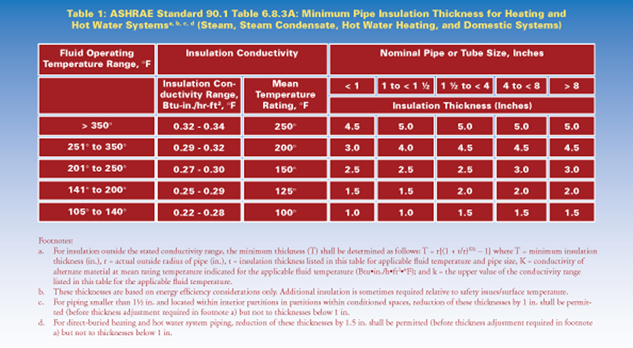

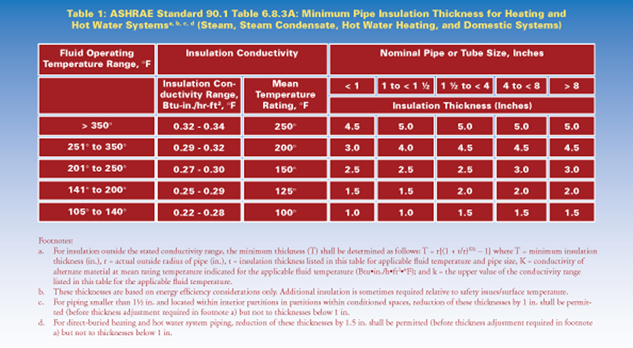

To determine the minimum pipe insulation thickness, it's essential to consider the guidelines set by the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE). The ASHRAE table provides a standardized approach to calculating the required insulation thickness based on various factors such as pipe size, temperature, and location. Additionally, a formula can be used to calculate the minimum insulation thickness, and a calculator can be employed to simplify the process. The ASHRAE standards aim to ensure energy efficiency and safety in buildings and industrial settings.

Introduction to ASHRAE Table for Pipe Insulation

The ASHRAE table for pipe insulation provides a comprehensive guide for determining the minimum insulation thickness required for various pipe sizes and operating temperatures. The table takes into account the type of insulation and the ambient temperature to ensure that the insulation meets the necessary thermal performance standards. By using the ASHRAE table, engineers and contractors can ensure that their pipe insulation systems are code-compliant and energy-efficient.

Calculating Minimum Pipe Insulation Thickness using Formula

The formula for calculating the minimum pipe insulation thickness involves several variables, including pipe diameter, temperature difference, and thermal conductivity of the insulation. The formula is: t = (Q / (2 π k (T1 - T2))) (1 / (h (T1 - T2))), where t is the insulation thickness, Q is the heat transfer rate, k is the thermal conductivity, T1 and T2 are the temperatures, and h is the convective heat transfer coefficient. This formula provides a precise calculation of the minimum insulation thickness required for a given pipe insulation system.

Using a Calculator for Minimum Pipe Insulation Thickness

A calculator can be used to simplify the process of determining the minimum pipe insulation thickness. The calculator takes into account the input values such as pipe size, temperature, and insulation type, and provides the output value of the minimum insulation thickness required. This calculator can be a useful tool for engineers and contractors who need to quickly and accurately determine the minimum insulation thickness for a given pipe insulation system.

Benefits of Proper Pipe Insulation

Proper pipe insulation offers several benefits, including energy savings, reduced heat loss, and improved safety. Insulation can also help to reduce noise and prevent condensation. By using the ASHRAE table, formula, or calculator to determine the minimum insulation thickness, engineers and contractors can ensure that their pipe insulation systems are effective and compliant with relevant codes and standards.

Comparison of Different Insulation Materials

Different insulation materials have varying thermal conductivity values, which affect the minimum insulation thickness required. A comparison of different insulation materials, such as fiberglass, mineral wool, and foam insulation, can help engineers and contractors select the most suitable material for their specific pipe insulation application. The following table compares the thermal conductivity values of different insulation materials:

| Insulation Material | Thermal Conductivity (W/m-K) |

|---|---|

| Fiberglass | 0.033 |

| Mineral Wool | 0.035 |

| Foam Insulation | 0.020 |

The thermal conductivity values highlight the importance of selecting the right insulation material for a given pipe insulation application to ensure optimal performance and energy efficiency. The use of ASHRAE standards and calculators can help to determine the minimum pipe insulation thickness required for a given application.

How do you calculate the thickness of Ashrae insulation?

To calculate the thickness of Ashrae insulation, you need to consider several factors, including the climate, building type, and desired level of energy efficiency. The Ashrae (American Society of Heating, Refrigerating, and Air-Conditioning Engineers) provides guidelines for calculating the required insulation thickness. The calculation involves determining the heat transfer coefficient (U-factor) of the building component, such as a wall or roof, and then using a chart or equation to determine the required insulation thickness.

Understanding Ashrae Insulation Requirements

The Ashrae insulation requirements are based on the climate zone and the building type. The requirements are outlined in the Ashrae Standard 90.1, which provides a prescriptive approach to determining the required insulation thickness. The standard takes into account the heating and cooling loads of the building, as well as the moisture and air infiltration. Some key factors to consider when calculating the required insulation thickness include:

- The climate zone and building type

- The desired level of energy efficiency

- The type of insulation being used

Calculating the U-Factor

The U-factor is a measure of the heat transfer coefficient of a building component. It is calculated using the thermal resistance of each layer of the component, including the insulation, drywall, and exterior finish. The U-factor is then used to determine the required insulation thickness. The calculation involves using the following formula: U = 1/R, where R is the thermal resistance. Some key steps in calculating the U-factor include:

- Determining the thermal resistance of each layer

- Calculating the total thermal resistance

- Using the U-factor equation to determine the required insulation thickness

Selecting the Right Insulation Type

The type of insulation being used can have a significant impact on the required insulation thickness. Different types of insulation, such as fiberglass, cellulose, and spray foam, have different thermal resistances and densities. The type of insulation should be selected based on the climate zone, building type, and desired level of energy efficiency. Some key factors to consider when selecting the type of insulation include:

- The thermal resistance of the insulation

- The density of the insulation

- The moisture resistance of the insulation

Using Ashrae Charts and Equations

The Ashrae provides charts and equations to help determine the required insulation thickness. The charts are based on the climate zone and building type, and provide a prescriptive approach to determining the required insulation thickness. The equations are more complex and take into account the U-factor, thermal resistance, and other factors. Some key steps in using the Ashrae charts and equations include:

- Determining the climate zone and building type

- Using the charts to determine the required insulation thickness

- Using the equations to calculate the U-factor and thermal resistance

Factors Affecting Insulation Thickness

There are several factors that can affect the required insulation thickness, including the climate zone, building type, and desired level of energy efficiency. Other factors, such as moisture and air infiltration, can also impact the required insulation thickness. Some key factors to consider when determining the required insulation thickness include:

- The climate zone and building type

- The desired level of energy efficiency

- The type of insulation being used

What is the formula for minimum thickness of insulation?

The formula for minimum thickness of insulation is typically determined by the heat transfer requirements and the thermal conductivity of the insulation material. The minimum thickness can be calculated using the following formula: t = (Q R) / (k A ΔT), where t is the minimum thickness, Q is the heat transfer rate, R is the thermal resistance, k is the thermal conductivity, A is the surface area, and ΔT is the temperature difference.

Types of Insulation

The type of insulation used can significantly impact the minimum thickness required. Some common types of insulation include fiberglass, cellulose, and spray foam. Each type has its own unique thermal conductivity and density, which affect the minimum thickness required.

- The thermal conductivity of the insulation material is a critical factor in determining the minimum thickness required.

- The density of the insulation material also plays a role in determining the minimum thickness required.

- The cost and availability of the insulation material can also impact the minimum thickness required.

Thermal Conductivity

The thermal conductivity of the insulation material is a measure of its ability to conduct heat. Materials with high thermal conductivity require a greater minimum thickness to achieve the same level of thermal insulation as materials with low thermal conductivity.

- Metals have high thermal conductivity and require a greater minimum thickness.

- Fiberglass has a lower thermal conductivity than metals and requires a smaller minimum thickness.

- Vacuum insulation has a very low thermal conductivity and requires a very small minimum thickness.

Heat Transfer Rate

The heat transfer rate is a critical factor in determining the minimum thickness of insulation required. A higher heat transfer rate requires a greater minimum thickness to achieve the same level of thermal insulation.

- Convection is a type of heat transfer that occurs through the movement of fluids.

- Conduction is a type of heat transfer that occurs through direct contact between particles.

- Radiation is a type of heat transfer that occurs through the emission of electromagnetic waves.

Temperature Difference

The temperature difference between the inside and outside of a building or system is a critical factor in determining the minimum thickness of insulation required. A greater temperature difference requires a greater minimum thickness to achieve the same level of thermal insulation.

- A large temperature difference requires a greater minimum thickness of insulation.

- A small temperature difference requires a smaller minimum thickness of insulation.

- The temperature difference can vary depending on the climate and location.

Energy Efficiency

The energy efficiency of a building or system is a critical factor in determining the minimum thickness of insulation required. A higher level of energy efficiency requires a greater minimum thickness to achieve the same level of thermal insulation.

- Energy-efficient buildings require a greater minimum thickness of insulation.

- Energy-inefficient buildings require a smaller minimum thickness of insulation.

- The energy efficiency of a building or system can be improved through the use of energy-efficient materials and designs.

What is the minimum thickness of insulation pipe?

The minimum thickness of insulation pipe is typically determined by the specific application, location, and regulatory requirements. In general, the minimum thickness of insulation pipe is around 1/2 inch (13 mm) for most industrial applications. However, this can vary depending on the type of insulation material used, the temperature range of the pipe, and the environmental conditions.

Insulation Pipe Materials

The minimum thickness of insulation pipe also depends on the type of insulation material used. Some common insulation materials used for pipes include fiberglass, mineral wool, and foam insulation. Each of these materials has its own unique thermal conductivity and density, which affect the minimum thickness required for effective insulation.

- Fiberglass insulation is a popular choice for pipes due to its high thermal resistance and moisture-resistant properties.

- Mineral wool insulation is another option, which offers high temperature resistance and sound absorption properties.

- Foam insulation is a type of rigid insulation that provides high thermal resistance and is often used for cryogenic applications.

Temperature Range and Insulation Thickness

The temperature range of the pipe is another critical factor in determining the minimum thickness of insulation pipe. For pipes operating at high temperatures, a thicker layer of insulation is required to prevent heat loss and ensure energy efficiency.

- High-temperature pipes require a minimum thickness of 1 inch (25 mm) of insulation to maintain a safe temperature.

- Low-temperature pipes, on the other hand, may require a minimum thickness of 1/2 inch (13 mm) of insulation.

- Cryogenic pipes require specialized insulation materials and a minimum thickness of 2 inches (51 mm) to maintain extremely low temperatures.

Environmental Conditions and Insulation Thickness

The environmental conditions in which the pipe is located also play a significant role in determining the minimum thickness of insulation pipe. For pipes exposed to harsh weather conditions, a thicker layer of insulation is required to prevent moisture ingress and corrosion.

- Outdoor pipes require a minimum thickness of 1 inch (25 mm) of insulation to protect against weathering and moisture.

- Indoor pipes may require a minimum thickness of 1/2 inch (13 mm) of insulation, depending on the indoor climate.

- Underground pipes require specialized insulation materials and a minimum thickness of 2 inches (51 mm) to prevent soil corrosion and moisture ingress.

Regulatory requirements also play a crucial role in determining the minimum thickness of insulation pipe. Various regulatory bodies, such as the ASME and ASTM, provide guidelines and standards for insulation pipe thickness.

- ASME standards require a minimum thickness of 1/2 inch (13 mm) of insulation for most industrial applications.

- ASTM standards provide guidelines for insulation materials and thickness requirements based on temperature range and environmental conditions.

- Local regulations may also require specific insulation thickness and materials for pipes in certain industries or locations.

Insulation Pipe Installation and Maintenance

The installation and maintenance of insulation pipe are critical factors in ensuring the effectiveness and longevity of the insulation. Proper installation techniques, such as seamless joints and secure fastening, are essential to prevent moisture ingress and heat loss.

- Regular inspections are necessary to ensure the insulation remains intact and effective.

- Maintenance activities, such as cleaning and repairing, should be performed regularly to prevent damage and corrosion.

- Training and certification programs are available for insulation installers to ensure they have the necessary skills and knowledge to install insulation pipe correctly.

What is the formula for thickness of insulation?

The formula for the thickness of insulation is typically determined by the heat transfer requirements of the system or application. The most common formula used is the heat transfer coefficient (U-factor) formula, which takes into account the thermal conductivity of the insulation material, the temperature difference between the inner and outer surfaces, and the surface area of the insulation. This formula is often used to determine the minimum thickness of insulation required to meet energy efficiency standards or to reduce heat loss.

Factors Affecting Insulation Thickness

The thickness of insulation required can be affected by several factors, including the climate and location of the building, the type of insulation material used, and the desired level of energy efficiency. Other factors that can impact the thickness of insulation include the building codes and regulations in the area, as well as the budget and cost constraints of the project. Some key factors to consider when determining the thickness of insulation include:

- Temperature: The temperature difference between the inner and outer surfaces of the insulation

- Humidity: The level of humidity in the air, which can affect the thermal conductivity of the insulation

- Air movement: The amount of air movement around the insulation, which can impact the convective heat transfer

Types of Insulation Materials

There are several types of insulation materials available, each with its own thermal conductivity and density. The type of insulation material used can affect the thickness of insulation required, as well as the installation costs and maintenance requirements. Some common types of insulation materials include fiberglass, cellulose, and spray foam. The choice of insulation material will depend on the specific application and climate, as well as the budget and performance requirements. Some key characteristics of insulation materials include:

- Thermal conductivity: The ability of the material to conduct heat

- Density: The weight of the material per unit volume

- Water absorption: The ability of the material to absorb water and moisture

Insulation Thickness Calculations

The thickness of insulation required can be calculated using the heat transfer coefficient (U-factor) formula, which takes into account the thermal conductivity of the insulation material, the temperature difference between the inner and outer surfaces, and the surface area of the insulation. The formula is typically expressed as: U = (Q/A) / (T1 - T2), where U is the heat transfer coefficient, Q is the heat transfer rate, A is the surface area, and T1 and T2 are the temperatures of the inner and outer surfaces. Some key steps in calculating the thickness of insulation include:

- Determine the heat transfer rate: Calculate the amount of heat that needs to be transferred

- Determine the surface area: Calculate the surface area of the insulation

- Determine the temperature difference: Calculate the temperature difference between the inner and outer surfaces

Benefits of Proper Insulation Thickness

Proper insulation thickness can provide several benefits, including reduced heat loss, improved energy efficiency, and increased comfort. Proper insulation thickness can also help to reduce energy costs, minimize moisture damage, and extend the lifespan of the building or system. Some key benefits of proper insulation thickness include:

- Energy savings: Reduced heat loss and improved energy efficiency can lead to significant energy savings

- Improved comfort: Proper insulation thickness can help to maintain a consistent temperature and improve occupant comfort

- Increased durability: Proper insulation thickness can help to reduce moisture damage and extend the lifespan of the building or system

Challenges and Limitations of Insulation Thickness

There are several challenges and limitations to consider when determining the thickness of insulation, including budget constraints, space limitations, and installation challenges. Other challenges and limitations include material availability, labor costs, and regulatory requirements. Some key challenges and limitations to consider include:

- Cost: The cost of insulation materials and installation can be a significant factor in determining the thickness of insulation

- Space: The available space for insulation can be limited, which can impact the thickness of insulation that can be installed

- Installation: The installation process can be complex and require specialized labor and equipment

Frequently Asked Questions (FAQs)

What is the minimum pipe insulation thickness required by ASHRAE standards?

The American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) provides standards for minimum pipe insulation thickness to ensure efficient energy use and prevent heat loss or gain in HVAC systems. According to ASHRAE standards, the minimum pipe insulation thickness varies depending on the pipe size, insulation material, and operating temperature. For example, for pipes operating at temperatures above 200°F (93°C), the minimum insulation thickness is typically 1 inch (2.5 cm) for pipes with a diameter of 1 inch (2.5 cm) or less, and 1.5 inches (3.8 cm) for pipes with a diameter of 1.5 inches (3.8 cm) or more. It's essential to consult the latest ASHRAE standards and tables to determine the minimum pipe insulation thickness required for specific applications. Additionally, calculators and software tools are available to help engineers and contractors determine the minimum insulation thickness required based on specific design conditions.

How is the minimum pipe insulation thickness calculated using ASHRAE formulas?

The ASHRAE formulas for calculating the minimum pipe insulation thickness take into account various factors, including pipe size, insulation material, operating temperature, and ambient temperature. The formulas are based on heat transfer principles and consider the thermal conductivity of the insulation material, as well as the convection coefficient and radiation coefficient. For instance, the ASHRAE formula for calculating the minimum insulation thickness for a pipe operating at a temperature above 200°F (93°C) is: t = (Q / (k A (T1 - T2))) (1 / (h (T1 - T2))), where t is the insulation thickness, Q is the heat transfer rate, k is the thermal conductivity of the insulation material, A is the pipe surface area, T1 is the operating temperature, T2 is the ambient temperature, and h is the convection coefficient. By using these formulas and calculators, engineers and contractors can determine the minimum pipe insulation thickness required to meet ASHRAE standards and ensure efficient energy use.

What are the benefits of using a calculator to determine the minimum pipe insulation thickness?

Using a calculator to determine the minimum pipe insulation thickness offers several benefits, including accuracy, efficiency, and cost savings. A calculator can quickly and accurately determine the minimum insulation thickness required based on specific design conditions, eliminating the need for manual calculations and reducing the risk of errors. Additionally, a calculator can help engineers and contractors optimize their designs by identifying the most cost-effective insulation solutions that meet ASHRAE standards. For example, a calculator can help determine the optimal insulation thickness for a specific pipe size and operating temperature, taking into account thermal conductivity, convection coefficient, and radiation coefficient. By using a calculator, engineers and contractors can ensure that their designs meet ASHRAE standards and local building codes, while also minimizing energy losses and costs.

How do ASHRAE tables provide guidance on minimum pipe insulation thickness?

The ASHRAE tables provide guidance on minimum pipe insulation thickness by listing the required insulation thickness for various pipe sizes, insulation materials, and operating temperatures. These tables are based on extensive research and testing and take into account heat transfer principles and thermal conductivity. The tables are organized by pipe size and operating temperature, making it easy for engineers and contractors to quickly determine the minimum insulation thickness required for specific applications. For example, the ASHRAE tables provide separate listings for hot water pipes, steam pipes, and chilled water pipes, each with its own set of minimum insulation thickness requirements. By consulting the ASHRAE tables, engineers and contractors can ensure that their designs meet ASHRAE standards and local building codes, while also minimizing energy losses and costs. The tables are regularly updated to reflect new research and advances in technology, making them a reliable and trustworthy resource for determining minimum pipe insulation thickness.

Deja una respuesta

Entradas Relacionadas