Minimum Length of Thread Engagement Calculator Per FED-STD-H28/2B

The Minimum Length of Thread Engagement Calculator is a crucial tool in determining the minimum length of thread engagement required for a specific bolt or screw. As per FED-STD-8/2B, a standard for screw thread standards, the calculator helps ensure that the thread engagement is sufficient to withstand the applied loads. This calculator takes into account factors such as thread size, material, and strength to provide an accurate calculation. By using this calculator, engineers and designers can ensure that their designs meet the required safety standards and avoid potential failures due to insufficient thread engagement. Accurate calculations are essential.

- Understanding the Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B

- How do you calculate the minimum thread engagement length?

- What is the minimum number of threads for engagement?

- What is the rule of thumb for thread length?

- What is the ISO standard for thread engagement length?

-

Frequently Asked Questions (FAQs)

- What is the Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B?

- How does the Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B work?

- What are the benefits of using the Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B?

- How accurate is the Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B?

Understanding the Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B

The Minimum Length of Thread Engagement Calculator is a crucial tool in the field of engineering, specifically in the context of threaded fasteners. It is used to determine the minimum length of thread engagement required to ensure the structural integrity of a threaded joint. The calculator is based on the guidelines outlined in FED-STD-8/2B, a standard that provides specifications for threaded fasteners. The calculator takes into account various factors such as the material properties, thread size, and load conditions to calculate the minimum thread engagement length.

Introduction to FED-STD-8/2B

FED-STD-8/2B is a standard that provides specifications for threaded fasteners. It outlines the requirements for the design, manufacture, and testing of threaded fasteners. The standard covers various aspects such as thread forms, materials, and dimensions. It is widely used in the aerospace, automotive, and industrial sectors.

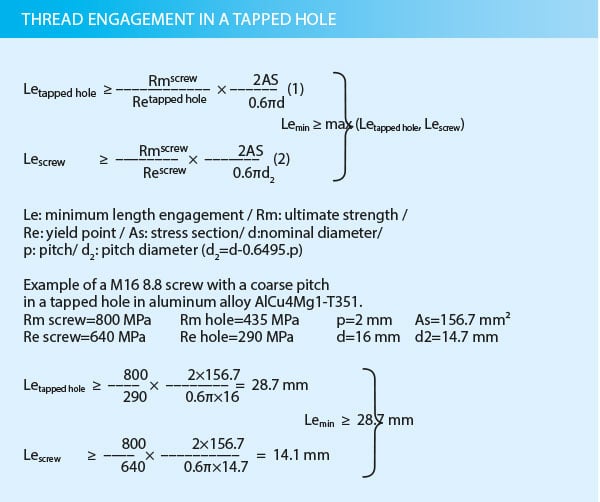

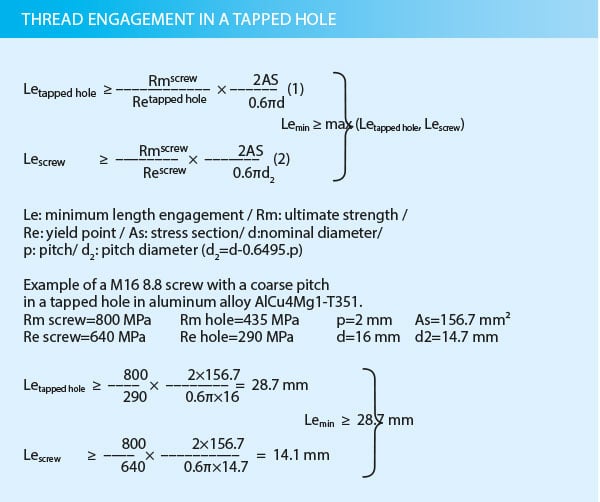

Calculating Minimum Thread Engagement Length

The Minimum Length of Thread Engagement Calculator uses a complex formula to calculate the minimum thread engagement length. The formula takes into account various factors such as the thread size, material properties, and load conditions. The calculator requires input values such as the thread diameter, thread pitch, and material strength. The output value is the minimum thread engagement length required to ensure the structural integrity of the threaded joint.

Factors Affecting Thread Engagement Length

Several factors affect the thread engagement length, including:

| Factor | Description |

|---|---|

| Material Properties | The strength and ductility of the material affect the thread engagement length |

| Thread Size | The diameter and pitch of the thread affect the thread engagement length |

| Load Conditions | The tensile and compressive loads affect the thread engagement length |

Benefits of Using the Calculator

The Minimum Length of Thread Engagement Calculator offers several benefits, including:

Improved accuracy: The calculator ensures that the minimum thread engagement length is calculated accurately, reducing the risk of thread failure.

Increased efficiency: The calculator saves time and effort by automating the calculation process.

Enhanced safety: The calculator helps to ensure the structural integrity of threaded joints, reducing the risk of accidents and injuries.

Common Applications of the Calculator

The Minimum Length of Thread Engagement Calculator is commonly used in various industries, including:

Aerospace: The calculator is used to design and manufacture aircraft components, such as fasteners and bolts.

Automotive: The calculator is used to design and manufacture vehicle components, such as engine blocks and transmissions.

Industrial: The calculator is used to design and manufacture industrial equipment, such as pumps and valves.

How do you calculate the minimum thread engagement length?

To calculate the minimum thread engagement length, you need to consider several factors, including the type of fastener, the material it's made of, and the load it will be subjected to. The thread engagement length is the distance between the thread and the nut or head of the fastener. A longer thread engagement length provides a stronger connection, but it also increases the risk of striping or cross-threading.

Understanding Thread Engagement Length

The thread engagement length is a critical factor in determining the strength and reliability of a threaded connection. To calculate the minimum thread engagement length, you need to consider the following factors:

- Thread size: The larger the thread size, the longer the thread engagement length needs to be.

- Material strength: The material strength of the fastener and the material it's being threaded into will affect the thread engagement length.

- Load requirements: The load that the threaded connection will be subjected to will also impact the thread engagement length.

Calculating Thread Engagement Length

To calculate the minimum thread engagement length, you can use the following formula: thread engagement length = (thread diameter x number of threads x material factor) / (load x safety factor). The material factor and safety factor will depend on the specific application and the desired level of safety.

- Determine the thread diameter: Measure the diameter of the thread to determine the thread size.

- Determine the number of threads: Count the number of threads per inch to determine the thread pitch.

- Determine the material factor: Research the material properties of the fastener and the material it's being threaded into to determine the material factor.

Factors Affecting Thread Engagement Length

Several factors can affect the thread engagement length, including the type of fastener, the material it's made of, and the load it will be subjected to. Other factors that can impact the thread engagement length include the thread pitch, the thread angle, and the surface finish of the threads.

- Thread pitch: A finer thread pitch will require a longer thread engagement length.

- Thread angle: A thread angle that is too steep or too shallow can affect the thread engagement length.

- Surface finish: A rough surface finish can reduce the thread engagement length.

Consequences of Insufficient Thread Engagement Length

If the thread engagement length is insufficient, it can lead to a weak connection that is prone to failure. This can result in equipment damage, injuries, and costly repairs. To avoid these consequences, it's essential to calculate the minimum thread engagement length carefully and ensure that it meets the required standards.

- Equipment damage: A weak connection can cause equipment damage and downtime.

- Injuries: A failed connection can result in injuries to people and damage to surrounding equipment.

- Costly repairs: Insufficient thread engagement length can lead to costly repairs and replacement of equipment.

Best Practices for Thread Engagement Length

To ensure a strong and reliable connection, it's essential to follow best practices for thread engagement length. This includes using a thread engagement length calculator, consulting industry standards, and testing the connection to ensure it meets the required specifications.

- Use a thread engagement length calculator: A calculator can help ensure the thread engagement length is sufficient.

- Consult industry standards: Industry standards can provide guidelines for thread engagement length.

- Test the connection: Testing the connection can ensure it meets the required specifications.

What is the minimum number of threads for engagement?

The minimum number of threads for engagement can vary depending on the context and goals of the online community or discussion forum. However, it is generally agreed that a minimum of 2-3 threads is necessary to create a sense of engagement and discussion. With only one thread, the conversation can become stagnant and lacking in diversity. On the other hand, having too many threads can lead to information overload and make it difficult for users to follow the conversation.

Importance of Thread Quantity for Engagement

The quantity of threads is crucial for engagement as it allows users to choose from a variety of topics and engage with the ones that interest them the most. This can lead to a more dynamic and interactive online community. Some key points to consider when determining the minimum number of threads for engagement include:

- Community size: Larger communities may require more threads to accommodate the diverse interests and opinions of its members.

- Thread relevance: Threads that are relevant and interesting to the community will encourage more engagement and participation.

- Thread frequency: The frequency at which new threads are created can also impact engagement, with a consistent stream of new threads keeping the community active and engaged.

Factors Affecting Minimum Thread Quantity

Several factors can affect the minimum number of threads required for engagement, including the type of online community, the level of user activity, and the purpose of the community. For example, a community focused on support may require fewer threads than a community focused on discussion. Some key factors to consider include:

- Community type: Different types of communities, such as support or discussion-based communities, may require different minimum thread quantities.

- User activity: Communities with high user activity may require more threads to accommodate the volume of posts and comments.

- Community purpose: The purpose of the community, such as education or entertainment, can also impact the minimum thread quantity required for engagement.

Consequences of Insufficient Thread Quantity

Having insufficient threads can lead to a range of negative consequences, including low engagement, high bounce rates, and poor user retention. When there are too few threads, users may become disengaged and lose interest in the community. Some key consequences of insufficient thread quantity include:

- Low engagement: Insufficient threads can lead to low engagement, as users have limited opportunities to participate in discussions.

- High bounce rates: Users may be more likely to leave the community if they find it unengaging or uninteresting.

- Poor user retention: Insufficient threads can also lead to poor user retention, as users may not see the community as a valuable or reliable resource.

Benefits of Optimal Thread Quantity

On the other hand, having an optimal number of threads can lead to a range of benefits, including high engagement, strong user retention, and positive user experience. When there are enough threads, users can engage with the community in a meaningful and interesting way. Some key benefits of optimal thread quantity include:

- High engagement: Optimal thread quantity can lead to high engagement, as users have multiple opportunities to participate in discussions.

- Strong user retention: Users are more likely to return to the community if they find it engaging and interesting.

- Positive user experience: Optimal thread quantity can also lead to a positive user experience, as users feel valued and supported by the community.

Best Practices for Thread Management

To ensure optimal thread quantity, community managers should follow best practices for thread management, including regularly reviewing and updating threads, encouraging user participation, and monitoring user engagement. Some key best practices for thread management include:

- Regular reviews: Community managers should regularly review threads to ensure they are relevant and interesting to the community.

- User participation: Community managers should encourage user participation by creating threads that are inclusive and engaging.

- Engagement monitoring: Community managers should monitor user engagement to identify areas for improvement and optimize thread quantity accordingly.

What is the rule of thumb for thread length?

The rule of thumb for thread length is a guideline that helps determine the optimal length of a thread in various applications, such as engineering, manufacturing, and construction. This guideline is essential to ensure that the thread is strong enough to withstand the stresses and loads it will be subjected to, while also being efficient in terms of material usage and production time.

Determining Thread Length

Determining the optimal thread length involves considering several factors, including the type of material, the diameter of the thread, and the application. A general rule of thumb is to use a thread length that is at least 1.5 to 2 times the diameter of the thread. For example, if the diameter of the thread is 1 inch, the thread length should be at least 1.5 to 2 inches. This can be broken down into:

- Material properties: The type of material used for the thread can affect its strength and durability.

- Thread diameter: The diameter of the thread is a critical factor in determining its strength and stability.

- Application requirements: The intended use of the thread will also influence the required thread length, with high-stress applications requiring longer threads.

Thread Length and Strength

The length of a thread can significantly impact its strength and stability. A thread that is too short may not provide enough grip or hold, leading to failure under stress or load. On the other hand, a thread that is too long can be inefficient in terms of material usage and production time. The optimal thread length will depend on the specific application and requirements, but a general rule of thumb is to use a thread length that provides a strong and stable connection. This can be achieved by:

- Using a thread length that is at least 1.5 to 2 times the diameter of the thread.

- Increasing the thread length for high-stress applications.

- Decreasing the thread length for low-stress applications.

Thread Length and Efficiency

The length of a thread can also impact efficiency in terms of material usage and production time. A thread that is too long can result in wasted material and increased production time, while a thread that is too short may require additional processing or rework. The optimal thread length will depend on the specific application and requirements, but a general rule of thumb is to use a thread length that provides a strong and stable connection while minimizing material waste and production time. This can be achieved by:

- Optimizing thread length for material usage and production time.

- Using standardized thread lengths to reduce variability and error.

- Implementing quality control measures to ensure consistent thread length.

Thread Length and Safety

The length of a thread can also have safety implications, particularly in high-risk applications such as aerospace or medical devices. A thread that is too short may not provide enough grip or hold, leading to failure under stress or load, which can result in accidents or injuries. On the other hand, a thread that is too long can be inefficient in terms of material usage and production time, but may provide a safer connection. The optimal thread length will depend on the specific application and requirements, but a general rule of thumb is to use a thread length that provides a strong and stable connection while ensuring safety and reliability. This can be achieved by:

- Conducting risk assessments to identify potential safety hazards.

- Implementing safety protocols to ensure safe thread length.

- Testing and validating thread length to ensure reliability and safety.

Thread Length and Standardization

The length of a thread can also be influenced by standardization, particularly in industries such as engineering or manufacturing. Standardized thread lengths can help reduce variability and error, while also improving efficiency and productivity. The optimal thread length will depend on the specific application and requirements, but a general rule of thumb is to use a thread length that conforms to industry standards or regulations. This can be achieved by:

- Adhering to industry standards for thread length.

- Implementing quality control measures to ensure consistent thread length.

- Training personnel on standardized thread length procedures.

What is the ISO standard for thread engagement length?

The ISO standard for thread engagement length is defined in the ISO 724 (ISO general-purpose metric screw threads) standard. This standard provides the requirements for the geometry and dimension of metric screw threads. The standard includes the thread engagement length, which is the minimum length of thread engagement required to ensure the safety and reliability of the threaded joint. The thread engagement length is calculated based on the diameter and pitch of the thread, as well as the material and load applied to the joint.

Calculation of Thread Engagement Length

The calculation of thread engagement length involves several parameters, including the diameter and pitch of the thread, as well as the material and load applied to the joint. The formula for calculating thread engagement length is provided in the ISO 724 standard. The calculation takes into account the strength and stiffness of the threaded joint, as well as the safety factor required for the specific application.

- The diameter of the thread is used to calculate the thread engagement length.

- The pitch of the thread is used to calculate the thread engagement length.

- The material and load applied to the joint are used to calculate the thread engagement length.

Importance of Thread Engagement Length

The thread engagement length is critical to ensuring the safety and reliability of the threaded joint. A short thread engagement length can result in a weak joint that is prone to failure, while a long thread engagement length can result in a strong joint that is more reliable. The thread engagement length is also important for ensuring the leak-tightness of the joint, as a short thread engagement length can result in leaks.

- A short thread engagement length can result in a weak joint.

- A long thread engagement length can result in a strong joint.

- The thread engagement length is important for ensuring the leak-tightness of the joint.

Thread Engagement Length for Different Materials

The thread engagement length required for a specific application depends on the material used for the threaded joint. Different materials have different strengths and stiffness, which affects the thread engagement length required. For example, steel has a higher strength and stiffness than aluminum, which means that a shorter thread engagement length may be sufficient for a steel joint.

- Steel has a higher strength and stiffness than aluminum.

- Aluminum requires a longer thread engagement length than steel.

- The thread engagement length required depends on the material used for the joint.

Thread Engagement Length for Different Load Conditions

The thread engagement length required for a specific application also depends on the load applied to the joint. Different load conditions, such as static or dynamic loads, require different thread engagement lengths. For example, a dynamic load requires a longer thread engagement length than a static load.

- A dynamic load requires a longer thread engagement length than a static load.

- A static load requires a shorter thread engagement length than a dynamic load.

- The thread engagement length required depends on the load applied to the joint.

Verification of Thread Engagement Length

The thread engagement length can be verified using various methods, including calculations and experiments. The Verification of thread engagement length is important to ensure that the threaded joint is safe and reliable. The verification process involves checking the thread engagement length against the requirements specified in the ISO 724 standard.

- The thread engagement length can be verified using calculations.

- The thread engagement length can be verified using experiments.

- The verification process involves checking the thread engagement length against the requirements specified in the ISO 724 standard.

Frequently Asked Questions (FAQs)

What is the Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B?

The Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B is a tool used to determine the minimum length of thread engagement required for a particular application. This calculator is based on the standards outlined in the FED-STD-8/2B document, which provides guidelines for the design and specification of threads and thread engagements. The calculator takes into account various factors, such as the material properties, thread size, and load conditions, to determine the minimum length of thread engagement required to ensure safety and reliability. By using this calculator, engineers and designers can ensure that their designs meet the requirements of the FED-STD-8/2B standard, which is crucial for aerospace and defense applications where safety and reliability are of utmost importance.

How does the Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B work?

The Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B works by using a combination of algorithms and formulas to calculate the minimum length of thread engagement required for a particular application. The calculator takes into account various input parameters, such as the thread size, material properties, and load conditions, and uses these parameters to calculate the minimum length of thread engagement required to ensure safety and reliability. The calculator also takes into account various factors, such as the thread type, coating, and surface finish, which can affect the thread engagement. The calculator then uses these inputs to calculate the minimum length of thread engagement required, which is displayed as a result. The calculator is designed to be user-friendly, with a simple and intuitive interface that makes it easy to input parameters and obtain results.

What are the benefits of using the Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B?

The benefits of using the Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B are numerous. One of the main benefits is that it helps to ensure safety and reliability in aerospace and defense applications, where failure can have catastrophic consequences. The calculator also helps to reduce the risk of thread failure, which can be costly and time-consuming to repair. Additionally, the calculator helps to streamline the design process, by providing a quick and accurate way to determine the minimum length of thread engagement required. This can help to save time and reduce costs, which is essential in today's competitive marketplace. Furthermore, the calculator is based on the latest standards and research, which ensures that the results are accurate and reliable.

How accurate is the Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B?

The Minimum Length of Thread Engagement Calculator Per FED-STD-8/2B is highly accurate, as it is based on the latest research and standards in the field of thread engagement. The calculator uses complex algorithms and formulas to calculate the minimum length of thread engagement required, which takes into account various factors that can affect the thread engagement. The calculator is also continuously updated to reflect the latest research and developments in the field, which ensures that the results are accurate and reliable. Additionally, the calculator has been validated through extensive testing and verification, which has shown that it is highly accurate and reliable. However, it is important to note that the accuracy of the calculator depends on the input parameters, and incorrect or incomplete input can result in inaccurate results. Therefore, it is essential to ensure that the input parameters are accurate and complete to obtain reliable results.

Deja una respuesta

Entradas Relacionadas