Mechanics and Machine Design, Equations and Calculators

Mechanics and machine design is a fundamental aspect of engineering that involves the application of mathematical equations and calculators to create and optimize mechanical systems. The field encompasses a broad range of topics, including kinematics, dynamics, and thermodynamics, all of which require a deep understanding of complex mathematical concepts. By utilizing equations and calculators, engineers can design and analyze machines, predict their behavior, and optimize their performance, leading to innovative solutions and increased efficiency in various industries, from robotics to aerospace engineering, and beyond. Equations and calculators are essential tools in this field.

- Mechanics and Machine Design: Understanding the Fundamentals of Equations and Calculators

- Which calculator is best for mechanical engineering?

- What formulas are used in mechanical engineering?

- What are the three types of mechanical design?

- What are the engineering design calculations?

-

Frequently Asked Questions (FAQs)

- What is the importance of Mechanics and Machine Design in engineering applications?

- How do equations and calculators aid in the design and analysis of mechanical systems?

- What are some common applications of Mechanics and Machine Design in industry and everyday life?

- How can engineers use Mechanics and Machine Design to improve the sustainability and efficiency of mechanical systems?

Mechanics and Machine Design: Understanding the Fundamentals of Equations and Calculators

Mechanics and machine design are essential components of engineering that involve the application of mathematical equations and calculators to design, analyze, and optimize mechanical systems. The field of mechanics and machine design encompasses a broad range of topics, including kinematics, dynamics, statics, and materials science. By understanding the fundamental principles of mechanics and machine design, engineers can create innovative solutions to real-world problems.

Introduction to Mechanics and Machine Design

Mechanics and machine design are interdisciplinary fields that combine principles from physics, mathematics, and engineering to design and develop mechanical systems. The field involves the application of mathematical models and computational methods to analyze and optimize the performance of mechanical systems. Engineers use CAD software and finite element analysis to design and simulate the behavior of mechanical systems, including robots, machines, and mechanisms.

Equations and Calculators in Mechanics and Machine Design

Equations and calculators play a crucial role in mechanics and machine design. Engineers use mathematical equations to model the behavior of mechanical systems and predict their performance. Calculators and computer programs are used to solve these equations and analyze the results. Some common equations used in mechanics and machine design include the equations of motion, energy equations, and force equations. These equations are used to calculate kinematic parameters, such as displacement, velocity, and acceleration, as well as dynamic parameters, such as force, torque, and power.

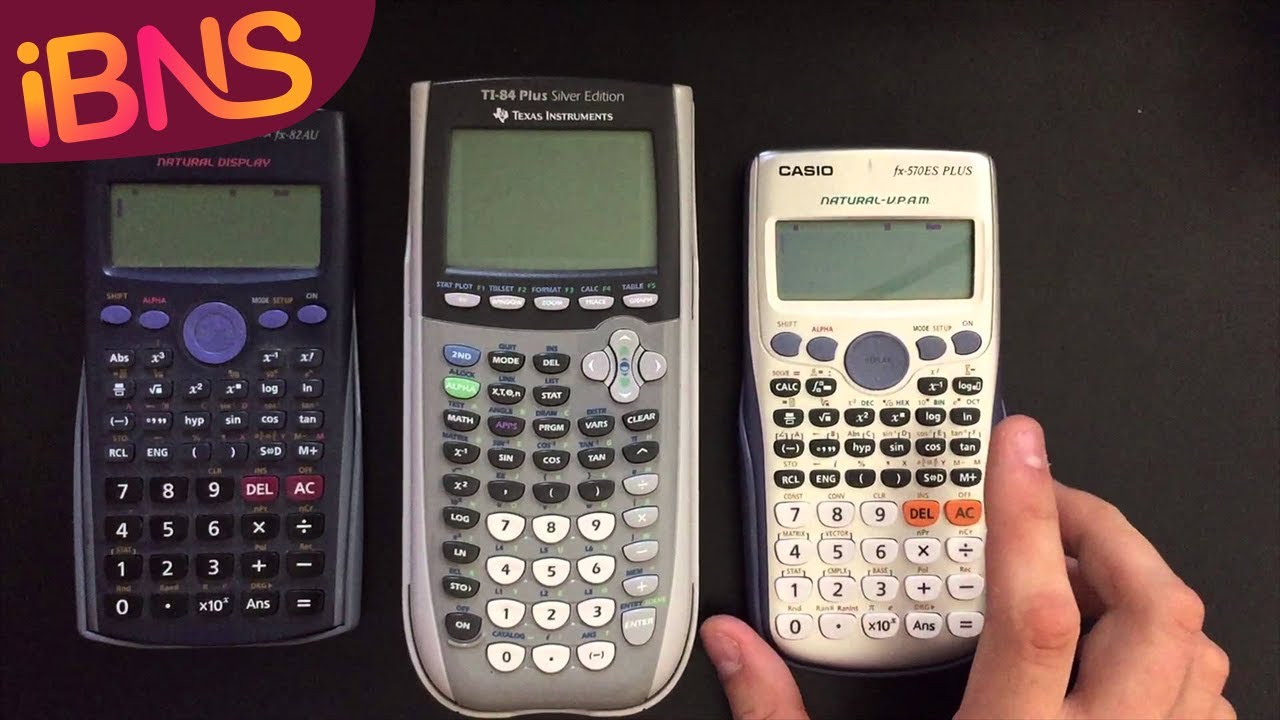

Types of Calculators Used in Mechanics and Machine Design

There are several types of calculators used in mechanics and machine design, including graphing calculators, scientific calculators, and computer-aided design (CAD) software. Graphing calculators are used to visualize and analyze mathematical functions, while scientific calculators are used to perform complex mathematical calculations. CAD software is used to design and simulate the behavior of mechanical systems, including 3D modeling and finite element analysis.

| Calculator Type | Description |

|---|---|

| Graphing Calculator | Used to visualize and analyze mathematical functions |

| Scientific Calculator | Used to perform complex mathematical calculations |

| CAD Software | Used to design and simulate the behavior of mechanical systems |

Applications of Mechanics and Machine Design

Mechanics and machine design have a wide range of applications in various fields, including aerospace engineering, automotive engineering, biomedical engineering, and robotics. Engineers use mechanics and machine design principles to design and develop innovative solutions to real-world problems, such as prosthetic limbs, robotic arms, and self-driving cars. The field of mechanics and machine design is constantly evolving, with new technologies and materials being developed to improve the performance and efficiency of mechanical systems.

Future Developments in Mechanics and Machine Design

The future of mechanics and machine design is exciting, with new technologies and materials being developed to improve the performance and efficiency of mechanical systems. Some of the future developments in mechanics and machine design include the use of artificial intelligence and machine learning to optimize the performance of mechanical systems, as well as the development of new materials and manufacturing techniques to improve the efficiency and sustainability of mechanical systems. The use of 3D printing and additive manufacturing is also becoming increasingly popular in mechanics and machine design, allowing for the creation of complex geometries and structures that cannot be produced using traditional manufacturing methods.

Which calculator is best for mechanical engineering?

When it comes to mechanical engineering, having the right calculator can make a significant difference in terms of efficiency and accuracy. The best calculator for mechanical engineering is one that can handle complex mathematical calculations, including trigonometry, calculus, and linear algebra. Some of the top calculators for mechanical engineering include the Texas Instruments TI-89, the HP 50g, and the Casio Prizm.

Key Features of a Mechanical Engineering Calculator

A mechanical engineering calculator should have certain key features, including computer algebra system (CAS), numerical analysis, and graphing capabilities. These features allow engineers to solve complex mathematical problems, visualize data, and perform simulations. Some of the key features of a mechanical engineering calculator include:

- Equation solver: The ability to solve complex equations, including differential equations and integral equations.

- Graphing: The ability to graph functions, including 2D and 3D graphs.

- Numerical analysis: The ability to perform numerical calculations, including root finding and optimization.

Top Calculators for Mechanical Engineering

Some of the top calculators for mechanical engineering include the Texas Instruments TI-89, the HP 50g, and the Casio Prizm. These calculators offer a range of features, including CAS, graphing, and numerical analysis. They are also programmable, allowing engineers to create custom programs and solve complex problems. Some of the key features of these calculators include:

- Texas Instruments TI-89: Features a CAS and graphing capabilities, making it ideal for mathematical modeling and data analysis.

- HP 50g: Offers numerical analysis and graphing capabilities, making it suitable for engineering applications.

- Casio Prizm: Features a color screen and graphing capabilities, making it ideal for visualizing data and solving complex problems.

Importance of Programming

Programming is an essential skill for mechanical engineers, and a good calculator should have programming capabilities. This allows engineers to create custom programs and solve complex problems. Some of the key benefits of programming include:

- Automation: The ability to automate repetitive tasks and solve complex problems.

- Customization: The ability to create custom programs and solve specific problems.

- Efficiency: The ability to increase efficiency and reduce errors.

Graphing Capabilities

Graphing is an essential feature of a mechanical engineering calculator, allowing engineers to visualize data and solve complex problems. Some of the key benefits of graphing include:

- Data visualization: The ability to visualize data and understand complex relationships.

- Problem solving: The ability to solve complex problems and optimize systems.

- Communication: The ability to communicate complex ideas and data to others.

Future of Mechanical Engineering Calculators

The future of mechanical engineering calculators is likely to involve advanced technologies, including artificial intelligence and machine learning. These technologies will allow calculators to solve complex problems and provide real-time feedback. Some of the key benefits of these technologies include:

- Increased accuracy: The ability to solve complex problems with high accuracy.

- Improved efficiency: The ability to increase efficiency and reduce errors.

- Enhanced user experience: The ability to provide a user-friendly and intuitive interface.

What formulas are used in mechanical engineering?

Mechanical engineering relies heavily on various mathematical formulas to design, develop, and optimize mechanical systems. These formulas are used to calculate stress, strain, force, motion, and energy in mechanical systems. Some of the most commonly used formulas in mechanical engineering include Newton's laws of motion, kinematics, dynamics, thermodynamics, and mechanics of materials. These formulas are used to analyze and design mechanical components, systems, and processes, such as gears, bearings, pumps, and engines.

Formulas for Motion and Kinematics

The study of motion and kinematics is crucial in mechanical engineering, and various formulas are used to describe the motion of objects. Some of the key formulas include:

- Distance = speed x time

- Velocity = distance / time

- Acceleration = change in velocity / time

These formulas are used to calculate the position, velocity, and acceleration of objects in mechanical systems, such as robots, vehicles, and machinery.

Formulas for Forces and Dynamics

The study of forces and dynamics is essential in mechanical engineering, and various formulas are used to describe the forces acting on objects. Some of the key formulas include:

- Force = mass x acceleration

- Torque = force x distance

- Energy = force x distance

These formulas are used to calculate the forces, torques, and energies involved in mechanical systems, such as engines, pumps, and gearboxes.

Formulas for Thermodynamics

The study of thermodynamics is critical in mechanical engineering, and various formulas are used to describe the thermal behavior of systems. Some of the key formulas include:

- Internal energy = kinetic energy + potential energy

- Entropy = heat / temperature

- Efficiency = output energy / input energy

These formulas are used to calculate the thermal efficiency, heat transfer, and energy conversion in mechanical systems, such as heat engines, refrigerators, and air conditioners.

Formulas for Mechanics of Materials

The study of mechanics of materials is essential in mechanical engineering, and various formulas are used to describe the mechanical behavior of materials. Some of the key formulas include:

- Stress = force / area

- Strain = deformation / original length

- Young's modulus = stress / strain

These formulas are used to calculate the stress, strain, and deformation of materials in mechanical systems, such as beams, columns, and shafts.

Formulas for Fluid Mechanics

The study of fluid mechanics is critical in mechanical engineering, and various formulas are used to describe the behavior of fluids. Some of the key formulas include:

- Pressure = force / area

- Velocity = distance / time

- Reynolds number = inertial forces / viscous forces

These formulas are used to calculate the pressure, velocity, and flow rate of fluids in mechanical systems, such as pumps, turbines, and pipes.

What are the three types of mechanical design?

The three types of mechanical design are mechanical systems design, mechanical component design, and mechanical product design. Mechanical systems design involves the design of complex systems, including pumps, turbines, and gearboxes. Mechanical component design involves the design of individual components, such as shafts, bearings, and gears. Mechanical product design involves the design of complete products, including machines, devices, and systems.

Types of Mechanical Design

The main types of mechanical design are based on the level of complexity and the scope of the project. The three types of mechanical design are:

- System design: involves the design of complex systems, including multiple components and subsystems.

- Component design: involves the design of individual components, including materials, manufacturing processes, and testing.

- Product design: involves the design of complete products, including user experience, safety, and regulatory compliance.

Importance of Mechanical Design

Mechanical design is a critical aspect of product development, as it involves the creation of prototypes, testing, and validation. The goal of mechanical design is to create a functional, safe, and efficient product that meets the requirements and specifications of the customer. A good mechanical design can reduce costs, improve performance, and increase customer satisfaction.

- Cost savings: a well-designed product can reduce production costs and maintenance costs.

- Improved performance: a good mechanical design can improve the efficiency, reliability, and performance of a product.

- Increased customer satisfaction: a product that meets the needs and expectations of the customer can increase customer satisfaction and loyalty.

Tools and Techniques of Mechanical Design

Mechanical designers use a variety of tools and techniques to create and analyze designs. These include computer-aided design (CAD) software, finite element analysis (FEA), and computational fluid dynamics (CFD). Mechanical designers also use prototyping and testing to validate their designs and make improvements.

- CAD software: allows designers to create 2D and 3D models of their designs.

- FEA: allows designers to analyze the stress and strain on a product under different loads and conditions.

- CFD: allows designers to analyze the flow of fluids and gases in a product.

Applications of Mechanical Design

Mechanical design has a wide range of applications in various industries, including aerospace, automotive, energy, and manufacturing. Mechanical designers work on the design of machines, devices, and systems that are used in daily life.

- Aerospace industry: mechanical designers work on the design of aircraft, spacecraft, and missiles.

- Automotive industry: mechanical designers work on the design of cars, trucks, and buses.

- Energy industry: mechanical designers work on the design of power plants, wind turbines, and solar panels.

Future of Mechanical Design

The future of mechanical design is likely to be shaped by advances in technology, including artificial intelligence (AI), machine learning (ML), and internet of things (IoT). Mechanical designers will need to adapt to these changes and develop new skills to remain competitive.

- AI and ML: will allow designers to create more complex and optimized designs.

- IoT: will allow designers to create connected and intelligent products.

- 3D printing: will allow designers to create complex and customized products quickly and efficiently.

What are the engineering design calculations?

The engineering design calculations are a crucial part of the design process in various fields of engineering, including mechanical, electrical, and civil engineering. These calculations involve the application of mathematical models and algorithms to predict the behavior of a system or component under various conditions. The goal of these calculations is to ensure that the design meets the required performance, safety, and efficiency standards.

Introduction to Engineering Design Calculations

The engineering design calculations are used to determine the dimensions, shape, and material properties of a component or system. These calculations take into account various parameters such as load, stress, strain, and temperature. The calculations are typically performed using computer-aided design (CAD) software and finite element analysis (FEA) tools. Some of the key calculations involved in engineering design include:

- Static analysis: calculation of stresses and strains in a component under static loads

- Dynamic analysis: calculation of vibrations and dynamics of a system under time-varying loads

- Thermal analysis: calculation of heat transfer and temperature distribution in a component or system

Types of Engineering Design Calculations

There are several types of engineering design calculations, including static, dynamic, thermal, and fluid flow calculations. Each type of calculation requires the use of specific equations and models to predict the behavior of the system or component. For example, static calculations involve the use of equilibrium equations to determine the stresses and strains in a component under static loads. Some of the key types of calculations include:

- Structural analysis: calculation of stresses and strains in a structure under external loads

- Mechanical analysis: calculation of forces, torques, and energies in a mechanical system

- Electrical analysis: calculation of voltages, currents, and powers in an electrical circuit

Importance of Engineering Design Calculations

The engineering design calculations are critical to ensuring the safety, performance, and efficiency of a component or system. These calculations help to identify potential failures and optimize the design to minimize risks and costs. The calculations also help to ensure that the design meets the required regulatory and industry standards. Some of the key benefits of engineering design calculations include:

- Improved safety: reduction of risks and hazards associated with a component or system

- Increased efficiency: optimization of performance and energy consumption

- Cost savings: reduction of costs associated with rework, maintenance, and repair

Tools and Software for Engineering Design Calculations

There are several tools and software available for performing engineering design calculations, including CAD software, FEA tools, and computer-aided engineering (CAE) software. These tools help to simplify and automate the calculation process, reducing the time and effort required to perform the calculations. Some of the key tools and software include:

- Autodesk Inventor: a CAD software for designing and simulating mechanical systems

- ANSYS: a FEA tool for simulating static and dynamic behavior of components and systems

- Matlab: a CAE software for simulating and analyzing mathematical models

Applications of Engineering Design Calculations

The engineering design calculations have a wide range of applications in various fields of engineering, including aerospace, automotive, energy, and construction. These calculations are used to design and optimize components and systems, such as aircraft, vehicles, power plants, and buildings. Some of the key applications include:

- Aerospace engineering: design and optimization of aircraft and spacecraft components and systems

- Automotive engineering: design and optimization of vehicle components and systems, such as engines and transmissions

- Energy engineering: design and optimization of power plants and energy systems, such as solar and wind power systems

Frequently Asked Questions (FAQs)

What is the importance of Mechanics and Machine Design in engineering applications?

The field of Mechanics and Machine Design plays a crucial role in engineering applications, as it enables the development of efficient and reliable machines and mechanisms. This field involves the application of mathematical models and physical principles to analyze and design mechanical systems, such as gears, bearings, and motors. By understanding the fundamentals of mechanics, engineers can create innovative solutions to real-world problems, improving the performance and safety of machines and systems. Furthermore, the use of equations and calculators in mechanics and machine design allows engineers to simulate and optimize their designs, reducing the need for physical prototypes and experimental testing.

How do equations and calculators aid in the design and analysis of mechanical systems?

Equations and calculators are essential tools in the design and analysis of mechanical systems, as they enable engineers to model and simulate the behavior of complex systems. By using mathematical equations and numerical methods, engineers can predict the performance and efficiency of their designs, identifying potential problems and areas for improvement. Additionally, calculators and computer-aided design (CAD) software allow engineers to visualize and analyze their designs in a virtual environment, reducing the need for physical prototypes and experimental testing. This enables engineers to iterate and refine their designs more quickly and efficiently, resulting in better performance, increased safety, and reduced costs.

What are some common applications of Mechanics and Machine Design in industry and everyday life?

Mechanics and Machine Design has a wide range of applications in industry and everyday life, from the design of consumer products and machinery to the development of aerospace and automotive systems. For example, mechanical engineers use mechanics and machine design principles to develop efficient and reliable systems for power generation, transportation, and manufacturing. Additionally, mechanics and machine design is used in the development of medical devices, robotics, and other technologies that improve human health and quality of life. In everyday life, mechanics and machine design is evident in the design and functionality of household appliances, tools, and equipment, highlighting the importance and relevance of this field to modern society.

How can engineers use Mechanics and Machine Design to improve the sustainability and efficiency of mechanical systems?

Engineers can use Mechanics and Machine Design to improve the sustainability and efficiency of mechanical systems by applying principles of energy conservation and environmental sustainability to their designs. For example, mechanical engineers can use mechanics and machine design to develop energy-efficient systems and machines that minimize energy consumption and waste generation. Additionally, mechanics and machine design can be used to develop sustainable materials and manufacturing processes that reduce the environmental impact of mechanical systems. By using equations and calculators to model and simulate the behavior of mechanical systems, engineers can optimize their designs for maximum efficiency and minimum environmental impact, resulting in more sustainable and environmentally friendly solutions.

Deja una respuesta

Entradas Relacionadas