Flat Circular Head Welded with Internal or External Pressure Equation and Calculator

The flat circular head welded with internal or external pressure is a crucial component in various engineering applications, including pressure vessels, tanks, and pipes. The calculation of stress and deformation in these components is essential to ensure their safety and reliability. This article provides an overview of the equation and calculator for flat circular heads welded with internal or external pressure, enabling engineers to accurately determine the required thickness and design parameters to withstand various operating conditions and loads. The equation and calculator are based on established engineering principles.

-

Flat Circular Head Welded with Internal or External Pressure Equation and Calculator

- Introduction to Flat Circular Head Welded with Internal or External Pressure

- Calculation of Flat Circular Head Welded with Internal or External Pressure

- Material Properties for Flat Circular Head Welded with Internal or External Pressure

- Applications of Flat Circular Head Welded with Internal or External Pressure

- Design and Fabrication of Flat Circular Head Welded with Internal or External Pressure

- What is the formula for the internal pressure of a pressure vessel?

- What is the formula for the internal pressure of a cylinder?

- How to calculate pressure vessels?

- What is the minimum wall thickness for a pressure vessel?

-

Frequently Asked Questions (FAQs)

- What is the significance of the Flat Circular Head Welded with Internal or External Pressure Equation and Calculator in engineering applications?

- How does the Flat Circular Head Welded with Internal or External Pressure Equation and Calculator account for different types of pressure and loading conditions?

- What are the key assumptions and limitations of the Flat Circular Head Welded with Internal or External Pressure Equation and Calculator?

- How can the Flat Circular Head Welded with Internal or External Pressure Equation and Calculator be used in conjunction with other engineering tools and software to optimize the design of pressure vessels and storage tanks?

Flat Circular Head Welded with Internal or External Pressure Equation and Calculator

The Flat Circular Head Welded is a type of vessel head that is commonly used in pressure vessels, such as tanks and pipes. The internal or external pressure equation is used to calculate the stress and thickness of the head, and it is an important consideration in the design and fabrication of these vessels. The calculator is a tool that is used to simplify the calculation process and ensure that the head is designed and fabricated to withstand the expected pressures and stresses.

Introduction to Flat Circular Head Welded with Internal or External Pressure

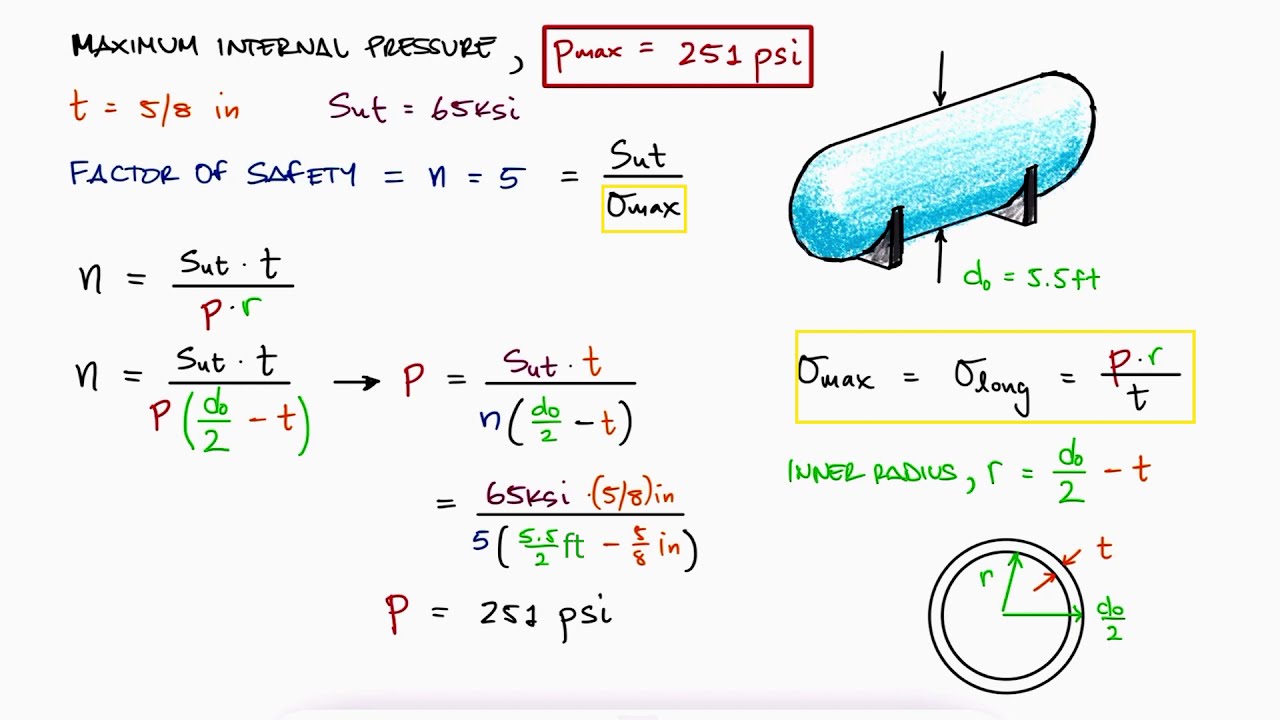

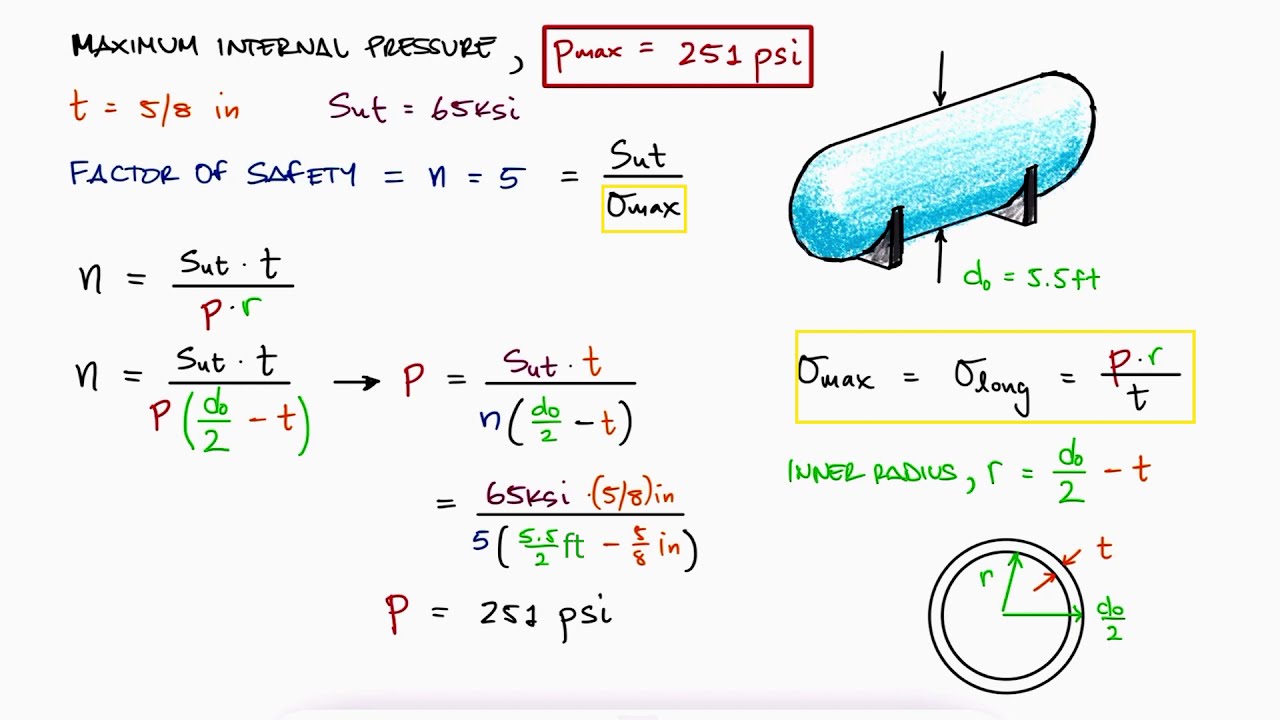

The Flat Circular Head Welded is a type of vessel head that is made by welding a flat circular plate to the end of a cylindrical vessel. The internal or external pressure equation is used to calculate the stress and thickness of the head, and it takes into account the pressure, radius, and thickness of the head. The equation is as follows: σ = (P r) / (2 t), where σ is the stress, P is the pressure, r is the radius, and t is the thickness.

Calculation of Flat Circular Head Welded with Internal or External Pressure

The calculation of the Flat Circular Head Welded with internal or external pressure involves using the equation σ = (P r) / (2 t) to determine the stress and thickness of the head. The calculator is a tool that is used to simplify the calculation process and ensure that the head is designed and fabricated to withstand the expected pressures and stresses. The calculation also takes into account the material properties, such as the yield strength and ultimate strength, to determine the factor of safety.

Material Properties for Flat Circular Head Welded with Internal or External Pressure

The material properties of the Flat Circular Head Welded are an important consideration in the design and fabrication of the vessel. The yield strength and ultimate strength of the material are used to determine the factor of safety, which is the ratio of the ultimate strength to the allowable stress. The material properties also include the elastic modulus, poisson's ratio, and density, which are used to calculate the stress and strain of the head.

Applications of Flat Circular Head Welded with Internal or External Pressure

The Flat Circular Head Welded with internal or external pressure is commonly used in a variety of applications, including pressure vessels, tanks, and pipes. The calculator is used to simplify the calculation process and ensure that the head is designed and fabricated to withstand the expected pressures and stresses. The applications also include chemical processing, power generation, and oil and gas industries.

Design and Fabrication of Flat Circular Head Welded with Internal or External Pressure

The design and fabrication of the Flat Circular Head Welded with internal or external pressure involves several steps, including design calculation, material selection, and fabrication. The design calculation involves using the equation σ = (P r) / (2 t) to determine the stress and thickness of the head. The material selection involves selecting a material that has the required material properties, such as yield strength and ultimate strength. The fabrication involves welding the flat circular plate to the end of the cylindrical vessel.

| Property | Value |

|---|---|

| Pressure | 1000 psi |

| Radius | 10 inches |

| Thickness | 0.5 inches |

| Yield Strength | 36000 psi |

| Ultimate Strength | 58000 psi |

What is the formula for the internal pressure of a pressure vessel?

The formula for the internal pressure of a pressure vessel is given by the Lame's equation, which is a mathematical expression that relates the internal pressure of a vessel to its dimensions, material properties, and other factors. The formula is: P = (2 σ t) / r, where P is the internal pressure, σ is the hoop stress of the material, t is the wall thickness of the vessel, and r is the radius of the vessel.

Introduction to Pressure Vessel Design

The design of pressure vessels involves calculating the internal pressure and ensuring that the vessel can withstand it. This requires a thorough understanding of the material properties, dimensional tolerances, and safety factors. The formula for internal pressure is used to determine the minimum wall thickness required to prevent failure of the vessel. Key considerations include:

- Material selection: choosing a material that can withstand the internal pressure and other environmental factors

- Dimensional analysis: calculating the dimensions of the vessel to ensure that it can withstand the internal pressure

- Safety factor: applying a safety factor to the design to account for uncertainties and variability

Calculating Hoop Stress

The hoop stress is a critical factor in determining the internal pressure of a pressure vessel. It is calculated using the formula: σ = P r / (2 t), where σ is the hoop stress, P is the internal pressure, r is the radius of the vessel, and t is the wall thickness. The hoop stress is a measure of the circumferential stress in the vessel, and it is used to determine the burst pressure of the vessel. Key considerations include:

- Material properties: understanding the strength and ductility of the material

- Dimensional tolerances: ensuring that the dimensions of the vessel are accurate and consistent

- Internal pressure: calculating the internal pressure and its effects on the vessel

Factors Affecting Internal Pressure

There are several factors that can affect the internal pressure of a pressure vessel, including temperature, corrosion, and mechanical loads. Changes in temperature can cause the material to expand or contract, which can affect the internal pressure. Corrosion can weaken the material and reduce its ability to withstand internal pressure. Mechanical loads, such as external pressure or impact, can also affect the internal pressure of the vessel. Key considerations include:

- Temperature effects: understanding how temperature changes affect the material and the vessel

- Corrosion protection: applying coatings or other measures to prevent corrosion

- Mechanical loading: calculating the effects of external loads on the vessel

Designing for Safety

Designing a pressure vessel requires a thorough understanding of the safety factors and failure modes. The designer must consider the worst-case scenario and ensure that the vessel can withstand it. This includes applying a safety factor to the design to account for uncertainties and variability. The safety factor is used to reduce the risk of failure and ensure that the vessel is reliable and maintainable. Key considerations include:

- Safety factor: applying a safety factor to the design to account for uncertainties

- Failure modes: understanding the potential failure modes and designing to prevent them

- Reliability: ensuring that the vessel is reliable and maintainable

Applications of Pressure Vessel Design

Pressure vessel design has a wide range of applications, including industrial processes, power generation, and aerospace engineering. The design of pressure vessels requires a thorough understanding of the material properties, dimensional tolerances, and safety factors. The formula for internal pressure is used to determine the minimum wall thickness required to prevent failure of the vessel. Key considerations include:

- Industrial processes: designing vessels for industrial processes such as chemical processing and oil refining

- Power generation: designing vessels for power generation applications such as nuclear power and fossil fuels

- Aerospace engineering: designing vessels for aerospace applications such as rocket propulsion and spacecraft

What is the formula for the internal pressure of a cylinder?

The formula for the internal pressure of a cylinder is given by the equation P = (2 σ t) / r, where P is the internal pressure, σ is the stress in the material, t is the thickness of the cylinder wall, and r is the radius of the cylinder.

Understanding the Variables

The variables in the equation are crucial to understanding the internal pressure of a cylinder. The stress in the material is a measure of the force per unit area that the material can withstand. The thickness of the cylinder wall is important because it affects the strength of the cylinder. The radius of the cylinder is also critical because it determines the volume of the cylinder.

- The stress in the material is a key factor in determining the internal pressure of a cylinder.

- The thickness of the cylinder wall must be sufficient to withstand the pressure inside the cylinder.

- The radius of the cylinder is important because it affects the surface area of the cylinder.

Applications of the Formula

The formula for the internal pressure of a cylinder has many practical applications in engineering and design. It is used to calculate the pressure inside pipes, tanks, and other cylindrical vessels. The formula is also used to determine the strength of materials and the safety of structures.

- The formula is used to calculate the pressure inside pipes and tanks.

- The formula is used to determine the strength of materials and the safety of structures.

- The formula is used to design cylindrical vessels that can withstand high pressures.

Limitations of the Formula

The formula for the internal pressure of a cylinder has some limitations. It assumes that the material is homogeneous and isotropic, and that the stress is uniform. It also assumes that the cylinder is closed at both ends and that the pressure is constant.

- The formula assumes that the material is homogeneous and isotropic.

- The formula assumes that the stress is uniform and constant.

- The formula assumes that the cylinder is closed at both ends.

Derivation of the Formula

The formula for the internal pressure of a cylinder can be derived using the principles of mechanics. It is based on the equilibrium of forces and the cons!ervation of energy. The formula can be derived by considering the forces acting on a small element of the cylinder wall.

- The formula can be derived using the principles of mechanics.

- The formula is based on the equilibrium of forces and the conservation of energy.

- The formula can be derived by considering the forces acting on a small element of the cylinder wall.

Real-World Examples

The formula for the internal pressure of a cylinder has many real-world applications. It is used to design pipes and tanks that can withstand high pressures. It is also used to determine the strength of materials and the safety of structures.

- The formula is used to design pipes and tanks that can withstand high pressures.

- The formula is used to determine the strength of materials and the safety of structures.

- The formula is used to calculate the pressure inside cylindrical vessels.

How to calculate pressure vessels?

To calculate pressure vessels, it is essential to consider the design and operating conditions of the vessel. The calculation involves determining the stress and strain on the vessel due to internal pressure, temperature, and other external loads. This requires a thorough understanding of the material properties and the geometry of the vessel. The calculation also involves selecting the correct codes and standards that govern the design and construction of pressure vessels.

Understanding Pressure Vessel Design

The design of a pressure vessel is critical to its safe operation. To calculate pressure vessels, one must consider the type of vessel, its size, and shape, as well as the material used for its construction. The design must also take into account the operating conditions, including pressure, temperature, and corrosion. Some key considerations in pressure vessel design include:

- Materials selection: Choosing the right material for the vessel, considering factors such as strength, ductility, and corrosion resistance.

- Geometry and dimensions: Determining the optimal size and shape of the vessel to minimize stress and strain.

- Safety factors: Applying safety factors to account for uncertainty and variability in the design and operating conditions.

Calculating Pressure Vessel Stress

Calculating the stress on a pressure vessel is a critical step in ensuring its safe operation. The stress calculation involves determining the hoop stress, longitudinal stress, and radial stress due to internal pressure. The calculation also involves considering external loads, such as weight and wind, and thermal stresses due to temperature changes. Some key considerations in calculating pressure vessel stress include:

- Hoop stress calculation: Determining the hoop stress using the Lame equation or finite element analysis.

- Longitudinal stress calculation: Determining the longitudinal stress using the Barlow equation or finite element analysis.

- Thermal stress calculation: Determining the thermal stress using thermal analysis or finite element analysis.

Applying Pressure Vessel Codes and Standards

Pressure vessels are designed and constructed to comply with codes and standards that govern their safe operation. These codes and standards provide guidelines for design, fabrication, inspection, and testing of pressure vessels. Some key considerations in applying pressure vessel codes and standards include:

- ASME Boiler and Pressure Vessel Code: Following the ASME code for the design, fabrication, and inspection of pressure vessels.

- API Standards: Following API standards for the design, fabrication, and inspection of pressure vessels in the oil and gas industry.

- European Standard EN 13445: Following the European Standard for the design, fabrication, and inspection of pressure vessels.

Using Finite Element Analysis for Pressure Vessel Design

Finite element analysis (FEA) is a powerful tool used to analyze the behavior of pressure vessels under various loads and conditions. FEA involves dividing the vessel into small elements and analyzing the stress and strain on each element. Some key considerations in using FEA for pressure vessel design include:

- Mesh generation: Creating a mesh that accurately represents the geometry of the vessel.

- Material modeling: Selecting the correct material model to accurately represent the behavior of the vessel material.

- Boundary conditions: Applying boundary conditions that accurately represent the operating conditions of the vessel.

Performing Pressure Vessel Safety Inspections

Regular safety inspections are essential to ensure the safe operation of pressure vessels. These inspections involve visual examination, non-destructive testing, and pressure testing to identify any defects or damage. Some key considerations in performing pressure vessel safety inspections include:

- Visual examination: Conducting a visual examination to identify any visible defects or damage.

- Non-destructive testing: Using non-destructive testing techniques, such as ultrasonic testing or radiography, to detect any hidden defects.

- Pressure testing: Performing a pressure test to ensure the vessel can withstand the design pressure.

What is the minimum wall thickness for a pressure vessel?

The minimum wall thickness for a pressure vessel is determined by the design codes and standards that govern the construction of these vessels. The most commonly used codes are the ASME Boiler and Pressure Vessel Code (BPVC) and the API 650 standard. These codes provide formulas and guidelines for calculating the minimum wall thickness based on the design pressure, temperature, and material properties of the vessel.

Design Considerations for Pressure Vessels

The design of a pressure vessel involves several key factors, including the type of fluid being stored, the operating conditions, and the material of construction. The minimum wall thickness is calculated to ensure that the vessel can withstand the internal pressure and external loads without failing. The following are some of the design considerations:

- The design pressure and temperature of the vessel

- The type of fluid being stored and its properties

- The material of construction and its mechanical properties

Calculation of Minimum Wall Thickness

The calculation of the minimum wall thickness involves using formulas and equations that take into account the design pressure, temperature, and material properties. The ASME BPVC provides a formula for calculating the minimum wall thickness, which is based on the Lame equation. The calculation also involves safety factors to account for uncertainties and variations in the design and construction of the vessel. The following are some of the steps involved:

- Determine the design pressure and temperature of the vessel

- Calculate the hoop stress and longitudinal stress using the Lame equation

- Apply safety factors to account for uncertainties and variations

Materials for Pressure Vessels

The material of construction is a critical factor in determining the minimum wall thickness of a pressure vessel. Steels are the most commonly used materials for pressure vessels due to their high strength, toughness, and resistance to corrosion. Other materials, such as aluminum and titanium, may also be used for specific applications. The following are some of the key properties of materials used for pressure vessels:

- Yield strength and tensile strength

- Fracture toughness and resistance to corrosion

- Thermal conductivity and thermal expansion

Inspection and Testing of Pressure Vessels

The inspection and testing of pressure vessels are critical to ensuring their safety and reliability. The ASME BPVC provides guidelines for the inspection and testing of pressure vessels, including non-destructive testing and hydrostatic testing. The following are some of the types of tests:

- Hydrostatic testing to verify the integrity of the vessel

- Non-destructive testing to detect defects and flaws

- Leak testing to verify the tightness of the vessel

Regulations and Standards for Pressure Vessels

The regulations and standards for pressure vessels vary by country and industry. The ASME BPVC and API 650 are widely used standards for the design, construction, and operation of pressure vessels. The following are some of the key regulations and standards:

- ASME BPVC for boilers and pressure vessels

- API 650 for welded steel tanks

- OSHA regulations for workplace safety

Frequently Asked Questions (FAQs)

What is the significance of the Flat Circular Head Welded with Internal or External Pressure Equation and Calculator in engineering applications?

The Flat Circular Head Welded with Internal or External Pressure Equation and Calculator is a crucial tool in engineering, particularly in the design and analysis of pressure vessels and storage tanks. This equation and calculator help engineers determine the stress and strain on the welded joint of a flat circular head, which is a critical component in many engineering applications. By using this equation and calculator, engineers can ensure that the welded joint can withstand the internal or external pressure applied to it, thereby preventing failure or rupture. The calculator takes into account various parameters, such as the thickness of the head, the radius of the head, the internal or external pressure, and the yield strength of the material, to calculate the required thickness of the head and the stress on the welded joint. This information is essential for ensuring the safety and reliability of the pressure vessel or storage tank.

How does the Flat Circular Head Welded with Internal or External Pressure Equation and Calculator account for different types of pressure and loading conditions?

The Flat Circular Head Welded with Internal or External Pressure Equation and Calculator is designed to account for different types of pressure and loading conditions, including internal pressure, external pressure, and combined loading. The equation and calculator use various formulas and correlations to determine the stress and strain on the welded joint under different loading conditions. For example, when calculating the stress on the welded joint due to internal pressure, the equation and calculator take into account the pressure, radius of the head, and thickness of the head. In contrast, when calculating the stress on the welded joint due to external pressure, the equation and calculator consider the pressure, radius of the head, and thickness of the head, as well as the elastic modulus and Poisson's ratio of the material. By accounting for different types of pressure and loading conditions, the equation and calculator provide a comprehensive and accurate analysis of the welded joint.

What are the key assumptions and limitations of the Flat Circular Head Welded with Internal or External Pressure Equation and Calculator?

The Flat Circular Head Welded with Internal or External Pressure Equation and Calculator is based on several key assumptions and limitations, which must be understood and considered when using the equation and calculator. One of the primary assumptions is that the welded joint is axisymmetric, meaning that the stress and strain are uniform around the circumference of the head. Additionally, the equation and calculator assume that the material is homogeneous and isotropic, and that the yield strength and ultimate strength of the material are known. The calculator also limits the input values for the parameters, such as the thickness and radius of the head, to ensure that the calculations are valid and accurate. Furthermore, the equation and calculator do not account for dynamic loading or cyclic loading, which can affect the fatigue life of the welded joint. By understanding these assumptions and limitations, engineers can ensure that the equation and calculator are used correctly and effectively.

How can the Flat Circular Head Welded with Internal or External Pressure Equation and Calculator be used in conjunction with other engineering tools and software to optimize the design of pressure vessels and storage tanks?

The Flat Circular Head Welded with Internal or External Pressure Equation and Calculator can be used in conjunction with other engineering tools and software to optimize the design of pressure vessels and storage tanks. For example, the equation and calculator can be used in conjunction with finite element analysis (FEA) software to simulate the behavior of the welded joint under different loading conditions. Additionally, the equation and calculator can be used with computer-aided design (CAD) software to model and analyze the design of the pressure vessel or storage tank. The equation and calculator can also be used in conjunction with optimization algorithms to minimize the weight and cost of the pressure vessel or storage tank while ensuring that it meets the required safety and reliability standards. By using the equation and calculator in conjunction with other engineering tools and software, engineers can optimize the design of pressure vessels and storage tanks, and ensure that they are safe, reliable, and efficient.

Deja una respuesta

Entradas Relacionadas