Bolt Torque and Clamping Force Formulas and Calculator per. JIS B 1083

Bolt torque and clamping force are crucial factors in ensuring the safety and reliability of bolted joints. The Japanese Industrial Standard JIS B 1083 provides guidelines for calculating these values. This article presents the formulas and a calculator for determining bolt torque and clamping force according to JIS B 1083. Understanding these calculations is essential for engineers and technicians to design and maintain reliable bolted connections. The provided formulas and calculator will help users to accurately calculate the required torque and clamping force for their specific applications, ensuring optimal performance and safety. Reliable calculations are therefore essential.

- Bolt Torque and Clamping Force Formulas and Calculator per JIS B 1083

- What is the formula for bolt torque to clamping force?

- How do you calculate clamping force?

- How do you calculate the force of a bolt based on torque?

- What is the clamp load of a bolt?

-

Frequently Asked Questions (FAQs)

- What is the significance of JIS B 1083 in relation to Bolt Torque and Clamping Force calculations?

- How do I calculate the clamping force of a bolt using the formulas provided in JIS B 1083?

- What are the key factors that affect the bolt torque and clamping force calculations according to JIS B 1083?

- Can I use online calculators or software tools to simplify the bolt torque and clamping force calculations according to JIS B 1083?

Bolt Torque and Clamping Force Formulas and Calculator per JIS B 1083

The JIS B 1083 standard provides a set of formulas and guidelines for calculating bolt Clamping Forces and torque values for bolts and nuts. These calculations are crucial in ensuring the proper assembly and safety of various mechanical systems, including engines, gearboxes, and other machinery. The standard takes into account the bolt diameter, thread pitch, friction coefficient, and other factors to determine the required torque and clamping force.

Introduction to Bolt Torque and Clamping Force Calculations

Bolt torque and clamping force calculations are essential in determining the tightening torque required to achieve a specific clamping force on a bolted joint. The calculations involve various parameters, including the bolt material, thread type, and friction conditions. The JIS B 1083 standard provides a comprehensive set of formulas and guidelines for these calculations, ensuring that engineers and technicians can accurately determine the required torque and clamping force for their specific applications.

Understanding the JIS B 1083 Formulas and Calculator

The JIS B 1083 formulas and calculator are designed to simplify the process of calculating bolt Clamping Forces and torque values. The standard provides a set of equations that take into account the bolt diameter, thread pitch, friction coefficient, and other factors to determine the required torque and clamping force. The calculator is a useful tool that allows users to input the relevant parameters and obtain the calculated torque and clamping force values.

Factors Affecting Bolt Torque and Clamping Force Calculations

Several factors can affect the accuracy of bolt torque and clamping force calculations, including the bolt material, thread type, friction conditions, and surface roughness. The JIS B 1083 standard takes these factors into account, providing a set of formulas and guidelines that ensure accurate calculations. Additionally, the standard provides a set of friction coefficients and surface roughness values that can be used in the calculations.

Applications of Bolt Torque and Clamping Force Calculations

Bolt torque and clamping force calculations have a wide range of applications, including engine assembly, gearbox design, and machine construction. The calculations are essential in ensuring the proper assembly and safety of these systems, as well as preventing bolt fatigue and joint failure. The JIS B 1083 standard provides a comprehensive set of formulas and guidelines that can be used in various industries, including automotive, aerospace, and industrial machinery.

Example Calculations and Results

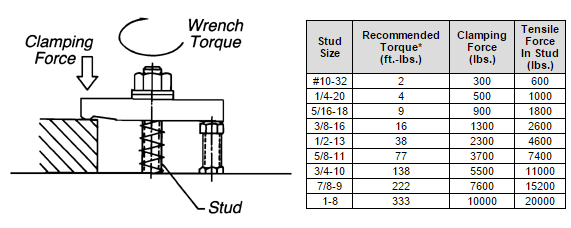

The following table provides an example of bolt torque and clamping force calculations using the JIS B 1083 formulas and calculator:

| Bolt Diameter | Thread Pitch | Friction Coefficient | Calculated Torque | Calculated Clamping Force |

|---|---|---|---|---|

| 10 mm | 1.5 mm | 0.1 | 50 Nm | 2000 N |

| 12 mm | 1.75 mm | 0.12 | 70 Nm | 3000 N |

The results show that the calculated torque and clamping force values vary depending on the bolt diameter, thread pitch, and friction coefficient. The JIS B 1083 standard provides a comprehensive set of formulas and guidelines that can be used to perform these calculations and ensure accurate results.

What is the formula for bolt torque to clamping force?

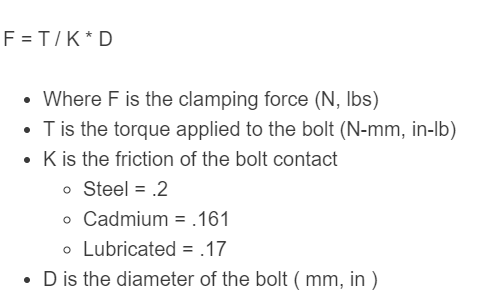

The formula for bolt torque to clamping force is a critical concept in mechanical engineering and is used to determine the amount of torque required to achieve a specific clamping force. The formula is: Clamping Force (F) = (Torque (T) x coefficient of friction (μ)) / (Thread Pitch (p) x bolt diameter (d)). This formula is essential in ensuring that the bolts and fasteners are properly tightened to achieve the desired clamping force without over- or under-tightening.

Understanding the Variables

The variables involved in the formula are crucial in determining the accuracy of the calculation. The torque applied to the bolt, the coefficient of friction between the bolt and the material, the thread pitch, and the bolt diameter all play a significant role in determining the clamping force. To calculate the clamping force, the following steps can be taken:

- Determine the torque required to achieve the desired clamping force

- Calculate the coefficient of friction between the bolt and the material

- Measure the thread pitch and bolt diameter

The accuracy of these variables is essential in ensuring that the calculated clamping force is accurate.

Importance of Coefficient of Friction

The coefficient of friction is a critical variable in the formula, as it affects the amount of torque required to achieve a specific clamping force. A higher coefficient of friction means that more torque is required to achieve the same clamping force. The coefficient of friction can vary depending on the surface finish, material, and lubrication. To ensure accuracy, the coefficient of friction should be carefully measured or estimated. The following factors can affect the coefficient of friction:

- Surface roughness of the bolt and material

- Lubrication between the bolt and material

- Material properties of the bolt and material

These factors can significantly impact the coefficient of friction and, subsequently, the clamping force.

Calculating Thread Pitch and Bolt Diameter

The thread pitch and bolt diameter are also essential variables in the formula. The thread pitch is the distance between two consecutive threads, and the bolt diameter is the diameter of the bolt. To calculate the clamping force, the thread pitch and bolt diameter must be accurately measured. The following steps can be taken to measure these variables:

- Use a caliper to measure the bolt diameter

- Use a thread gauge to measure the thread pitch

- Consult the bolt specification for the thread pitch and bolt diameter

The accuracy of these measurements is crucial in ensuring that the calculated clamping force is accurate.

Applying the Formula in Practice

The formula for bolt torque to clamping force has numerous practical applications in mechanical engineering. It is used to determine the torque required to achieve a specific clamping force in a variety of applications, including pipe fittings, flanges, and bolted joints. To apply the formula in practice, the following steps can be taken:

- Determine the required clamping force for the application

- Calculate the torque required to achieve the desired clamping force

- Use a torque wrench to apply the calculated torque

The formula is essential in ensuring that the bolts and fasteners are properly tightened to achieve the desired clamping force without over- or under-tightening.

Common Mistakes and Considerations

There are several common mistakes and considerations that must be taken into account when using the formula for bolt torque to clamping force. One of the most common mistakes is using an incorrect coefficient of friction or thread pitch. To avoid these mistakes, the following precautions can be taken:

- Use a reliable source for the coefficient of friction and thread pitch

- Double-check the calculations for accuracy

- Use a torque wrench to apply the calculated torque

By taking these precautions, the accuracy of the calculated clamping force can be ensured, and the risk of over- or under-tightening can be minimized. Torque and clamping force are critical parameters in mechanical engineering, and the formula for bolt torque to clamping force is a powerful tool for ensuring that bolts and fasteners are properly tightened.

How do you calculate clamping force?

To calculate clamping force, you need to consider several factors, including the type of material being clamped, the surface area of the material, and the desired pressure. The clamping force is typically measured in pounds per square inch (PSI) or kilograms per square centimeter (kg/cm²). The calculation of clamping force involves determining the required pressure to hold the material in place and then multiplying it by the surface area of the material.

Understanding Clamping Force Requirements

The calculation of clamping force requires understanding the mechanical properties of the material being clamped, including its strength, stiffness, and ductility. The clamping force must be sufficient to overcome the frictional forces and external loads that may be applied to the material. Some key factors to consider when calculating clamping force include:

- Material properties: The yield strength, ultimate strength, and elongation of the material must be considered when calculating clamping force.

- Surface roughness: The surface roughness of the material can affect the frictional forces and clamping pressure required.

- Clamping configuration: The clamping configuration, including the number and location of clamps, can impact the required clamping force.

Calculating Clamping Pressure

The clamping pressure is calculated by dividing the required clamping force by the surface area of the material. The clamping pressure must be sufficient to overcome the frictional forces and external loads that may be applied to the material. Some key factors to consider when calculating clamping pressure include:

- Material thickness: The thickness of the material can affect the required clamping pressure.

- Clamping distance: The distance between the clamps can impact the required clamping pressure.

- Clamping speed: The speed at which the clamps are applied can affect the required clamping pressure.

Types of Clamping Forces

There are several types of clamping forces, including static clamping force, dynamic clamping force, and residual clamping force. The type of clamping force required depends on the specific application and the mechanical properties of the material being clamped. Some key factors to consider when selecting a clamping force type include:

- Static clamping force: Used for applications where the material is not subjected to external loads or vibrations.

- Dynamic clamping force: Used for applications where the material is subjected to external loads or vibrations.

- Residual clamping force: Used for applications where the material must be held in place for an extended period.

Clamping Force Measurement

The clamping force can be measured using various techniques, including strain gauges, load cells, and pressure sensors. The measurement of clamping force is critical to ensure that the required pressure is applied to the material. Some key factors to consider when measuring clamping force include:

- Accuracy: The accuracy of the measurement device is critical to ensure that the required clamping force is applied.

- Resolution: The resolution of the measurement device can affect the accuracy of the clamping force measurement.

- Calibration: The calibration of the measurement device is essential to ensure that the clamping force measurement is accurate.

Applications of Clamping Force

The calculation of clamping force is critical in various industrial applications, including manufacturing, assembly, and testing. The clamping force must be carefully calculated to ensure that the material is held in place securely and that the required pressure is applied. Some key factors to consider when applying clamping force in industrial applications include:

- Material handling: The clamping force must be sufficient to handle the weight and size of the material.

- Assembly operations: The clamping force must be sufficient to hold the material in place during assembly operations.

- Testing and inspection: The clamping force must be sufficient to hold the material in place during testing and inspection operations.

How do you calculate the force of a bolt based on torque?

To calculate the force of a bolt based on torque, you need to consider the thread pitch and the coefficient of friction. The torque applied to a bolt is related to the force it exerts by the formula: Torque = Force x Distance. In the case of a bolt, the distance is the radius of the bolt. By rearranging this formula, you can calculate the force of the bolt: Force = Torque / Distance. However, this calculation assumes a frictionless system, which is not the case in reality. To account for friction, you need to consider the coefficient of friction and the thread pitch of the bolt.

Understanding the Relationship Between Torque and Force

The relationship between torque and force is fundamental to calculating the force of a bolt. The torque applied to a bolt is a measure of the rotational force that causes the bolt to turn. This rotational force is related to the linear force exerted by the bolt by the formula: Torque = Force x Distance. To understand this relationship, consider the following points:

- The distance from the center of the bolt to the point where the force is applied is critical in determining the torque.

- The coefficient of friction between the bolt and the surrounding material affects the force required to achieve a given torque.

- The thread pitch of the bolt also plays a role in determining the force exerted by the bolt.

Calculating Force Based on Torque and Distance

To calculate the force of a bolt based on torque and distance, you can use the formula: Force = Torque / Distance. This calculation assumes a frictionless system, which is not the case in reality. However, it provides a good approximation of the force exerted by the bolt. Consider the following points:

- The distance from the center of the bolt to the point where the force is applied is critical in determining the force.

- The torque applied to the bolt is directly proportional to the force exerted by the bolt.

- The coefficient of friction can be ignored for this calculation, but it should be considered for more accurate results.

Accounting for Friction in Force Calculations

Friction plays a significant role in the calculation of the force of a bolt. The coefficient of friction between the bolt and the surrounding material affects the force required to achieve a given torque. To account for friction, you need to consider the thread pitch and the coefficient of friction. Consider the following points:

- The coefficient of friction is a measure of the resistance to motion between two surfaces.

- The thread pitch of the bolt affects the force exerted by the bolt due to friction.

- The force required to overcome friction can be significant, especially in high-torque applications.

Thread Pitch and Its Effect on Force Calculations

The thread pitch of a bolt is the distance between two consecutive threads. The thread pitch affects the force exerted by the bolt due to the angle of the threads. A finer thread pitch results in a greater force exerted by the bolt, while a coarser thread pitch results in a lower force. Consider the following points:

- The thread pitch is a critical factor in determining the force exerted by the bolt.

- A finer thread pitch results in a greater force due to the increased angle of the threads.

- The coefficient of friction also plays a role in determining the force exerted by the bolt, especially in high-torque applications.

Real-World Applications of Force Calculations Based on Torque

The calculation of the force of a bolt based on torque has many real-world applications. In engineering, force calculations are critical in determining the stability and safety of structures and machines. Consider the following points:

- The force exerted by a bolt can be critical in determining the stability of a structure.

- In high-torque applications, such as aerospace and automotive engineering, force calculations are especially important.

- The coefficient of friction and thread pitch must be carefully considered in real-world applications to ensure accurate and reliable results.

What is the clamp load of a bolt?

The clamp load of a bolt refers to the amount of force that is applied to the bolt to ensure a tight and secure connection between two or more components. This force is typically measured in units of pounds per square inch (PSI) or kilopascals (kPa). The clamp load is an important factor in determining the overall strength and stability of a bolted joint, as it can affect the resistance to slip, separation, and fatigue.

What is the purpose of clamp load?

The purpose of clamp load is to provide a secure and reliable connection between two or more components. This is achieved by applying a sufficient amount of force to the bolt to ensure that the threads are fully engaged and the components are properly aligned. The clamp load also helps to prevent loosening of the bolt over time due to vibration, thermal expansion, or other external factors. Some key points to consider when determining the clamp load include:

- The strength of the bolt and the components being connected

- The type of material being used for the bolt and components

- The size and thread pitch of the bolt

How is clamp load calculated?

The clamp load can be calculated using a variety of formulas and equations, depending on the specific application and design requirements. One common method is to use the torque formula, which takes into account the torque applied to the bolt, the thread pitch, and the friction coefficient. Another method is to use the bolt load formula, which considers the bolt diameter, thread pitch, and material strength. Some key factors to consider when calculating clamp load include:

- The coefficient of friction between the bolt threads and the component threads

- The yield strength of the bolt material

- The ultimate strength of the component material

What are the factors that affect clamp load?

Several factors can affect the clamp load of a bolt, including the type of material used for the bolt and components, the size and thread pitch of the bolt, and the environmental conditions in which the bolt will be used. Other factors, such as vibration, thermal expansion, and corrosion, can also impact the clamp load over time. Some key factors to consider when evaluating the clamp load include:

- The temperature range in which the bolt will be used

- The exposure to chemicals or other corrosive substances

- The level of vibration or cyclic loading

How is clamp load measured?

The clamp load can be measured using a variety of techniques, including torque wrenches, bolt load meters, and strain gauges. These instruments can provide an accurate measurement of the force applied to the bolt, allowing for precise control over the clamp load. Some key points to consider when measuring clamp load include:

- The accuracy and precision of the measuring instrument

- The calibration and certification of the instrument

- The procedure and protocol for taking measurements

What are the benefits of proper clamp load?

Proper clamp load can provide several benefits, including improved safety, reduced maintenance, and increased reliability. A secure and reliable connection between components can help to prevent accidents and equipment failure, while also reducing the need for frequent inspections and repairs. Some key benefits of proper clamp load include:

- Reduced risk of equipment failure or accident

- Improved performance and efficiency

- Increased lifespan of the bolt and components

Frequently Asked Questions (FAQs)

What is the significance of JIS B 1083 in relation to Bolt Torque and Clamping Force calculations?

The Japanese Industrial Standard (JIS) B 1083 provides a set of guidelines and formulas for calculating bolt torque and clamping force. This standard is crucial in ensuring the safety and reliability of bolted joints in various industries, including construction, automotive, and aerospace. The formulas outlined in JIS B 1083 take into account factors such as bolt diameter, thread pitch, and friction coefficient to determine the required torque and clamping force for a given application. By following these guidelines, engineers and technicians can ensure that bolted joints are properly secured, reducing the risk of failure and accidents. The use of calculators and software tools can also facilitate the calculation process, making it easier to apply the formulas and standards outlined in JIS B 1083.

How do I calculate the clamping force of a bolt using the formulas provided in JIS B 1083?

To calculate the clamping force of a bolt using the formulas provided in JIS B 1083, you need to consider several factors, including the bolt diameter, thread pitch, and friction coefficient. The clamping force is calculated using the formula: F = (T x d) / (K x D), where F is the clamping force, T is the torque, d is the bolt diameter, K is the friction coefficient, and D is the thread pitch. The friction coefficient is a critical factor in this calculation, as it affects the amount of torque required to achieve a given clamping force. The JIS B 1083 standard provides guidelines for determining the friction coefficient based on the bolt material and surface finish. By plugging in the relevant values and using a calculator or software tool, you can quickly and accurately calculate the clamping force required for your specific application.

What are the key factors that affect the bolt torque and clamping force calculations according to JIS B 1083?

The key factors that affect the bolt torque and clamping force calculations according to JIS B 1083 include the bolt diameter, thread pitch, friction coefficient, and material properties. The bolt diameter and thread pitch determine the amount of torque required to achieve a given clamping force, while the friction coefficient affects the amount of torque required to overcome friction and achieve the desired clamping force. The material properties, such as the yield strength and tensile strength, also play a critical role in determining the clamping force required to ensure the safety and reliability of the bolted joint. Additionally, factors such as surface finish and lubrication can also impact the friction coefficient and therefore the torque and clamping force calculations. By carefully considering these factors and using the formulas and guidelines provided in JIS B 1083, engineers and technicians can ensure accurate and reliable calculations.

Can I use online calculators or software tools to simplify the bolt torque and clamping force calculations according to JIS B 1083?

Yes, there are many online calculators and software tools available that can simplify the bolt torque and clamping force calculations according to JIS B 1083. These tools can quickly and accurately calculate the required torque and clamping force based on input values such as bolt diameter, thread pitch, and friction coefficient. Many of these calculators and software tools also provide guidelines and recommendations for determining the friction coefficient and other factors that affect the calculations. Additionally, some software tools can also perform stress analysis and fatigue analysis to help engineers and technicians optimize their designs and ensure the safety and reliability of the bolted joint. By using these online calculators and software tools, engineers and technicians can save time and reduce the risk of errors and miscalculations, ensuring that their bolt torque and clamping force calculations are accurate and reliable. JIS B 1083 provides a set of standards and guidelines that can be used in conjunction with these tools to ensure compliance with industry regulations and best practices.

Deja una respuesta

Entradas Relacionadas