Bolt Thread Pitch Circle Calculator

The Bolt Thread Pitch Circle Calculator is a valuable tool for engineers and manufacturers working with threaded fasteners. This calculator determines the pitch circle diameter of a bolt thread, which is essential for ensuring proper fit and function. By inputting the thread diameter, pitch, and number of threads, users can quickly calculate the pitch circle diameter. This information is crucial for designing and assembling mechanical components, as it affects the overall performance and safety of the system. The calculator simplifies the process, reducing errors and saving time. It is a straightforward and efficient solution.

- Bolt Thread Pitch Circle Calculator: Understanding its Importance in Engineering

- How do you calculate the pitch of a bolt thread?

- What is the pitch circle of a bolt?

- What is the formula for thread pitch diameter?

- How do you dimension a bolt hole circle?

-

Frequently Asked Questions (FAQs)

- What is the Bolt Thread Pitch Circle Calculator and how does it work?

- What are the benefits of using the Bolt Thread Pitch Circle Calculator in engineering applications?

- How does the Bolt Thread Pitch Circle Calculator handle different types of bolt threads and materials?

- Can the Bolt Thread Pitch Circle Calculator be used for other applications beyond engineering and manufacturing?

Bolt Thread Pitch Circle Calculator: Understanding its Importance in Engineering

The Bolt Thread Pitch Circle Calculator is a crucial tool in engineering, particularly in the design and manufacture of threaded fasteners. It is used to calculate the pitch circle diameter of a bolt or screw, which is the diameter of the circle that passes through the center of the threads. This calculation is essential in ensuring that the threaded fastener fits properly with its corresponding nut or threaded hole.

What is the Pitch Circle Diameter?

The pitch circle diameter is the diameter of the circle that intersects the thread at the pitch point, which is the point where the thread is in contact with the nut or threaded hole. The pitch circle diameter is calculated using the thread pitch and the major diameter of the bolt or screw. The thread pitch is the distance between two consecutive threads, and the major diameter is the largest diameter of the bolt or screw.

How to Calculate the Pitch Circle Diameter

To calculate the pitch circle diameter, you can use the following formula: P = (d - (0.5413 x p)), where P is the pitch circle diameter, d is the major diameter, and p is the thread pitch. However, this formula can be complex to apply, especially for multi-threaded bolts or screws. That's where the Bolt Thread Pitch Circle Calculator comes in handy, as it can quickly and accurately calculate the pitch circle diameter.

Applications of the Bolt Thread Pitch Circle Calculator

The Bolt Thread Pitch Circle Calculator has a wide range of applications in engineering, including:

| Application | Description |

|---|---|

| Aerospace engineering | Design and manufacture of aircraft and spacecraft components |

| Automotive engineering | Design and manufacture of vehicle components, such as engine blocks and cylinder heads |

| Industrial equipment manufacturing | Design and manufacture of machines and equipment, such as pumps and gearboxes |

| Construction engineering | Design and construction of buildings, bridges, and other structures |

| Mechanical engineering | Design and manufacture of mechanical components, such as gears and bearings |

Benefits of Using the Bolt Thread Pitch Circle Calculator

Using the Bolt Thread Pitch Circle Calculator offers several benefits, including increased accuracy, reduced design time, and improved productivity. By quickly and accurately calculating the pitch circle diameter, engineers can ensure that their designs are feasible and functional, and that the threaded fasteners fit properly with their corresponding nuts or threaded holes.

Common Errors to Avoid When Using the Bolt Thread Pitch Circle Calculator

When using the Bolt Thread Pitch Circle Calculator, there are several common errors to avoid, including invalid input values, incorrect thread pitch, and insufficient precision. It's essential to ensure that the input values are accurate and consistent, and that the calculator is configured correctly to avoid these errors. By avoiding these errors, engineers can ensure that their calculations are reliable and trustworthy, and that their designs are safe and functional.

How do you calculate the pitch of a bolt thread?

To calculate the pitch of a bolt thread, you need to understand the basics of thread geometry. The pitch is the distance between two consecutive thread crests, measured parallel to the axis of the thread. It is an essential parameter in determining the thread size and thread type. The pitch can be calculated using a screw pitch gauge or by measuring the distance between two consecutive threads using a caliper or micrometer. The formula to calculate the pitch is: pitch = 1 / threads per inch (TPI).

Understanding Thread Geometry

To calculate the pitch of a bolt thread, it is crucial to understand the thread geometry, which includes the thread angle, thread depth, and thread crest. The thread angle is the angle between the thread and the axis of the bolt, while the thread depth is the distance from the thread crest to the thread root. The thread crest is the highest point of the thread, and the thread root is the lowest point. The pitch diameter is the diameter of the bolt at the point where the thread crest and thread root intersect.

- The thread angle is typically 60 degrees for most bolt threads.

- The thread depth is usually between 0.5 and 1.5 times the pitch.

- The thread crest is the highest point of the thread, and it is where the pitch is measured.

Measuring Pitch using a Screw Pitch Gauge

A screw pitch gauge is a tool used to measure the pitch of a bolt thread. It consists of a series of pins or blades with different pitch values. To measure the pitch, simply insert the gauge into the thread and find the pin or blade that fits snugly into the thread. The pitch value corresponding to the pin or blade is the pitch of the bolt thread.

- Choose the correct pin or blade for the thread size.

- Insert the pin or blade into the thread, making sure it is seated properly.

- Read the pitch value from the gauge.

Calculating Pitch using Thread Measurements

If a screw pitch gauge is not available, the pitch can be calculated using thread measurements. Measure the distance between two consecutive threads using a caliper or micrometer, and then use the formula: pitch = 1 / threads per inch (TPI).

- Measure the distance between two consecutive threads using a caliper or micrometer.

- Count the number of threads per inch (TPI).

- Calculate the pitch using the formula.

Importance of Accurate Pitch Calculation

Accurate pitch calculation is crucial in ensuring the proper fit and functionality of the bolt thread. An incorrect pitch can lead to thread stripping, over-tightening, or loosening of the bolt, which can result in serious consequences.

- Thread stripping can occur if the pitch is too large or too small.

- Over-tightening can occur if the pitch is too small.

- Loosening can occur if the pitch is too large.

Common Applications of Pitch Calculation

Pitch calculation is essential in various industrial applications, including mechanical engineering, manufacturing, and construction. It is used to determine the thread size and thread type for bolts, screws, and nuts.

- Mechanical engineering requires precise pitch calculation for machine design.

- Manufacturing requires accurate pitch calculation for mass production.

- Construction requires pitch calculation for structural integrity.

What is the pitch circle of a bolt?

The pitch circle of a bolt is an imaginary circle that passes through the center of the thread of the bolt. It is the circle that is used to define the diameter of the bolt and is typically used to determine the size and thread of the bolt. The pitch circle is also known as the centerline of the thread and is the reference point for measuring the thread pitch and thread angle.

What is the importance of the pitch circle in bolt design?

The pitch circle is a critical component in bolt design as it determines the strength and stability of the bolt. The pitch circle is used to calculate the stress and strain on the bolt, and it is also used to determine the torque required to tighten the bolt. The pitch circle is also important in determining the compatibility of the bolt with other fasteners and components.

- The pitch circle is used to calculate the thread engagement and thread depth.

- The pitch circle is used to determine the bolt length and bolt diameter.

- The pitch circle is used to calculate the thread pitch and thread angle.

How is the pitch circle measured?

The pitch circle is measured using a caliper or a micrometer. The measurement is taken at the centerline of the thread, and it is typically measured in inches or millimeters. The pitch circle is also measured using a thread gauge or a pitch gauge, which is a specialized tool designed to measure the thread pitch and thread angle.

- The pitch circle is measured at the centerline of the thread.

- The pitch circle is measured using a caliper or a micrometer.

- The pitch circle is measured in inches or millimeters.

What are the factors that affect the pitch circle?

The pitch circle is affected by several factors, including the material of the bolt, the thread type, and the thread pitch. The pitch circle is also affected by the manufacturing process and the surface finish of the bolt. The pitch circle can be affected by wear and tear, and it can also be affected by corrosion and erosion.

- The pitch circle is affected by the material of the bolt.

- The pitch circle is affected by the thread type and thread pitch.

- The pitch circle is affected by the manufacturing process and surface finish.

How does the pitch circle relate to the thread pitch?

The pitch circle is directly related to the thread pitch, which is the distance between two adjacent threads. The pitch circle is used to calculate the thread pitch, and it is also used to determine the thread angle. The pitch circle and the thread pitch are critical components in bolt design, and they must be carefully calculated to ensure the strength and stability of the bolt.

- The pitch circle is used to calculate the thread pitch.

- The pitch circle is used to determine the thread angle.

- The pitch circle and the thread pitch are critical components in bolt design.

What are the applications of the pitch circle in engineering?

The pitch circle is widely used in engineering applications, including mechanical engineering, aerospace engineering, and civil engineering. The pitch circle is used to design and manufacture bolts, screws, and other fasteners. The pitch circle is also used to calculate the stress and strain on structures and components.

- The pitch circle is used in mechanical engineering to design and manufacture bolts and screws.

- The pitch circle is used in aerospace engineering to design and manufacture fasteners for aircraft and spacecraft.

- The pitch circle is used in civil engineering to calculate the stress and strain on structures and components.

What is the formula for thread pitch diameter?

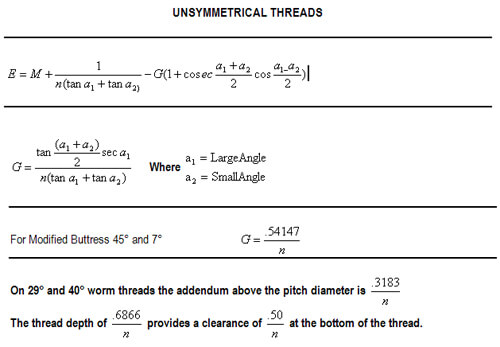

The formula for thread pitch diameter is calculated using the following equation: D = (OD - (0.54125 x P)), where D is the pitch diameter, OD is the outside diameter, and P is the pitch. This formula is used to determine the pitch diameter of a thread, which is the diameter of the thread at the point where the thread is in contact with the nut or mate.

Understanding Thread Pitch Diameter

The thread pitch diameter is a critical dimension in the design and manufacture of threads. It is used to determine the tightness or looseness of a threaded joint. To calculate the thread pitch diameter, you need to know the outside diameter and the pitch of the thread. The pitch is the distance between two adjacent threads, and it is typically measured in inches or millimeters.

- The thread pitch diameter is used to determine the strength of a threaded joint.

- The thread pitch diameter is affected by the material and manufacturing process used to create the thread.

- The thread pitch diameter can be measured using a variety of techniques, including calipers and microscopes.

Calculating Thread Pitch Diameter

To calculate the thread pitch diameter, you can use the formula: D = (OD - (0.54125 x P)). This formula is applicable to most types of threads, including metric and inch threads. However, it is essential to note that the pitch diameter can vary depending on the thread form and size.

- The outside diameter must be measured accurately to ensure a correct calculation.

- The pitch must be known to calculate the thread pitch diameter.

- The thread pitch diameter can be used to determine the class of fit of a threaded joint.

Applications of Thread Pitch Diameter

The thread pitch diameter has numerous applications in engineering and manufacturing. It is used to design and manufacture threads for various applications, including aerospace, automotive, and industrial. The thread pitch diameter is also used to determine the torque and tension of a threaded joint.

- The thread pitch diameter is used to determine the strength of a threaded joint.

- The thread pitch diameter is used to determine the stiffness of a threaded joint.

- The thread pitch diameter can be used to optimize the design of a threaded joint.

Importance of Thread Pitch Diameter

The thread pitch diameter is a critical dimension in the design and manufacture of threads. It is essential to ensure that the thread pitch diameter is accurate to guarantee the performance and reliability of a threaded joint. The thread pitch diameter can affect the tightness or looseness of a threaded joint, which can lead to failure or malfunction.

- The thread pitch diameter can affect the safety of a threaded joint.

- The thread pitch diameter can affect the efficiency of a threaded joint.

- The thread pitch diameter can affect the cost of a threaded joint.

Measurement of Thread Pitch Diameter

The thread pitch diameter can be measured using a variety of techniques, including calipers, microscopes, and -thread measuring instruments. The measurement of the thread pitch diameter is critical to ensure that the thread is manufactured to the correct specifications. The thread pitch diameter can be measured at various points along the thread, including the root, crest, and pitch.

- The thread pitch diameter must be measured accurately to ensure a correct calculation.

- The thread pitch diameter can be measured using contact or non-contact methods.

- The thread pitch diameter can be measured using optical or mechanical methods.

How do you dimension a bolt hole circle?

To dimension a bolt hole circle, you need to provide information about the size and position of the holes. This typically involves specifying the diameter of the holes, the distance between the centers of the holes, and the pattern or arrangement of the holes. The dimensioning of a bolt hole circle is critical in engineering and manufacturing to ensure that the parts fit together properly and function as intended.

Understanding Bolt Hole Circle Dimensioning

The process of dimensioning a bolt hole circle requires a thorough understanding of geometric dimensioning and tolerancing. This involves specifying the nominal size of the holes, as well as any tolerances or variations that are allowed. The dimensioning must also take into account the material and manufacturing process used to create the part. Some key considerations include:

- Hole diameter: The diameter of the holes, which can be specified using a nominal size and tolerance.

- Hole spacing: The distance between the centers of the holes, which can be specified using a distance and tolerance.

- Hole pattern: The arrangement of the holes, which can be specified using a pattern or configuration.

Specifying Bolt Hole Circle Dimensions

When specifying the dimensions of a bolt hole circle, it is essential to use clear and concise language. The dimensions should be specified using a standardized system, such as the ASME Y14.5 standard. The specification should include information about the hole diameter, hole spacing, and hole pattern. Some key considerations include:

- Dimensioning method: The method used to specify the dimensions, such as coordinate dimensioning or geometric dimensioning.

- Tolerance specification: The tolerances or variations allowed in the dimensions, such as plus or minus tolerances.

- Material specification: The material used to create the part, which can affect the dimensioning and tolerancing.

Bolt Hole Circle Dimensioning Standards

There are several standards and guidelines available for dimensioning bolt hole circles. These standards provide a framework for specifying dimensions and tolerances, and can help ensure that the parts are interchangeable and functional. Some key considerations include:

- ASME Y14.5: A standard for geometric dimensioning and tolerancing, which provides a framework for specifying dimensions and tolerances.

- ISO 286-1: A standard for geometric dimensioning and tolerancing, which provides a framework for specifying dimensions and tolerances.

- ANSI B18.2.2: A standard for metric bolt hole circles, which provides a framework for specifying dimensions and tolerances.

Common Mistakes in Bolt Hole Circle Dimensioning

There are several common mistakes that can be made when dimensioning a bolt hole circle. These mistakes can result in parts that do not fit together properly, or that do not function as intended. Some key considerations include:

- Inconsistent dimensioning: Using inconsistent dimensioning methods or tolerances, which can result in parts that do not fit together properly.

- Insufficient tolerancing: Not providing sufficient tolerancing, which can result in parts that do not function as intended.

- Incorrect material specification: Not specifying the correct material, which can affect the dimensioning and tolerancing.

Best Practices for Bolt Hole Circle Dimensioning

To ensure that the bolt hole circle is dimensioned correctly, it is essential to follow best practices. These practices include using clear and concise language, specifying dimensions and tolerances using a standardized system, and verifying that the parts fit together properly. Some key considerations include:

- Use standardized dimensioning: Using a standardized system for dimensioning, such as the ASME Y14.5 standard.

- Specify tolerances: Specifying tolerances or variations allowed in the dimensions, such as plus or minus tolerances.

- Verify part fit: Verifying that the parts fit together properly, using inspection or testing methods.

Frequently Asked Questions (FAQs)

What is the Bolt Thread Pitch Circle Calculator and how does it work?

The Bolt Thread Pitch Circle Calculator is a tool used to calculate the pitch circle diameter of a bolt thread, which is the diameter of the circle that passes through the threads of the bolt. This calculator is essential in various engineering and manufacturing applications, where precise calculations are crucial to ensure the proper fit and function of bolted joints. The calculator takes into account the thread pitch, major diameter, and minor diameter of the bolt thread to calculate the pitch circle diameter. By using this calculator, users can quickly and accurately determine the pitch circle diameter of a bolt thread, which is essential for designing and manufacturing purposes.

What are the benefits of using the Bolt Thread Pitch Circle Calculator in engineering applications?

The Bolt Thread Pitch Circle Calculator offers several benefits in engineering applications, including increased accuracy and efficiency in calculating the pitch circle diameter of bolt threads. By using this calculator, engineers can save time and reduce errors associated with manual calculations, which can be prone to human error. Additionally, the calculator enables engineers to optimize their designs by selecting the most suitable bolt thread configuration for their specific application, taking into account factors such as load capacity, stiffness, and corrosion resistance. The calculator also facilitates collaboration and communication among engineers and manufacturers by providing a common language and set of standards for bolt thread calculations.

How does the Bolt Thread Pitch Circle Calculator handle different types of bolt threads and materials?

The Bolt Thread Pitch Circle Calculator is designed to handle various types of bolt threads and materials, including metric and imperial threads, as well as standard and custom thread configurations. The calculator takes into account the thread pitch, major diameter, and minor diameter of the bolt thread, as well as the material properties of the bolt and surrounding components. This enables users to calculate the pitch circle diameter of bolt threads made from various materials, such as steel, aluminum, and titanium. The calculator also considers the effects of thread wear and corrosion on the bolt thread, allowing users to account for these factors in their calculations.

Can the Bolt Thread Pitch Circle Calculator be used for other applications beyond engineering and manufacturing?

While the Bolt Thread Pitch Circle Calculator is primarily designed for engineering and manufacturing applications, it can also be used in other fields where precise calculations are required, such as architecture, construction, and product design. The calculator's ability to calculate the pitch circle diameter of bolt threads makes it a valuable tool for anyone working with bolted joints or threaded fasteners. Additionally, the calculator's user-friendly interface and intuitive design make it accessible to users without extensive technical expertise, allowing it to be used in a variety of contexts beyond traditional engineering and manufacturing applications.

Deja una respuesta

Entradas Relacionadas