Belleville Washer Design Formulae and Calculator

The Belleville washer is a type of disc spring that is widely used in various engineering applications due to its unique properties. Its design allows for a high degree of flexibility and versatility, making it an essential component in many industries. To ensure optimal performance and safety, accurate calculations are crucial in the design of Belleville washers. This article provides a comprehensive overview of the Belleville washer design formulae and introduces a calculator tool to facilitate the calculation process, enabling engineers to efficiently and accurately design these critical components. The formulae and calculator are essential for precise design.

- Understanding Belleville Washer Design Formulae and Calculator

- How to design a Belleville washer?

- How to measure a Belleville washer?

- How to choose Belleville washer?

- How to specify a Belleville washer?

-

Frequently Asked Questions (FAQs)

- What is the purpose of the Belleville Washer Design Formulae and Calculator?

- How does the Belleville Washer Design Formulae and Calculator work?

- What are the advantages of using the Belleville Washer Design Formulae and Calculator?

- What are the limitations of the Belleville Washer Design Formulae and Calculator?

Understanding Belleville Washer Design Formulae and Calculator

The Belleville washer is a type of spring washer that is used to maintain a constant force or tension in a bolted joint. The design formulae for Belleville washers are used to calculate the dimensions and properties of the washer, such as its thickness, outer diameter, and inner diameter. A calculator is often used to simplify the calculations and ensure accuracy.

Introduction to Belleville Washer Design Formulae

The design formulae for Belleville washers are based on the stress and strain of the material, as well as the load and deflection of the washer. The formulae take into account the thickness, outer diameter, and inner diameter of the washer, as well as the material properties such as the modulus of elasticity and Poisson's ratio. The calculator uses these formulae to calculate the optimal dimensions of the washer for a given application.

The design parameters for a Belleville washer include the thickness, outer diameter, and inner diameter. The thickness of the washer determines its stiffness and load-carrying capacity, while the outer diameter and inner diameter determine the contact area and stress distribution. The calculator allows the user to input these parameters and calculate the resulting stress and strain on the washer.

Calculating Stress and Strain in Belleville Washers

The stress and strain in a Belleville washer can be calculated using the design formulae. The stress is calculated as a function of the load, thickness, and outer diameter, while the strain is calculated as a function of the stress and material properties. The calculator uses these formulae to calculate the maximum stress and strain in the washer, ensuring that it can withstand the expected loads and deflections.

Material Selection for Belleville Washers

The material selection for a Belleville washer is critical to its performance and reliability. The material properties, such as the modulus of elasticity and Poisson's ratio, determine the stiffness and load-carrying capacity of the washer. The calculator allows the user to select from a range of materials, including steel, aluminum, and copper, and calculate the resulting stress and strain on the washer.

Applications of Belleville Washers

Belleville washers have a range of applications, including industrial, automotive, and aerospace. They are used in bolted joints to maintain a constant force or tension, and to prevent loosening or vibration. The calculator can be used to design Belleville washers for specific applications, taking into account the load, deflection, and material properties.

| Parameter | Unit | Description |

|---|---|---|

| Thickness | mm | The thickness of the Belleville washer |

| Outer Diameter | mm | The outer diameter of the Belleville washer |

| Inner Diameter | mm | The inner diameter of the Belleville washer |

| Material | The material used to manufacture the Belleville washer | |

| Load | N | The load applied to the Belleville washer |

How to design a Belleville washer?

To design a Belleville washer, it's essential to understand its functionality and the principles behind its operation. A Belleville washer is a type of disc spring used to apply a consistent axial load to a joint or a bolted connection. The design of a Belleville washer involves calculating the required spring rate, deflection, and load capacity to ensure it meets the specific application requirements.

Understanding the Basic Principles of Belleville Washers

The design of a Belleville washer starts with understanding the basic principles of disc springs and how they work. A Belleville washer is essentially a conical spring that is designed to apply a consistent axial load when compressed. The spring rate of a Belleville washer is determined by its thickness, outer diameter, and inner diameter. To design a Belleville washer, the following factors must be considered:

- Calculating the required spring rate and load capacity

- Determining the deflection and stiffness of the spring

- Selecting the material and geometry of the washer

Calculating the Spring Rate and Load Capacity

Calculating the spring rate and load capacity of a Belleville washer is crucial to ensure it meets the application requirements. The spring rate is calculated using the formula: k = (4 E t^3) / (π (D_o^2 - D_i^2)), where k is the spring rate, E is the modulus of elasticity, t is the thickness, D_o is the outer diameter, and D_i is the inner diameter. The load capacity is calculated using the formula: F = (k δ), where F is the load capacity, k is the spring rate, and δ is the deflection. To calculate the spring rate and load capacity, the following steps must be taken:

- Determining the material properties and geometry of the washer

- Calculating the spring rate using the formula

- Calculating the load capacity using the formula

Selecting the Material and Geometry

Selecting the material and geometry of a Belleville washer is critical to ensure it meets the application requirements. The material selection depends on the operating temperature, corrosion resistance, and strength requirements. The geometry selection depends on the space constraints, load requirements, and deflection requirements. To select the material and geometry, the following factors must be considered:

- Material properties, such as strength, corrosion resistance, and ductility

- Geometry, such as thickness, outer diameter, and inner diameter

- Space constraints and load requirements

Designing for Specific Applications

Designing a Belleville washer for specific applications requires careful consideration of the operating conditions and load requirements. For example, in high-temperature applications, the material selection is critical to ensure the washer can withstand the thermal stresses. In high-load applications, the geometry selection is critical to ensure the washer can withstand the axial loads. To design for specific applications, the following steps must be taken:

- Identifying the operating conditions, such as temperature, corrosion, and vibration

- Determining the load requirements, such as axial load and torsional load

- Selecting the material and geometry, based on the operating conditions and load requirements

Manufacturing and Testing Considerations

Manufacturing and testing a Belleville washer requires careful consideration of the manufacturing process and testing procedures. The manufacturing process can affect the quality and consistency of the washer, while the testing procedures can ensure the washer meets the application requirements. To manufacture and test a Belleville washer, the following steps must be taken:

- Selecting the manufacturing process, such as stamping or machining

- Developing the testing procedures, such as load testing and deflection testing

- Verifying the washer's performance, using quality control measures

How to measure a Belleville washer?

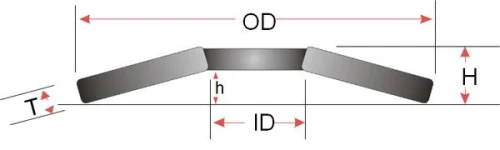

To measure a Belleville washer, it is essential to understand the key dimensions that define its size and functionality. A Belleville washer, also known as a Belleville spring or conical spring, is a type of spring that is designed to provide a high amount of deflection under load, while maintaining a relatively constant spring rate. To measure a Belleville washer, you will need to record its outside diameter, inside diameter, thickness, conical angle, and material thickness. These measurements will help you determine the washer's load capacity, deflection, and spring rate, which are critical factors in selecting the right Belleville washer for your application.

Understanding the Key Dimensions of a Belleville Washer

The key dimensions of a Belleville washer include its outside diameter, inside diameter, thickness, conical angle, and material thickness. These dimensions can be measured using a variety of tools, including calipers, micrometers, and protractors. To measure the outside diameter, simply place the calipers or micrometer across the outer edge of the washer and record the reading. The inside diameter can be measured in a similar manner, by placing the calipers or micrometer across the inner edge of the washer. The thickness of the washer can be measured using a micrometer or caliper, and the conical angle can be measured using a protractor. Some important factors to consider when measuring a Belleville washer include:

- Accuracy: It is essential to ensure that your measurements are accurate, as small variations in dimensions can affect the performance of the washer.

- Precision: Use high-precision tools, such as digital calipers or micrometers, to ensure that your measurements are precise.

- Repeatability: Take multiple measurements to ensure that your results are repeatable and consistent.

Measuring the Outside Diameter of a Belleville Washer

Measuring the outside diameter of a Belleville washer is a critical step in determining its size and functionality. The outside diameter is typically measured using calipers or micrometers, and is usually recorded in units of inches or millimeters. To measure the outside diameter, simply place the calipers or micrometer across the outer edge of the washer and record the reading. Some important factors to consider when measuring the outside diameter include:

- Orientation: Ensure that the washer is properly oriented, with the conical surface facing upwards.

- Positioning: Place the calipers or micrometer across the outer edge of the washer, ensuring that they are parallel to the surface.

- Reading: Record the reading from the calipers or micrometer, ensuring that it is accurate and precise.

Measuring the Inside Diameter of a Belleville Washer

Measuring the inside diameter of a Belleville washer is also an essential step in determining its size and functionality. The inside diameter is typically measured using calipers or micrometers, and is usually recorded in units of inches or millimeters. To measure the inside diameter, simply place the calipers or micrometer across the inner edge of the washer and record the reading. Some important factors to consider when measuring the inside diameter include:

- Accessibility: Ensure that the inner edge of the washer is accessible, and that the calipers or micrometer can be properly positioned.

- Alignment: Align the calipers or micrometer with the inner edge of the washer, ensuring that they are parallel to the surface.

- Reading: Record the reading from the calipers or micrometer, ensuring that it is accurate and precise.

Measuring the Thickness of a Belleville Washer

Measuring the thickness of a Belleville washer is a critical step in determining its load capacity and deflection. The thickness is typically measured using a micrometer, and is usually recorded in units of inches or millimeters. To measure the thickness, simply place the micrometer across the washer, ensuring that it is properly positioned and aligned. Some important factors to consider when measuring the thickness! include:

- Positioning: Place the micrometer across the washer, ensuring that it is properly positioned and aligned.

- Reading: Record the reading from the micrometer, ensuring that it is accurate and precise.

- Repeatability: Take multiple measurements to ensure that your results are repeatable and consistent.

Measuring the Conical Angle of a Belleville Washer

Measuring the conical angle of a Belleville washer is an essential step in determining its spring rate and load capacity. The conical angle is typically measured using a pro! tractor, and is usually recorded in units of degrees. To measure the conical angle, simply place the protractor across the washer, ensuring that it is properly positioned and aligned. Some important factors to consider when measuring the conical angle include:

- Orientation: Ensure that the washer is properly oriented, with the conical surface facing upwards.

- Positioning: Place the protractor across the washer, ensuring that it is properly positioned and aligned.

- Reading: Record the reading from the protractor, ensuring that it is accurate and precise.

How to choose Belleville washer?

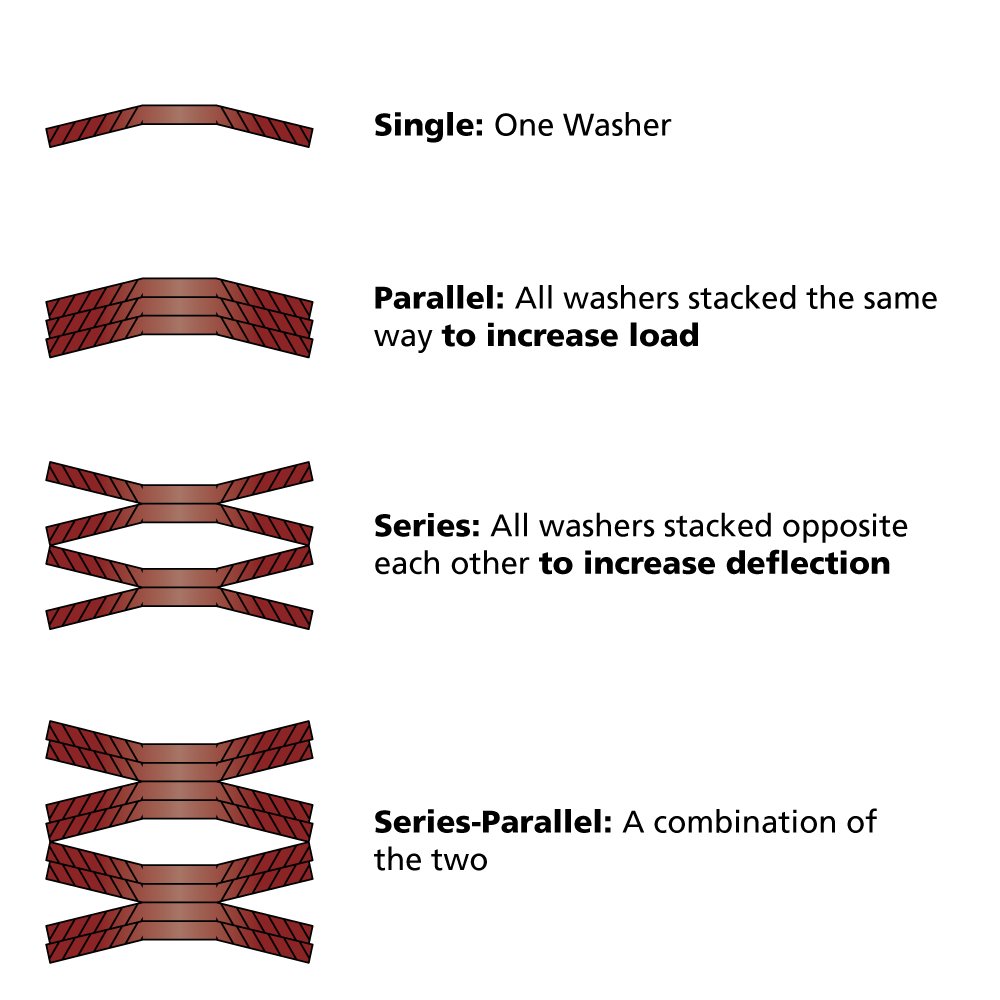

Choosing the correct Belleville washer is crucial for ensuring the optimal performance and safety of various mechanical systems. To select the right Belleville washer, one must consider several key factors, including the application, load requirements, and environmental conditions. A Belleville washer is a type of disc spring that is designed to provide a high amount of deflection and load in a compact space. They are commonly used in bolting applications where high clamping forces are required.

Understanding Belleville Washer Types

There are several types of Belleville washers available, each with its own unique characteristics and advantages. To choose the right type, one must consider the specific requirements of the application. The main types of Belleville washers include:

- Standard Belleville washers: These are the most common type and are suitable for most applications.

- Heavy-duty Belleville washers: These are designed for high-load applications and provide a higher clamping force.

- High-temperature Belleville washers: These are made from heat-resistant materials and are suitable for high-temperature applications.

The choice of Belleville washer type depends on the specific requirements of the application, including the load, temperature, and environmental conditions.

Belleville Washer Materials

The material of the Belleville washer is also an important consideration. Different materials have different strengths, weaknesses, and corrosion resistances. The most common materials used for Belleville washers include:

- Stainless steel: This is a popular choice due to its high corrosion resistance and strength.

- Carbon steel: This is a cost-effective option that provides a high load capacity.

- Inconel: This is a high-temperature alloy that is suitable for extreme environments.

The choice of material depends on the specific requirements of the application, including the environmental conditions and load requirements.

Belleville Washer Sizes

The size of the Belleville washer is critical to ensuring the optimal performance of the system. The size depends on the bolt diameter, thread pitch, and load requirements. To choose the right size, one must consult the manufacturer's dimensional charts and load tables. The main considerations when selecting a Belleville washer size include:

- The outside diameter of the washer must be compatible with the bolt diameter.

- The inside diameter of the washer must be compatible with the thread pitch.

- The thickness of the washer must be sufficient to provide the required load capacity.

The correct size of the Belleville washer ensures a secure fit and optimal performance.

Belleville Washer Load Capacity

The load capacity of the Belleville washer is a critical consideration. The load capacity depends on the material, size, and type of the washer. To choose the right load capacity, one must consult the manufacturer's load tables and consider the specific requirements of the application. The main considerations when selecting a Belleville washer load capacity include:

- The maximum load that the washer can withstand without deformation.

- The minimum load that the washer requires to maintain a secure fit.

- The load-deflection curve of the washer, which indicates the relationship between the load and deflection.

The correct load capacity of the Belleville washer ensures a secure fit and optimal performance.

Belleville Washer Installation

The installation of the Belleville washer is also an important consideration. The washer must be installed correctly to ensure optimal performance and safety. The main considerations when installing a Belleville washer include:

- The washer must be properly seated on the bolt or stud.

- The washer must be oriented correctly to ensure the load is applied in the correct direction.

- The washer must be tightened securely to prevent loosening over time.

The correct installation of the Belleville washer ensures a secure fit and optimal performance, and helps to prevent accidents and injuries.

How to specify a Belleville washer?

To specify a Belleville washer, it is essential to understand the key characteristics and parameters that define its performance and functionality. A Belleville washer is a type of disc spring that is used to apply a constant force or deflection in a given application. The specification process involves considering factors such as the material, size, thickness, and load capacity of the washer.

Understanding Belleville Washer Types

When specifying a Belleville washer, it is crucial to understand the different types available, including conical, convex, and flat washers. Each type has its unique characteristics and is suited for specific applications. The choice of type depends on the required load capacity, deflection, and operating conditions. Some key factors to consider when selecting a Belleville washer type include:

- The material used to manufacture the washer, such as stainless steel or spring steel

- The size and thickness of the washer, which affect its load capacity and deflection

- The load capacity required for the application, which depends on the force and deflection needed

Material Selection for Belleville Washers

The material used to manufacture a Belleville washer is critical in determining its performance and durability. Common materials used include stainless steel, spring steel, and inconel. The choice of material depends on factors such as corrosion resistance, temperature resistance, and load capacity. Some key considerations when selecting a material for a Belleville washer include:

- The corrosion resistance required for the application, which depends on the environment and exposure to chemicals

- The temperature range in which the washer will operate, which affects its material properties and performance

- The load capacity required for the application, which depends on the force and deflection needed

Calculating Load Capacity and Deflection

To specify a Belleville washer, it is essential to calculate the load capacity and deflection required for the application. This involves considering factors such as the force and distance over which the force is applied. The load capacity and deflection can be calculated using formulas and charts provided by manufacturers or by using software specifically designed for spring design. Some key factors to consider when calculating load capacity and deflection include:

- The force required for the application, which depends on the load and operating conditions

- The distance over which the force is applied, which affects the deflection and load capacity

- The material properties of the washer, which affect its load capacity and deflection

Dimensional Considerations for Belleville Washers

When specifying a Belleville washer, it is crucial to consider the dimensional requirements of the application. This includes the outside diameter, inside diameter, and thickness of the washer. The dimensional requirements depend on the space constraints and mounting requirements of the application. Some key factors to consider when specifying the dimensions of a Belleville washer include:

- The outside diameter of the washer, which affects its load capacity and deflection

- The inside diameter of the washer, which depends on the shaft or bolt diameter

- The thickness of the washer, which affects its load capacity and deflection

Manufacturing and Quality Considerations

Finally, when specifying a Belleville washer, it is essential to consider the manufacturing and quality requirements of the application. This includes factors such as surface finish, material certification, and testing. The manufacturing process and quality control measures can affect the performance and reliability of the washer. Some key considerations when specifying the manufacturing and quality requirements of a Belleville washer include:

- The surface finish required for the application, which depends on the corrosion resistance and wear resistance needed

- The material certification required for the application, which depends on the industry and regulatory requirements

- The testing and inspection requirements for the washer, which depend on the quality and reliability needed

Frequently Asked Questions (FAQs)

What is the purpose of the Belleville Washer Design Formulae and Calculator?

The Belleville Washer Design Formulae and Calculator is a tool used to design and calculate the dimensions and properties of Belleville washers, which are a type of spring washer used in various engineering applications. The purpose of this tool is to provide engineers and designers with a quick and accurate way to calculate the deflection, stress, and load characteristics of Belleville washers, allowing them to optimize their design for specific applications. By using the Belleville Washer Design Formulae and Calculator, engineers can ensure that their designs meet the required performance and safety standards, while also minimizing costs and weight. The calculator takes into account various input parameters, such as the material properties, washer dimensions, and load conditions, to provide a comprehensive analysis of the Belleville washer's behavior.

How does the Belleville Washer Design Formulae and Calculator work?

The Belleville Washer Design Formulae and Calculator works by using a set of mathematical equations and algorithms to calculate the behavior of Belleville washers under various load conditions. The calculator takes into account the geometric parameters of the washer, such as the outer diameter, inner diameter, thickness, and number of turns, as well as the material properties, such as the Young's modulus, Poisson's ratio, and yield strength. The calculator then uses these input parameters to calculate the deflection, stress, and load characteristics of the Belleville washer, including the spring rate, maximum load, and minimum load. The calculator also provides graphs and plots to visualize the behavior of the Belleville washer, allowing engineers to easily understand and interpret the results. By using the Belleville Washer Design Formulae and Calculator, engineers can rapidly iterate on their design and optimize it for performance, cost, and weight.

What are the advantages of using the Belleville Washer Design Formulae and Calculator?

The Belleville Washer Design Formulae and Calculator offers several advantages over traditional design methods, including increased accuracy, reduced design time, and improved performance. By using the calculator, engineers can quickly and easily calculate the behavior of Belleville washers, without the need for complex mathematical derivations or extensive testing. The calculator also provides a comprehensive analysis of the Belleville washer's behavior, including the deflection, stress, and load characteristics, allowing engineers to optimize their design for specific applications. Additionally, the calculator can reduce costs by minimizing the need for prototyping and testing, and can also improve safety by ensuring that the design meets the required performance and safety standards. Overall, the Belleville Washer Design Formulae and Calculator is a powerful tool that can help engineers to design and optimize Belleville washers for a wide range of applications.

What are the limitations of the Belleville Washer Design Formulae and Calculator?

The Belleville Washer Design Formulae and Calculator has several limitations that engineers should be aware of when using the tool. One of the main limitations is that the calculator assumes a linear elastic behavior of the material, which may not be accurate for all materials or load conditions. Additionally, the calculator does not account for non-linear effects, such as plasticity or creep, which can be important in certain applications. The calculator also requires accurate input parameters, including material properties and geometric parameters, which can be difficult to obtain in some cases. Furthermore, the calculator is limited to a specific range of Belleville washer designs and load conditions, and may not be applicable to all types of applications. Therefore, engineers should carefully evaluate the results of the calculator and validate them through testing or simulation before using them in practical applications. By understanding the limitations of the Belleville Washer Design Formulae and Calculator, engineers can use the tool effectively and safely.

Deja una respuesta

Entradas Relacionadas