Weight of Pipe Hollow Cylinder Equation and Calculator

The weight of a pipe or hollow cylinder is a crucial calculation in various engineering and construction applications. To determine this weight, a specific equation is used, taking into account the material density, inner and outer radius, and length of the cylinder. This equation provides a precise calculation, which is essential for ensuring the structural integrity and safety of the system. The calculator accompanying this equation allows for quick and accurate computations, making it a valuable tool for professionals in the field. Accurate calculations are vital for successful project outcomes.

- Understanding the Weight of Pipe Hollow Cylinder Equation and Calculator

- How to calculate hollow pipe weight formula?

- What is the formula for a hollow cylinder?

-

Frequently Asked Questions (FAQs)

- What is the Weight of Pipe Hollow Cylinder Equation and how is it calculated?

- How does the material density affect the weight of a hollow cylinder?

- What are the limitations and assumptions of the Weight of Pipe Hollow Cylinder Equation?

- How can I use the Weight of Pipe Hollow Cylinder Calculator to simplify my calculations?

Understanding the Weight of Pipe Hollow Cylinder Equation and Calculator

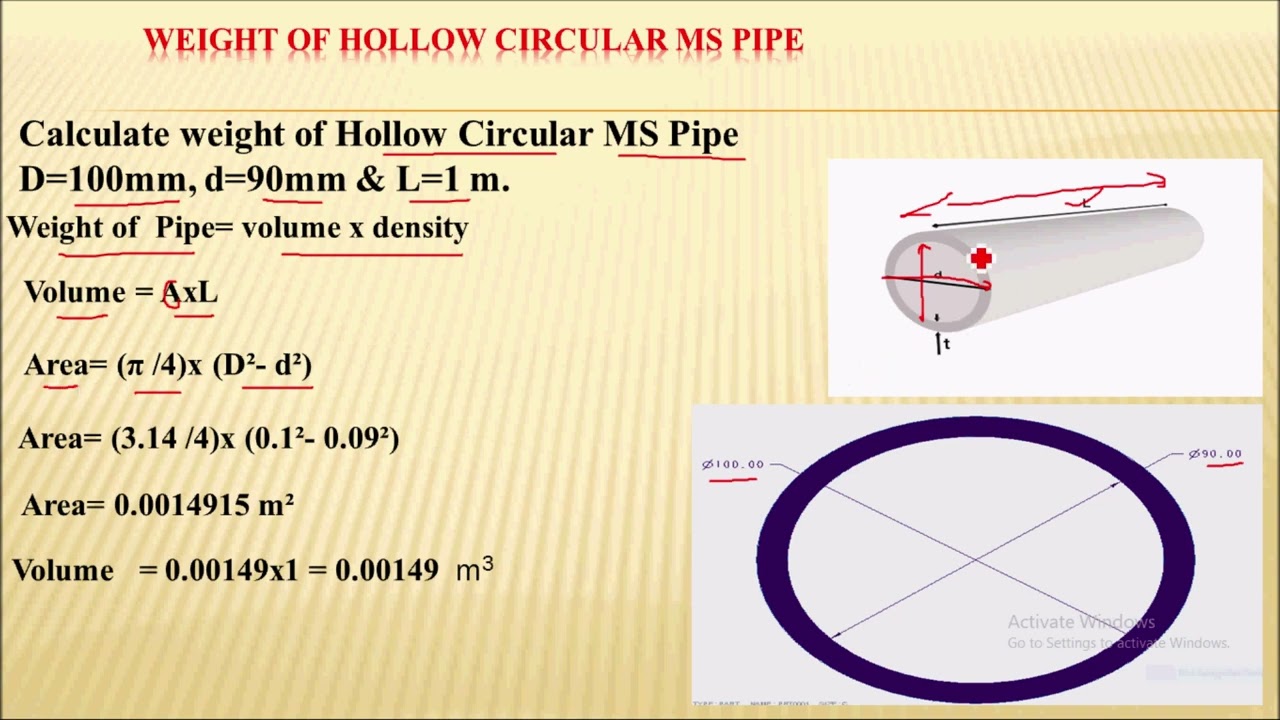

The weight of a pipe hollow cylinder is a crucial parameter in various engineering applications, including construction, mechanical engineering, and piping systems. Calculating the weight of a hollow cylinder requires a thorough understanding of its dimensions, material density, and the equation that governs its weight. The weight of a hollow cylinder can be calculated using the formula: W = π (R^2 - r^2) h ρ, where W is the weight, π (pi) is a mathematical constant, R is the outer radius, r is the inner radius, h is the height, and ρ is the density of the material.

Introduction to Hollow Cylinder Weight Calculation

Calculating the weight of a hollow cylinder involves understanding the geometry of the cylinder and the properties of the material it is made of. The formula for calculating the weight of a hollow cylinder is based on the principle of subtracting the volume of the inner cylinder from the volume of the outer cylinder and then multiplying the result by the density of the material. This calculation is essential for determining the structural integrity and stability of the cylinder under various loads and conditions.

Key Parameters in Hollow Cylinder Weight Calculation

The key parameters in calculating the weight of a hollow cylinder include the outer diameter, inner diameter, height, and material density. These parameters are crucial in determining the volume and weight of the cylinder. The outer diameter and inner diameter are used to calculate the wall thickness of the cylinder, which affects its strength and stability. The height of the cylinder also plays a significant role in determining its weight and structural integrity.

Equation for Calculating Hollow Cylinder Weight

The equation for calculating the weight of a hollow cylinder is: W = π (R^2 - r^2) h ρ. This equation takes into account the geometry of the cylinder and the properties of the material. The π (pi) is a mathematical constant that is approximately equal to 3.14159. The R and r represent the outer radius and inner radius of the cylinder, respectively. The h represents the height of the cylinder, and the ρ represents the density of the material.

| Parameter | Unit | Description |

|---|---|---|

| W | kg or lbs | Weight of the hollow cylinder |

| π | - | Mathematical constant (approximately 3.14159) |

| R | m or ft | Outer radius of the cylinder |

| r | m or ft | Inner radius of the cylinder |

| h | m or ft | Height of the cylinder |

| ρ | kg/m^3 or lbs/ft^3 | Density of the material |

Applications of Hollow Cylinder Weight Calculation

The calculation of the weight of a hollow cylinder has numerous applications in various fields, including construction, mechanical engineering, and piping systems. In construction, the weight of a hollow cylinder is crucial in determining the structural integrity and stability of buildings and bridges. In mechanical engineering, the weight of a hollow cylinder is essential in designing machinery and equipment that require precise calculations of weight and balance.

Challenges in Hollow Cylinder Weight Calculation

Calculating the weight of a hollow cylinder can be challenging due to the complexity of the equation and the need for precise measurements of the dimensions and material properties. Additionally, the density of the material can vary depending on the temperature and pressure conditions, which can affect the accuracy of the calculation. Therefore, it is essential to use reliable and accurate data and to consider the uncertainties associated with the calculation.

How to calculate hollow pipe weight formula?

To calculate the weight of a hollow pipe, you need to know the outer diameter, inner diameter, length, and density of the material. The formula to calculate the weight of a hollow pipe is: Weight = (π/4) (Outer Diameter^2 - Inner Diameter^2) Length Density.

Understanding the Formula

The formula for calculating the weight of a hollow pipe involves several key components, including the outer diameter and inner diameter. To apply this formula, you need to know the length of the pipe and the density of the material it is made of. The calculation is as follows:

- The area of the pipe is calculated by subtracting the inner diameter squared from the outer diameter squared.

- This result is then multiplied by the length of the pipe to get the volume.

- Finally, the volume is multiplied by the density of the material to get the weight.

Importance of Density

The density of the material is a crucial factor in calculating the weight of a hollow pipe. Different materials have different densities, and using the wrong density can result in an incorrect calculation. For example, the density of steel is approximately 7.9 g/cm^3, while the density of aluminum is approximately 2.7 g/cm^3.

- Steel pipes will generally be heavier than aluminum pipes of the same size due to the difference in density.

- Copper pipes have a density of approximately 8.96 g/cm^3, making them even heavier than steel pipes.

- Plastic pipes have a much lower density, typically around 1.1-1.4 g/cm^3, making them much lighter than metal pipes.

Calculating Volume

To calculate the volume of a hollow pipe, you need to subtract the inner diameter squared from the outer diameter squared, then multiply the result by the length of the pipe. This will give you the volume of the pipe in cubic units.

- First, calculate the area of the pipe by subtracting the inner diameter squared from the outer diameter squared.

- Then, multiply this result by the length of the pipe to get the volume.

- Finally, multiply the volume by the density of the material to get the weight.

Practical Applications

Calculating the weight of a hollow pipe is important in a variety of practical applications, including engineering, construction, and transportation.

- In engineering, calculating the weight of a pipe is crucial for designing structures that can support the weight of the pipe and its contents.

- In construction, knowing the weight of a pipe is important for safety and logistical reasons.

- In transportation, the weight of a pipe can affect the cost of shipping and handling.

Common Mistakes

There are several common mistakes that can be made when calculating the weight of a hollow pipe, including using the wrong density, forgetting to subtract the inner diameter squared from the outer diameter squared, and not accounting for the thickness of the pipe.

- Using the wrong density can result in a significant error in the calculation.

- Forgetting to subtract the inner diameter squared from the outer diameter squared can result in an incorrect calculation of the area.

- Not accounting for the thickness of the pipe can result in an incorrect calculation of the volume.

What is the formula for a hollow cylinder?

The formula for a hollow cylinder is given by the equation: 2πh(R + r), where h is the height of the cylinder, R is the outer radius, and r is the inner radius. This formula is used to calculate the lateral surface area of the hollow cylinder.

Understanding the Components of a Hollow Cylinder

The formula for a hollow cylinder involves several key components, including the height, outer radius, and inner radius. To calculate the lateral surface area, it is essential to understand the relationship between these components. The formula can be broken down into the following steps:

- Identify the height of the cylinder, which is the distance between the two bases.

- Determine the outer radius, which is the distance from the center of the cylinder to the outer edge.

- Calculate the inner radius, which is the distance from the center of the cylinder to the inner edge.

Calculating the Lateral Surface Area of a Hollow Cylinder

The lateral surface area of a hollow cylinder is the area of the curved surface, excluding the two bases. The formula for the lateral surface area is given by: 2πh(R + r). This formula can be used to calculate the surface area of the hollow cylinder, which is essential in various engineering and design applications. The lateral surface area can be calculated by:

- Using the formula: 2πh(R + r), where h is the height, R is the outer radius, and r is the inner radius.

- Plugging in the values of h, R, and r into the formula to obtain the lateral surface area.

- Verifying the calculation to ensure that the result is accurate and reliable.

Application of the Formula in Real-World Scenarios

The formula for a hollow cylinder has numerous practical applications in various fields, including engineering, architecture, and design. For example, the formula can be used to calculate the surface area of a pipeline, tubing, or ductwork. The formula is also useful in calculating the volume of a hollow cylinder, which is essential in fluid dynamics and thermodynamics. The application of the formula involves:

- Identifying the parameters of the hollow cylinder, including the height, outer radius, and inner radius.

- Using the formula to calculate the lateral surface area or volume of the hollow cylinder.

- Applying the result to the specific application or problem at hand.

Derivation of the Formula for a Hollow Cylinder

The formula for a hollow cylinder can be derived by considering the geometry of the cylinder. The lateral surface area of the hollow cylinder is equal to the sum of the areas of the two curved surfaces. The formula can be derived by:

- Considering the geometry of the hollow cylinder, including the height, outer radius, and inner radius.

- Using calculus or geometric methods to derive the formula for the lateral surface area.

- Verifying the result to ensure that it is accurate and reliable.

Common Mistakes to Avoid When Using the Formula

When using the formula for a hollow cylinder, there are several common mistakes to avoid. These include:

- Incorrectly identifying the parameters of the hollow cylinder, including the height, outer radius, and inner radius.

- Failing to use the correct units when calculating the lateral surface area or volume.

- Neglecting to verify the result to ensure that it is accurate and reliable.

Frequently Asked Questions (FAQs)

What is the Weight of Pipe Hollow Cylinder Equation and how is it calculated?

The Weight of Pipe Hollow Cylinder Equation is a mathematical formula used to calculate the weight of a hollow cylinder, which is a type of pipe or tube with a circular cross-section. The equation takes into account the material density, outer diameter, inner diameter, and length of the cylinder. The formula is: W = π/4 (D^2 - d^2) L ρ, where W is the weight, π is a constant approximately equal to 3.14, D is the outer diameter, d is the inner diameter, L is the length, and ρ is the material density. This equation is widely used in engineering and construction applications to determine the weight of pipes and tubes.

How does the material density affect the weight of a hollow cylinder?

The material density plays a crucial role in calculating the weight of a hollow cylinder. The density of a material is defined as its mass per unit volume. Different materials have different densities, and this affects the overall weight of the cylinder. For example, a hollow cylinder made of steel will have a higher weight than one made of aluminum, given the same dimensions, due to the higher density of steel. The material density is typically measured in units of kilograms per cubic meter (kg/m^3) or pounds per cubic foot (lb/ft^3). By knowing the material density, engineers and designers can accurately calculate the weight of a hollow cylinder using the Weight of Pipe Hollow Cylinder Equation.

What are the limitations and assumptions of the Weight of Pipe Hollow Cylinder Equation?

The Weight of Pipe Hollow Cylinder Equation is based on several assumptions and has some limitations. One assumption is that the cylinder is uniformly thick, meaning that the wall thickness is constant throughout the length of the cylinder. Another assumption is that the material is homogeneous, meaning that it has the same density and composition throughout. The equation also assumes that the cylinder is straight and not bent or curved. Additionally, the equation does not take into account any external loads or stresses that may be acting on the cylinder. These assumptions and limitations must be considered when using the equation to calculate the weight of a hollow cylinder, especially in real-world applications where these assumptions may not always hold true.

How can I use the Weight of Pipe Hollow Cylinder Calculator to simplify my calculations?

The Weight of Pipe Hollow Cylinder Calculator is a tools that can be used to simplify the calculation of the weight of a hollow cylinder. By inputting the outer diameter, inner diameter, length, and material density into the calculator, you can quickly and easily obtain the weight of the cylinder. The calculator uses the Weight of Pipe Hollow Cylinder Equation to perform the calculation, eliminating the need for manual calculations and reducing the chance of error. The calculator can be particularly useful for engineers, designers, and manufacturers who need to calculate the weight of pipes and tubes on a regular basis. By using the calculator, you can save time and effort, and ensure that your calculations are accurate and reliable.

Deja una respuesta

Entradas Relacionadas