Standard Size Steel Pipe Weights Calculator

Calculating the weight of steel pipes is a crucial task in various industries, including construction, engineering, and manufacturing. The Standard Size Steel Pipe Weights Calculator is a valuable tool that helps professionals determine the weight of steel pipes based on their size, material, and specifications. This calculator takes into account the different types of steel pipes, including Schedule 40, Schedule 80, and other standard sizes. By using this calculator, users can quickly and accurately determine the weight of steel pipes, making it easier to plan and execute projects efficiently. It saves time and reduces errors.

- Understanding the Standard Size Steel Pipe Weights Calculator

- How much does a 1 inch steel pipe weight per foot?

- How much does sch 80 pipe weigh per foot?

-

Frequently Asked Questions (FAQs)

- What is the Standard Size Steel Pipe Weights Calculator and how does it work?

- What are the benefits of using the Standard Size Steel Pipe Weights Calculator?

- How does the Standard Size Steel Pipe Weights Calculator account for different types of steel pipes?

- Can the Standard Size Steel Pipe Weights Calculator be used for other types of pipes, such as copper or PVC pipes?

Understanding the Standard Size Steel Pipe Weights Calculator

The Standard Size Steel Pipe Weights Calculator is a tool used to calculate the weight of steel pipes based on their size, material, and other factors. This calculator is essential in various industries, including construction, engineering, and manufacturing, where accurate weight calculations are critical for planning, designing, and executing projects. The calculator takes into account the nominal diameter, wall thickness, length, and material density of the pipe to provide an accurate weight calculation.

Introduction to Steel Pipe Weights Calculator

The Steel Pipe Weights Calculator is a simple and user-friendly tool that allows users to input the pipe's dimensions and material properties to obtain the weight. This calculator is particularly useful for engineers, architects, and contractors who need to estimate the weight of steel pipes for various applications, including building construction, bridge construction, and industrial piping systems. The calculator can handle different types of steel pipes, including carbon steel, stainless steel, and alloy steel, each with its unique properties and applications.

How to Use the Standard Size Steel Pipe Weights Calculator

To use the Standard Size Steel Pipe Weights Calculator, users need to input the following parameters:

- Nominal diameter (in inches or millimeters)

- Wall thickness (in inches or millimeters)

- Length (in feet or meters)

- Material density (in pounds per cubic foot or kilograms per cubic meter)

The calculator will then provide the weight of the steel pipe in pounds or kilograms. Users can also select the unit of measurement for the output, making it easy to work with different units.

Factors Affecting Steel Pipe Weights

Several factors can affect the weight of steel pipes, including:

- Material density: Different materials have varying densities, which impact the overall weight of the pipe.

- Nominal diameter: The diameter of the pipe affects its weight, with larger diameters resulting in heavier pipes.

- Wall thickness: The thickness of the pipe's wall also influences its weight, with thicker walls resulting in heavier pipes.

- Length: The length of the pipe is a direct factor in its weight, with longer pipes being heavier.

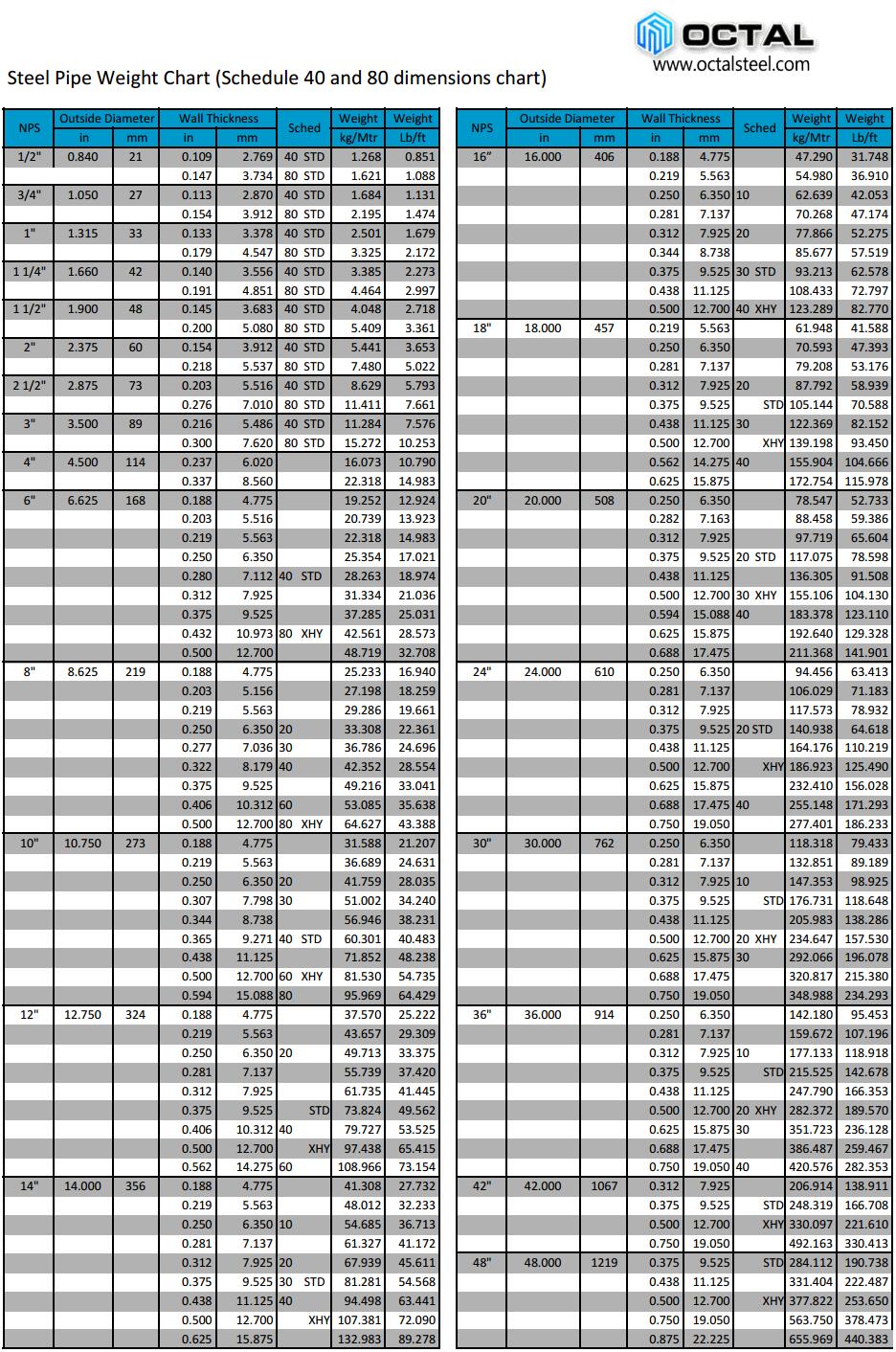

| Pipe Size | Wall Thickness | Length | Weight |

|---|---|---|---|

| 1 inch | 0.125 inches | 10 feet | 25 pounds |

| 2 inches | 0.25 inches | 20 feet | 100 pounds |

Applications of the Standard Size Steel Pipe Weights Calculator

The Standard Size Steel Pipe Weights Calculator has various applications in industries where steel pipes are used. Some of the key applications include:

- Construction: Accurate weight calculations are essential for building construction, bridge construction, and other infrastructure projects.

- Engineering: The calculator is useful for mechanical engineers, civil engineers, and chemical engineers who design and develop piping systems.

- Manufacturing: The calculator helps manufacturers estimate the weight of steel pipes for production planning and quality control.

Benefits of Using the Standard Size Steel Pipe Weights Calculator

Using the Standard Size Steel Pipe Weights Calculator offers several benefits, including:

- Accurate weight calculations: The calculator provides accurate weight calculations, reducing errors and cost overruns.

- Time-saving: The calculator saves time and effort, as users can quickly estimate the weight of steel pipes without manual calculations.

- Improved planning: The calculator helps users plan and design piping systems more effectively, taking into account material properties and structural integrity.

How much does a 1 inch steel pipe weight per foot?

The weight of a 1 inch steel pipe per foot can vary depending on the schedule and type of pipe. Typically, a 1 inch schedule 40 steel pipe weighs around 1.68 pounds per foot, while a 1 inch schedule 80 steel pipe weighs around 2.17 pounds per foot. However, these values can vary depending on the specific application and manufacturer.

Understanding Steel Pipe Schedules

The schedule of a steel pipe refers to its wall thickness, which can affect its weight and strength. A higher schedule means a thicker wall, which can result in a heavier pipe. For example, a 1 inch schedule 40 steel pipe has a wall thickness of 0.133 inches, while a 1 inch schedule 80 steel pipe has a wall thickness of 0.179 inches. Here are some key points to consider:

- The schedule of a steel pipe is determined by its wall thickness, which is measured in inches.

- A higher schedule means a thicker wall, which can result in a heavier pipe.

- The weight of a steel pipe can vary depending on the schedule and type of pipe.

Types of Steel Pipe

There are several types of steel pipe, each with its own unique characteristics and applications. For example, seamless steel pipes are made from a single piece of steel, while welded steel pipes are made from multiple pieces of steel that are welded together. Here are some key points to consider:

- Seamless steel pipes are made from a single piece of steel, which can result in a stronger pipe.

- Welded steel pipes are made from multiple pieces of steel that are welded together, which can result in a weaker pipe.

- The type of steel pipe can affect its weight, strength, and durability.

Factors Affecting Steel Pipe Weight

Several factors can affect the weight of a steel pipe, including its schedule, type, and length. For example, a longer pipe will weigh more than a shorter pipe, while a pipe with a thicker wall will weigh more than a pipe with a thinner wall. Here are some key points to consider:

- The length of a steel pipe can affect its weight, with longer pipes weighing more than shorter pipes.

- The schedule of a steel pipe can affect its weight, with higher schedules resulting in heavier pipes.

- The type of steel pipe can affect its weight, with seamless pipes weighing more than welded pipes.

Calculating Steel Pipe Weight

To calculate the weight of a steel pipe, you will need to know its length, schedule, and type. You can use a formula or a chart to calculate the weight of the pipe. For example, you can use the following formula: weight = (length x schedule x type) / constant. Here are some key points to consider:

- To calculate the weight of a steel pipe, you will need to know its length, schedule, and type.

- You can use a formula or a chart to calculate the weight of the pipe.

- The constant in the formula will depend on the unit of measurement, such as pounds per foot.

Applications of Steel Pipe

Steel pipes are used in a variety of applications, including plumbing, heating, and cooling systems. They are also used in industrial settings, such as oil and gas pipelines. The weight of the pipe can be an important factor in these applications, as it can affect the stability and safety of the system. Here are some key points to consider:

- Steel pipes are used in a variety of applications, including plumbing, heating, and cooling systems.

- The weight of the pipe can be an important factor in these applications, as it can affect the stability and safety of the system.

- The type and schedule of the pipe can also be important factors in these applications, as they can affect the strength and durability of the pipe.

How much does sch 80 pipe weigh per foot?

The weight of SCH 80 pipe per foot depends on the material and size of the pipe. For example, a 1-inch SCH 80 pipe made of carbon steel can weigh around 2.17 pounds per foot, while a 12-inch SCH 80 pipe made of the same material can weigh around 43.77 pounds per foot. It's essential to check the specifications of the pipe to determine its exact weight per foot.

Understanding SCH 80 Pipe Weights

To calculate the weight of SCH 80 pipe per foot, you need to consider the pipe size, material, and schedule number. The schedule number refers to the wall thickness of the pipe, with higher numbers indicating thicker walls and heavier weights. Here are some factors to consider:

- The material density of the pipe, which affects its overall weight

- The pipe size, which determines the volume of material used to manufacture the pipe

- The wall thickness, which is specified by the schedule number and affects the pipe's strength and weight

Factors Affecting SCH 80 Pipe Weights

Several factors can influence the weight of SCH 80 pipe per foot, including the manufacturing process, material composition, and pipe dimensions. For instance, pipes made from stainless steel tend to be heavier than those made from carbon steel, while pipes with thicker walls are heavier than those with thinner walls. Here are some key factors to consider:

- The type of material used to manufacture the pipe, such as carbon steel, stainless steel, or aluminum

- The manufacturing process, which can affect the pipe's density and weight

- The pipe dimensions, including the outside diameter, inside diameter, and wall thickness

Calculating SCH 80 Pipe Weights

To calculate the weight of SCH 80 pipe per foot, you can use a pipe weight calculator or consult a pipe weight chart. These resources provide the weight per foot for different pipe sizes and materials. Here are some steps to follow:

- Determine the pipe size and material to find the corresponding weight per foot

- Use a pipe weight calculator or consult a pipe weight chart to find the weight per foot

- Consider any additional factors, such as pipe fittings or valves, that may affect the overall weight of the pipe

Applications of SCH 80 Pipe

SCH 80 pipe is commonly used in various industrial applications, including oil and gas, chemical processing, and power generation. The heavy-duty nature of SCH 80 pipe makes it suitable for high-pressure and high-temperature applications. Here are some examples:

- Oil and gas pipelines, where SCH 80 pipe is used to transport crude oil and natural gas

- Chemical processing plants, where SCH 80 pipe is used to handle corrosive and toxic substances

- Power generation, where SCH 80 pipe is used in boilers and heat exchangers

Importance of Accurate Pipe Weights

Accurate pipe weights are crucial in engineering and construction projects, as they affect the structural integrity and safety of the pipeline. Inaccurate pipe weights can lead to design errors, installation problems, and maintenance issues. Here are some reasons why accurate pipe weights are important:

- Structural integrity, as pipe weights affect the stress and strain on the pipeline

- Safety, as inaccurate pipe weights can lead to accidents and injuries

- Cost savings, as accurate pipe weights can help reduce waste and optimize materials

Frequently Asked Questions (FAQs)

What is the Standard Size Steel Pipe Weights Calculator and how does it work?

The Standard Size Steel Pipe Weights Calculator is a tool designed to calculate the weight of steel pipes based on their size, material, and wall thickness. This calculator is widely used in the engineering and construction industries to determine the weight of steel pipes for various applications, such as plumbing, piping, and structural purposes. The calculator takes into account the nominal diameter, schedule, and length of the pipe to provide an accurate calculation of its weight. By using the Standard Size Steel Pipe Weights Calculator, users can quickly and easily determine the weight of steel pipes, which is essential for design, planning, and budgeting purposes.

What are the benefits of using the Standard Size Steel Pipe Weights Calculator?

The Standard Size Steel Pipe Weights Calculator offers several benefits to users, including accuracy, efficiency, and convenience. By using this calculator, users can avoid manual calculations, which can be time-consuming and prone to errors. The calculator provides instant results, allowing users to quickly determine the weight of steel pipes and make informed decisions. Additionally, the Standard Size Steel Pipe Weights Calculator helps users to save time and reduce costs by minimizing the need for manual calculations and reducing errors. Furthermore, the calculator is easy to use, even for users who are not familiar with complex calculations, making it a valuable tool for a wide range of industries and applications.

How does the Standard Size Steel Pipe Weights Calculator account for different types of steel pipes?

The Standard Size Steel Pipe Weights Calculator takes into account different types of steel pipes, including carbon steel, stainless steel, and alloy steel. The calculator considers the density of each type of steel, as well as the wall thickness and schedule, to provide an accurate calculation of the weight. For example, carbon steel pipes have a different density than stainless steel pipes, and the calculator adjusts the weight calculation accordingly. The calculator also accounts for different pipe sizes, including nominal diameters and actual diameters, to ensure that the weight calculation is accurate. By considering these factors, the Standard Size Steel Pipe Weights Calculator provides a comprehensive and reliable calculation of the weight of steel pipes.

Can the Standard Size Steel Pipe Weights Calculator be used for other types of pipes, such as copper or PVC pipes?

The Standard Size Steel Pipe Weights Calculator is specifically designed for steel pipes, and it is not intended for use with other types of pipes, such as copper or PVC pipes. While the calculator can be modified to accommodate other types of pipes, it is not recommended to use it for non-steel pipes without proper validation and verification. The density and properties of copper and PVC pipes are different from those of steel pipes, and using the calculator for these types of pipes could result in inaccurate calculations. However, users can contact the developer of the calculator to request a customized version that can accommodate other types of pipes, or to suggest new features and improvements to the existing calculator. By using the Standard Size Steel Pipe Weights Calculator for its intended purpose, users can ensure accurate and reliable results for steel pipes.

Deja una respuesta

Entradas Relacionadas