Pipe Thread Pitch Diameter Formulas and Calculator

The pipe thread pitch diameter is a critical parameter in determining the strength and leakage integrity of threaded pipe connections. Understanding the formulas and calculations involved in determining the pitch diameter is essential for engineers and technicians working with piping systems. This article provides an overview of the formulas and calculations used to determine the pitch diameter of pipe threads, as well as a calculator tool to simplify the process and ensure accurate results. The formulas and calculator presented here can be applied to various pipe thread types and sizes.

- Pipe Thread Pitch Diameter Formulas and Calculator

- What is the formula for thread pitch diameter?

- What is the formula for pipe threading?

- How to calculate NPT thread pitch?

- How to measure thread pitch and diameter?

-

Frequently Asked Questions (FAQs)

- What is the significance of Pipe Thread Pitch Diameter Formulas and Calculator in engineering applications?

- How do Pipe Thread Pitch Diameter Formulas and Calculator help in ensuring the quality of pipe connections?

- What are the key factors that affect the calculation of Pipe Thread Pitch Diameter using the formulas and calculator?

- How can engineers use the Pipe Thread Pitch Diameter Formulas and Calculator to optimize their pipe connection designs?

Pipe Thread Pitch Diameter Formulas and Calculator

The Pipe Thread Pitch Diameter Formulas and Calculator are essential tools in the field of piping and tubing. These formulas and calculators are used to determine the pitch diameter of a pipe thread, which is the diameter of the thread at a point where the thread depth is equal to half of the thread pitch. The pitch diameter is a critical parameter in determining the strength and leak-tightness of a pipe connection.

Understanding Pipe Thread Pitch Diameter Formulas

The pipe thread pitch diameter formulas are based on the American National Standard for pipe threads, which defines the dimensions and tolerances for pipe threads. The formulas take into account the nominal diameter of the pipe, the thread pitch, and the thread depth. The pitch diameter is calculated using the formula:

D = (Dn - 0.5P) / 2

where D is the pitch diameter, Dn is the nominal diameter, and P is the thread pitch.

Pipe Thread Pitch Diameter Calculator

A pipe thread pitch diameter calculator is a tool that uses the formulas to calculate the pitch diameter of a pipe thread. The calculator typically requires the user to input the nominal diameter and thread pitch of the pipe, and then calculates the pitch diameter using the formula. Some calculators may also provide additional information, such as the thread depth and major diameter.

Applications of Pipe Thread Pitch Diameter Formulas and Calculator

The pipe thread pitch diameter formulas and calculator have a wide range of applications in the field of piping and tubing. These include:

Determining the strength and leak-tightness of a pipe connection

Selecting the correct thread size and type for a pipe connection

Verifying the thread dimensions of a pipe or fitting

Ensuring compatibility between pipes and fittings from different manufacturers

Factors Affecting Pipe Thread Pitch Diameter

Several factors can affect the pipe thread pitch diameter, including:

Thread pitch: The number of threads per inch

Thread depth: The depth of the thread

Nominal diameter: The diameter of the pipe

Material: The type of material used for the pipe or fitting

Manufacturing process: The method used to manufacture the pipe or fitting

Comparison of Different Pipe Thread Types

There are several types of pipe threads, each with its own unique characteristics and applications. The following table compares some of the most common types of pipe threads:

| Thread Type | Description | Applications |

|---|---|---|

| NPT | National Pipe Taper | General-purpose piping and tubing |

| PTF | Pipe Thread Fine | Aerospace and high-pressure applications |

| SAE | Society of Automotive Engineers | Automotive and industrial applications |

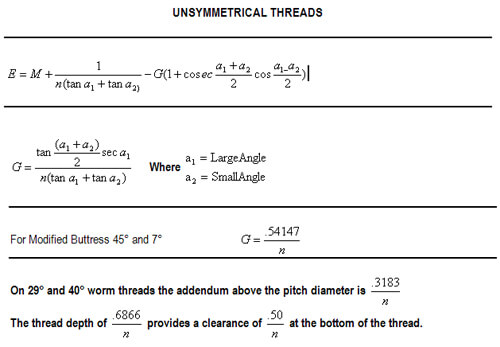

What is the formula for thread pitch diameter?

The formula for thread pitch diameter is calculated using the following equation: D = (Major Diameter - (0.5 x Pitch x sec(1/2 x Thread Angle))). This formula takes into account the major diameter, pitch, and thread angle to determine the pitch diameter. The pitch diameter is an important dimension in threaded fasteners as it affects the thread engagement and overall strength of the joint.

Understanding the Components of the Formula

The formula for thread pitch diameter involves several key components, including major diameter, pitch, and thread angle. To calculate the pitch diameter, one must first understand the terminology and significance of these components. The formula can be broken down into the following steps:

- Identify the major diameter, which is the largest diameter of the thread.

- Determine the pitch, which is the distance between threads.

- Calculate the thread angle, which is the angle between the threads.

Importance of Thread Pitch Diameter in Engineering

The thread pitch diameter plays a crucial role in engineering applications, particularly in the design and manufacture of threaded fasteners. A correct calculation of the thread pitch diameter ensures proper thread engagement, which is essential for the integrity and safety of the joint. The thread pitch diameter also affects the strength and stability of the connection.

- The thread pitch diameter influences the torque required to tighten or loosen the fastener.

- A smaller thread pitch diameter can result in a stronger joint.

- An accurate calculation of the thread pitch diameter is necessary to avoid thread stripping or galling.

Calculation Methods for Thread Pitch Diameter

There are various methods to calculate the thread pitch diameter, including analytical and numerical approaches. The choice of method depends on the complexity of the thread geometry and the required accuracy. Some common methods include:

- Using thread tables or charts to determine the pitch diameter based on the major diameter and pitch.

- Employing mathematical models to calculate the pitch diameter using the thread angle and pitch.

- Utilizing computer-aided design (CAD) software to simulate and calculate the pitch diameter.

Factors Affecting Thread Pitch Diameter

Several factors can influence the thread pitch diameter, including material properties, manufacturing processes, and thread geometry. These factors can affect the accuracy and reliability of the thread pitch diameter calculation. For example:

- The material properties, such as elasticity and hardness, can impact the thread deformation and engagement.

- The manufacturing process, such as cutting or rolling, can influence the thread accuracy and surface finish.

- The thread geometry, including the thread angle and pitch, can affect the thread strength and stability.

Applications of Thread Pitch Diameter in Industry

The thread pitch diameter has numerous applications in various industries, including aerospace, automotive, and construction. The accuracy and reliability of the thread pitch diameter calculation are critical in these applications, as they can impact the safety and performance of the system or structure. Some examples include:

- Aerospace engineering, where threaded fasteners are used in aircraft and spacecraft components.

- Automotive engineering, where threaded fasteners are used in vehicle components, such as engines and transmissions.

- Construction engineering, where threaded fasteners are used in building and bridge components.

What is the formula for pipe threading?

The formula for pipe threading is based on the thread angle, thread pitch, and nominal pipe size. To calculate the thread depth, you can use the following formula: Thread Depth = (0.54127 x Thread Pitch) / (2 x tan(Thread Angle / 2)). This formula is essential for ensuring that the threaded pipe connections are secure and leak-free.

Pipe Threading Basics

Pipe threading involves cutting threads into the end of a pipe to create a connection with another pipe or fitting. The process requires a thorough understanding of the thread geometry, including the thread angle, pitch, and depth. To achieve accurate pipe threading, it's crucial to use the correct threading tools and follow established threading standards.

- The American National Standards Institute (ANSI) provides guidelines for pipe threading, including the standard thread forms and sizes.

- The thread angle is typically 60 degrees for most pipe threading applications.

- The thread pitch varies depending on the pipe size and material, with smaller pipes having a finer thread pitch.

Thread Pitch and Depth Calculation

The thread pitch and depth are critical factors in determining the thread strength and sealing ability of the pipe connection. The thread pitch is calculated based on the number of threads per inch, while the thread depth is determined by the thread form and material properties. By using the correct thread pitch and depth, you can ensure that the pipe connection is leak-free and secure.

- The thread pitch is calculated as the reciprocal of the number of threads per inch.

- The thread depth is typically between 0.5 and 0.7 times the thread pitch.

- The thread form can be either straight or tapered, depending on the application and pipe material.

Pipe Threading Tools and Equipment

Pipe threading requires specialized tools and equipment, including pipe threading machines, dies, and chasing tools. The choice of tool depends on the pipe size, material, and thread form. It's essential to use the correct tools to achieve accurate and efficient pipe threading.

- The pipe threading machine is used to cut the threads into the pipe.

- The die is used to form the thread shape and size.

- The chasing tool is used to clean and deburr the threads after cutting.

Thread Geometry and Tolerancing

The thread geometry and tolerancing are critical factors in ensuring that the pipe connection is secure and leak-free. The thread geometry includes the thread angle, pitch, and depth, while tolerancing refers to the allowable deviations from the nominal thread dimensions. By controlling the thread geometry and tolerancing, you can achieve consistent and reliable pipe threading.

- The thread angle tolerance is typically ±1 degree.

- The thread pitch tolerance is typically ±0.01 inches.

- The thread depth tolerance is typically ±0.01 inches.

Pipe Material and Threading Considerations

The pipe material and threading considerations are essential factors in determining the thread strength and sealing ability of the pipe connection. Different pipe materials, such as copper, steel, and plastic, have varying threading requirements and limitations. By understanding the pipe material and threading considerations, you can ensure that the pipe connection is safe and reliable.

- The pipe material affects the thread strength and corrosion resistance.

- The threading process can affect the pipe material properties.

- The threading considerations include factors such as thread lubrication and thread protection.

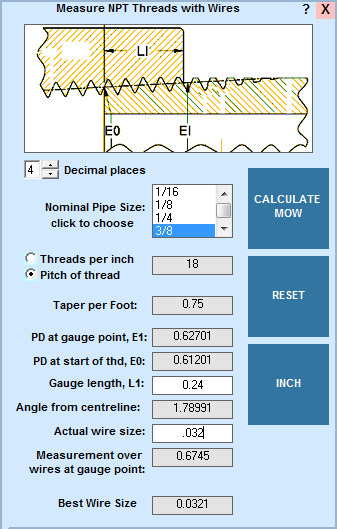

How to calculate NPT thread pitch?

To calculate the NPT thread pitch, you need to understand the basic components of the thread. The NPT (National Pipe Taper) thread is a type of thread used for piping and tubing in various industries. The thread pitch is the distance between two consecutive threads, measured in threads per inch (TPI). The calculation of the thread pitch involves determining the number of threads per inch and the diameter of the thread.

Understanding NPT Thread Basics

To calculate the NPT thread pitch, you need to understand the basics of the thread, including the major diameter, minor diameter, and pitch diameter. The major diameter is the outer diameter of the thread, while the minor diameter is the inner diameter. The pitch diameter is the average diameter of the thread. The calculation of the thread pitch involves using these diameters to determine the number of threads per inch.

- The major diameter is the outer diameter of the thread, which is the largest diameter of the thread.

- The minor diameter is the inner diameter of the thread, which is the smallest diameter of the thread.

- The pitch diameter is the average diameter of the thread, which is used to calculate the thread pitch.

Calculating Thread Pitch

The calculation of the NPT thread pitch involves using the pitch diameter and the number of threads to determine the thread pitch. The thread pitch is calculated by dividing the pitch diameter by the number of threads per inch. This gives you the distance between threads, which is the thread pitch.

- Determine the pitch diameter of the thread, which is the average diameter of the thread.

- Determine the number of threads per inch (TPI), which is the number of threads in one inch of the thread.

- Calculate the thread pitch by dividing the pitch diameter by the number of threads per inch.

Using Thread Pitch Tables

Another way to calculate the NPT thread pitch is to use thread pitch tables. These tables provide the thread pitch for different sizes of NPT threads. By looking up the thread size in the table, you can determine the thread pitch.

- Look up the thread size in the thread pitch table to determine the thread pitch.

- Use the thread pitch table to determine the major diameter, minor diameter, and pitch diameter of the thread.

- Verify the thread pitch by calculating it using the pitch diameter and number of threads per inch.

Measuring Thread Pitch

The thread pitch can also be measured using a thread pitch gauge or a caliper. The thread pitch gauge is a tool specifically designed to measure the thread pitch, while a caliper can be used to measure the diameter of the thread and calculate the thread pitch.

- Use a thread pitch gauge to measure the thread pitch directly.

- Use a caliper to measure the diameter of the thread and calculate the thread pitch.

- Verify the measurement by comparing it to the calculated thread pitch.

Importance of Accurate Thread Pitch

Accurate calculation of the NPT thread pitch is critical for ensuring proper fitting and functioning of the piping system. An incorrect thread pitch can result in leaks, damage to the threads, and reduced system performance.

- Ensure accurate calculation of the thread pitch to prevent leaks and damage to the threads.

- Use high-quality threads and threading tools to ensure accurate thread pitch.

- Verify the thread pitch regularly to ensure proper fitting and functioning of the piping system.

How to measure thread pitch and diameter?

To measure thread pitch and diameter, you need to use a combination of tools and techniques. The thread pitch is the distance between two consecutive threads, while the diameter is the overall size of the thread. Measuring these values accurately is crucial in various industries, such as manufacturing, engineering, and construction.

Understanding Thread Pitch

Measuring thread pitch requires a pitch gauge or a thread gauge, which is a specialized tool designed to measure the distance between threads. To measure the thread pitch, place the pitch gauge on the thread and adjust it until the threads match. Then, read the measurement from the gauge. Here are the steps to measure thread pitch:

- Choose the correct pitch gauge for the thread type

- Place the pitch gauge on the thread and adjust it until the threads match

- Read the measurement from the gauge and record the thread pitch value

Measuring Thread Diameter

Measuring thread diameter requires a caliper or a micrometer, which are precision instruments used to measure the size of an object. To measure the thread diameter, place the caliper or micrometer around the thread and take the measurement. Here are the steps to measure thread diameter:

- Choose the correct caliper or micrometer for the thread size

- Place the caliper or micrometer around the thread and take the measurement

- Read the measurement from the instrument and record the thread diameter value

Using Thread Measuring Tools

There are various thread measuring tools available, including thread gauges, pitch gauges, calipers, and micrometers. Each tool has its own specific use and application. To choose the correct thread measuring tool, consider the type of thread, the size of the thread, and the level of precision required. Here are some common thread measuring tools:

- Thread gauges for measuring thread pitch and diameter

- Pitch gauges for measuring thread pitch

- Calipers for measuring thread diameter

Thread Measurement Techniques

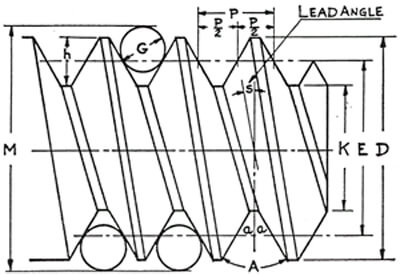

There are various thread measurement techniques used to measure thread pitch and diameter, including the three-wire method and the two-wire method. The three-wire method involves using three wires of different diameters to measure the thread pitch, while the two-wire method involves using two wires to measure the thread diameter. Here are the steps for the three-wire method:

- Choose three wires of different diameters

- Place the wires on the thread and measure the distance between them

- Calculate the thread pitch using the measurements

Critical Factors in Thread Measurement

There are several critical factors to consider when measuring thread pitch and diameter, including precision, accuracy, and repeatability. Precision refers to the ability of the measuring tool to produce consistent results, while accuracy refers to the ability of the measuring tool to produce results that are close to the true value. Repeatability refers to the ability of the measuring tool to produce the same results under different conditions. Here are some critical factors to consider:

- Precision of the measuring tool

- Accuracy of the measuring tool

- Repeatability of the measuring results

Frequently Asked Questions (FAQs)

What is the significance of Pipe Thread Pitch Diameter Formulas and Calculator in engineering applications?

The Pipe Thread Pitch Diameter Formulas and Calculator is a crucial tool in engineering, particularly in the fields of mechanical engineering and civil engineering. It is used to calculate the pitch diameter of pipe threads, which is essential in ensuring the proper fitting and sealing of pipes. The pitch diameter is the distance between the threads on a pipe, and it must be accurately calculated to ensure that the pipe can be properly connected to other pipes or fittings. The formulas used to calculate the pitch diameter take into account various factors, including the pipe size, thread type, and material properties. By using the Pipe Thread Pitch Diameter Formulas and Calculator, engineers can ensure that their pipe connections are safe, reliable, and efficient.

How do Pipe Thread Pitch Diameter Formulas and Calculator help in ensuring the quality of pipe connections?

The Pipe Thread Pitch Diameter Formulas and Calculator play a vital role in ensuring the quality of pipe connections by providing accurate calculations of the pitch diameter. This is particularly important in high-pressure and high-temperature applications, where pipe failures can have catastrophic consequences. By using the formulas and calculator, engineers can ensure that the pipe threads are properly dimensioned and toleranced, which helps to prevent leaks, corrosion, and other failures. Additionally, the calculator can help engineers to optimize their pipe connections by selecting the most suitable thread type and material for their specific application. This can help to reduce costs, improve safety, and increase efficiency.

What are the key factors that affect the calculation of Pipe Thread Pitch Diameter using the formulas and calculator?

The calculation of Pipe Thread Pitch Diameter using the formulas and calculator is affected by several key factors, including the pipe size, thread type, material properties, and tolerances. The pipe size is a critical factor, as it determines the nominal diameter of the pipe, which is used as a reference point for calculating the pitch diameter. The thread type is also important, as different thread types have different pitch diameters and thread forms. The material properties, such as the strength and ductility of the pipe material, also play a significant role in determining the pitch diameter. Finally, the tolerances on the pipe threads and fittings must be carefully considered to ensure that the connection is properly dimensioned and assembled.

How can engineers use the Pipe Thread Pitch Diameter Formulas and Calculator to optimize their pipe connection designs?

Engineers can use the Pipe Thread Pitch Diameter Formulas and Calculator to optimize their pipe connection designs by iterating on different design parameters, such as the pipe size, thread type, and material. By using the calculator to quickly and accurately calculate the pitch diameter for different design scenarios, engineers can compare and evaluate the performance of different design options. This can help them to identify the most suitable design solution for their specific application, taking into account factors such as cost, safety, and efficiency. Additionally, the formulas and calculator can be used to validate and verify the design of existing pipe connections, helping to identify and address any potential issues or problems. By using the Pipe Thread Pitch Diameter Formulas and Calculator in this way, engineers can ensure that their pipe connections are reliable, safe, and efficient, and that they meet the required standards and regulations.

Deja una respuesta

Entradas Relacionadas