Pipe Flow Flow Rate and Velocity Equations and Calculator

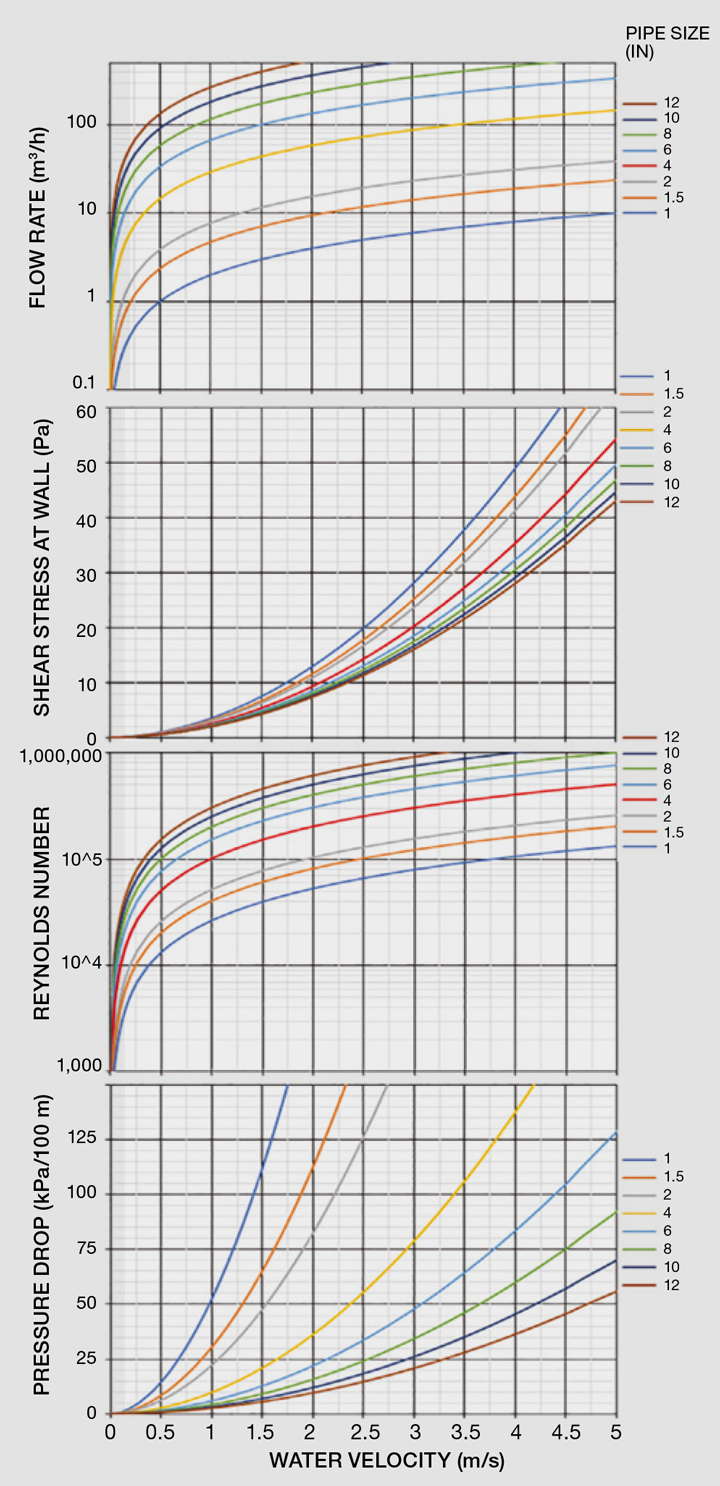

The flow rate and velocity of fluids in pipes are crucial parameters in various engineering applications, including hydraulic systems, water supply networks, and chemical processing plants. Calculating these parameters accurately is essential to ensure efficient and safe operation of these systems. The pipe flow flow rate and velocity equations provide a mathematical framework for determining these parameters. This article presents a comprehensive overview of these equations, along with a calculator to simplify the calculation process, enabling engineers and technicians to quickly and accurately determine flow rates and velocities in pipes. The calculator is based on standard hydraulic formulas.

- Pipe Flow Flow Rate and Velocity Equations and Calculator

- How do you calculate velocity from flow rate in a pipe?

- What is the rule of thumb for pipe flow velocity?

- How do you calculate pipeline velocity?

-

Frequently Asked Questions (FAQs)

- What are the key factors that affect the flow rate and velocity of a fluid in a pipe?

- How do the equations for pipe flow rate and velocity differ from those for other types of fluid flow?

- What are some common applications of pipe flow rate and velocity calculations in engineering practice?

- How can a pipe flow rate and velocity calculator be used to optimize pipe flow systems and improve performance?

Pipe Flow Flow Rate and Velocity Equations and Calculator

The calculation of flow rate and velocity in pipe flow is crucial for various engineering applications, including water supply systems, hydraulic systems, and chemical processing plants. The flow rate and velocity of a fluid in a pipe can be calculated using various equations, including the continuity equation, Bernoulli's equation, and the Darcy-Weisbach equation. These equations take into account factors such as the pipe's diameter, length, and roughness, as well as the fluid's density, viscosity, and pressure.

Introduction to Pipe Flow Equations

The study of pipe flow equations is essential for understanding the behavior of fluids in pipes. The continuity equation states that the mass flow rate of a fluid remains constant throughout a pipe, while Bernoulli's equation relates the pressure and velocity of a fluid in a pipe. The Darcy-Weisbach equation is used to calculate the friction loss in a pipe due to the fluid's viscosity and the pipe's roughness. These equations are used to calculate the flow rate and velocity of a fluid in a pipe, and are essential for designing and optimizing pipe flow systems.

Flow Rate Calculations

The flow rate of a fluid in a pipe can be calculated using the continuity equation, which states that the mass flow rate of a fluid remains constant throughout a pipe. The flow rate can be calculated using the following equation: Q = A v, where Q is the flow rate, A is the cross-sectional area of the pipe, and v is the velocity of the fluid. The flow rate can also be calculated using the Darcy-Weisbach equation, which takes into account the friction loss in the pipe due to the fluid's viscosity and the pipe's roughness.

| Parameter | Unit | Description |

|---|---|---|

| Q | m³/s | Flow rate |

| A | m² | Cross-sectional area |

| v | m/s | Velocity |

Velocty Calculations

The velocity of a fluid in a pipe can be calculated using the continuity equation and the Bernoulli's equation. The velocity can be calculated using the following equation: v = Q / A, where v is the velocity, Q is the flow rate, and A is the cross-sectional area of the pipe. The velocity can also be calculated using the Darcy-Weisbach equation, which takes into account the friction loss in the pipe due to the fluid's viscosity and the pipe's roughness.

Pipe Flow Calculator

A pipe flow calculator is a tool used to calculate the flow rate and velocity of a fluid in a pipe. The calculator uses the continuity equation, Bernoulli's equation, and the Darcy-Weisbach equation to calculate the flow rate and velocity of the fluid. The calculator takes into account factors such as the pipe's diameter, length, and roughness, as well as the fluid's density, viscosity, and pressure. The calculator can be used to design and optimize pipe flow systems, and to calculate the friction loss in a pipe due to the fluid's viscosity and the pipe's roughness.

Applications of Pipe Flow Equations

The pipe flow equations have various applications in engineering, including the design and optimization of water supply systems, hydraulic systems, and chemical processing plants. The equations are used to! calculate the flow rate and velocity of a fluid in a pipe, and to design and optimize pipe flow systems. The equations are also used to calculate the friction loss in a pipe due to the fluid's viscosity and the pipe's roughness, and to design and optimize pipe flow systems to minimize energy losses. The continuity equation, Bernoulli's equation, and the Darcy-Weisbach equation are essential for understanding the behavior of fluids in pipes, and are widely used in various engineering applications.

How do you calculate velocity from flow rate in a pipe?

To calculate velocity from flow rate in a pipe, you can use the formula: velocity = flow rate / cross-sectional area. This formula is based on the principle of conservation of mass, which states that the mass flow rate of a fluid remains constant throughout a pipe. By rearranging the formula, you can solve for velocity: velocity = flow rate / (π (diameter/2)^2), where diameter is the diameter of the pipe.

Understanding the Formula

The formula to calculate velocity from flow rate is based on the principles of fluid dynamics. The flow rate is the volume of fluid that flows through a pipe per unit time, typically measured in cubic meters per second (m^3/s) or gallons per minute (gpm). The cross-sectional area of the pipe is the area of the pipe that the fluid flows through, typically measured in square meters (m^2) or square inches (in^2). To calculate velocity, you need to know the flow rate and the cross-sectional area of the pipe. Here are the steps to follow:

- Measure the flow rate of the fluid in the pipe using a flow meter or other device.

- Measure the diameter of the pipe to calculate the cross-sectional area.

- Use the formula to calculate the velocity of the fluid in the pipe.

Factors Affecting Velocity

There are several factors that can affect the velocity of a fluid in a pipe, including the viscosity of the fluid, the roughness of the pipe, and the pressure of the fluid. Viscosity is a measure of the fluid's resistance to flow, with higher viscosities resulting in lower velocities. Roughness of the pipe can also affect velocity, as rougher pipes can cause more turbulence and reduce the velocity of the fluid. Pressure of the fluid can also affect velocity, as higher pressures can result in higher velocities.

- The viscosity of the fluid can affect the velocity of the fluid in the pipe.

- The roughness of the pipe can cause turbulence and reduce the velocity of the fluid.

- The pressure of the fluid can affect the velocity of the fluid in the pipe.

Measuring Flow Rate

Flow rate can be measured using a variety of devices, including flow meters and venturi tubes. Flow meters are devices that measure the flow rate of a fluid in a pipe, typically by measuring the pressure or volume of the fluid. Venturi tubes are devices that measure the flow rate of a fluid by creating a constriction in the pipe, which increases the velocity of the fluid and allows for measurement of the flow rate. To measure flow rate, you need to follow these steps:

- Choose a flow meter or other device that is suitable for the fluid and pipe size.

- Install the flow meter or device in the pipe according to the manufacturer's instructions.

- Read the flow rate from the device and record the data.

Calculating Cross-Sectional Area

The cross-sectional area of a pipe can be calculated using the formula: area = π (diameter/2)^2. This formula is based on the geometry of a circle, where the diameter is the distance across the circle and the radius is half the diameter. To calculate the cross-sectional area, you need to know the diameter of the pipe. Here are the steps to follow:

- Measure the diameter of the pipe using a caliper or other device.

- Calculate the radius of the pipe by dividing the diameter by 2.

- Use the formula to calculate the cross-sectional area of the pipe.

Applications of Velocity Calculation

Calculating velocity from flow rate has several applications in fluid dynamics and engineering, including designing pipelines and pumps, and optimizing fluid flow systems. By calculating the velocity of a fluid in a pipe, engineers can design pipelines and pumps that are efficient and effective, and optimize fluid flow systems to reduce energy consumption and increase productivity. Here are some examples of applications:

- Designing pipelines and pumps for water supply systems.

- Optimizing fluid flow systems in chemical processing plants.

- Designing hydraulic systems for heavy machinery and equipment.

What is the rule of thumb for pipe flow velocity?

The rule of thumb for pipe flow velocity is to maintain a velocity between 2 and 5 feet per second (fps) to minimize the risk of erosion and corrosion. This velocity range allows for efficient transportation of fluids while reducing the likelihood of damage to the pipe and its components. It's essential to consider the viscosity and density of the fluid, as well as the pipe material and diameter, when determining the optimal flow velocity.

Factors Affecting Pipe Flow Velocity

The flow rate and pipe size are critical factors in determining the optimal pipe flow velocity. A larger pipe diameter can accommodate higher flow rates without exceeding the recommended velocity range. Consider the following factors:

- Fluid properties: Viscosity, density, and surface tension affect the flow velocity.

- Pipe material: The roughness and corrosion resistance of the pipe material impact the flow velocity.

- System pressure: The pressure drop across the pipe affects the flow velocity and must be considered in system design.

Pipe Flow Velocity and System Design

When designing a piping system, it's crucial to consider the pipe flow velocity to ensure efficient and safe operation. A well-designed system should balance the flow rate, pipe size, and pump power to maintain the optimal velocity range. Consider the following:

- System layout: The pipe configuration and fittings used can impact the flow velocity and pressure drop.

- Pump selection: Choosing the right pump type and size is critical to maintaining the optimal flow velocity.

- Control valves: The valve type and sizing can affect the flow velocity and system pressure.

Consequences of High Pipe Flow Velocity

Exceeding the recommended pipe flow velocity can lead to erosion, corrosion, and cavitation, resulting in pipe damage and system downtime. It's essential to monitor the flow velocity and take corrective action if it exceeds the recommended range. Consider the following consequences:

- Pipe damage: High velocities can cause abrasion and corrosion, leading to pipe failure.

- System downtime: Pipe damage or failure can result in costly repairs and downtime.

- Environmental impact: Leaks or spills can occur, posing environmental and health risks.

Pipe Flow Velocity Measurement and Monitoring

Measuring and monitoring the pipe flow velocity is crucial to ensuring the safe and efficient operation of the piping system. Various flow measurement devices can be used to monitor the flow velocity, including ultrasonic flow meters and venturi tubes. Consider the following:

- Flow measurement devices: Choose the right device type and size for accurate flow measurement.

- Installation location: Install flow measurement devices in a location that provides accurate and representative flow data.

- Data analysis: Regularly analyze flow data to identify trends and take corrective action if necessary.

Optimizing Pipe Flow Velocity for Efficient System Operation

Optimizing the pipe flow velocity is critical to achieving efficient and cost-effective system operation. By maintaining the optimal velocity range, you can minimize energy consumption, reduce maintenance costs, and ensure system reliability. Consider the following optimization strategies:

- Pipe sizing: Optimize pipe size to balance flow rate and velocity.

- Pump optimization: Select the right pump type and size to match the system requirements.

- System design: Consider system layout and component selection to minimize pressure drop and optimize flow velocity.

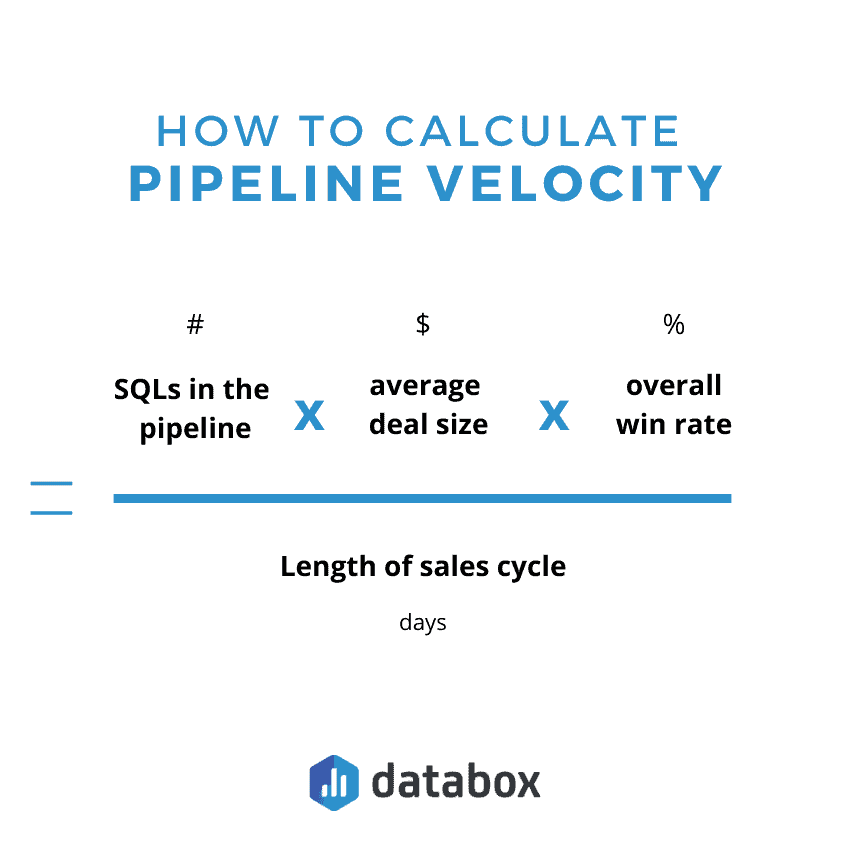

How do you calculate pipeline velocity?

To calculate pipeline velocity, you need to track the amount of work that is being completed by a team over a specific period of time. This can be done by measuring the number of user stories, tasks, or features that are being completed during each iteration or sprint. The velocity is then calculated by adding up the story points or task durations associated with each completed item.

Understanding Pipeline Velocity

Pipeline velocity is a key metric that helps teams understand their productivity and efficiency. To calculate pipeline velocity, teams need to define what constitutes a completed item and how to measure its size or complexity. This can be done using story points, task hours, or other estimation techniques. The team then needs to track the number of completed items over a specific period of time, such as a sprint or iteration, to calculate the velocity.

- The team needs to define what constitutes a completed item.

- The team needs to measure the size or complexity of each item using story points or task hours.

- The team needs to track the number of completed items over a specific period of time.

Methods for Calculating Pipeline Velocity

There are several methods for calculating pipeline velocity, including the story point method, the task hour method, and the cycle time method. The story point method involves assigning a story point value to each item based on its size or complexity, and then calculating the total number of story points completed during each iteration. The task hour method involves estimating the number of hours required to complete each item, and then calculating the total number of hours completed during each iteration.

- The story point method is a popular way to calculate pipeline velocity.

- The task hour method is another way to calculate pipeline velocity.

- The cycle time method involves measuring the time it takes for an item to move through the pipeline.

Benefits of Calculating Pipeline Velocity

Calculating pipeline velocity provides several benefits, including improved forecasting, increased transparency, and better decision-making. By understanding the team's velocity, managers and stakeholders can make more informed decisions about project timelines and resource allocation. Additionally, calculating pipeline velocity helps teams identify bottlenecks and inefficiencies in the development process, which can be addressed through process improvements.

- Calculating pipeline velocity helps teams forecast more accurately.

- Calculating pipeline velocity provides increased transparency into the development process.

- Calculating pipeline velocity enables better decision-making about project timelines and resource allocation.

Challenges in Calculating Pipeline Velocity

There are several challenges associated with calculating pipeline velocity, including variations in team velocity, changes in scope, and inefficiencies in the development process. Teams need to be aware of these challenges and take steps to mitigate them, such as normalizing team velocity, re-estimating scope, and optimizing the development process.

- Variations in team velocity can make it difficult to calculate pipeline velocity.

- Changes in scope can impact the accuracy of pipeline velocity calculations.

- Inefficiencies in the development process can reduce pipeline velocity.

Tools for Calculating Pipeline Velocity

There are several tools available to help teams calculate pipeline velocity, including project management software, agile tools, and spreadsheet templates. These tools can help teams track completed items, estimate story points or task hours, and calculate velocity. Some popular tools for calculating pipeline velocity include Jira, Trello, and Excel.

- Jira is a popular tool for calculating pipeline velocity.

- Trello is another tool that can be used to calculate pipeline velocity.

- Excel can be used to create custom spreadsheet templates for calculating pipeline velocity.

Frequently Asked Questions (FAQs)

What are the key factors that affect the flow rate and velocity of a fluid in a pipe?

The flow rate and velocity of a fluid in a pipe are affected by several key factors, including the diameter of the pipe, the viscosity of the fluid, the density of the fluid, and the pressure difference between the two ends of the pipe. The flow rate, which is the volume of fluid that flows through the pipe per unit time, is also influenced by the roughness of the pipe surface and the length of the pipe. Additionally, the velocity of the fluid, which is the speed at which it flows through the pipe, is affected by the гравитационное acceleration and the friction between the fluid and the pipe wall. Understanding these factors is crucial for designing and optimizing pipe flow systems.

How do the equations for pipe flow rate and velocity differ from those for other types of fluid flow?

The equations for pipe flow rate and velocity are distinct from those for other types of fluid flow, such as open-channel flow or compressible flow, due to the unique characteristics of pipe flow. In particular, the Hagen-Poiseuille equation and the Darcy-Weisbach equation are commonly used to calculate the flow rate and velocity of incompressible fluids in circular pipes. These equations take into account the viscous effects and turbulent effects that occur in pipe flow, and are widely used in engineering applications such as water supply systems and oil pipelines. In contrast, other types of fluid flow, such as open-channel flow, require different equations and models to accurately predict the flow behavior.

What are some common applications of pipe flow rate and velocity calculations in engineering practice?

Pipe flow rate and velocity calculations have numerous practical applications in engineering practice, including the design and operation of water distribution systems, wastewater treatment plants, and oil and gas pipelines. These calculations are also essential for pumping system design, where the flow rate and velocity of the fluid must be carefully matched to the pump characteristics to ensure efficient and reliable operation. Additionally, pipe flow rate and velocity calculations are used in hydraulic engineering to design and optimize irrigation systems, stormwater drainage systems, and flood control systems. Furthermore, these calculations are critical in chemical engineering and process engineering, where the flow rate and velocity of fluids can impact the efficiency and safety of chemical reactions and process operations.

How can a pipe flow rate and velocity calculator be used to optimize pipe flow systems and improve performance?

A pipe flow rate and velocity calculator can be a powerful tool for optimizing pipe flow systems and improving performance. By inputting the relevant parameters, such as the pipe diameter, fluid properties, and pressure difference, the calculator can quickly and accurately determine the flow rate and velocity of the fluid. This information can then be used to identify bottlenecks and inefficiencies in the system, and to optimize the pipe size, pump selection, and operating conditions to achieve the desired flow rate and velocity. Additionally, the calculator can be used to evaluate the impact of design changes or operating conditions on the flow behavior, allowing engineers to refine and improve their designs. By using a pipe flow rate and velocity calculator, engineers can streamline their design and optimization process, reduce the risk of errors, and improve the overall performance and efficiency of the pipe flow system.

Deja una respuesta

Entradas Relacionadas