Helical Spring Fatigue Loading and Factor of Safety Formulas and Calculator

Helical spring fatigue loading is a critical consideration in engineering design, as it can lead to premature failure. The factor of safety is a crucial parameter in ensuring the reliability and longevity of springs under cyclic loading conditions. This article provides an overview of the key formulas and calculations used to determine the fatigue life and factor of safety of helical springs, along with a calculator to simplify the process. By understanding and applying these principles, engineers can design and optimize springs for a wide range of applications. The calculator will facilitate quick and accurate calculations.

- Helical Spring Fatigue Loading and Factor of Safety Formulas and Calculator

- What is the formula for factor of safety for spring?

- How do you calculate compression spring load?

- What is fatigue loading of spring?

-

Frequently Asked Questions (FAQs)

- What is Helical Spring Fatigue Loading and its Importance in Engineering Design?

- How do Factor of Safety Formulas and Calculators Work in Helical Spring Design?

- What are the Key Factors that Influence Helical Spring Fatigue Loading and Factor of Safety Calculations?

- How can Engineers Use Helical Spring Fatigue Loading and Factor of Safety Formulas to Optimize their Designs?

Helical Spring Fatigue Loading and Factor of Safety Formulas and Calculator

Helical springs are a type of compression spring that is commonly used in various applications, including automotive, aerospace, and industrial machinery. These springs are designed to store energy and release it when needed, but they can be prone to fatigue failure due to repeated loading and unloading cycles. The fatigue loading of helical springs is a critical consideration in design and engineering, as it can lead to premature failure and potentially catastrophic consequences.

Introduction to Helical Spring Fatigue Loading

Helical spring fatigue loading occurs when the spring is subjected to repeated cycles of loading and unloading, causing the material to degrade over time. This can lead to crack initiation and propagation, ultimately resulting in spring failure. The factor of safety is a critical consideration in helical spring design, as it takes into account the ultimate strength of the material and the applied loads to ensure that the spring can withstand the expected loading conditions.

Factors Affecting Helical Spring Fatigue Loading

Several factors can affect the fatigue loading of helical springs, including the spring material, design parameters, and operating conditions. The spring material can affect the fatigue strength of the spring, with some materials being more resistant to fatigue than others. The design parameters, such as the spring diameter, wire diameter, and number of coils, can also impact the fatigue loading of the spring. Additionally, operating conditions, such as temperature, humidity, and vibration, can influence the fatigue loading of the spring.

Helical Spring Fatigue Loading Formulas

Several formulas can be used to calculate the fatigue loading of helical springs, including the S-N curve and the Palmgren-Miner rule. The S-N curve is a plot of the stress versus the number of cycles that a spring can withstand before failing, while the Palmgren-Miner rule is a method for calculating the cumulative damage of a spring under varying loading conditions.

Factor of Safety Formulas for Helical Springs

The factor of safety for helical springs can be calculated using several formulas, including the static factor of safety and the dynamic factor of safety. The static factor of safety takes into account the ultimate strength of the material and the applied loads, while the dynamic factor of safety considers the fatigue strength of the material and the expected loading cycles.

Calculator for Helical Spring Fatigue Loading and Factor of Safety

A calculator can be used to simplify the calculation of helical spring fatigue loading and factor of safety. The calculator can take into account various input parameters, such as the spring material, design parameters, and operating conditions, to calculate the fatigue loading and factor of safety of the spring.

| Spring Material | Design Parameters | Operating Conditions | Fatigue Loading | Factor of Safety |

|---|---|---|---|---|

| Steel | Diameter: 10 mm, Wire diameter: 2 mm, Number of coils: 10 | Temperature: 20°C, Humidity: 50%, Vibration: 10 Hz | 1000 cycles | 1.5 |

| Aluminum | Diameter: 15 mm, Wire diameter: 3 mm, Number of coils: 15 | Temperature: 30°C, Humidity: 60%, Vibration: 20 Hz | 500 cycles | 2.0 |

What is the formula for factor of safety for spring?

The formula for the factor of safety for a spring is typically defined as the ratio of the ultimate strength of the spring material to the allowable stress or working stress. Mathematically, this can be expressed as: Factor of Safety (FoS) = Ultimate Strength / Allowable Stress. This formula is crucial in ensuring that the spring can withstand the expected loads and stresses without failing, thereby providing a margin of safety against unexpected events or material weaknesses.

Understanding Spring Design and Safety Factors

When designing a spring, engineers must consider several factors, including the material properties, operating conditions, and load requirements. The factor of safety is a critical component of this design process, as it helps to ensure that the spring can perform its intended function without failing. Key considerations include:

- Material selection: Choosing a material with appropriate strength and durability characteristics.

- Load calculation: Accurately determining the expected loads and stresses the spring will experience.

- Safety factor determination: Selecting an appropriate factor of safety based on the application and required reliability.

Importance of Material Properties in Spring Design

The material properties of a spring are essential in determining its factor of safety. Properties such as yield strength, tensile strength, and elongation at break are critical in assessing the spring's ability to withstand stresses and strains. By understanding these properties, designers can select materials that provide the necessary strength and durability for the application. Important material characteristics for spring design include:

- High strength-to-weight ratio: Allowing for efficient use of material while maintaining performance.

- Corrosion resistance: Protecting the spring from environmental degradation.

- Fatigue resistance: Ensuring the spring can withstand repeated loading and unloading cycles.

Calculating Allowable Stress for Spring Design

Calculating the allowable stress for a spring involves considering the ultimate strength of the material, the factor of safety, and any relevant design codes or standards. This calculation is critical in ensuring that the spring is not overloaded and that it operates within a safe and reliable envelope. Factors to consider when calculating allowable stress include:

- Ultimate tensile strength: The maximum stress the material can withstand without failing.

- Yield strength: The stress at which the material begins to deform plastically.

- Factor of safety: The ratio of ultimate strength to allowable stress, providing a margin against failure.

Factors Influencing the Factor of Safety for Springs

Several factors can influence the factor of safety for a spring, including the operating environment, load characteristics, and material properties. For example, springs operating in high-temperature or corrosive environments may require a higher factor of safety to account for potential material degradation. Other influential factors include:

- Cycle life: The number of load cycles the spring is expected to endure.

- Impact loads: Sudden or dynamic loads that can cause additional stress.

- Manufacturing variability: Potential variations in material properties or spring dimensions.

Applications and Considerations for Spring Safety Factors

The factor of safety for a spring can have significant implications for its application and performance. For example, in safety-critical applications such as aerospace or medical devices, a higher factor of safety may be required to ensure reliability and fail-safe operation. Key considerations for spring safety factors in different applications include:

- Weight and space constraints: Minimizing spring size and weight while maintaining performance.

- Cost and manufacturability: Balancing safety factors with production costs and feasibility.

- Regulatory compliance: Meeting relevant standards and certifications for the application.

How do you calculate compression spring load?

To calculate the compression spring load, you need to understand the spring's properties and the forces acting upon it. The compression spring load is calculated using the Hooke's Law, which states that the force exerted by a spring is proportional to its displacement from its equilibrium position. The spring constant is a critical factor in determining the compression spring load, and it is typically measured in units of force per unit length.

Understanding Spring Properties

To calculate the compression spring load, you need to understand the spring's properties, including its wire diameter, coil diameter, number of coils, and material properties. The spring's properties can be used to calculate the spring constant, which is essential for determining the compression spring load. Some key factors to consider when understanding spring properties include:

- The wire diameter and coil diameter affect the spring's stiffness and strength.

- The number of coils influences the spring's overall length and compression load.

- The material properties, such as elastic modulus and yield strength, determine the spring's ability to withstand loads.

Calculating Spring Constant

The spring constant is a critical factor in determining the compression spring load. The spring constant can be calculated using the spring's properties, including its wire diameter, coil diameter, and number of coils. The spring constant is typically measured in units of force per unit length, and it can be used to calculate the compression spring load. Some key factors to consider when calculating the spring constant include:

- The wire diameter and coil diameter affect the spring's stiffness and strength.

- The number of coils influences the spring's overall length and compression load.

- The material properties, such as elastic modulus and yield strength, determine the spring's ability to withstand loads.

Applying Hooke's Law

Hooke's Law states that the force exerted by a spring is proportional to its displacement from its equilibrium position. The Hooke's Law can be used to calculate the compression spring load by multiplying the spring constant by the displacement from the equilibrium position. Some key factors to consider when applying Hooke's Law include:

- The spring constant affects the force exerted by the spring.

- The displacement from the equilibrium position affects the force exerted by the spring.

- The spring's properties, such as wire diameter and coil diameter, influence the spring's stiffness and strength.

Considering Force and Displacement

The force and displacement are critical factors in calculating the compression spring load. The force exerted by the spring is proportional to its displacement from the equilibrium position, and the spring constant is used to calculate the force. Some key factors to consider when considering force and displacement include:

- The force exerted by the spring affects the displacement from the equilibrium position.

- The displacement from the equilibrium position affects the force exerted by the spring.

- The spring's properties, such as wire diameter and coil diameter, influence the spring's stiffness and strength.

Accounting for External Factors

External factors, such as temperature, humidity, and corrosion, can affect the compression spring load. The external factors can influence the spring's properties, such as its wire diameter and coil diameter, and affect the spring constant. Some key factors to consider when accounting for external factors include:

- The temperature affects the spring's material properties and strength.

- The humidity affects the spring's corrosion resistance and strength.

- The corrosion affects the spring's material properties and strength.

What is fatigue loading of spring?

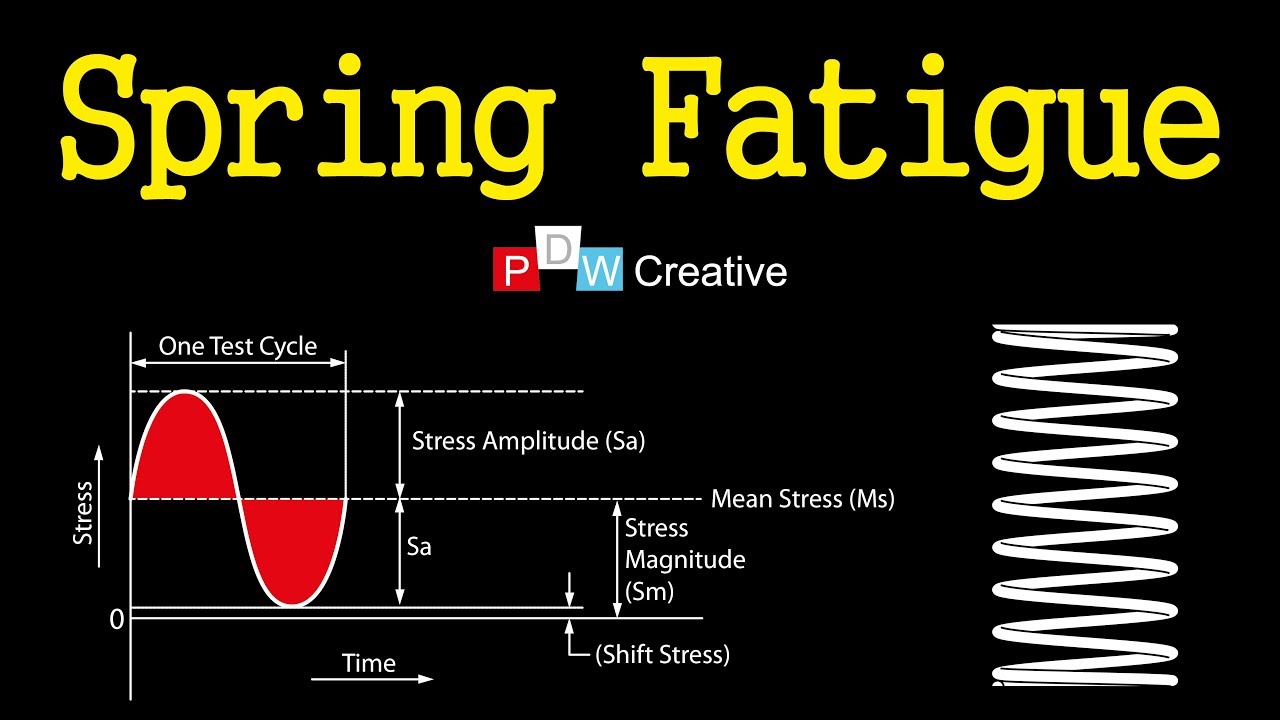

Fatigue loading of a spring refers to the repeated application of stress and strain on the spring over a period of time, leading to a reduction in its strength and stiffness. This type of loading can cause the spring to fail prematurely, even if the individual loads are within its design limits. The cyclic nature of the loading can lead to the formation of cracks and fractures in the spring material, ultimately resulting in failure.

Types of Fatigue Loading

Fatigue loading of a spring can occur in various forms, including tension, compression, and torsion. The type of loading depends on the application and the design of the spring. For example, a spring used in a valve may be subject to cyclic tension and compression loads, while a spring used in a shaft may be subject to torsional loads. The following are some common types of fatigue loading:

- Low-cycle fatigue: This type of loading occurs when the spring is subjected to a small number of high-stress cycles.

- High-cycle fatigue: This type of loading occurs when the spring is subjected to a large number of low-stress cycles.

- Thermal fatigue: This type of loading occurs when the spring is subjected to temperature fluctuations, causing expansion and contraction of the material.

Causes of Fatigue Loading

The causes of fatigue loading of a spring can be attributed to various factors, including improper design, manufacturing defects, and operating conditions. For example, a spring that is designed to operate at a high temperature may be more prone to fatigue loading due to the thermal stresses induced by the temperature fluctuations. The following are some common causes of fatigue loading:

- Overloading: Subjecting the spring to loads that exceed its design limits.

- Corrosion: The presence of corrosive substances can weaken the spring material and increase the risk of fatigue loading.

- Vibration: Vibrational loads can cause the spring to fail prematurely, especially if the frequency of the vibration is close to the natural frequency of the spring.

Effects of Fatigue Loading

The effects of fatigue loading on a spring can be catastrophic, leading to sudden failure and downtime. The repeated application of stress and strain can cause the spring to deform and lose its shape, resulting in a reduction in its performance and lifespan. The following are some common effects of fatigue loading:

- Reduced strength: The spring's strength and stiffness are reduced due to the formation of cracks and fractures.

- Increased creep: The spring's material may creep over time, leading to a reduction in its dimensional stability.

- Premature failure: The spring may fail prematurely, even if the individual loads are within its design limits.

Prevention of Fatigue Loading

Preventing fatigue loading of a spring requires a combination of proper design, material selection, and operating conditions. The spring should be designed to operate within its design limits, and the material should be selected based on its strength, stiffness, and corrosion resistance. The following are some common methods for preventing fatigue loading:

- Design optimization: Optimizing the spring's design to reduce stress concentrations and strain.

- Material selection: Selecting a material that is resistant to corrosion and fatigue.

- Regular maintenance: Regularly inspecting and maintaining the spring to prevent deterioration and failure.

Testing for Fatigue Loading

Testing for fatigue loading of a spring is crucial to ensure its reliability and performance. The testing can be done using various methods, including cyclic testing, static testing, and dynamic testing. The following are some common types of testing for fatigue loading:

- Cyclic testing: Subjecting the spring to cyclic loads to simulate the operating conditions.

- Static testing: Subjecting the spring to static loads to determine its strength and stiffness.

- Dynamic testing: Subjecting the spring to dynamic loads to simulate the vibrational and impact loads.

Frequently Asked Questions (FAQs)

What is Helical Spring Fatigue Loading and its Importance in Engineering Design?

Helical spring fatigue loading refers to the repeated cyclic loading and unloading of a helical spring, which can lead to fatigue failure over time. This type of loading is common in many engineering applications, such as automotive suspension systems, aerospace engineering, and industrial machinery. The importance of understanding helical spring fatigue loading lies in its potential to cause premature failure of the spring, which can have serious consequences, including equipment downtime, maintenance costs, and even safety risks. To mitigate these risks, engineers use factor of safety formulas and calculators to design and analyze helical springs that can withstand the expected loading conditions. By applying these formulas and tools, engineers can ensure that their designs meet the required performance standards and safety margins.

How do Factor of Safety Formulas and Calculators Work in Helical Spring Design?

Factor of safety formulas and calculators are essential tools in helical spring design, as they enable engineers to determine the minimum safety factor required to prevent fatigue failure. These formulas take into account various design parameters, such as the spring's material properties, geometry, and loading conditions. The factor of safety is calculated by dividing the ultimate strength of the material by the maximum stress expected in the spring. This ratio provides a margin of safety against failure, which is critical in ensuring the reliability and performance of the spring. Calculators can be used to iterate on design parameters, such as the wire diameter, coil diameter, and number of turns, to optimize the spring's design and achieve the desired factor of safety. By using these formulas and calculators, engineers can validate their designs and ensure that they meet the required industry standards and regulations.

What are the Key Factors that Influence Helical Spring Fatigue Loading and Factor of Safety Calculations?

Several key factors influence helical spring fatigue loading and factor of safety calculations, including the material properties of the spring, such as its yield strength, ultimate strength, and endurance limit. The geometry of the spring, including its wire diameter, coil diameter, and number of turns, also plays a crucial role in determining its fatigue behavior. Additionally, the loading conditions, such as the maximum load, minimum load, and loading frequency, must be carefully considered. Other factors, such as surface finish, corrosion resistance, and operating temperature, can also impact the spring's fatigue performance. To accurately calculate the factor of safety, engineers must carefully consider these factors and use reliable data and tested formulas to ensure that their designs are consistently accurate and reliable. By accounting for these factors, engineers can optimize their designs and minimize the risk of premature failure.

How can Engineers Use Helical Spring Fatigue Loading and Factor of Safety Formulas to Optimize their Designs?

Engineers can use helical spring fatigue loading and factor of safety formulas to optimize their designs by iterating on design parameters and analyzing the results. By using calculators and simulation tools, engineers can quickly evaluate different design scenarios and compare their performance. This process enables engineers to identify the most critical design parameters and optimize their values to achieve the desired factor of safety and performance characteristics. Additionally, engineers can use sensitivity analysis to study the impact of varying design parameters on the spring's fatigue behavior. By applying these methods, engineers can develop more efficient and reliable designs, which can improve the overall performance of the system and reduce the risk of premature failure. Furthermore, by using industry-standard formulas and tested methods, engineers can ensure that their designs meet the required regulatory requirements and industry standards, which is critical in high-reliability applications.

Deja una respuesta

Entradas Relacionadas