Ventilation Duct Stack Pressure Review, Formulas and Calculator

Proper ventilation is crucial for maintaining a healthy and safe environment in buildings. One key aspect of ventilation systems is the duct stack pressure, which plays a significant role in ensuring efficient airflow and preventing potential hazards. The calculation of duct stack pressure is a complex process that involves various formulas and factors. This article aims to provide a comprehensive review of ventilation duct stack pressure, including relevant formulas and a calculator to help engineers and technicians accurately determine and manage duct stack pressure in various applications. Accurate calculations are critical for optimal system performance.

- Ventilation Duct Stack Pressure Review, Formulas and Calculator

- What is the formula for stack ventilation?

- How do you calculate ductwork pressure?

- What is the formula for ventilation pressure?

- What is the stack effect in ventilation?

-

Frequently Asked Questions (FAQs)

- What is Ventilation Duct Stack Pressure Review and its Importance in HVAC Systems?

- How are Formulas Used in Ventilation Duct Stack Pressure Review to Calculate Pressure Drops and Flow Rates?

- What is the Purpose of a Ventilation Duct Stack Pressure Calculator, and How Does it Support the Review Process?

- What are the Benefits of Conducting Regular Ventilation Duct Stack Pressure Reviews, and How Can they Impact Indoor Air Quality and Energy Efficiency?

Ventilation Duct Stack Pressure Review, Formulas and Calculator

The ventilation duct stack pressure review, formulas, and calculator are essential tools for designing and optimizing ventilation systems in buildings. The ventilation duct is a critical component of the system, responsible for distributing air throughout the building. The stack pressure is the pressure exerted by the column of air in the duct, which can affect the overall performance of the system.

Introduction to Ventilation Duct Stack Pressure

The ventilation duct stack pressure is an important factor in designing ventilation systems. The pressure in the duct is affected by the velocity of the air, the density of the air, and the friction losses in the duct. The stack pressure is typically measured in inches of water gauge (in.wg) or pascals (Pa). A higher stack pressure can result in a more efficient system, but it can also increase the energy consumption of the system.

Formulas for Calculating Ventilation Duct Stack Pressure

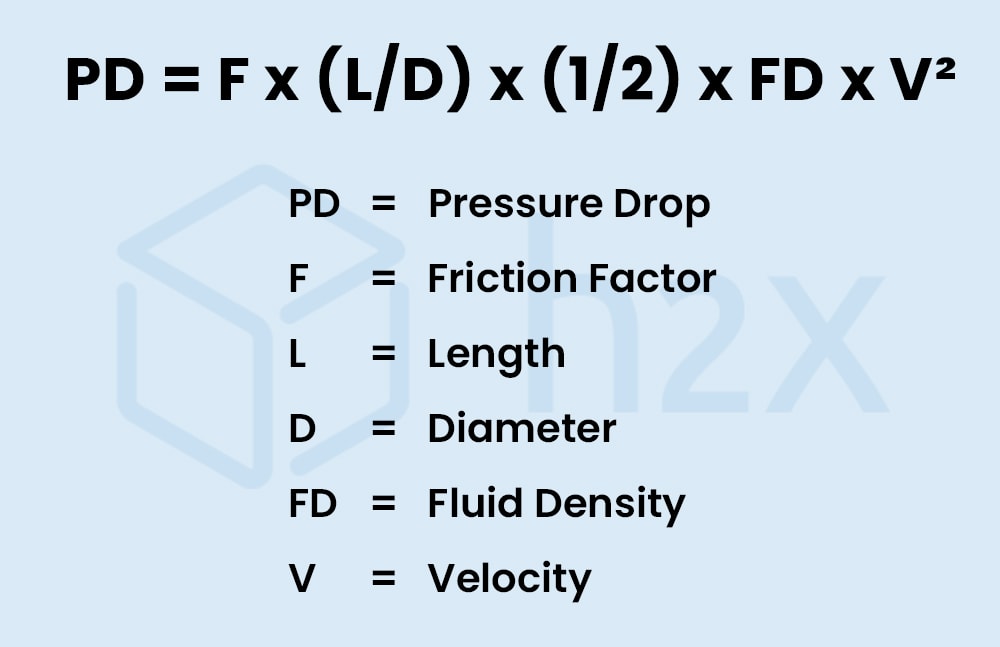

There are several formulas that can be used to calculate the ventilation duct stack pressure. One common formula is the Darcy-Weisbach equation, which takes into account the friction losses in the duct. The equation is as follows:

P = (f L ρ v^2) / (2 D)

Where:

P = pressure drop (in.wg or Pa)

f = friction factor

L = length of the duct (ft or m)

ρ = density of the air (lb/ft^3 or kg/m^3)

v = velocity of the air (ft/s or m/s)

D = diameter of the duct (ft or m)

Ventilation Duct Stack Pressure Calculator

A ventilation duct stack pressure calculator is a tool that can be used to calculate the stack pressure in a ventilation duct. The calculator typically requires input values such as the duct diameter, duct length, air velocity, and air density. The calculator can then use the Darcy-Weisbach equation or other formulas to calculate the stack pressure.

Factors Affecting Ventilation Duct Stack Pressure

There are several factors that can affect the ventilation duct stack pressure. These include:

| Factor | Description |

|---|---|

| Duct Diameter | The diameter of the duct can affect the stack pressure. A smaller duct diameter can result in a higher stack pressure. |

| Duct Length | The length of the duct can also affect the stack pressure. A longer duct can result in a higher stack pressure due to increased friction losses. |

| Air Velocity | The velocity of the air in the duct can affect the stack pressure. A higher air velocity can result in a higher stack pressure. |

| Air Density | The density of the air can also affect the stack pressure. A higher air density can result in a higher stack pressure. |

| Friction Losses | The friction losses in the duct can affect the stack pressure. A higher friction loss can result in a higher stack pressure. |

Applications of Ventilation Duct Stack Pressure Review, Formulas and Calculator

The ventilation duct stack pressure review, formulas, and calculator have several applications in the field of heating, ventilation, and air conditioning (HVAC). These include:

The design of new ventilation systems, the optimization of existing systems, and the troubleshooting of problems in existing systems. The calculator can also be used to compare different design options and to evaluate the performance of different ventilation systems.

What is the formula for stack ventilation?

The formula for stack ventilation is based on the principle of natural ventilation, where the pressure difference between the inside and outside of a building is utilized to drive airflow through a ventilation stack. The formula takes into account various factors such as the height of the stack, the temperature difference between the inside and outside, and the resistance to airflow. The basic formula for stack ventilation is: Q = (A ΔT g H) / (2 T ρ), where Q is the airflow rate, A is the cross-sectional area of the stack, ΔT is the temperature difference, g is the acceleration due to gravity, H is the height of the stack, T is the average temperature, and ρ is the air density.

Introduction to Stack Ventilation Formula

The stack ventilation formula is a fundamental concept in building design and engineering, as it helps to determine the airflow rates and pressure differences required for effective ventilation. The formula is based on the principles of fluid dynamics and thermodynamics, and takes into account various factors that affect airflow through a ventilation stack. Some of the key factors that influence the formula include:

- Temperature difference: The temperature difference between the inside and outside of a building is a critical factor in determining the airflow rate through a ventilation stack.

- Height of the stack: The height of the stack is another important factor, as it affects the pressure difference and airflow rate.

- Cross-sectional area: The cross-sectional area of the stack is also an important factor, as it determines the volume of air that can flow through the stack.

Factors Affecting Stack Ventilation Formula

Several factors can affect the stack ventilation formula, including climate, building design, and occupancy. For example, in hot and humid climates, the temperature difference between the inside and outside of a building may be smaller, resulting in reduced airflow rates through the ventilation stack. Similarly, the design of the building, including the layout and orientation of the ventilation stack, can also impact the formula. Some of the key factors that affect the formula include:

- Climate and weather conditions: The climate and weather conditions can affect the temperature difference and airflow rate through the ventilation stack.

- Building design and layout: The design and layout of the building, including the ventilation stack, can impact the airflow rate and pressure difference.

- Occupancy and indoor air quality: The occupancy and indoor air quality can also affect the formula, as they can impact the temperature difference and airflow rate.

Applications of Stack Ventilation Formula

The stack ventilation formula has various applications in building design and engineering, including natural ventilation, mechanical ventilation, and hybrid ventilation systems. The formula can be used to determine the airflow rates and pressure differences required for effective ventilation, and to design and optimize ventilation systems. Some of the key applications of the formula include:

- Designing natural ventilation systems: The formula can be used to design and optimize natural ventilation systems, including ventilation stacks and chimneys.

- Optimizing mechanical ventilation systems: The formula can also be used to optimize mechanical ventilation systems, including fans and ducts.

- Evaluating indoor air quality: The formula can be used to evaluate indoor air quality and determine the effectiveness of ventilation systems.

Limitations of Stack Ventilation Formula

The stack ventilation formula has several limitations, including assumptions about airflow patterns and temperature distributions. The formula assumes that airflow through the ventilation stack is laminar and one-dimensional, which may not always be the case. Additionally, the formula does not account for turbulence and complex airflow patterns, which can affect the accuracy of the results. Some of the key limitations of the formula include:

- Assumptions about airflow patterns: The formula assumes that airflow through the ventilation stack is laminar and one-dimensional, which may not always be the case.

- Assumptions about temperature distributions: The formula also assumes that the temperature distribution is uniform, which may not always be the case.

- Ignoring turbulence and complex airflow patterns: The formula does not account for turbulence and complex airflow patterns, which can affect the accuracy of the results.

Future Developments in Stack Ventilation Formula

There are several future developments that can improve the accuracy and applicability of the stack ventilation formula, including computational fluid dynamics and building information modeling. These tools can be used to simulate airflow patterns and temperature distributions in buildings, and to optimize ventilation systems. Some of the key future developments include:

- Integrating computational fluid dynamics: Computational fluid dynamics can be used to simulate airflow patterns and temperature distributions in buildings, and to optimize ventilation systems.

- Using building information modeling: Building information modeling can be used to design and optimize buildings, including ventilation systems.

- Developing more accurate and complex models: More accurate and complex models can be developed to account for turbulence and complex airflow patterns, and to improve the accuracy of the results.

How do you calculate ductwork pressure?

To calculate ductwork pressure, you need to consider several factors, including the velocity of the air, the density of the air, and the friction loss in the duct. The calculation typically involves using the Darcy-Weisbach equation, which takes into account the pressure drop due to friction, as well as the velocity pressure and static pressure. This equation is commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems to determine the required fan pressure and duct sizing.

Understanding Ductwork Pressure Basics

Calculating ductwork pressure requires a thorough understanding of the basics, including the types of pressure involved, such as static pressure, velocity pressure, and total pressure. To calculate ductwork pressure, you need to consider the following factors:

- Duct size and shape: The size and shape of the duct can affect the friction loss and pressure drop.

- Air flow rate: The air flow rate affects the velocity of the air, which in turn affects the pressure.

- Duct material: The duct material can affect the friction loss and pressure drop, with smoother materials resulting in less friction.

Calculating Friction Loss

Calculating friction loss is a critical step in determining ductwork pressure. This involves using the Darcy-Weisbach equation, which takes into account the length of the duct, the diameter of the duct, and the air flow rate. To calculate friction loss, you need to consider the following factors:

- Duct length: The length of the duct affects the friction loss, with longer ducts resulting in greater friction.

- Duct diameter: The diameter of the duct affects the friction loss, with smaller ducts resulting in greater friction.

- Air flow rate: The air flow rate affects the velocity of the air, which in turn affects the friction loss.

Using the Darcy-Weisbach Equation

The Darcy-Weisbach equation is a widely used equation for calculating ductwork pressure. The equation takes into account the pressure drop due to friction, as well as the velocity pressure and static pressure. To use the equation, you need to know the following factors:

- Duct size and shape: The size and shape of the duct affect the friction loss and pressure drop.

- Air flow rate: The air flow rate affects the velocity of the air, which in turn affects the pressure.

- Duct material: The duct material can affect the friction loss and pressure drop, with smoother materials resulting in less friction.

Considering Velocity Pressure

Velocity pressure is an important factor in calculating ductwork pressure. The velocity pressure is affected by the air flow rate and the duct size. To calculate velocity pressure, you need to consider the following factors:

- Air flow rate: The air flow rate affects the velocity of the air, which in turn affects the velocity pressure.

- Duct size: The duct size affects the velocity of the air, with smaller ducts resulting in greater velocity.

- Duct shape: The duct shape can affect the velocity of the air,! with straight ducts resulting in less friction.

Applying the Calculation in Practice

Applying the calculation in practice involves using the Darcy-Weisbach equation to determine the required fan pressure and duct sizing. This requires considering the system requirements, including the air flow rate, static pressure, and velocity pressure. To apply the calculation in practice, you need to consider the following factors:

- System requirements: The system requirements affect the air flow rate, static pressure, and velocity pressure.

- Duct size and shape: The duct size and shape affect the friction loss and pressure drop.

- Fan selection: The fan selection affects the fan pressure and efficiency, with more efficient fans resulting in less energy consumption.

What is the formula for ventilation pressure?

The formula for ventilation pressure is a complex calculation that takes into account several factors, including the lung volume, airway resistance, and breathing rate. The formula is: P = (V x R) / (B x T), where P is the ventilation pressure, V is the lung volume, R is the airway resistance, B is the breathing rate, and T is the time. This formula is used to calculate the pressure required to ventilate the lungs, which is essential for maintaining adequate oxygenation and carbon dioxide removal.

Ventilation Pressure Calculation

The calculation of ventilation pressure is a critical step in mechanical ventilation, as it helps to determine the optimal ventilator settings for a patient. The formula takes into account the compliance of the lungs and chest wall, as well as the resistance of the airways. The calculation is typically performed using a ventilator and involves the following steps:

- Measure the lung volume and airway resistance using a spirometer and plethysmograph

- Calculate the breathing rate and time using a respiratory monitor

- Plug in the values into the formula to calculate the ventilation pressure

Factors Affecting Ventilation Pressure

Several factors can affect the ventilation pressure, including lung disease, airway obstruction, and chest wall deformities. These factors can increase the resistance and compliance of the lungs and chest wall, making it more difficult to ventilate the patient. The formula takes into account these factors, which is why it is essential to monitor the patient's respiratory status closely. The ventilator settings may need to be adjusted to accommodate changes in the patient's physiology.

- Chronic obstructive pulmonary disease (COPD) can increase airway resistance

- Pneumonia can decrease lung compliance

- Chest wall deformities can increase the work of breathing

Ventilation Modes

There are several ventilation modes that can be used to calculate the ventilation pressure, including volume-controlled and pressure-controlled ventilation. Volume-controlled ventilation delivers a set tidal volume at a set breathing rate, while pressure-controlled ventilation delivers a set pressure at a set breathing rate. The formula is used to calculate the optimal ventilator settings for each mode.

- Volume-controlled ventilation is used for patients with stable lung function

- Pressure-controlled ventilation is used for patients with unstable lung function

- Spontaneous breathing is used for patients who can breathe on their own

Monitoring Ventilation Pressure

Monitoring ventilation pressure is crucial to ensure that the patient is receiving adequate ventilation. The ventilator monitors the pressure and flow of gas into the lungs, and adjusts the ventilator settings accordingly. The healthcare provider must also closely monitor the patient's respiratory status, including oxygen saturation, carbon dioxide levels, and breathing rate.

- Oxygen saturation is monitored using a pulse oximeter

- Carbon dioxide levels are monitored using a capnometer

- Breathing rate is monitored using a respiratory monitor

Complications of Ventilation Pressure

Complications of ventilation pressure can occur if the ventilator settings are not adjusted correctly. Barotrauma can occur if the pressure is too high, causing lung damage. Hypoxia can occur if the oxygenation is inadequate, causing tissue damage. The healthcare provider must closely monitor the patient's respiratory status to prevent these complications.

- Barotrauma can cause pneumothorax or lung rupture

- Hypoxia can cause brain damage or organ failure

- Ventilator-induced lung injury can cause acute respiratory distress syndrome (ARDS)

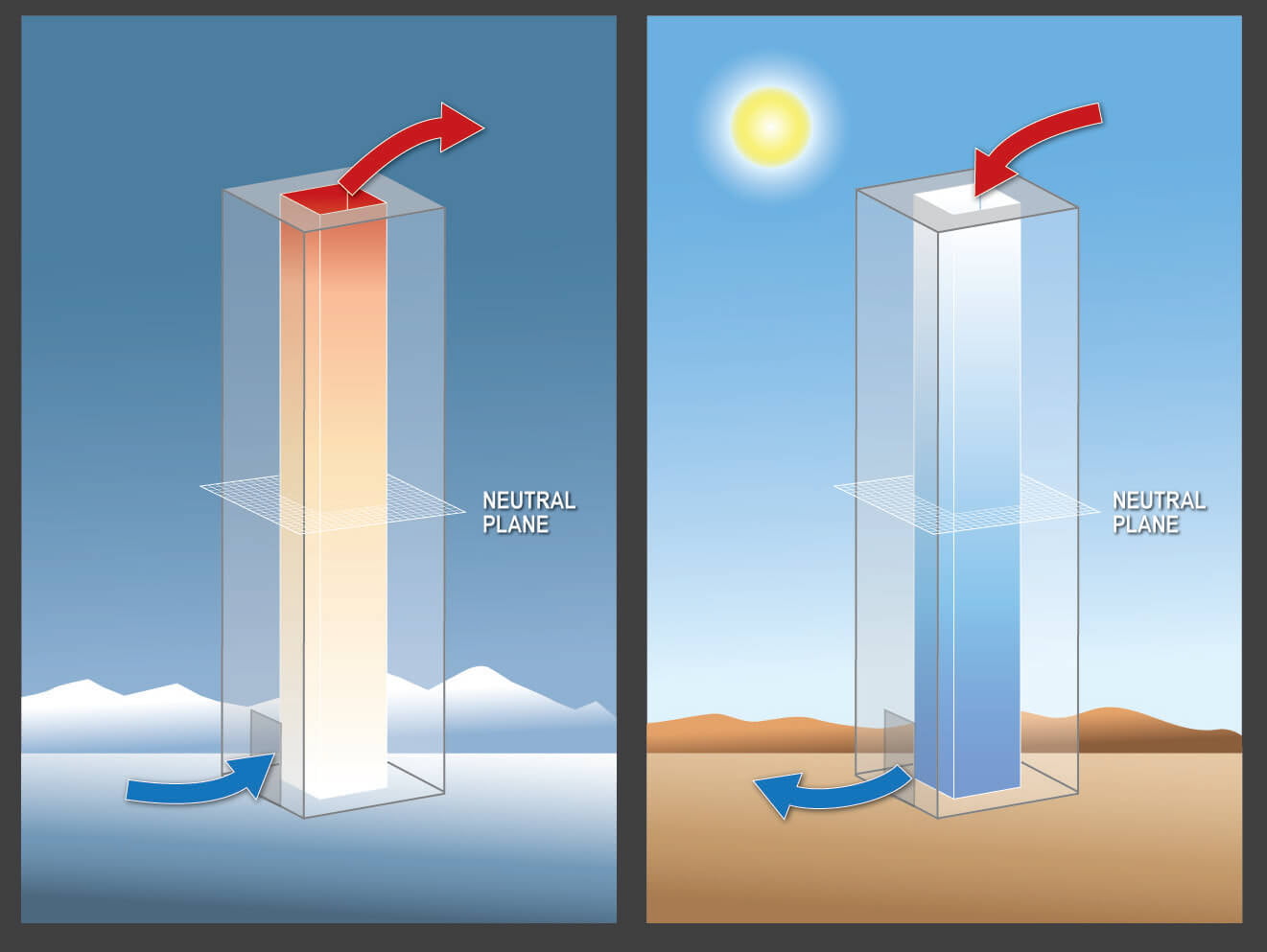

What is the stack effect in ventilation?

The stack effect in ventilation refers to the movement of air in a building due to the difference in pressure and temperature between the inside and outside of the building. This phenomenon occurs when there is a significant height difference between the inlet and outlet of the building, causing the air to rise or fall due to its density. The stack effect is an important factor to consider in building design and ventilation systems, as it can affect the indoor air quality, energy efficiency, and comfort of occupants.

Causes of Stack Effect

The stack effect is caused by the difference in temperature between the inside and outside of a building, which creates a pressure gradient. As warm air rises, it creates a positive pressure at the top of the building and a negative pressure at the bottom. This pressure difference drives the movement of air from the inlet to the outlet. The main factors that contribute to the stack effect are:

- Temperature difference: The greater the temperature difference between the inside and outside, the stronger the stack effect.

- Height of the building: Taller buildings are more prone to the stack effect due to the increased pressure difference.

- Inlet and outlet locations: The location and design of the inlet and outlet can either enhance or reduce the stack effect.

Effects of Stack Effect on Ventilation

The stack effect can have a significant impact on the ventilation system of a building. It can lead to imbalanced airflow, reduced ventilation rates, and increased energy consumption. The stack effect can also cause moisture accumulation and condensation issues, particularly in buildings with high humidity levels. To mitigate these effects, building designers and ventilation engineers must consider the stack effect when designing and commissioning ventilation systems. The stack effect can be influenced by:

- Building design: The design of the building, including the layout and location of inlets and outlets, can either enhance or reduce the stack effect.

- Ventilation system design: The design of the ventilation system, including the type and location of fans and ducts, can also impact the stack effect.

- Operating conditions: The operating conditions of the building, including the temperature and humidity levels, can affect the stack effect.

Stack Effect in High-Rise Buildings

High-rise buildings are particularly susceptible to the stack effect due to their height. The stack effect can cause significant pressure differences between the top and bottom of the building, leading to imbalanced airflow and reduced ventilation rates. To mitigate the stack effect in high-rise buildings, designers and engineers can use pressure-controlled ventilation systems, variable air volume systems, and stack effect mitigation strategies. The stack effect in high-rise buildings can be influenced by:

- Building height: The taller the building, the greater the pressure difference and the stronger the stack effect.

- Inlet and outlet design: The design of the inlet and outlet can either enhance or reduce the stack effect.

- Ventilation system design: The design of the ventilation system can also impact the stack effect.

Mitigating Stack Effect

To mitigate the stack effect, building designers and ventilation engineers can use various strategies and technologies. These include pressure-controlled ventilation systems, variable air volume systems, and stack effect mitigation strategies. The goal of these strategies is to reduce the pressure difference between the inside and outside of the building, balance the airflow, and improve ventilation rates. The most effective mitigation strategies include:

- Using pressure-controlled ventilation systems to regulate the airflow and reduce the pressure difference.

- Implementing variable air volume systems to balance the airflow and reduce energy consumption.

- Designing inlets and outlets to minimize the stack effect and promote balanced airflow.

Importance of Stack Effect in Building Design

The stack effect is a critical factor to consider in building design and ventilation systems. Ignoring the stack effect can lead to imbalanced airflow, reduced ventilation rates, and increased energy consumption. By understanding and addressing the stack effect, building designers and ventilation engineers can create more efficient, more comfortable, and healthier buildings. The stack effect is particularly important in:

- High-rise buildings, where the stack effect can be more pronounced due to the height.

- Buildings with high humidity levels, where the stack effect can cause moisture accumulation and condensation issues.

- Buildings with sensitive or high-occupancy areas, where the stack effect can impact indoor air quality and occupant comfort.

Frequently Asked Questions (FAQs)

What is Ventilation Duct Stack Pressure Review and its Importance in HVAC Systems?

Ventilation duct stack pressure review is a critical process in HVAC (Heating, Ventilation, and Air Conditioning) systems that involves evaluating the pressure within the ductwork to ensure efficient and safe operation. The review process helps to identify any pressure imbalances or leaks in the ducts, which can lead to reduced system performance, increased energy consumption, and potential health risks. By conducting a thorough review of the ventilation duct stack pressure, building owners and facilities managers can ensure that their HVAC systems are operating at optimal levels, providing a healthy and comfortable indoor environment for occupants. The review process typically involves using specialized equipment, such as manometers and anemometers, to measure the pressure and airflow within the ducts.

How are Formulas Used in Ventilation Duct Stack Pressure Review to Calculate Pressure Drops and Flow Rates?

Formulas play a crucial role in ventilation duct stack pressure review, as they enable engineers and technicians to calculate pressure drops and flow rates within the ductwork. The most commonly used formulas in this context are the Darcy-Weisbach equation and the Hazen-Williams equation, which take into account factors such as duct diameter, length, roughness, and air density. By using these formulas, professionals can calculate the pressure loss and flow rate within each section of the ductwork, identifying areas where improvements or repairs are needed. Additionally, formulas can be used to determine the optimal duct size and layout to minimize pressure drops and ensure efficient airflow. The use of calculator tools and software programs can also facilitate the calculation process, reducing the risk of human error and providing more accurate results.

What is the Purpose of a Ventilation Duct Stack Pressure Calculator, and How Does it Support the Review Process?

A ventilation duct stack pressure calculator is a software tool or spreadsheet designed to support the review process by providing accurate calculations of pressure drops and flow rates within the ductwork. The calculator typically requires input data such as duct geometry, air properties, and system operating conditions, which are then used to calculate the pressure loss and flow rate within each section of the ductwork. The purpose of the calculator is to simplify the calculation process, reduce the risk of human error, and provide quick and accurate results. By using a ventilation duct stack pressure calculator, professionals can identify areas where improvements or repairs are needed, optimize duct sizing and layout, and ensure that the HVAC system is operating at optimal levels. The calculator can also be used to simulate different scenarios and predict the impact of changes to the system, allowing for more informed decision-making.

What are the Benefits of Conducting Regular Ventilation Duct Stack Pressure Reviews, and How Can they Impact Indoor Air Quality and Energy Efficiency?

Conducting regular ventilation duct stack pressure reviews can have numerous benefits, including improved indoor air quality, increased energy efficiency, and extended equipment lifespan. By identifying and addressing pressure imbalances and leaks in the ductwork, building owners and facilities managers can ensure that their HVAC systems are operating at optimal levels, providing a healthy and comfortable indoor environment for occupants. Regular reviews can also help to reduce energy consumption, as improperly sized or leaky ducts can lead to increased energy losses and higher utility bills. Furthermore, regular reviews can help to prevent mold growth and moisture accumulation, which can have serious health implications for occupants. By prioritizing regular ventilation duct stack pressure reviews, building owners and facilities managers can create a healthier, more sustainable, and more energy-efficient indoor environment, while also reducing maintenance costs and extending the lifespan of their HVAC equipment.

Deja una respuesta

Entradas Relacionadas