Thermo-Kinetics Thermowell Excel Calculator Spreadsheet

The Thermo-Kinetics Thermowell Excel Calculator Spreadsheet is a valuable tool for engineers and technicians involved in thermowell installation and maintenance. This spreadsheet provides a convenient and accurate method for calculating thermowell dimensions, insertion lengths, and other critical parameters. By utilizing this calculator, users can ensure compliance with industry standards and optimize thermowell performance, reducing the risk of damage or failure. The spreadsheet's user-friendly interface and comprehensive calculations make it an essential resource for anyone working with thermowells in various industrial applications, including oil and gas, chemical processing, and power generation. It streamlines the calculation process.

- Understanding the Thermo-Kinetics Thermowell Excel Calculator Spreadsheet

- How to calculate thermowell?

- What is the thermowell wake frequency?

- Have you conducted wake frequency calculations?

-

Frequently Asked Questions (FAQs)

- What is the Thermo-Kinetics Thermowell Excel Calculator Spreadsheet and how does it work?

- What are the key features and benefits of using the Thermo-Kinetics Thermowell Excel Calculator Spreadsheet?

- How does the Thermo-Kinetics Thermowell Excel Calculator Spreadsheet handle complex thermowell installations and configurations?

- Can the Thermo-Kinetics Thermowell Excel Calculator Spreadsheet be customized and integrated with other software tools and systems?

Understanding the Thermo-Kinetics Thermowell Excel Calculator Spreadsheet

The Thermo-Kinetics Thermowell Excel Calculator Spreadsheet is a powerful tool designed to assist in the calculation and analysis of thermowell installations. This spreadsheet is particularly useful in the field of temperature measurement and process control, where precise calculations are crucial for optimal performance and safety. The spreadsheet is built to handle various variables and parameters related to thermowell design, installation, and operation, making it an essential resource for engineers and technicians working in industries such as chemical processing, oil and gas, and power generation.

Introduction to Thermowell Design Calculations

Thermowell design calculations are critical for ensuring that temperature sensors operate accurately and reliably in various process environments. The Thermo-Kinetics Thermowell Excel Calculator Spreadsheet provides a structured approach to performing these calculations, taking into account factors such as thermowell material, process fluid characteristics, and installation conditions. By using this spreadsheet, users can easily input relevant data and obtain calculations for key parameters like thermowell insertion length, tip style, and protection tube size.

Key Parameters and Formulas Used

The spreadsheet utilizes a range of formulas and algorithms to calculate the necessary parameters for thermowell design and installation. These include calculations for heat transfer rates, flow velocities, and stress analysis to ensure that the thermowell can withstand the operating conditions. The use of Excel as the platform for these calculations provides a familiar and user-friendly interface, making it easier for engineers to input data, perform calculations, and analyze results.

Benefits of Using the Thermo-Kinetics Thermowell Excel Calculator Spreadsheet

The Thermo-Kinetics Thermowell Excel Calculator Spreadsheet offers several benefits to users, including increased accuracy in calculations, reduced calculation time, and improved decision-making. By using this tool, engineers and technicians can quickly evaluate different thermowell designs and installation scenarios, allowing for optimized performance and enhanced safety in process operations. The spreadsheet also facilitates documentation and record-keeping of thermowell installations, which is essential for regulatory compliance and maintenance purposes.

Common Applications and Industries

The Thermo-Kinetics Thermowell Excel Calculator Spreadsheet is applicable in a variety of industries where temperature measurement and control are critical. These include:

| Industry | Application |

|---|---|

| Chemical Processing | Process Optimization, Safety Monitoring |

| Oil and Gas | Wellhead Monitoring, Flow Metering |

| Power Generation | Boiler Monitoring, Turbine Efficiency |

Future Developments and Integration with Other Tools

As technology continues to evolve, there is potential for the Thermo-Kinetics Thermowell Excel Calculator! Spreadsheet to be integrated with other software tools and digital platforms, enhancing its functionality and usability. This could include integration with computer-aided design (CAD) software for more detailed design work, or with data analytics platforms for real-time monitoring and performance optimization. Such developments would further increase the value of the spreadsheet as a comprehensive solution for thermowell design, installation, and operation.

How to calculate thermowell?

To calculate thermowell, it's essential to understand the parameters involved in the process. Thermowell is a protective tube that houses a temperature sensor, such as a thermocouple or resistance temperature detector (RTD), to measure the temperature of a fluid or gas in a pipeline or vessel.

Understanding Thermowell Design

The design of a thermowell is critical in calculating its performance. The thermowell design includes factors such as the material, length, and diameter of the thermowell, as well as the installation method. When calculating thermowell, consider the following factors:

- The material of the thermowell should be compatible with the fluid or gas being measured to prevent corrosion or erosion.

- The length and diameter of the thermowell should be sufficient to allow for accurate temperature measurement without causing flow restrictions or pressure drop.

- The installation method, such as welding or threading, should be suitable for the pipeline or vessel material and operating conditions.

Calculating Thermowell Time Constant

The time constant of a thermowell is a critical parameter in calculating its performance. The time constant is the time it takes for the temperature sensor to respond to a change in temperature. When calculating the time constant, consider the following factors:

- The thermal conductivity of the thermowell material affects the time constant, with higher thermal conductivity resulting in a faster response time.

- The thickness and core diameter of the thermowell also impact the time constant, with thinner walls and larger core diameters resulting in faster response times.

- The fluid velocity and temperature also influence the time constant, with higher fluid velocities and temperatures resulting in faster response times.

Determining Thermowell Insertion Length

The insertion length of a thermowell is critical in calculating its performance. The insertion length is the distance the thermowell is inserted into the pipeline or vessel. When calculating the insertion length, consider the following factors:

- The flow regime and fluid velocity affect the insertion length, with higher fluid velocities requiring shorter insertion lengths to prevent vortex shedding.

- The pipeline or vessel diameter and geometry also impact the insertion length, with larger diameters and more complex geometries requiring longer insertion lengths.

- The temperature measurement requirements also influence the insertion length, with more accurate measurements requiring longer insertion lengths.

Calculating Thermowell Pressure Drop

The pressure drop across a thermowell is an essential parameter in calculating its performance. The pressure drop is the difference in pressure between the upstream and !downstream sides of the thermowell. When calculating the pressure drop, consider the following factors:

- The fluid velocity and density affect the pressure drop, with higher fluid velocities and densities resulting in greater pressure drops.

- The thermowell diameter and length also impact the pressure drop, with larger diameters and longer lengths resulting in greater pressure drops.

- The pipeline or vessel geometry and flow regime also influence the pressure drop, with more complex geometries and turbulent flow resulting in greater pressure drops.

Ensuring Thermowell Accuracy and Reliability

To ensure accurate and reliable temperature measurement, it's essential to consider the following factors when calculating thermowell:

- The thermowell material and construction should be suitable for the operating conditions, including temperature, pressure, and corrosion.

- The temperature sensor should be calibrated and validated to ensure accurate measurements.

- The thermowell installation should be properly done to prevent leaks, vibration, and other mechanical issues that can affect accuracy and reliability.

What is the thermowell wake frequency?

The thermowell wake frequency refers to the frequency at which the flow of fluid around a thermowell, a cylindrical tube that houses a temperature sensor, creates a wake or a region of disturbed flow behind the thermowell. This frequency is important in the design and installation of thermowells, as it can affect the accuracy and response time of the temperature measurement.

Introduction to Thermowell Wake Frequency

The thermowell wake frequency is a critical parameter in the design of thermowells, as it can impact the performance and reliability of the temperature measurement system. The wake frequency is influenced by the shape and size of the thermowell, as well as the velocity and density of the fluid flowing around it. Some key factors that affect the thermowell wake frequency include:

- Thermowell diameter: The diameter of the thermowell affects the wake frequency, with larger diameters resulting in lower frequencies.

- Fluid velocity: The velocity of the fluid flowing around the thermowell also impacts the wake frequency, with higher velocities resulting in higher frequencies.

- Fluid density: The density of the fluid affects the wake frequency, with denser fluids resulting in lower frequencies.

Factors Affecting Thermowell Wake Frequency

Several factors can affect the thermowell wake frequency, including the thermowell design, fluid properties, and flow conditions. The shape of the thermowell, such as its diameter and length, can impact the wake frequency, as can the material and surface roughness of the thermowell. Additionally, the velocity profile and turbulence of the fluid flow can also influence the wake frequency. Some key factors that affect the thermowell wake frequency include:

- Thermowell material: The material of the thermowell can affect the wake frequency, with different materials having different thermal conductivity and density.

- Fluid viscosity: The viscosity of the fluid affects the wake frequency, with more viscous fluids resulting in lower frequencies.

- Flow regime: The flow regime, such as laminar or turbulent, can also impact the wake frequency.

Measurement of Thermowell Wake Frequency

The thermowell wake frequency can be measured using various techniques, including hot-wire anemometry and particle image velocimetry. These techniques allow for the measurement of the velocity and turbulence of the fluid flow around the thermowell, which can be used to calculate the wake frequency. Additionally, computational fluid dynamics (CFD) simulations can also be used to predict the thermowell wake frequency. Some key methods for measuring the thermowell wake frequency include:

- Experimental methods: Experimental methods, such as hot-wire anemometry and particle image velocimetry, can be used to measure the velocity and turbulence of the fluid flow.

- CFD simulations: CFD simulations can be used to predict the thermowell wake frequency and validate experimental results.

- Sensors and transducers: Sensors and transducers, such as thermocouples and pressure sensors, can be used to measure the temperature and pressure of the fluid flow.

Applications of Thermowell Wake Frequency

The thermowell wake frequency has several applications in various fields, including process control, temperature measurement, and fluid dynamics. Understanding the thermowell wake frequency is essential for the design and installation of thermowells, as well as for the calibration and validation of temperature measurement systems. Some key applications of the thermowell wake frequency include:

- Temperature measurement: The thermowell wake frequency is critical for accurate temperature measurement, as it affects the response time and accuracy of the measurement.

- Process control: The thermowell wake frequency is important for process control, as it can impact the stability and reliability of the process.

- Fluid dynamics research: The thermowell wake frequency is also relevant for fluid dynamics research, as it can provide insights into the behavior of fluids and flow phenomena.

Importance of Thermowell Wake Frequency in Temperature Measurement

The thermowell wake frequency is crucial for accurate and reliable temperature measurement, as it can impact the response time and accuracy of the measurement. The wake frequency can affect the heat transfer between the fluid and the thermowell, which can result in errors in the temperature measurement. Therefore, understanding the thermowell wake frequency is essential for the design and installation of thermowells, as well as for the calibration and validation of temperature measurement systems. Some key reasons why the thermowell wake frequency is important for temperature measurement include:

- Response time: The thermowell wake frequency affects the response time of the temperature measurement, with higher frequencies resulting in faster response times.

- Accuracy: The thermowell wake frequency also impacts the accuracy of the temperature measurement, with higher frequencies resulting in more accurate measurements.

- Reliability: The thermowell wake frequency can also affect the reliability of the temperature measurement system, with higher frequencies resulting in more reliable measurements.

Have you conducted wake frequency calculations?

Wake frequency calculations are a crucial aspect of understanding the dynamics of fluids and gases in various fields, including engineering, physics, and meteorology. These calculations help determine the frequency at which waves or oscillations occur in a system, which is essential for predicting behavior, stability, and performance. By conducting wake frequency calculations, researchers and engineers can gain valuable insights into the interaction between fluids, gases, and solid objects, ultimately informing the design and optimization of systems, such as wind turbines, aircraft, and ships.

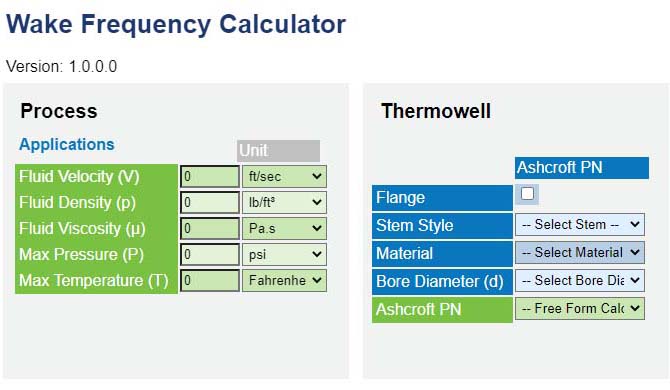

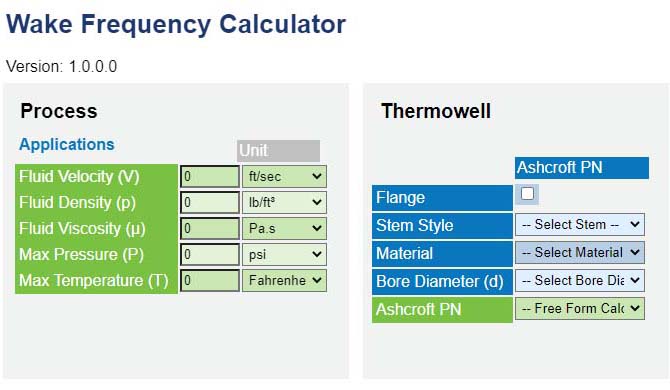

Introduction to Wake Frequency Calculations

Wake frequency calculations involve the use of mathematical models and numerical methods to simulate the behavior of fluids and gases in different environments. The calculations take into account various factors, including velocity, density, and viscosity, to determine the frequency and amplitude of waves or oscillations. This information is critical for understanding the wake effects, which can impact the efficiency, safety, and reliability of systems.

- The governing equations of fluid motion, such as the Navier-Stokes equations, are used to model the behavior of fluids and gases.

- Numerical methods, such as the finite element method or computational fluid dynamics, are employed to solve the governing equations and simulate the behavior of the system.

- The results of the calculations are analyzed to determine the wake frequency and its impact on the system.

Applications of Wake Frequency Calculations

Wake frequency calculations have numerous applications in various fields, including renewable energy, aerospace, and marine engineering. By understanding the wake effects, researchers and engineers can design more efficient and reliable systems, such as wind farms, aircraft, and ships.

- The design of wind turbines and wind farms can be optimized to minimize wake effects and maximize energy production.

- The performance of aircraft and ships can be improved by reducing wake effects and drag.

- The safety of systems can be enhanced by understanding the wake effects and mitigating potential hazards.

Methodologies for Wake Frequency Calculations

Various methodologies are used to conduct wake frequency calculations, including experimental, numerical, and analytical methods. Each methodology has its advantages and disadvantages, and the choice of methodology depends on the specific application and requirements.

- Experimental methods involve measuring the wake effects in a physical model or prototype.

- Numerical methods involve simulating the behavior of fluids and gases using computational models.

- Analytical methods involve solving the governing equations using mathematical techniques.

Challenges and Limitations of Wake Frequency Calculations

Wake frequency calculations can be challenging and complex, particularly when dealing with turbulent flows or nonlinear systems. The calculations require advanced mathematical models and numerical methods, as well as high-performance computing resources.

- The accuracy of the calculations can be affected by numerical errors or modeling assumptions.

- The computational cost of the calculations can be prohibitive, particularly for large-scale systems.

- The interpretation of the results can be difficult, particularly for non-experts.

Future Developments in Wake Frequency Calculations

The field of wake frequency calculations is evolving rapidly, driven by advances in computational power, mathematical modeling, and experimental techniques. Future developments are expected to focus on improving accuracy, reducing computational cost, and increasing applicability.

- The development of new mathematical models and numerical methods is expected to improve the accuracy and efficiency of wake frequency calculations.

- The integration of experimental and numerical methods is expected to provide more comprehensive understanding of wake effects.

- The application of wake frequency calculations to new fields, such as biomedical engineering, is expected to expand the scope of the field.

Frequently Asked Questions (FAQs)

What is the Thermo-Kinetics Thermowell Excel Calculator Spreadsheet and how does it work?

The Thermo-Kinetics Thermowell Excel Calculator Spreadsheet is a software tool designed to calculate and analyze thermowell installations in various industrial applications. This spreadsheet is built on the popular Microsoft Excel platform, allowing users to easily input data, perform calculations, and generate reports. The calculator takes into account various parameters such as temperature, pressure, and flow rate to determine the optimal thermowell design and installation configuration. By using this tool, users can ensure that their thermowell installations are safe, efficient, and compliant with industry standards. The spreadsheet also includes built-in formulas and algorithms to perform complex calculations, making it a valuable resource for engineers, technicians, and other professionals working in the field of process control and instrumentation.

What are the key features and benefits of using the Thermo-Kinetics Thermowell Excel Calculator Spreadsheet?

The Thermo-Kinetics Thermowell Excel Calculator Spreadsheet offers several key features that make it an essential tool for professionals working with thermowells. One of the main benefits is its ability to perform rapid calculations and analyses, saving users time and effort. The spreadsheet also includes a comprehensive database of thermowell designs and configurations, allowing users to easily select and compare different options. Additionally, the calculator provides detailed reports and prints, making it easy to document and communicate results. The spreadsheet is also fully customizable, allowing users to modify and extend its functionality to meet their specific needs. By using this tool, users can improve the accuracy and reliability of their thermowell installations, reduce costs and risks, and ensure compliance with industry regulations and standards.

How does the Thermo-Kinetics Thermowell Excel Calculator Spreadsheet handle complex thermowell installations and configurations?

The Thermo-Kinetics Thermowell Excel Calculator Spreadsheet is designed to handle complex thermowell installations and configurations with ease. The spreadsheet includes advanced algorithms and formulas that take into account various parameters such as temperature gradients, flow rates, and pressure drops. The calculator can also handle multiple thermowell installations and configurations, allowing users to compare and optimize different designs. Additionally, the spreadsheet includes a built-in database of thermowell designs and configurations, which can be updated and modified by users to reflect their specific needs. The calculator also provides detailed reports and prints, making it easy to document and communicate results. By using this tool, users can ensure that their thermowell installations are safe, efficient, and compliant with industry standards, even in the most complex and challenging applications.

Can the Thermo-Kinetics Thermowell Excel Calculator Spreadsheet be customized and integrated with other software tools and systems?

The Thermo-Kinetics Thermowell Excel Calculator Spreadsheet is fully customizable and can be integrated with other software tools and systems. The spreadsheet is built on the popular Microsoft Excel platform, making it easy to modify and extend its functionality using Visual Basic for Applications (VBA) or other programming languages. Users can also import and export data from other software tools and systems, such as computer-aided design (CAD) software or process simulation tools. Additionally, the spreadsheet can be integrated with other instrumentation and control systems, allowing users to automate and streamline their thermowell installation and maintenance processes. By using this tool, users can improve the efficiency and productivity of their thermowell installations, reduce costs and risks, and ensure compliance with industry regulations and standards. The spreadsheet's customization and integration capabilities make it a valuable resource for professionals working in the field of process control and instrumentation.

Deja una respuesta

Entradas Relacionadas