Shaft Keyway Shear and Yield Strength Formulae and Calculator

The shaft keyway is a critical component in mechanical power transmission systems, and its design requires careful consideration of shear and yield strength to ensure reliable operation. Shear and yield strength are essential parameters in determining the shaft's ability to withstand various loads and stresses. To facilitate the calculation of these parameters, specific formulae have been developed, which can be used in conjunction with a calculator to determine the optimal design for a shaft keyway. These formulae and calculator tools enable engineers to make informed decisions and create robust designs. Accurate calculations are crucial for safety and performance.

- Shaft Keyway Shear and Yield Strength Formulae and Calculator

- How do you calculate keyway shear stress?

- How do you calculate yield strength of a shaft?

- How do you calculate the shear strength of a shaft?

- What is the formula for keyway cutting?

-

Frequently Asked Questions (FAQs)

- What is the significance of Shaft Keyway Shear and Yield Strength in mechanical engineering?

- How do I calculate the Shaft Keyway Shear and Yield Strength using the formulae and calculator?

- What are the factors that affect the Shaft Keyway Shear and Yield Strength?

- What are the applications of Shaft Keyway Shear and Yield Strength Formulae and Calculator in industry?

Shaft Keyway Shear and Yield Strength Formulae and Calculator

The calculation of shear and yield strength in shaft keyway design is crucial for ensuring the reliability and safety of mechanical systems. The shaft keyway is a critical component in power transmission, and its design must consider various factors, including material properties, geometric dimensions, and operating conditions. The shear strength of the keyway is determined by the material's ultimate shear strength, while the yield strength is a measure of the material's resistance to plastic deformation.

Introduction to Shaft Keyway Design

Shaft keyway design involves the selection of keyway dimensions, material properties, and operating conditions to ensure the safe and reliable transmission of power. The keyway is a slot or groove cut into the shaft, which accommodates a key that transmits torque to a gear or other component. The design of the keyway must consider factors such as stress concentrations, material fatigue, and wear resistance.

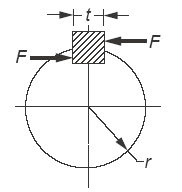

Shear Strength Formulae

The shear strength of the keyway can be calculated using the following formula: τ = F / A, where τ is the shear stress, F is the force applied to the key, and A is the area of the keyway. The shear strength can also be calculated using the ultimate shear strength of the material, which is typically specified in material property tables.

Yield Strength Formulae

The yield strength of the keyway can be calculated using the following formula: σy = F / A, where σy is the yield stress, F is the force applied to the key, and A is the area of the keyway. The yield strength is an important measure of the material's resistance to plastic deformation and is typically specified in material property tables.

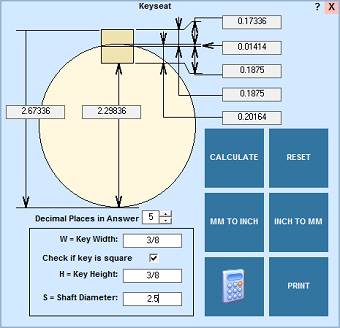

Calculator for Shaft Keyway Design

A calculator for shaft keyway design can be used to determine the optimal keyway dimensions and material properties for a given application. The calculator can take into account factors such as operating conditions, material properties, and geometric dimensions to provide a detailed design report. The report can include calculations for shear strength, yield strength, and stress concentrations, as well as recommendations for keyway dimensions and material selection.

Material Properties for Shaft Keyway Design

The material properties of the shaft and key are critical in determining the shear and yield strength of the keyway. The material properties can include ultimate tensile strength, ultimate shear strength, yield strength, and modulus of elasticity. The following table provides a summary of common material properties for shaft keyway design:

| Material | Ultimate Tensile Strength | Ultimate Shear Strength | Yield Strength | Modulus of Elasticity |

|---|---|---|---|---|

| Steel | 800 MPa | 400 MPa | 400 MPa | 200 GPa |

| Aluminum | 300 MPa | 150 MPa | 150 MPa | 70 GPa |

The material properties can vary depending on the specific alloy and manufacturing process, and it is essential to consult material property tables or manufacturer's specifications for accurate values.

How do you calculate keyway shear stress?

To calculate keyway shear stress, you need to understand the forces acting on the key and the material properties of the shaft and key. The keyway is a slot or groove in the shaft that accepts a key, which is a piece of material that fits into the keyway and helps to transmit torque from the shaft to a connected component. Shear stress occurs when the key is subjected to a force that causes it to deform by sliding over the shaft.

Understanding Keyway Geometry

The keyway geometry plays a crucial role in calculating the shear stress. The keyway is typically a rectangular or square slot with a specific width and depth. To calculate the shear stress, you need to know the dimensions of the keyway, including the width, depth, and length. Keyway dimensions are critical in determining the shear stress because they affect the area of the key that is in contact with the shaft. Here are some key factors to consider:

- The width of the keyway, which affects the shear area of the key

- The depth of the keyway, which affects the moment arm of the force acting on the key

- The length of the keyway, which affects the beam length of the key and its ability to resist shear stress

Calculating Shear Force

The shear force acting on the key is a critical factor in calculating the shear stress. The shear force is the force that causes the key to deform by sliding over the shaft. To calculate the shear force, you need to know the torque being transmitted by the shaft and the radius of the shaft. Torque and radius are related to the shear force by the following equation: Shear Force = Torque / Radius. Here are some key factors to consider:

- The torque being transmitted by the shaft, which affects the shear force acting on the key

- The radius of the shaft, which affects the moment arm of the force acting on the key

- The friction coefficient between the key and the shaft, which affects the shear force required to cause the key to slip

Determining Material Properties

The material properties of the shaft and key are critical in calculating the shear stress. The material properties include the yield strength, ultimate strength, and elastic modulus of the materials. Yield strength and ultimate strength are important because they determine the maximum shear stress that the key can withstand without failing. Here are some key factors to consider:

- The yield strength of the key material, which determines the maximum shear stress that the key can withstand without deforming plastically

- The ultimate strength of the key material, which determines the maximum shear stress that the key can withstand without failing

- The elastic modulus of the key material, which affects the stiffness of the key and its ability to resist shear stress

Applying Failure Theories

Failure theories are used to predict the shear stress at which the key will fail. There are several failure theories available, including the maximum shear stress theory and the von Mises theory. The maximum shear stress theory predicts that the key will fail when the shear stress reaches a maximum value, while the von Mises theory predicts that the key will fail when the shear stress reaches a value that causes the material to yield. Here are some key factors to consider:

- The maximum shear stress theory, which predicts that the key will fail when the shear stress reaches a maximum value

- The von Mises theory, which predicts that the key will fail when the shear stress reaches a value that causes the material to yield

- The factor of safety, which is used to account for uncertainties in the material properties and loading conditions

Verifying Results with Testing

Testing is an essential step in verifying the results of the shear stress calculation. Testing can be used to validate the material properties and loading conditions assumed in the calculation, and to verify that the key can withstand the shear stress predicted by the calculation. Here are some key factors to consider:

- The testing procedure, which should be designed to simulate the loading conditions expected in service

- The testing equipment, which should be capable of applying the shear force and torque required to test the key

- The test results, which should be used to validate the shear stress calculation and verify that the key can withstand the shear stress predicted by the calculation

How do you calculate yield strength of a shaft?

To calculate the yield strength of a shaft, you need to understand the material properties and the loading conditions. The yield strength is the stress at which a material exhibits a specified deviation from the proportionality of stress to strain. In the case of a shaft, the yield strength is typically determined by the material's yield point, which is the point at which the material begins to deform plastically.

Understanding Material Properties

To calculate the yield strength of a shaft, you need to understand the material properties, such as the elastic modulus, poisson's ratio, and the yield point. The elastic modulus is a measure of the stiffness of the material, while the poisson's ratio is a measure of the lateral strain that occurs when a material is subjected to a tensile load. The yield point is the point at which the material begins to deform plastically. Here are some key material properties to consider:

- Elastic modulus: a measure of the stiffness of the material

- Poisson's ratio: a measure of the lateral strain that occurs when a material is subjected to a tensile load

- Yield point: the point at which the material begins to deform plastically

Calculating Yield Strength

To calculate the yield strength of a shaft, you can use the yield strength formula, which is typically expressed as σy = F / A, where σy is the yield strength, F is the force applied to the shaft, and A is the cross-sectional area of the shaft. The force applied to the shaft can be calculated using the torque and the radius of the shaft. Here are some key steps to follow:

- Determine the force applied to the shaft: using the torque and radius of the shaft

- Calculate the cross-sectional area of the shaft: using the radius and diameter of the shaft

- Apply the yield strength formula: σy = F / A

Considering Loading Conditions

When calculating the yield strength of a shaft, you need to consider the loading conditions, such as the torque, bending moment, and axial load. The torque is a measure of the rotational force applied to the shaft, while the bending moment is a measure of the flexural load applied to the shaft. The axial load is a measure of the tensile or compressive load applied to the shaft. Here are some key loading conditions to consider:

- Torque: a measure of the rotational force applied to the shaft

- Bending moment: a measure of the flexural load applied to the shaft

- Axial load: a measure of the tensile or compressive load applied to the shaft

Accounting for Shaft Geometry

When calculating the yield strength of a shaft, you need to account for the shaft geometry, such as the radius, diameter, and length. The radius and diameter of the shaft affect the cross-sectional area, while the length of the shaft affects the moment of inertia. Here are some key geometric parameters to consider:

- Radius: affects the cross-sectional area of the shaft

- Diameter: affects the cross-sectional area of the shaft

- Length: affects the moment of inertia of the shaft

Using Design Codes and Standards

When calculating the yield strength of a shaft, you can use design codes and standards, such as the ASME Boiler and Pressure Vessel Code or the API Standards. These codes and standards provide guidelines for calculating the yield strength of a shaft, as well as other design parameters, such as the safety factor and the factor of safety. Here are some key design codes and standards to consider:

- ASME Boiler and Pressure Vessel Code: provides guidelines for calculating the yield strength of a shaft

- API Standards: provides guidelines for calculating the yield strength of a shaft

- Safety factor: a measure of the margin of safety against failure

How do you calculate the shear strength of a shaft?

To calculate the shear strength of a shaft, you need to consider several factors, including the material properties, geometry, and loading conditions. The shear strength of a shaft is typically calculated using the Torque formula, which is given by T = (π/16) d^3 τ, where T is the torque, d is the diameter of the shaft, and τ is the shear stress. The shear stress can be calculated using the Tresca or Von Mises criteria, which take into account the yield strength and ultimate strength of the material.

Understanding Shaft Geometry

The geometry of the shaft plays a crucial role in calculating its shear strength. The diameter, length, and cross-sectional area of the shaft all affect the shear stress and torque that the shaft can withstand. To calculate the shear strength, you need to know the geometry of the shaft, including:

- The diameter of the shaft, which affects the cross-sectional area and shear stress

- The length of the shaft, which affects the torque and bending moment

- The cross-sectional area of the shaft, which affects the shear stress and torque

Material Properties and Selection

The material properties of the shaft also play a significant role in calculating its shear strength. The yield strength, ultimate strength, and elastic modulus of the material all affect the shear stress and torque that the shaft can withstand. To calculate the shear strength, you need to know the material properties, including:

- The yield strength of the material, which affects the shear stress and torque

- The ultimate strength of the material, which affects the shear stress and torque

- The elastic modulus of the material, which affects the shear stress and torque

Calculating Shear Stress and Torque

To calculate the shear strength of a shaft, you need to calculate the shear stress and torque that the shaft can withstand. The shear stress can be calculated using the Tresca or Von Mises criteria, which take into account the yield strength and ultimate strength of the material. The torque can be calculated using the Torque formula, which is given by T = (π/16) d^3 τ. To calculate the shear stress and torque, you need to:

- Calculate the shear stress using the Tresca or Von Mises criteria

- Calculate the torque using the Torque formula

- Check the shear stress and torque against the material properties and geometry of the shaft

Effects of Loading Conditions

The loading conditions of the shaft also affect its shear strength. The loading conditions can include axial loading, bending loading, and torsional loading, each of which affects the shear stress and torque that the shaft can withstand. To calculate the shear strength, you need to consider the loading conditions, including:

- The axial loading, which affects the shear stress and torque

- The bending loading, which! affects the shear stress and torque

- The torsional loading, which affects the shear stress and torque

Design and Optimization

To design and optimize a shaft for maximum shear strength, you need to consider the material properties, geometry, and loading conditions. The design and optimization process involves calculating the shear strength of the shaft and checking it against the material properties and geometry. To design and optimize a shaft, you need to:

- Calculate the shear strength of the shaft using the Torque formula and Tresca or Von Mises criteria

- Check the shear strength against the material properties and geometry of the shaft

- Optimize the design of the shaft to maximize its shear strength and minimize its weight and cost

What is the formula for keyway cutting?

The formula for keyway cutting is based on the dimensions of the keyway and the cutting tool used. The keyway is a slot or groove cut in a shaft or hub to receive a key, which is a piece of metal that helps to secure a pulley, gear, or other rotating component in place. The formula typically involves calculating the width, depth, and length of the keyway, as well as the radius of the corner of the keyway.

Understanding Keyway Dimensions

To cut a keyway, it is essential to understand the dimensions involved. The width of the keyway is typically equal to the width of the key, while the depth is usually equal to the diameter of the shaft or hub. The length of the keyway depends on the length of the key and the type of cutting tool used. Some common dimensions for keyways include:

- Width: 1/4 inch to 1 inch (6 mm to 25 mm)

- Depth: 1/8 inch to 1/2 inch (3 mm to 13 mm)

- Length: 1 inch to 6 inches (25 mm to 152 mm)

Types of Keyway Cutting Tools

There are several types of cutting tools that can be used to cut keyways, including keyway broaches, milling cutters, and grinding wheels. Each type of tool has its own advantages and disadvantages, and the choice of tool depends on the material being cut, the size of the keyway, and the desired level of precision. Some common features of keyway cutting tools include:

- High-speed steel or tungsten carbide tips for increased durability

- Specialized cutting edges for improved accuracy

- Adjustable guide rails for easier setup

Machining Techniques for Keyway Cutting

There are several machining techniques that can be used to cut keyways, including milling, grinding, and broaching. Each technique has its own advantages and disadvantages, and the choice of technique depends on the material being cut, the size of the keyway, and the desired level of precision. Some common techniques include:

- Conventional milling: using a milling cutter to remove material and create the keyway

- Climb milling: using a milling cutter to remove material and create the keyway, with the cutting edge moving in the same direction as the rotating component

- Broaching: using a keyway broach to remove material and create the keyway

Factors Affecting Keyway Cutting Accuracy

There are several factors that can affect the accuracy of keyway cutting, including the type of cutting tool used, the material being cut, and the setup of the machining operation. Some common factors include:

- Tool wear: the wear on the cutting tool can affect the accuracy of the keyway

- Material hardness: the hardness of the material being cut can affect the accuracy of the keyway

- Setup errors: errors in the setup of the machining operation can affect the accuracy of the keyway

Applications of Keyway Cutting

Keyway cutting is used in a variety of industries, including aerospace, automotive, and manufacturing. Some common applications include:

- Power transmission: keyways are used to secure pulleys and gears in power transmission systems

- Rotating equipment: keyways are used to secure rotating components such as shafts and hubs

- Machinery: keyways are used to secure moving parts in machinery

Frequently Asked Questions (FAQs)

What is the significance of Shaft Keyway Shear and Yield Strength in mechanical engineering?

The Shaft Keyway Shear and Yield Strength Formulae and Calculator are essential tools in mechanical engineering, particularly in the design and analysis of shafts and keyways. The shear strength of a material is its ability to withstand deformation caused by a shear force, which is a force that causes the material to deform by sliding along a plane parallel to the direction of the force. In the context of shafts and keyways, shear strength is critical in determining the maximum torque that a shaft can transmit without failing. The yield strength, on the other hand, is the stress at which a material begins to deform plastically, meaning that it will not return to its original shape when the stress is removed. Understanding the yield strength of a material is crucial in ensuring that a shaft can withstand the stress and strain caused by various types of loading, including torsional, bending, and axial loads.

How do I calculate the Shaft Keyway Shear and Yield Strength using the formulae and calculator?

To calculate the Shaft Keyway Shear and Yield Strength, you need to use the formulae provided, which take into account various parameters such as the shaft diameter, keyway width, keyway depth, and material properties. The calculator is a useful tool that can simplify the calculation process by allowing you to input the relevant parameters and obtain the results quickly. The formulae are based on the theories of mechanics of materials, which provide a mathematical framework for analyzing the behavior of materials under different types of loading. By using the formulae and calculator, you can determine the maximum shear stress and yield stress that a shaft can withstand, which is essential in ensuring the safety and reliability of mechanical systems.

What are the factors that affect the Shaft Keyway Shear and Yield Strength?

There are several factors that can affect the Shaft Keyway Shear and Yield Strength, including the material properties, such as the ultimate tensile strength, yield strength, and shear modulus. The shaft diameter and keyway dimensions also play a critical role in determining the shear strength and yield strength. Additionally, the surface finish and machining process used to create the keyway can also impact the strength and durability of the shaft. Other factors, such as the operating temperature and environmental conditions, can also influence the behavior of the material and the performance of the shaft. By understanding these factors, designers and engineers can optimize the design of shafts and keyways to ensure that they can withstand the stress and strain caused by various types of loading.

What are the applications of Shaft Keyway Shear and Yield Strength Formulae and Calculator in industry?

The Shaft Keyway Shear and Yield Strength Formulae and Calculator have numerous applications in various industries, including aerospace, automotive, industrial machinery, and power generation. In these industries, shafts and keyways are critical components that transmit power and torque in mechanical systems. The formulae and calculator can be used to design and analyze shafts and keyways for a wide range of applications, including gearboxes, pumps, motors, and generators. By using these tools, designers and engineers can ensure that their designs are safe, reliable, and efficient, which is critical in maintaining the performance and productivity of mechanical systems. The formulae and calculator can also be used in research and development to optimize the design of new materials and components, and to improve the performance of existing systems.

Deja una respuesta

Entradas Relacionadas