Pipe per. Threads EN 10226-1 Calculator

The Pipe Thread Calculator based on EN 10226-1 is a valuable tool for engineers and technicians working with tapered threads. This standard specifies the requirements for pipe threads where pressure-tight joints are made on the threads. The calculator helps determine the dimensions and tolerances of the threads, ensuring a secure and leak-free connection. With its user-friendly interface, the calculator simplifies the process of calculating thread dimensions, making it an essential resource for industries such as oil and gas, chemical processing, and piping systems. Accurate calculations are crucial for safe and reliable operations.

Pipe Threads EN 10226-1 Calculator: A Comprehensive Guide

The Pipe Threads EN 10226-1 Calculator is a tool used to calculate the dimensions of pipe threads according to the EN 10226-1 standard. This standard specifies the requirements for the design, manufacture, and testing of pipe threads. The calculator takes into account various parameters such as the pipe diameter, thread type, and pitch to calculate the thread dimensions.

Introduction to EN 10226-1 Standard

The EN 10226-1 standard is a European standard that specifies the requirements for pipe threads. It covers the design, manufacture, and testing of pipe threads, including the dimensions, tolerances, and threads per inch (TPI). The standard also provides guidelines for the inspection and testing of pipe threads.

Pipe Thread Types and Dimensions

There are several types of pipe threads, including NPT (National Pipe Taper), BSP (British Standard Pipe), and metric threads. Each type of thread has its own set of dimensions and tolerances. The Pipe Threads EN 10226-1 Calculator takes into account these different thread types and calculates the dimensions according to the selected thread type.

Calculation Parameters and Formulas

The Pipe Threads EN 10226-1 Calculator uses various parameters and formulas to calculate the thread dimensions. These parameters include the pipe diameter, thread type, pitch, and major diameter. The calculator uses formulas such as the thread pitch formula and the major diameter formula to calculate the thread dimensions.

Benefits and Applications of the Calculator

The Pipe Threads EN 10226-1 Calculator has several benefits and applications. It provides accurate calculations of thread dimensions, which is essential for ensuring the quality and safety of pipe threads. The calculator is also useful for design engineers and manufacturers who need to design and manufacture pipe threads according to the EN 10226-1 standard.

Example Calculations and Results

The following table shows an example calculation using the Pipe Threads EN 10226-1 Calculator:

| Parameter | Value |

|---|---|

| Pipe Diameter | 1 inch |

| Thread Type | NPT |

| Pitch | 1/16 inch |

| Major Diameter | 1.031 inches |

| Threads per Inch (TPI) | 11.5 TPI |

The calculator calculates the thread dimensions, including the major diameter and threads per inch (TPI), based on the input parameters.

What is DIN EN 10226-1 standard?

The DIN EN 10226-1 standard is a European standard that specifies the requirements for pipe threads where pressure-tight joints are not made on the threads. This standard is applicable to pipe threads for tubes and fittings where the thread is used as a mechanical means of connecting the components. The standard defines the dimensions and tolerances for pipe threads, as well as the requirements for thread forms and thread engagement.

Introduction to DIN EN 10226-1

The DIN EN 10226-1 standard provides a comprehensive set of requirements for pipe threads, including the dimensions, tolerances, and thread forms. The standard is applicable to a wide range of industries, including petroleum, natural gas, and chemical processing. Some of the key aspects of the standard include:

- Thread dimensions: The standard specifies the nominal sizes and dimensional tolerances for pipe threads.

- Thread forms: The standard defines the thread forms and thread angles that are permitted for use in pipe threads.

- Thread engagement: The standard specifies the requirements for thread engagement, including the minimum and maximum engagement lengths.

Scope of DIN EN 10226-1

The DIN EN 10226-1 standard has a broad scope that covers a wide range of applications. The standard is applicable to pipe threads for tubes and fittings where the thread is used as a mechanical means of connecting the components. Some of the key aspects of the standard's scope include:

- Pipe threads: The standard applies to pipe threads for tubes and fittings, including union nuts, elbows, and tees.

- Thread sizes: The standard covers a range of thread sizes, from 1/16 to 6 inches.

- Materials: The standard applies to pipe threads made from a variety of materials, including carbon steel, stainless steel, and copper alloys.

Requirements of DIN EN 10226-1

The DIN EN 10226-1 standard specifies a range of requirements for pipe threads, including dimensions, tolerances, and thread forms. Some of the key requirements include:

- Thread dimensions: The standard specifies the nominal sizes and dimensional tolerances for pipe threads.

- Thread forms: The standard defines the thread forms and thread angles that are permitted for use in pipe threads.

- Surface finish: The standard specifies the requirements for surface finish, including the maximum roughness values.

Benefits of DIN EN 10226-1

The DIN EN 10226-1 standard provides a number of benefits to manufacturers and users of pipe threads. Some of the key benefits include:

- Interchangeability: The standard ensures interchangeability between pipe threads from different manufacturers.

- Safety: The standard helps to ensure safety by specifying requirements for thread engagement and surface finish.

- Reliability: The standard provides a reliable means of connecting components, reducing the risk of leaks and failures.

Future Developments of DIN EN 10226-1

The DIN EN 10226-1 standard is subject to periodic review and revision to ensure that it remains relevant and effective. Some of the potential future developments of the standard include:

- New materials: The standard may be updated to include new materials, such as composites and advanced alloys.

- Improved tolerances: The standard may be revised to include improved tolerances and dimensional accuracy.

- Increased scope: The standard may be expanded to cover a wider range of applications and industries.

How do you calculate pipe thread?

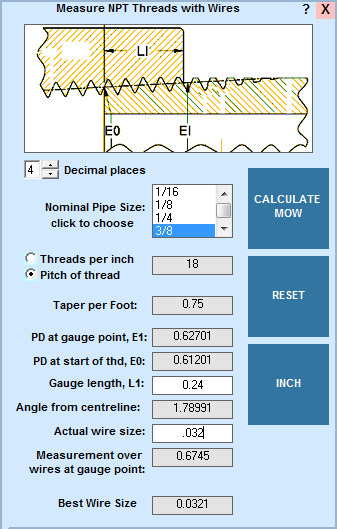

To calculate pipe thread, you need to understand the different parameters involved in the process. The first step is to determine the nominal diameter of the pipe, which is the diameter of the pipe without considering the thread. Then, you need to consider the thread type, such as NPT (National Pipe Taper) or PT (Pipe Thread), as well as the thread size, which is typically measured in inches or millimeters. The pitch of the thread, which is the distance between two consecutive threads, is also an important factor in calculating pipe thread.

Understanding Pipe Thread Types

When calculating pipe thread, it's essential to understand the different types of threads, including NPT, PT, and BSPT (British Standard Pipe Taper). Each type of thread has its own unique characteristics, such as the thread angle and pitch. To calculate pipe thread, you need to know the specific type of thread being used. Here are some key points to consider:

- The NPT thread type is commonly used in North America and has a thread angle of 60 degrees.

- The PT thread type is commonly used in Europe and has a thread angle of 55 degrees.

- The BSPT thread type is commonly used in the UK and has a thread angle of 55 degrees.

Calculating Pipe Thread Size

To calculate pipe thread size, you need to consider the nominal diameter of the pipe and the thread size. The thread size is typically measured in inches or millimeters and is used to determine the major diameter of the thread, which is the largest diameter of the thread. The major diameter is an essential parameter in calculating pipe thread. Here are some key points to consider:

- The nominal diameter of the pipe is the diameter of the pipe without considering the thread.

- The thread size is typically measured in inches or millimeters and is used to determine the major diameter of the thread.

- The major diameter is the largest diameter of the thread and is an essential parameter in calculating pipe thread.

Determining Pipe Thread Pitch

The pitch of the thread is the distance between two consecutive threads and is an essential parameter in calculating pipe thread. The pitch is typically measured in inches or millimeters and is used to determine the thread length. Here are some key points to consider:

- The pitch of the thread is the distance between two consecutive threads.

- The pitch is typically measured in inches or millimeters and is used to determine the thread length.

- The thread length is the length of the thread and is an essential parameter in calculating pipe thread.

Calculating Pipe Thread Length

To calculate pipe thread length, you need to consider the nominal diameter of the pipe, the thread size, and the pitch. The thread length is the length of the thread and is an essential parameter in calculating pipe thread. Here are some key points to consider:

- The nominal diameter of the pipe is the diameter of the pipe without considering the thread.

- The thread size is typically measured in inches or millimeters and is used to determine the major diameter of the thread.

- The pitch of the thread is the distance between two consecutive threads and is used to determine the thread length.

Using Pipe Thread Calculators

There are many pipe thread calculators available online that can help you calculate pipe thread. These calculators typically require you to input the nominal diameter of the pipe, the thread size, and the pitch, and then provide the major diameter, thread length, and other essential parameters. Here are some key points to consider:

- Pipe thread calculators can help you calculate pipe thread quickly and accurately.

- These calculators typically require you to input the nominal diameter of the pipe, the thread size, and the pitch.

- The calculators provide the major diameter, thread length, and other essential parameters needed to calculate pipe thread.

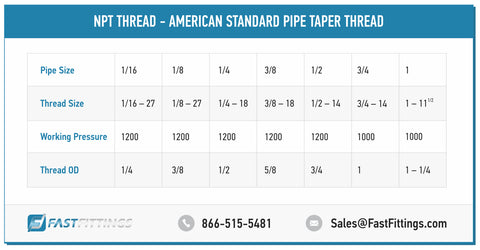

How many threads are on an 1 inch pipe?

The number of threads on a 1-inch pipe can vary depending on the type of pipe and the thread standard being used. Typically, a 1-inch pipe has 11.5 threads per inch (TPI) for a National Pipe Tapered (NPT) thread, which is a common thread standard in the United States.

Understanding Thread Standards

Understanding the thread standard is crucial in determining the number of threads on a pipe. The National Pipe Tapered (NPT) thread standard is commonly used in the United States, while the British Standard Pipe (BSP) thread standard is used in Europe and other parts of the world. The number of threads per inch can vary depending on the thread standard being used. For example:

- The NPT thread standard has 11.5 threads per inch (TPI) for a 1-inch pipe.

- The BSP thread standard has 14 threads per inch (TPI) for a 1-inch pipe.

- The metric thread standard has 12 threads per inch (TPI) for a 1-inch pipe.

Types of Pipe Threads

There are several types of pipe threads, including tapered threads, straight threads, and parallel threads. The tapered thread is the most common type of pipe thread and is used for NPT and BSP threads. The straight thread is used for metric threads and is less common than the tapered thread. The number of threads on a pipe can vary depending on the type of thread being used. For example:

- Tapered threads have a taper of 1/16 inch per inch of thread length.

- Straight threads have no taper and are used for metric threads.

- Parallel threads are used for hydraulic and pneumatic applications.

Measuring Thread Pitch

The thread pitch is the distance between two threads and is typically measured in inches or millimeters. The thread pitch can be measured using a caliper or a thread gauge. The number of threads on a pipe can be calculated by measuring the thread pitch and dividing it by the thread length. For example:

- The thread pitch for a 1-inch NPT pipe is 0.0866 inches.

- The thread pitch for a 1-inch BSP pipe is 0.0714 inches.

- The thread pitch for a 1-inch metric pipe is 0.0833 inches.

Calculating Thread Count

The number of threads on a pipe can be calculated by measuring the thread length and dividing it by the thread pitch. For example, if the thread length is 1 inch and the thread pitch is 0.0866 inches, the number of threads can be calculated as follows:

- Number of threads = thread length / thread pitch = 1 / 0.0866 = 11.5 threads.

- Number of threads = thread length / thread pitch = 1 / 0.0714 = 14 threads.

- Number of threads = thread length / thread pitch = 1 / 0.0833 = 12 threads.

Importance of Thread Count

The number of threads on a pipe is critical in ensuring a leak-free connection. If the number of threads is incorrect, it can result in a leaky connection, which can lead to fluid loss, pressure drop, and equipment failure. The thread count must be accurate to ensure a proper connection. For example:

- A incorrect thread count can result in a leaky connection.

- A correct thread count can ensure a leak-free connection.

- The thread count must be verified before making a connection.

What is pipe thread per inch?

Pipe thread per inch refers to the measurement of the threads on a pipe, which is crucial for ensuring a secure and leak-free connection between pipes and fittings. The thread pitch is the distance between two adjacent threads, and it is measured in inches. The pipe thread is the spiraling groove cut into the pipe to create a secure connection. The thread per inch measurement is essential for determining the correct pipe size and thread type for a specific application.

Understanding Pipe Thread Measurements

To understand pipe thread measurements, it is essential to know the different thread types, including National Pipe Taper (NPT) and National Pipe Straight (NPS). The thread per inch measurement is critical for ensuring a secure connection between pipes and fittings. The following are key points to consider when working with pipe thread measurements:

- The thread pitch is the distance between two adjacent threads, which is measured in inches.

- The pipe size is determined by the thread per inch measurement, which is critical for ensuring a secure connection.

- The thread type is essential for determining the correct pipe size and thread pitch for a specific application.

Importance of Pipe Thread Per Inch in Plumbing

The pipe thread per inch measurement is crucial in plumbing applications, where a secure and leak-free connection is essential. The thread pitch and pipe size must be carefully matched to ensure a secure connection between pipes and fittings. The following are key factors to consider when working with pipe thread per inch in plumbing:

- The thread per inch measurement must be matched to the pipe size and thread type to ensure a secure connection.

- The pipe thread must be properly cut and tapered to create a secure connection.

- The thread sealant must be applied correctly to prevent leaks and ensure a secure connection.

Pipe Thread Per Inch in Industrial Applications

The pipe thread per inch measurement is also critical in industrial applications, where high-pressure and high-temperature pipes are used. The thread pitch and pipe size must be carefully matched to ensure a secure connection between pipes and fittings. The following are key factors to consider when working with pipe thread per inch in industrial applications:

- The thread per inch measurement must be matched to the pipe size and thread type to ensure a secure connection.

- The pipe thread must be properly cut and tapered to create a secure connection.

- The thread sealant must be applied correctly to prevent leaks and ensure a secure connection.

Common Pipe Thread Per Inch Measurements

There are several common pipe thread per inch measurements, including 1/8 inch, 1/4 inch, 1/2 inch, and 1 inch. Each pipe size has a specific thread per inch measurement, which is critical for ensuring a secure connection between pipes and fittings. The following are key points to consider when working with common pipe thread per inch measurements:

- The 1/8 inch pipe size has a thread per inch measurement of 27 threads per inch.

- The 1/4 inch pipe size has a thread per inch measurement of 18 threads per inch.

- The 1/2 inch pipe size has a thread per inch measurement of 14 threads per inch.

Pipe Thread Per Inch Tools and Equipment

There are several tools and equipment available for working with pipe thread per inch, including pipe threaders, taps, and dies. These tools are essential for cutting and tapering pipes to create a secure connection. The following are key points to consider when working with pipe thread per inch tools and equipment:

- The pipe threader is used to cut and taper pipes to create a secure connection.

- The tap is used to cut the threads on a pipe to create a secure connection.

- The die is used to cut the threads on a pipe to create a secure connection.

Frequently Asked Questions (FAQs)

What is the purpose of the Pipe Threads EN 10226-1 Calculator?

The Pipe Threads EN 10226-1 Calculator is a mathematical tool designed to calculate the dimensions and tolerances of pipe threads according to the European standard EN 10226-1. This standard specifies the requirements for taper threads and parallel threads used in piping systems. The calculator is used to determine the thread diameter, thread pitch, and thread length, as well as the tolerances and limits of the threads. By using this calculator, engineers and designers can ensure that their pipe threads meet the requirements of the standard, which is essential for safe and reliable operation of piping systems.

How does the Pipe Threads EN 10226-1 Calculator work?

The Pipe Threads EN 10226-1 Calculator works by inputting the nominal diameter and thread type of the pipe, and then calculating the corresponding thread dimensions and tolerances. The calculator uses a set of algorithms and formulas based on the EN 10226-1 standard to perform the calculations. The user can input the nominal diameter in millimeters or inches, and select the thread type from a drop-down menu. The calculator then outputs the thread diameter, thread pitch, thread length, and tolerances in a table format, making it easy to read and understand the results. The calculator also includes a help section that provides explanations and examples of how to use the calculator.

What are the benefits of using the Pipe Threads EN 10226-1 Calculator?

The Pipe Threads EN 10226-1 Calculator offers several benefits to engineers and designers working with pipe threads. One of the main benefits is time-saving, as the calculator can perform complex calculations quickly and accurately. Another benefit is reduced errors, as the calculator eliminates the risk of human error when performing calculations manually. The calculator also provides consistent results, which is essential for quality control and quality assurance. Additionally, the calculator can be used to optimize pipe thread designs, which can lead to cost savings and improved performance. Overall, the Pipe Threads EN 10226-1 Calculator is a valuable tool for anyone working with pipe threads, as it helps to ensure compliance with the EN 10226-1 standard.

Can the Pipe Threads EN 10226-1 Calculator be used for other types of threads?

The Pipe Threads EN 10226-1 Calculator is specifically designed for calculating the dimensions and tolerances of pipe threads according to the EN 10226-1 standard. While it may be possible to use the calculator for other types of threads, it is not recommended. The calculator is based on the specific requirements of the EN 10226-1 standard, and using it for other types of threads may result in inaccurate or incomplete calculations. If you need to calculate the dimensions and tolerances of other types of threads, it is recommended to use a calculator or software that is specifically designed for that purpose. For example, if you need to calculate the dimensions and tolerances of metric threads, you should use a calculator or software that is based on the ISO 261 standard. Similarly, if you need to calculate the dimensions and tolerances of inch threads, you should use a calculator or software that is based on the ANSI/ASME B1.1 standard.

Deja una respuesta

Entradas Relacionadas