Horsepower Required to Compress Air Equations and Calculator

Determining the horsepower required to compress air is crucial in various industrial applications, including pneumatic systems and air compression equipment. The calculation involves several factors, such as compressor efficiency, air flow rate, and pressure. To simplify this process, equations and calculators can be used to estimate the horsepower required. This article provides an overview of the equations and calculator used to determine the horsepower required to compress air, helping engineers and technicians design and optimize their air compression systems efficiently. The provided equations and calculator ensure accurate calculations and improved system performance.

- Horsepower Required to Compress Air Equations and Calculator

- How to calculate air compressor HP?

- What is the formula for power of compressed air?

- How much horsepower do I need for air compressor?

- How do you calculate compressed air requirements?

-

Frequently Asked Questions (FAQs)

- ¿Qué es la ecuación para calcular la potencia de caballo requerida para comprimir aire?

- ¿Cómo se utiliza un calculador de potencia de caballo para comprimir aire?

- ¿Cuáles son los factores que afectan la potencia de caballo requerida para comprimir aire?

- ¿Por qué es importante calcular la potencia de caballo requerida para comprimir aire?

Horsepower Required to Compress Air Equations and Calculator

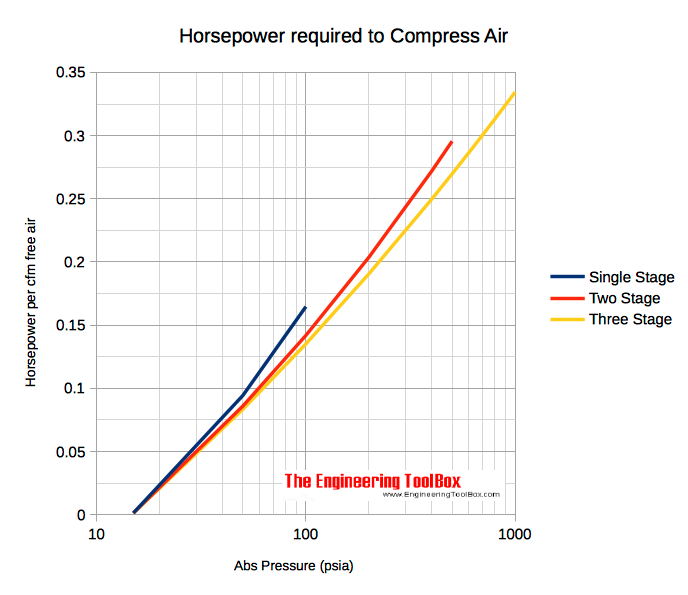

The calculation of horsepower required to compress air is a crucial aspect of designing and operating air compression systems. It involves understanding the principles of thermodynamics, fluid mechanics, and the characteristics of the compressor itself. Compressor efficiency, air density, and compression ratio are key factors that influence the horsepower required. The horsepower calculation can be complex, but it is essential for determining the size and type of compressor needed for a specific application, as well as for optimizing energy consumption.

Understanding Compressor Efficiency

Compressor efficiency is a measure of how effectively a compressor converts electrical energy into compressed air energy. It is affected by factors such as the compressor design, motor efficiency, and heat dissipation. A higher efficiency means less energy is wasted as heat, resulting in lower energy costs and reduced environmental impact. The efficiency of a compressor is typically expressed as a percentage and can be calculated using the formula: Efficiency = (Compressed Air Energy) / (Electrical Energy Input).

Air Density and Its Impact

Air density plays a significant role in determining the horsepower required for air compression. Density is affected by temperature and humidity; higher temperatures and humidity levels result in lower air density, which can reduce the horsepower needed. However, this also means that the compressor must work harder to achieve the same level of compression. Understanding how air density varies under different conditions is essential for accurately calculating horsepower requirements.

Compression Ratio and Its Effects

The compression ratio is the ratio of the absolute pressure of the compressed air to the absolute pressure of the inlet air. A higher compression ratio requires more horsepower to achieve the same volume of compressed air. This is because the compressor must do more work to compress the air to a higher pressure. The compression ratio is a critical factor in designing compression systems and selecting the appropriate compressor.

Calculating Horsepower Requirements

Calculating the horsepower required to compress air involves several factors, including the volume of air to be compressed, the inlet pressure, the outlet pressure, and the efficiency of the compressor. The formula for calculating horsepower is: HP = (CFM (P2 - P1)) / (3960 Efficiency), where CFM is the volume of air in cubic feet per minute, P2 and P1 are the outlet and inlet pressures in pounds per square inch, and Efficiency is the compressor efficiency as a decimal.

Using a Horsepower Calculator

A horsepower calculator for air compression systems can simplify the process of determining the required horsepower. These calculators typically require input of the compressor's specifications, the desired flow rate, and the pressure differential. They then calculate the horsepower needed based on these inputs and the assumed efficiency of the compressor. Using a calculator can help ensure accurate calculations and facilitate the selection of the right compressor for the application.

| Factor | Description | Influence on Horsepower |

|---|---|---|

| Compressor Efficiency | Measure of how effectively a compressor converts energy | Directly affects horsepower requirements |

| Air Density | Affected by temperature and humidity | Influences the work required for compression |

| Compression Ratio | Ratio of outlet to inlet pressure | Higher ratios require more horsepower |

| Calculator Tools | Simplify horsepower calculations | Help in selecting the appropriate compressor |

| Energy Costs | Affected by compressor efficiency and usage | Impact the overall cost of operating a compressor |

How to calculate air compressor HP?

To calculate air compressor HP, you need to understand the relationship between the compressor's power consumption and its ability to produce compressed air. The horsepower (HP) of an air compressor is a measure of its power output, and it's an important factor in determining the compressor's capacity to deliver compressed air to tools and equipment. The calculation typically involves the compressor's displacement (the volume of air it can move), efficiency, and pressure.

Understanding Air Compressor Basics

To calculate air compressor HP, you first need to understand the basics of air compressors. This includes knowing the type of compressor (e.g., reciprocating, rotary screw, or centrifugal), its displacement in cubic feet per minute (CFM), and the pressure it operates at, usually measured in pounds per square inch (PSI). Here are the key points to consider:

- The type of compressor affects its efficiency and HP requirements.

- The displacement of the compressor is crucial for determining its HP.

- The operating pressure impacts the compressor's power consumption and HP.

Calculating Air Compressor HP

Calculating the HP of an air compressor involves using a formula that takes into account the compressor's CFM and PSI. The basic formula is: HP = (CFM x PSI) / (1720 x efficiency). The efficiency of the compressor is a factor that represents how effectively the compressor converts electrical energy into compressed air. Here are the steps to follow:

- Determine the CFM and PSI of the compressor.

- Estimate the efficiency of the compressor (typically around 10-20%).

- Plug the values into the formula to calculate the HP.

Factors Affecting Air Compressor HP

Several factors can affect the HP of an air compressor, including the ambient temperature, humidity, and altitude. These factors can impact the compressor's efficiency and ability to produce compressed air. Here are some key considerations:

- High temperatures can reduce the compressor's efficiency and increase its HP requirements.

- High humidity can lead to moisture accumulation in the compressor and reduce its efficiency.

- Altitude can affect the compressor's performance, with higher altitudes requiring more HP to produce the same amount of compressed air.

Measuring Air Compressor Performance

Measuring the performance of an air compressor involves monitoring its pressure, flow rate, and power consumption. This can be done using various instruments and meters. Here are some key points to consider:

- Use a pressure gauge to monitor the compressor's output pressure.

- Use a flow meter to measure the compressor's CFM.

- Use a power meter to monitor the compressor's power consumption.

Improving Air Compressor Efficiency

Improving the efficiency of an air compressor can help reduce its HP requirements and lower energy costs. This can be achieved through various maintenance and upgrade strategies, including regular filter maintenance, lubrication, and upgrade to more efficient compressors. Here are some key considerations:

- Regularly clean and replace filters to ensure optimal air flow.

- Lubricate the compressor regularly to reduce friction and wear.

- Consider upgrading to a more efficient compressor or variable speed drive.

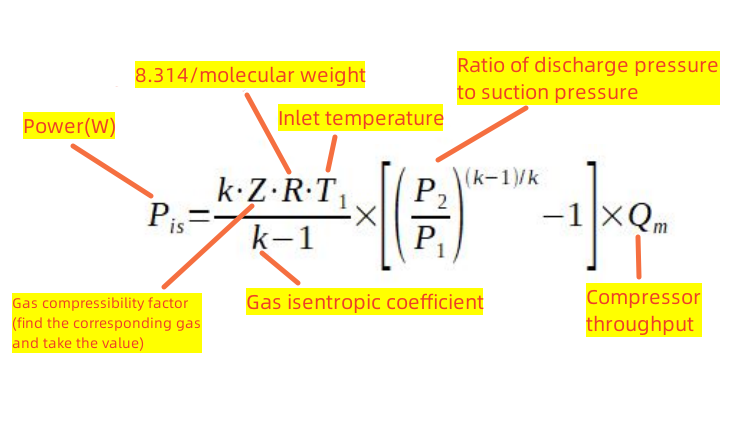

What is the formula for power of compressed air?

The formula for power of compressed air is P = (p1 - p2) Q / (p1 / p2), where P is the power, p1 and p2 are the initial and final pressures, and Q is the volume flow rate. This formula is used to calculate the power required to compress air in a system.

Understanding the Variables

To calculate the power of compressed air, it is essential to understand the variables involved in the formula. The variables include the initial pressure and final pressure, which are the pressures at the inlet and outlet of the compressor, respectively. The volume flow rate is also a critical variable, as it determines the amount of air being compressed. The formula can be broken down into the following components:

- The difference in pressure (p1 - p2) determines the pressure ratio of the system.

- The volume flow rate (Q) affects the mass flow rate of the air being compressed.

- The ratio of the initial to final pressure (p1 / p2) is used to calculate the compression ratio.

Importance of Compression Ratio

The compression ratio is a crucial factor in determining the power required to compress air. A higher compression ratio results in a greater power requirement, as more energy is needed to compress the air to a higher pressure. The compression ratio can be calculated using the formula CR = p1 / p2, where CR is the compression ratio. The following points highlight the importance of compression ratio:

- A higher compression ratio increases the temperature of the compressed air.

- A higher compression ratio also increases the energy required to compress the air.

- The compression ratio affects the efficiency of the compressor, with higher ratios resulting in lower efficiencies.

Effects of Pressure and Volume Flow Rate

The pressure and volume flow rate have a significant impact on the power required to compress air. An increase in pressure or volume flow rate results in a higher power requirement, as more energy is needed to compress the air. The following points highlight the effects of pressure and volume flow rate:

- An increase in pressure increases the power requirement, as more energy is needed to compress the air to a higher pressure.

- An increase in volume flow rate increases the mass flow rate of the air being compressed, resulting in a higher power requirement.

- The interplay between pressure and volume flow rate affects the overall efficiency of the compressor.

Applications of Compressed Air Power

Compressed air power has a wide range of applications, including industrial and commercial uses. The formula for power of compressed air is essential in designing and optimizing compressed air systems. The following points highlight some of the applications:

- Industrial applications, such as manufacturing and processing, rely heavily on compressed air power.

- Commercial applications, such as HVAC and refrigeration, also utilize compressed air power.

- Medical and pharmaceutical applications require high-purity compressed air, which demands precise control over the compression process.

Efficiency and Optimization

Efficiency and optimization are critical aspects of compressed air systems, as they directly impact the power requirement and cost of operation. The following points highlight some ways to improve efficiency and optimize compressed air systems:

- Regular maintenance is essential to ensure the compressor is operating at peak efficiency.

- Optimizing the compression ratio and volume flow rate can help reduce the power requirement.

- Using high-efficiency compressors and advanced control systems can also improve efficiency and reduce costs.

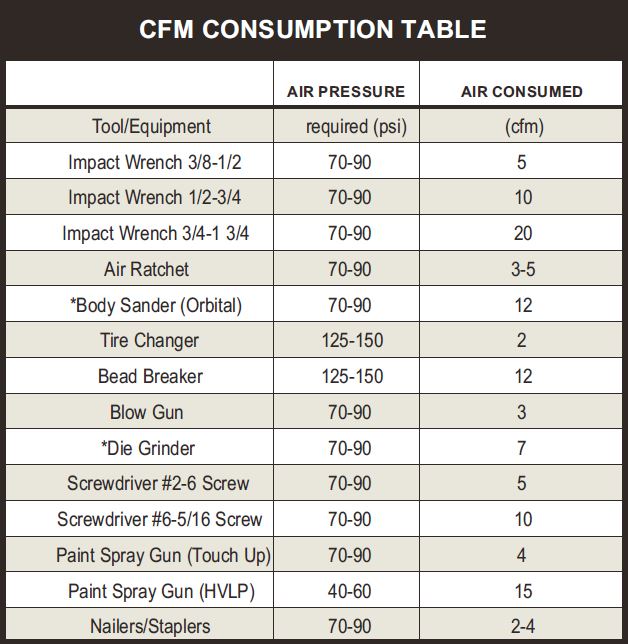

How much horsepower do I need for air compressor?

To determine how much horsepower you need for an air compressor, you need to consider the specific requirements of your application. The horsepower of an air compressor is a measure of its ability to deliver a certain amount of compressed air. A higher horsepower rating generally indicates a more powerful air compressor that can handle more demanding tasks. The amount of horsepower needed will depend on the size of the air compressor, the type of air compressor, and the intended use of the compressed air.

Understanding Air Compressor Requirements

When selecting an air compressor, it's essential to understand the specific requirements of your application. This includes considering the flow rate, pressure, and duty cycle of the air compressor. A higher flow rate and pressure will require more horsepower, while a lower duty cycle may allow for a smaller air compressor. Some key factors to consider when determining the required horsepower include:

- Flow rate: The amount of compressed air required, measured in cubic feet per minute (CFM) or liters per second (L/s)

- Pressure: The pressure at which the compressed air is delivered, measured in pounds per square inch (PSI) or bar

- Duty cycle: The percentage of time the air compressor is in operation, with higher duty cycles requiring more horsepower

Types of Air Compressors

There are several types of air compressors available, each with its own unique characteristics and horsepower requirements. Reciprocating air compressors are commonly used for small to medium-sized applications, while rotary screw air compressors are often used for larger, more demanding applications. Centrifugal air compressors are typically used for very large applications, such as industrial processes. Some key characteristics of each type include:

- Reciprocating air compressors: Low horsepower, low flow rate, and high pressure

- Rotary screw air compressors: Medium horsepower, medium flow rate, and medium pressure

- Centrifugal air compressors: High horsepower, high flow rate, and high pressure

Air Compressor Sizing

Proper sizing of an air compressor is critical to ensure it meets the requirements of your application. A horsepower that is too low may result in inadequate compressed air supply, while a horsepower that is too high may waste energy and increase costs. Some key factors to consider when sizing an air compressor include:

- Maximum flow rate: The highest flow rate required by the application

- Minimum pressure: The lowest pressure required by the application

- Duty cycle: The percentage of time the air compressor is in operation

Energy Efficiency Considerations

Energy efficiency is an essential consideration when selecting an air compressor. A more energy-efficient air compressor can help reduce energy costs and minimize environmental impact. Some key factors to consider when evaluating the energy efficiency of an air compressor include:

- Motor efficiency: The efficiency of the motor used to power the air compressor

- Compressor efficiency: The efficiency of the compressor itself, including the compression ratio and heat transfer

- Controls and automation: The use of controls and automation to optimize air compressor operation and reduce energy waste

Maintenance and Repair Considerations

Regular maintenance and repair are essential to ensure the air compressor operates efficiently and effectively. A well-maintained air compressor can help reduce downtime, minimize repair costs, and extend the life of the air compressor. Some key factors to consider when maintaining and repairing an air compressor include:

- Filter maintenance: Regular filter replacement to ensure clean air and prevent contamination

- Lubrication: Regular lubrication to reduce wear and prevent corrosion

- Inspection and testing: Regular inspection and testing to identify and address potential issues before they become major problems

How do you calculate compressed air requirements?

To calculate compressed air requirements, you need to consider several factors, including the air flow rate, pressure, and usage patterns of the equipment. The calculation involves determining the total air demand of the system, taking into account the compressor efficiency, pipe size, and leakage rates. This information is crucial to ensure that the compressed air system is properly sized and configured to meet the needs of the equipment and processes.

Understanding Compressed Air Demand

The compressed air demand is the total amount of air required by the system, including the air flow rate and pressure. To calculate the demand, you need to consider the usage patterns of the equipment, including the duty cycle, run time, and idle time. This information can be used to determine the average air flow rate and peak demand.

- Determine the air flow rate required by each piece of equipment

- Calculate the total air demand by summing the air flow rates of all equipment

- Consider the compressor efficiency and pipe size to determine the required compressor size

Calculating Compressor Size

The compressor size is critical to ensuring that the compressed air system can meet the air demand. To calculate the compressor size, you need to consider the air flow rate, pressure, and efficiency of the compressor. This information can be used to determine the required compressor power and size.

- Determine the required air flow rate and pressure

- Calculate the compressor power required using the air flow rate and pressure

- Select a compressor size that meets the required power and efficiency

Determining Pipe Size and Layout

The pipe size and layout are critical to ensuring that the compressed air system is properly configured. To determine the pipe size, you need to consider the air flow rate, pressure, and distance between equipment. This information can be used to determine the required pipe size and layout.

- Determine the air flow rate and pressure required by each piece of equipment

- Calculate the required pipe size using the air flow rate and pressure

- Design the pipe layout to minimize pressure drop and leakage

Accounting for Leakage and Pressure Drop

Leakage and pressure drop can significantly impact the compressed air system, reducing efficiency and increasing energy costs. To account for leakage and pressure drop, you need to consider the pipe size, layout, and equipment. This information can be used to determine the required compressor size and pipe layout.

- Determine the leakage rate and pressure drop in the system

- Calculate the required compressor size to account for leakage and pressure drop

- Design the pipe layout to minimize pressure drop and leakage

Monitoring and maintaining the compressed air system is critical to ensuring that it operates efficiently and effectively. To monitor and maintain the system, you need to consider the air flow rate, pressure, and equipment. This information can be used to determine the required maintenance and upgrades.

- Monitor the air flow rate and pressure to ensure they are within the required range

- Perform regular maintenance to minimize leakage and pressure drop

- Consider upgrading the system to improve efficiency and reduce energy costs

Frequently Asked Questions (FAQs)

¿Qué es la ecuación para calcular la potencia de caballo requerida para comprimir aire?

La ecuación para calcular la potencia de caballo requerida para comprimir aire es una fórmula que tiene en cuenta varios factores, como el volumen de aire a comprimir, la presión inicial y final, y la eficiencia del compresor. La fórmula generalmente se expresa como: Potencia de caballo = (Volumen de aire x (Presión final - Presión inicial)) / (1716 x Eficiencia del compresor). Esta ecuación es fundamental para determinar la potencia requerida para comprimir un determinado volumen de aire a una presión específica, lo que es crucial en diversas aplicaciones industriales, como la industria manufacturera y la industria de procesos. Un calculador de potencia de caballo puede ser una herramienta valiosa para simplificar este proceso y asegurarse de que se utilice la cantidad adecuada de energía para lograr el trabajo requerido.

¿Cómo se utiliza un calculador de potencia de caballo para comprimir aire?

Un calculador de potencia de caballo para comprimir aire es una herramienta que puede ser utilizada para determinar la potencia requerida para comprimir un determinado volumen de aire a una presión específica. Para utilizar este tipo de calculador, se deben ingresar varios parámetros, como el volumen de aire a comprimir, la presión inicial y final, y la eficiencia del compresor. Una vez que se han ingresado estos parámetros, el calculador puede proporcionar la potencia de caballo requerida para lograr la compresión del aire. Esto puede ser especialmente útil en aplicaciones donde se requiere una gran cantidad de potencia, como en la industria pesada o en la industria de procesos químicos. Al utilizar un calculador de potencia de caballo, se puede asegurarse de que se utilice la cantidad adecuada de energía para lograr el trabajo requerido, lo que puede ayudar a reducir costos y mejorar la eficiencia en general.

¿Cuáles son los factores que afectan la potencia de caballo requerida para comprimir aire?

La potencia de caballo requerida para comprimir aire puede ser afectada por varios factores, como el volumen de aire a comprimir, la presión inicial y final, y la eficiencia del compresor. El volumen de aire es un factor importante, ya que un mayor volumen de aire requiere más energía para comprimir. La presión inicial y final también son factores importantes, ya que una mayor presión final requiere más energía para lograr. La eficiencia del compresor también es un factor importante, ya que un compresor más eficiente puede requerir menos energía para lograr la misma cantidad de trabajo. Otros factores que pueden afectar la potencia de caballo requerida incluyen la temperatura del aire, la humedad del aire y el tamaño del compresor. Al entender estos factores, se puede diseñar un sistema de compresión de aire que sea más eficiente y eficaz en general.

¿Por qué es importante calcular la potencia de caballo requerida para comprimir aire?

Calcular la potencia de caballo requerida para comprimir aire es importante por varias razones. En primer lugar, puede ayudar a reducir costos al asegurarse de que se utilice la cantidad adecuada de energía para lograr el trabajo requerido. Si se utiliza demasiada energía, se pueden generar costos adicionales que no son necesarios. En segundo lugar, puede ayudar a mejorar la eficiencia del sistema de compresión de aire, lo que puede ser beneficioso para el medio ambiente y para la productividad en general. En tercer lugar, puede ayudar a prevenir problemas con el compresor, como la sobrecarga o la falla prematura, que pueden ser costosos y peligrosos. Al calcular la potencia de caballo requerida para comprimir aire, se puede diseñar un sistema de compresión de aire que sea más eficiente, eficaz y seguro en general, lo que puede ser beneficioso para una variedad de aplicaciones industriales y comerciales.

Deja una respuesta

Entradas Relacionadas