Heat Gain from Electric Motors and their Loads Formula and Calculator

Electric motors are a crucial component in various industrial and commercial applications, converting electrical energy into mechanical energy to power equipment and machinery. However, during operation, they also generate heat, which can lead to reduced efficiency, increased energy consumption, and potential damage to the motor and its load. Understanding heat gain from electric motors and their loads is essential for optimizing system performance, minimizing energy losses, and ensuring reliable operation. This article provides a comprehensive overview of the heat gain formula and calculator for electric motors and their loads.

- Understanding Heat Gain from Electric Motors and their Loads Formula and Calculator

- What is the formula for calculating heat load?

- What is the formula for heat gain?

- How much heat does a 1 hp motor produce?

- What is the heat transfer of electric motors?

-

Frequently Asked Questions (FAQs)

- What is the Heat Gain from Electric Motors and their Loads Formula and Calculator?

- How does the Heat Gain from Electric Motors and their Loads Formula and Calculator work?

- What are the key factors that affect the Heat Gain from Electric Motors and their Loads Formula and Calculator?

- How can the Heat Gain from Electric Motors and their Loads Formula and Calculator be used in practice?

Understanding Heat Gain from Electric Motors and their Loads Formula and Calculator

The heat gain from electric motors and their loads is a critical factor in determining the overall efficiency and performance of electrical systems. Electric motors convert electrical energy into mechanical energy, but a significant portion of the input energy is lost as heat due to various losses. The heat gain from electric motors and their loads can be calculated using a formula that takes into account the motor's efficiency, power output, and operating conditions. A calculator can also be used to simplify the calculation process.

Introduction to Heat Gain from Electric Motors

Heat gain from electric motors occurs due to the conversion of electrical energy into mechanical energy. The motor's efficiency plays a significant role in determining the amount of heat generated. A motor with high efficiency will generate less heat compared to a motor with low efficiency. The heat gain from electric motors can be calculated using the formula: Q = (1 - η) P, where Q is the heat gain, η is the motor efficiency, and P is the power output.

Factors Affecting Heat Gain from Electric Motors

Several factors affect the heat gain from electric motors, including the motor's design, operating conditions, and load characteristics. The motor's design, such as the type of winding and insulation, can impact the heat generated. Operating conditions, such as ambient temperature and altitude, can also affect the heat gain. The load characteristics, such as the type of load and operating schedule, can also influence the heat generated.

Heat Gain Formula and Calculator

The heat gain formula for electric motors is: Q = (1 - η) P, where Q is the heat gain, η is the motor efficiency, and P is the power output. A calculator can be used to simplify the calculation process by inputting the motor's efficiency, power output, and operating conditions. The calculator can provide the heat gain in watts or BTUs per hour.

Types of Electric Motors and their Heat Gain Characteristics

Different types of electric motors have distinct heat gain characteristics. For example, induction motors tend to generate more heat compared to synchronous motors. DC motors also have different heat gain characteristics compared to AC motors. The heat gain characteristics of each motor type can be determined using the formula: Q = (1 - η) P, where Q is the heat gain, η is the motor efficiency, and P is the power output.

Applications of Heat Gain Calculation in Electric Motors

The calculation of heat gain from electric motors has various applications in the design and operation of electrical systems. For example, it can be used to determine the cooling requirements of a motor, select the appropriate motor size, and optimize the motor operating schedule. The heat gain calculation can also be used to estimate the energy losses and efficiency of the motor.

| Motor Type | Efficiency | Power Output | Heat Gain |

|---|---|---|---|

| Induction Motor | 0.85 | 10 kW | 1.5 kW |

| Synchronous Motor | 0.9 | 10 kW | 1 kW |

| DC Motor | 0.8 | 5 kW | 1 kW |

What is the formula for calculating heat load?

The formula for calculating heat load is a complex equation that takes into account various factors such as the temperature difference between the inside and outside of a building, the insulation properties of the building envelope, and the solar radiation that enters the building through windows and other openings. The basic formula for calculating heat load is: Q = (U x A x ΔT) + (SHGC x A x I) + (N x P), where Q is the heat load, U is the thermal transmittance of the building envelope, A is the area of the building envelope, ΔT is the temperature difference between the inside and outside of the building, SHGC is the solar heat gain coefficient of the windows, I is the solar radiation, N is the number of people in the building, and P is the power consumption of the building.

Understanding the Variables

The variables used in the heat load formula are crucial to obtaining an accurate calculation. The thermal transmittance (U) of the building envelope is a measure of how easily heat can pass through it. The solar heat gain coefficient (SHGC) is a measure of how much solar radiation is transmitted through the windows. The temperature difference (ΔT) between the inside and outside of the building is also an important factor. Other variables such as the number of people (N) and power consumption (P) of the building also play a significant role in the calculation.

- The thermal mass of the building can also affect the heat load calculation.

- The orientation of the building and its windows can also impact the solar radiation that enters the building.

- The type of insulation used in the building envelope can also affect the thermal transmittance.

Calculating the Heat Load

To calculate the heat load, it is essential to first determine the thermal transmittance (U) of the building envelope. This can be done by using the thermal resistance (R) of the different components of the building envelope, such as the walls, roof, and windows. The temperature difference (ΔT) between the inside and outside of the building must also be determined. The solar radiation (I) that enters the building through windows and other openings must also be calculated.

- The ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers) handbook provides tables and charts to help determine the thermal transmittance and solar radiation.

- The building orientation and window size can also affect the solar radiation that enters the building.

- The type of glass used in the windows can also impact the solar heat gain coefficient.

Importance of Accurate Calculations

Accurate calculations of the heat load are essential for designing and operating energy-efficient buildings. An overestimation of the heat load can result in oversized heating and cooling systems, which can lead to increased energy consumption and higher costs. On the other hand, an underestimation of the heat load can result in undersized heating and cooling systems, which can lead to reduced comfort and increased maintenance.

- Energy audits can help identify areas where energy efficiency can be improved.

- Building information modeling (BIM) can help architects and engineers design and operate buildings more efficiently.

- Commissioning of heating and cooling systems can help ensure that they are operating as intended.

Factors Affecting Heat Load

Several factors can affect the heat load of a building, including the climate and location of the building, the type of construction, and the occupancy and usage of the building. The orientation of the building and its windows can also impact the solar radiation that enters the building. The type of insulation used in the building envelope can also affect the thermal transmittance.

- The heat island effect can increase the temperature in urban areas.

- The type of roofing material can also affect the heat load.

- The landscaping around the building can also impact the heat load.

Using Software for Heat Load Calculations

There are several software programs available that can help calculate the heat load of a building. These programs can take into account various factors such as the thermal transmittance of the building envelope, the solar radiation that enters the building, and the occupancy and usage of the building. Some popular software programs for heat load calculations include eQUEST, EnergyPlus, and IESVE.

- These software programs can help streamline the calculation process.

- They can also help identify areas where energy efficiency can be improved.

- They can also help compare different design options and scenarios.

What is the formula for heat gain?

The formula for heat gain is Q = UA(Ti - Te), where Q is the heat gain, U is the overall heat transfer coefficient, A is the surface area, Ti is the indoor temperature, and Te is the outdoor temperature. This formula is used to calculate the amount of heat that enters a building or a system.

Understanding the Variables

The variables in the formula for heat gain are crucial in determining the amount of heat that enters a system. The overall heat transfer coefficient (U) takes into account the different modes of heat transfer, including conduction, convection, and radiation. The surface area (A) is also an important factor, as it determines the amount of area that is exposed to the heat. The indoor temperature (Ti) and outdoor temperature (Te) are also critical in determining the heat gain. Here are some key points to consider:

- The overall heat transfer coefficient (U) is a measure of the ability of a material to transfer heat.

- The surface area (A) can be increased or decreased to control the amount of heat gain.

- The indoor temperature (Ti) and outdoor temperature (Te) can be controlled to minimize heat gain.

Factors Affecting Heat Gain

Several factors can affect the heat gain of a system, including the climate, orientation, and insulation. The climate can have a significant impact on heat gain, as areas with high temperatures and high humidity can experience higher heat gain. The orientation of a building can also affect heat gain, as buildings that face the sun can experience higher heat gain. Insulation can also play a crucial role in reducing heat gain. Here are some key points to consider:

- The climate can have a significant impact on heat gain, with areas with high temperatures and high humidity experiencing higher heat gain.

- The orientation of a building can affect heat gain, with buildings that face the sun experiencing higher heat gain.

- Insulation can be used to reduce heat gain, by reducing the amount of heat that enters a system.

Methods of Reducing Heat Gain

There are several methods that can be used to reduce heat gain, including shading, insulation, and ventilation. Shading can be used to reduce the amount of direct sunlight that enters a building, while insulation can be used to reduce the amount of heat that enters a building. Ventilation can also be used to reduce heat gain, by allowing hot air to escape. Here are some key points to consider:

- Shading can be used to reduce the amount of direct sunlight that enters a building.

- Insulation can be used to reduce the amount of heat that enters a building.

- Ventilation can be used to reduce heat gain, by allowing hot air to escape.

Importance of Reducing Heat Gain

Reducing heat gain is essential in many applications, including buildings and electronic systems. In buildings, reducing heat gain can help to reduce the energy required for cooling, which can lead to cost savings and a reduction in greenhouse gas emissions. In electronic systems, reducing heat gain can help to prevent overheating, which can lead to system failure. Here are some key points to consider:

- Reducing heat gain can help to reduce the energy required for cooling, which can lead to cost savings.

- Reducing heat gain can help to prevent overheating, which can lead to system failure.

- Reducing heat gain can help to reduce greenhouse gas emissions, which can contribute to climate change.

Calculating Heat Gain

Calculating heat gain is a complex process that requires a thorough understanding of the variables involved. The formula Q = UA(Ti - Te) can be used to calculate the heat gain, but it is important to ensure that the values used are accurate. The overall heat transfer coefficient (U) and the surface area (A) must be determined, and the indoor temperature (Ti) and outdoor temperature (Te) must be measured. Here are some key points to consider:

- The overall heat transfer coefficient (U) and the surface area (A) must be determined.

- The indoor temperature (Ti) and outdoor temperature (Te) must be measured.

- The formula Q = UA(Ti - Te) can be used to calculate the heat gain, but it is important to ensure that the values used are accurate.

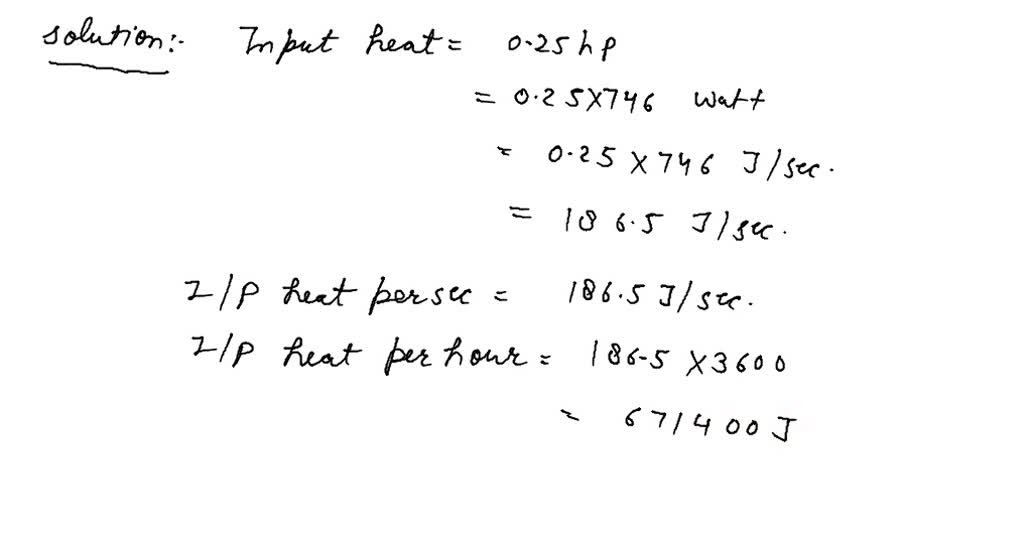

How much heat does a 1 hp motor produce?

The amount of heat a 1 hp (horsepower) motor produces depends on various factors, including the motor's efficiency, design, and operating conditions. Generally, a 1 hp motor can produce around 746 watts of power, which can result in a significant amount of heat being generated. The heat produced by a motor is typically measured in watts or British Thermal Units (BTUs) per hour.

Motor Efficiency and Heat Production

The efficiency of a motor plays a significant role in determining the amount of heat it produces. A more efficient motor will produce less heat compared to a less efficient one. The efficiency of a motor is typically measured by its power factor, which is the ratio of real power to apparent power. Some key factors that affect motor efficiency and heat production include:

- Motor design: The design of the motor, including the type of winding, bearings, and cooling system, can impact its efficiency and heat production.

- Operating conditions: The temperature, humidity, and altitude at which the motor operates can affect its efficiency and heat production.

- Load: The load on the motor, including the type of application and duty cycle, can impact its efficiency and heat production.

Types of Motors and Heat Production

Different types of motors produce varying amounts of heat. For example, induction motors tend to produce more heat than permanent magnet motors. The type of motor used can impact the overall heat production, with some motors being more efficient than others. Some key factors that affect motor heat production include:

- Motor type: The type of motor, including induction, permanent magnet, and synchronous, can impact its heat production.

- Motor size: The size of the motor, including its power rating and physical dimensions, can affect its heat production.

- Motor cooling: The type of cooling system used, including air-cooled and liquid-cooled, can impact the motor's heat production.

Application and Heat Production

The application in which a motor is used can impact the amount of heat it produces. For example, a motor used in a high-temperature environment will produce more heat than one used in a low-temperature environment. The duty cycle of the motor, including the amount of time it is on and off, can also affect its heat production. Some key factors that affect motor heat production include:

- Application type: The type of application, including industrial, commercial, and residential, can impact the motor's heat production.

- Duty cycle: The duty cycle of the motor, including the amount of time it is on and off, can affect its heat production.

- Environmental conditions: The environmental conditions, including temperature, humidity, and altitude, can impact the motor's heat production.

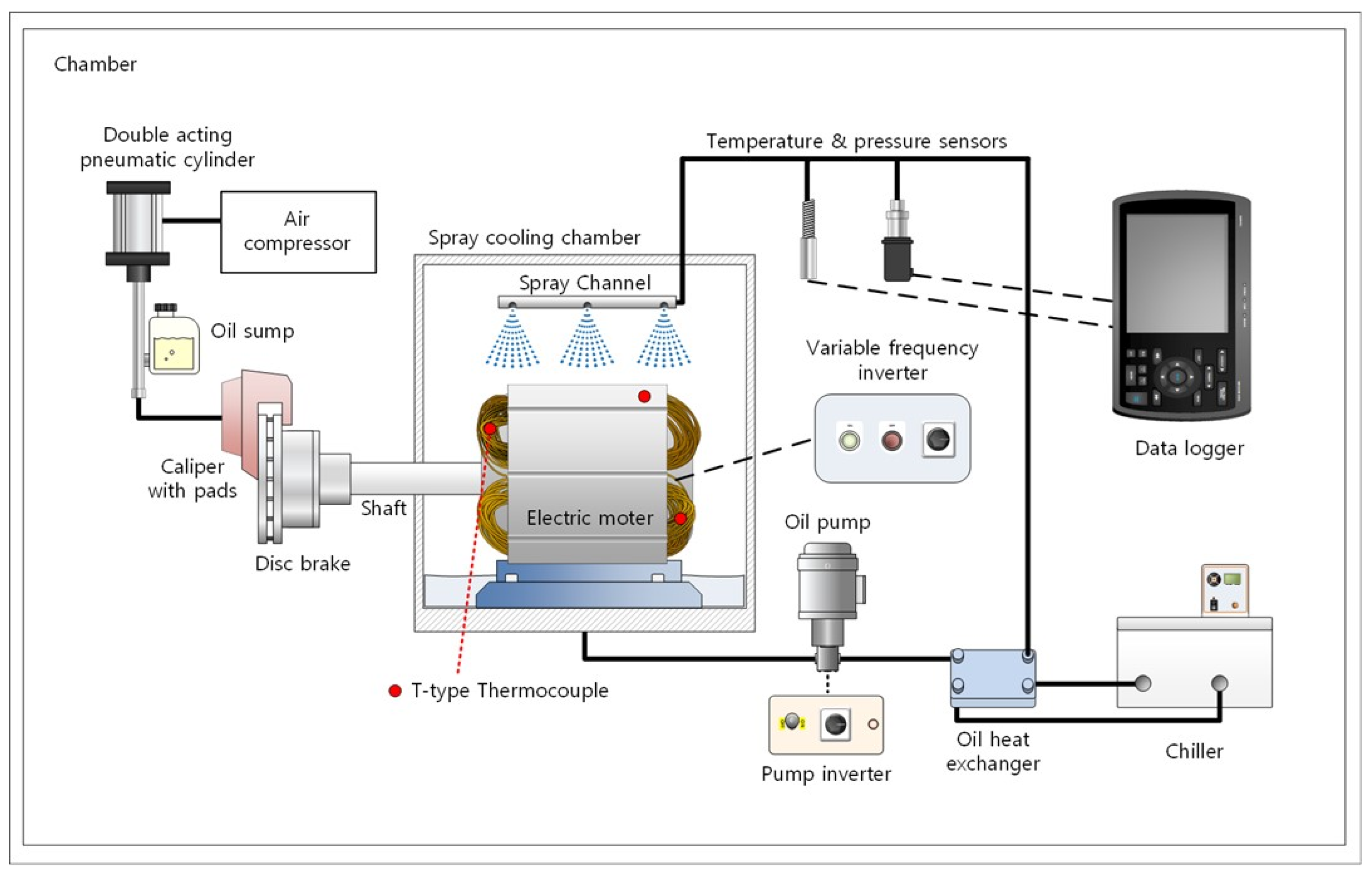

Measuring the heat produced by a motor can be done using various methods, including thermocouples, infrared cameras, and heat flux meters. The accuracy of the measurement depends on the method used and the conditions under which the measurement is taken. Some key factors that affect the measurement of motor heat production include:

- Measurement method: The method used to measure the motor's heat production, including thermocouples and infrared cameras, can impact the accuracy of the measurement.

- Measurement conditions: The conditions under which the measurement is taken, including temperature, humidity, and altitude, can affect the accuracy of the measurement.

- Motor operating conditions: The motor's operating conditions, including load and speed, can impact the measurement of its heat production.

Reducing Heat Production

Reducing the heat produced by a motor can be achieved through various means, including improving motor efficiency, using cooling systems, and optimizing motor operating conditions. Proper maintenance of the motor, including regular cleaning and lubrication, can also help reduce heat production. Some key factors that can help reduce motor heat production include:

- Improving motor efficiency: Improving the motor's efficiency through design and material changes can reduce its heat production.

- Using cooling systems: Using cooling systems, including air-cooled and liquid-cooled, can help reduce the motor's heat production.

- Optimizing motor operating conditions: Optimizing the motor's operating conditions, including load and speed, can help reduce its heat production.

What is the heat transfer of electric motors?

The heat transfer of electric motors is a critical aspect of their design and operation. Electric motors convert electrical energy into mechanical energy, and during this process, they generate heat as a byproduct. This heat must be transferred away from the motor to prevent overheating, which can lead to reduced efficiency, increased wear and tear, and even premature failure. The heat transfer of electric motors is influenced by various factors, including the motor's design, materials, and operating conditions.

Types of Heat Transfer in Electric Motors

The heat transfer of electric motors occurs through three main modes: conduction, convection, and radiation. Conduction occurs when heat is transferred between objects in direct contact, while convection occurs when heat is transferred through a fluid, such as air or water. Radiation occurs when heat is transferred through electromagnetic waves. The design of the motor, including the materials used and the configuration of the windings, can affect the heat transfer. For example:

- Conduction is enhanced by using materials with high thermal conductivity, such as copper or aluminum.

- Convection is enhanced by using fins or heat sinks to increase the surface area of the motor.

- Radiation is enhanced by using coatings or surfaces that have high emissivity.

Factors Affecting Heat Transfer in Electric Motors

Several factors can affect the heat transfer of electric motors, including the ambient temperature, humidity, and airflow. The power and speed of the motor also play a significant role, as they affect the amount of heat generated. Additionally, the design and materials used in the motor can influence the heat transfer. For example:

- High-power motors generate more heat and are therefore more challenging to cool.

- High-speed motors generate more heat due to increased friction and windage losses.

- Low-humidity environments can reduce the cooling effectiveness of convection and radiation.

Heat Transfer Mechanisms in Electric Motors

The heat transfer mechanisms in electric motors involve the transfer of heat from the stator and rotor to the surrounding environment. The stator and rotor are the primary sources of heat, and the heat transfer mechanisms must be designed to efficiently transfer this heat away. The bearings and housing also play a role in the heat transfer, as they can affect the thermal resistance and convection. For example:

- Stator heat is transferred to the housing through conduction and convection.

- Rotor heat is transferred to the housing through conduction and radiation.

- Bearings can generate heat due to friction, which must be transferred away through convection or conduction.

Design Considerations for Heat Transfer in Electric Motors

When designing electric motors, several factors must be considered to ensure efficient heat transfer. The materials used, configuration of the windings, and cooling systems must be carefully selected to optimize the heat transfer. Additionally, the thermal management of the motor, including the housing and bearings, must be considered. For example:

- Thermal interfaces can be used to enhance conduction and convection.

- Cooling systems, such as fans or water jackets, can be used to enhance convection.

- Thermal modeling and simulation can be used to optimize the design and operation of the motor.

Applications of Heat Transfer in Electric Motors

The heat transfer of electric motors is critical in various applications, including industrial, automotive, and aerospace. The design and operation of electric motors in these applications must be carefully considered to ensure efficient heat transfer and prevent overheating. For example:

- Electric vehicles require efficient heat transfer to optimize range and performance.

- Industrial motors require efficient heat transfer to optimize efficiency and reliability.

- Aerospace motors require efficient heat transfer to optimize performance and safety.

Frequently Asked Questions (FAQs)

What is the Heat Gain from Electric Motors and their Loads Formula and Calculator?

The Heat Gain from Electric Motors and their Loads Formula and Calculator is a tool used to calculate the amount of heat generated by an electric motor and its associated loads. This calculator takes into account various factors such as the motor efficiency, power output, and operating time to determine the total heat gain. The formula used in this calculator is based on the principle that the heat generated by an electric motor is equal to the difference between the input power and the output power. The input power is the electrical power supplied to the motor, while the output power is the mechanical power delivered by the motor to the load. By using this formula and calculator, users can easily determine the heat gain from their electric motors and take necessary measures to mitigate its effects.

How does the Heat Gain from Electric Motors and their Loads Formula and Calculator work?

The Heat Gain from Electric Motors and their Loads Formula and Calculator works by first inputting the relevant parameters such as the motor efficiency, power output, and operating time. The calculator then uses these inputs to calculate the heat gain using a complex formula that takes into account the thermal properties of the motor and its associated loads. The formula used in this calculator is based on the fundamental principles of thermodynamics and electromagnetism, and is validated by experimental data. The calculator provides a user-friendly interface that allows users to input the required parameters and obtain the results in a clear and concise manner. The results provided by the calculator include the total heat gain, heat gain rate, and temperature rise, which can be used to optimize the design and operation of the electric motor and its associated systems.

What are the key factors that affect the Heat Gain from Electric Motors and their Loads Formula and Calculator?

The key factors that affect the Heat Gain from Electric Motors and their Loads Formula and Calculator include the motor efficiency, power output, operating time, ambient temperature, and thermal conductivity of the motor and its associated loads. The motor efficiency is a critical factor, as it determines the amount of electrical energy that is converted into mechanical energy, and the amount of heat that is generated as a byproduct. The power output and operating time also play a significant role, as they determine the total energy consumed by the motor and the duration of heat generation. The ambient temperature and thermal conductivity of the motor and its associated loads also affect the heat gain, as they determine the rate at which heat is dissipated from the system. By understanding these key factors, users can optimize the design and operation of their electric motors and minimize the heat gain.

How can the Heat Gain from Electric Motors and their Loads Formula and Calculator be used in practice?

The Heat Gain from Electric Motors and their Loads Formula and Calculator can be used in practice to optimize the design and operation of electric motors and their associated systems. By using this calculator, users can predict the heat gain from their electric motors and take necessary measures to mitigate its effects, such as improving the motor efficiency, reducing the power output, or increasing the cooling capacity. The calculator can also be used to compare the heat gain from different motor designs or operating conditions, and to identify the most efficient and cost-effective solutions. Additionally, the calculator can be used to validate the performance of electric motors and their associated systems, and to troubleshoot any problems that may arise during operation. By using this calculator, users can improve the reliability, efficiency, and safety of their electric motors and associated systems.

Deja una respuesta

Entradas Relacionadas