Floating Fastener Tolerance Calculator

The Floating Fastener Tolerance Calculator is a valuable tool for engineers and designers working with assemblies that require precise fits. This calculator helps determine the maximum and minimum sizes of holes and shafts to ensure proper fit and function. By inputting the nominal size, tolerance, and type of fit, users can calculate the acceptable limits for their fasteners. This calculator is essential for achieving accurate and reliable assemblies, reducing errors and improving overall product quality. It simplifies the process of calculating tolerances, saving time and increasing efficiency in the design and manufacturing process. Calculations are precise and reliable.

Floating Fastener Tolerance Calculator: Understanding the Importance of Precision

The Floating Fastener Tolerance Calculator is a crucial tool in the engineering and manufacturing industries. It is used to determine the tolerance of a floating fastener, which is a type of fastener that allows for some degree of movement or flexibility. This calculator takes into account various factors such as the material of the fastener, the size and type of the fastener, and the operating conditions in which it will be used.

Introduction to Floating Fastener Tolerance Calculator

The Floating Fastener Tolerance Calculator is designed to help engineers and manufacturers ensure that their fasteners meet the required standards and specifications. By using this calculator, users can determine the minimum and maximum tolerances for their fasteners, which is essential for ensuring the quality and reliability of their products. The calculator uses complex algorithms and mathematical formulas to calculate the tolerance of the fastener, taking into account various factors such as temperature, humidity, and vibration.

Benefits of Using a Floating Fastener Tolerance Calculator

The Floating Fastener Tolerance Calculator offers several benefits to users. It helps to reduce errors and improve accuracy, which can lead to cost savings and increased productivity. Additionally, the calculator can help users to optimize their fastener design, which can result in improved performance and reliability. The calculator can also be used to compare different fastener materials and designs, which can help users to make informed decisions about their products.

How to Use a Floating Fastener Tolerance Calculator

Using a Floating Fastener Tolerance Calculator is relatively straightforward. Users simply need to input the required parameters, such as the fastener material, size, and type, as well as the operating conditions. The calculator will then use complex algorithms and mathematical formulas to calculate the tolerance of the fastener. The results can be displayed in a variety of formats, including tables and graphs.

Factors Affecting Floating Fastener Tolerance Calculator

There are several factors that can affect the accuracy of a Floating Fastener Tolerance Calculator. These include the material of the fastener, the size and type of the fastener, and the operating conditions in which it will be used. Additionally, temperature, humidity, and vibration can all impact the tolerance of the fastener. Users should carefully consider these factors when using the calculator to ensure accurate results.

Common Applications of Floating Fastener Tolerance Calculator

The Floating Fastener Tolerance Calculator has a variety of applications in the engineering and manufacturing industries. It is commonly used in the aerospace, automotive, and industrial sectors, where precision and accuracy are critical. The calculator can be used to design and optimize fasteners for a range of applications, including engines, transmissions, and gearboxes.

| Material | Size | Type | Operating Conditions | Tolerance |

|---|---|---|---|---|

| Steel | 10mm | Bolt | High Temperature | 0.01mm |

| Aluminum | 5mm | Screw | Low Temperature | 0.05mm |

| Copper | 15mm | Nut | High Vibration | 0.1mm |

What is the formula for fixed fastener tolerance?

The formula for fixed fastener tolerance is a mathematical expression that determines the acceptable limits of variation in the dimensions of a fastener. The formula is based on the nominal size of the fastener and the tolerance grade, which is a measure of the precision required for the application. The formula is as follows: Tolerance = (Nominal size x Tolerance grade) / 100.

Understanding Tolerance Grades

The tolerance grade is a critical component of the formula, as it determines the level of precision required for the application. The tolerance grade is typically expressed as a number, with higher numbers indicating a tighter tolerance. The tolerance grade is influenced by factors such as the material of the fastener, the manufacturing process, and the application. For example:

- The ISO 286-1 standard defines a range of tolerance grades, from f8 to f3, with f8 being the loosest tolerance and f3 being the tightest tolerance.

- The ASME B18.2.2 standard defines a range of tolerance grades, from 1A to 3B, with 1A being the loosest tolerance and 3B being the tightest tolerance.

- The tolerance grade can be influenced by factors such as the surface finish of the fastener, with a smooth surface finish typically requiring a tighter tolerance.

Calculating Tolerance

Calculating the tolerance of a fastener involves using the formula: Tolerance = (Nominal size x Tolerance grade) / 100. For example, if the nominal size of a fastener is 10 mm and the tolerance grade is f7, the tolerance would be: Tolerance = (10 mm x f7) / 100 = 0.1 mm. This means that the fastener can have a diameter of between 9.9 mm and 10.1 mm and still be within the acceptable tolerance. For example:

- The tolerance calculation can be influenced by factors such as the unit of measurement, with metric units typically using millimeters and imperial units typically using inches.

- The tolerance calculation can be influenced by factors such as the type of fastener, with screws typically requiring a tighter tolerance than bolts.

- The tolerance calculation can be influenced by factors such as the application, with aerospace applications typically requiring a tighter tolerance than automotive applications.

Importance of Tolerance

The tolerance of a fastener is critical to ensuring the proper fit and function of the fastener in its application. A fastener with a loose tolerance may not fit properly, while a fastener with a tight tolerance may be too expensive to produce. For example:

- A loose tolerance can result in a fastener that is too loose, which can lead to vibration and noise in the application.

- A tight tolerance can result in a fastener that is too tight, which can lead to difficulty in assembly and increased manufacturing costs.

- A proper tolerance can result in a fastener that is properly fitted, which can lead to increased performance and reliability in the application.

Tolerance and Precision

The tolerance of a fastener is closely related to its precision, with a tighter tolerance indicating a higher precision. The precision of a fastener is influenced by factors such as the manufacturing process, the material of the fastener, and the application. For example:

- The precision of a fastener can be influenced by factors such as the surface finish, with a smooth surface finish typically indicating a higher precision.

- The precision of a fastener can be influenced by factors such as the dimensional accuracy, with a high dimensional accuracy typically indicating a higher precision.

- The precision of a fastener can be influenced by factors such as the geometric tolerance, with a tight geometric tolerance typically indicating a higher precision.

Applications of Tolerance

The tolerance of a fastener has a wide range of applications, from aerospace to automotive to industrial. The tolerance of a fastener is critical to ensuring the proper fit and function of the fastener in its application. For example:

- The tolerance of a fastener is critical in aerospace applications, where high precision and reliability are required.

- The tolerance of a fastener is critical in automotive applications, where high performance and reliability are required.

- The tolerance of a fastener is critical in industrial applications, where high precision and reliability are required.

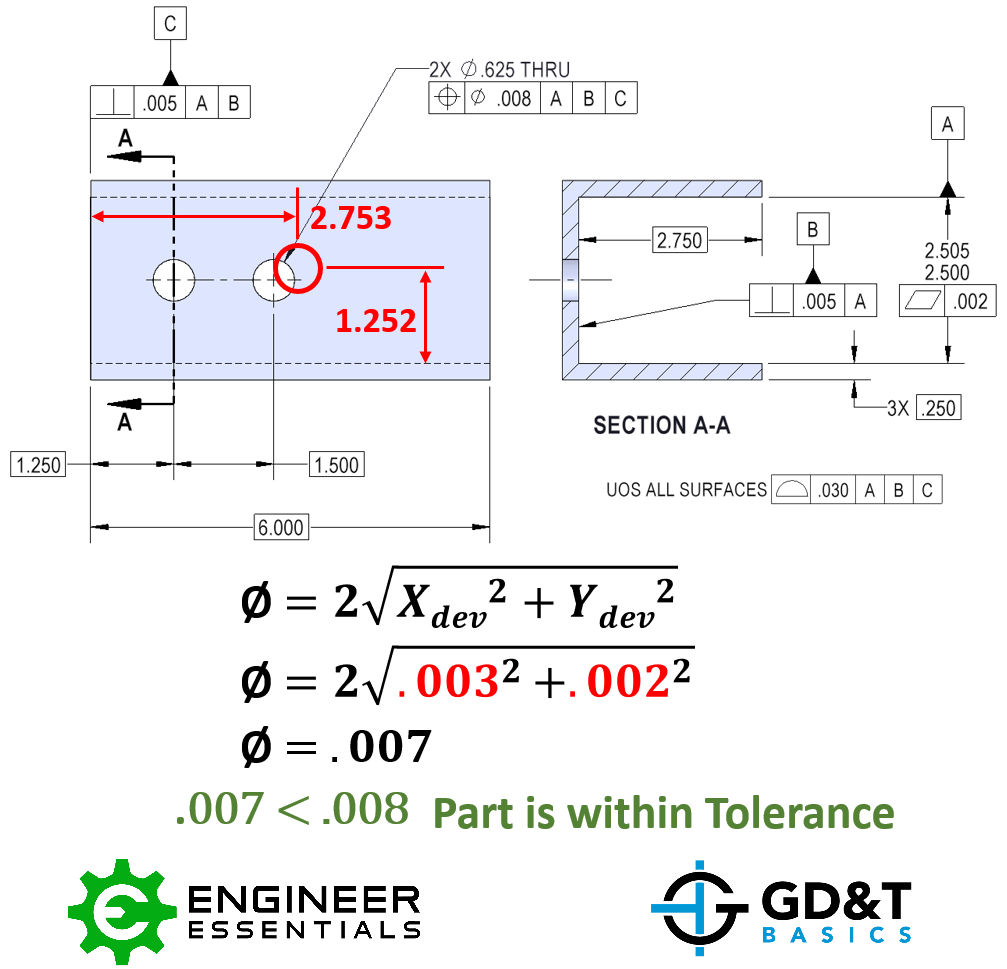

What is the formula for calculating position tolerance?

The formula for calculating position tolerance is based on the geometric dimensioning and tolerancing (GD&T) principles. The formula takes into account the tolerance zone, datum features, and bonus tolerance. The position tolerance formula is: Position Tolerance = (Tolerance Zone / 2) + Bonus Tolerance.

Understanding Position Tolerance

Position tolerance is a critical concept in geometric dimensioning and tolerancing (GD&T). It refers to the permissible variation in the location of a feature or a group of features within a specified tolerance zone. To calculate position tolerance, one must consider the following factors:

- Tolerance zone: The area within which the feature or group of features must be located.

- Datum features: The reference features used to establish the datum plane or datum axis.

- Bonus tolerance: The additional tolerance allowed due to the angularity or perpendicularity of the feature.

Calculating Position Tolerance

Calculating position tolerance involves determining the maximum permissible variation in the location of a feature or group of features. This is done by applying the formula: Position Tolerance = (Tolerance Zone / 2) + Bonus Tolerance. The tolerance zone is divided by 2 to account for the bilateral tolerance, and the bonus tolerance is added to account for any angularity or perpendicularity.

- Determine the tolerance zone: Establish the tolerance zone based on the design requirements and manufacturing constraints.

- Calculate the bonus tolerance: Determine the bonus tolerance based on the angularity or perpendicularity of the feature.

- Apply the formula: Use the formula to calculate the position tolerance.

Types of Position Tolerance

There are several types of position tolerance, including unilateral, bilateral, and eccentric. Each type has its own set of calculations and considerations.

- Unilateral position tolerance: The tolerance zone is only on one side of the datum feature.

- Bilateral position tolerance: The tolerance zone is on both sides of the datum feature.

- Eccentric position tolerance: The tolerance zone is eccentric or offset from the datum feature.

Applications of Position Tolerance

Position tolerance has numerous applications in engineering and manufacturing, including aerospace, automotive, and medical devices. It is used to ensure the proper location and orientation of features and components.

- Aerospace engineering: Position tolerance is critical in the design and manufacturing of aircraft and spacecraft components.

- Automotive engineering: Position tolerance is used to ensure the proper location and orientation of engine and transmission components.

- Medical device manufacturing: Position tolerance is crucial in the design and manufacturing of medical implants and surgical instruments.

Best Practices for Position Tolerance

To ensure accurate and reliable position tolerance calculations, it is essential to follow best practices, including clear documentation, proper training, and regular verification.

- Clear documentation: Ensure that all design and manufacturing documentation is clear and concise.

- Proper training: Provide proper training to designers and manufacturers on position tolerance calculations and applications.

- Regular verification: Regularly verify and validate position tolerance calculations to ensure accuracy and reliability.

What is float in GD&T?

Float in GD&T refers to the amount of tolerance allowed in a part's or assembly's dimensional or geometric characteristics. It is a measure of how much difference is permissible between the nominal value and the actual value of a feature or part. In other words, float represents the acceptable range of variation within which a part or assembly can still meet its functional requirements.

What is the purpose of float in GD&T?

The primary purpose of float is to allow for manufacturing and assembly variability while still ensuring that the part or assembly functions as intended. By specifying a reasonable amount of float, designers can account for inherent variations in production processes and material properties. This helps to prevent overly restrictive tolerances that can drive up production costs and lead to unacceptable levels of scrap. Some key aspects of float in GD&T include:

- Enabling more efficient manufacturing and assembly processes

- Reducing the risk of part or assembly failure due to overly tight tolerances

- Allowing for design flexibility and innovation by accommodating variability in materials and production methods

How is float applied in GD&T?

Float is applied in GD&T through the specification of tolerances and geometric controls. By using GD&T symbols and notations, designers can clearly communicate the acceptable range of variation for each feature or part. This involves identifying the critical characteristics that affect functionality and performance, and then allocating the available tolerance accordingly. Key considerations when applying float in GD&T include:

- Balancing the need for precision with the need for manufacturing efficiency

- Selecting the most appropriate tolerance and geometric controls for each feature or part

- Verifying that the specified tolerances are achievable and verifiable using available manufacturing and inspection methods

What are the benefits of float in GD&T?

The use of float in GD&T offers several significant benefits, including:

- Improved manufacturing efficiency and productivity by allowing for more flexibility in production processes

- Reduced production costs and scrap rates by minimizing the risk of overly tight tolerances

- Enhanced design flexibility and innovation by accommodating variability in materials and production methods

By specifying a reasonable amount of float, designers can create more robust and reliable products that meet customer requirements while minimizing production costs.

What are the challenges of float in GD&T?

Despite its benefits, the use of float in GD&T also presents several challenges, including:

- Determining the optimal amount of float for each feature or part, which requires a deep understanding of manufacturing processes and material properties

- Communicating the specified tolerances and geometric controls clearly and unambiguously to manufacturing and inspection teams

- Verifying that the specified tolerances are achievable and verifiable using available manufacturing and inspection methods

To overcome these challenges, designers must carefully consider the interplay between tolerances, geometric controls, and manufacturing processes when specifying float in GD&T.

How does float impact GD&T analysis?

Float has a significant impact on GD&T analysis, as it directly affects the results of tolerance stack-up and sensitivity analyses. By accounting for the acceptable range of variation in each feature or part, analysts can assess the robustness and reliability of the design more accurately. Key aspects of float in GD&T analysis include:

- Assessing the impact of float on tolerance stack-up and sensitivity analyses

- Identifying the critical characteristics that affect functionality and performance, and allocating the available tolerance accordingly

- Using GD&T software tools to simulate and analyze the effects of float on the design

By considering the effects of float, analysts can optimize the design to meet customer requirements while minimizing production costs and scrap rates.

Frequently Asked Questions (FAQs)

What is the purpose of the Floating Fastener Tolerance Calculator?

The Floating Fastener Tolerance Calculator is a tool designed to help engineers and manufacturers calculate the tolerances of floating fasteners in various assemblies. The calculator takes into account the material properties, fastener type, and assembly conditions to provide an accurate calculation of the tolerance. This is particularly useful in industries where precision and accuracy are crucial, such as aerospace, automotive, and medical devices. By using the Floating Fastener Tolerance Calculator, users can avoid errors and ensure that their assemblies meet the required specifications.

How does the Floating Fastener Tolerance Calculator work?

The Floating Fastener Tolerance Calculator works by using a complex algorithm that takes into account the input parameters provided by the user. These parameters include the fastener type, material properties, assembly conditions, and desired tolerance. The calculator then uses these parameters to calculate the tolerance of the floating fastener based on industry-recognized standards and formulas. The calculator also provides options for units and decimal places, allowing users to customize the output to their specific needs. The results are then displayed in a clear and easy-to-understand format, allowing users to quickly and easily interpret the data.

What are the benefits of using the Floating Fastener Tolerance Calculator?

The benefits of using the Floating Fastener Tolerance Calculator are numerous. One of the main advantages is that it saves time and reduces errors. By using the calculator, users can quickly and easily calculate the tolerance of floating fasteners, without having to manually perform complex calculations. This increases productivity and reduces the risk of human error. Additionally, the calculator provides accurate results, which is critical in industries where precision and accuracy are paramount. The calculator also helps users to optimize their designs and assemblies, by providing valuable insights into the behavior of floating fasteners under different conditions.

Can the Floating Fastener Tolerance Calculator be used for all types of fasteners?

The Floating Fastener Tolerance Calculator is designed to be used with a wide range of fastener types, including screws, bolts, nuts, and rivets. However, it is important to note that the calculator is specifically designed for floating fasteners, and may not be suitable for other types of fasteners, such as locknuts or welds. Additionally, the calculator is based on industry-recognized standards and formulas, which may not be applicable to all types of fasteners or assemblies. Therefore, it is recommended that users consult the calculator's documentation and user manual to ensure that it is suitable for their specific needs and applications. Users should also verify the results of the calculator with experimental data or other calculation methods to ensure accuracy and reliability.

Deja una respuesta

Entradas Relacionadas