Axial Tension Compression Spring Stiffness Constant Equations and Calculator

Axial tension compression spring stiffness is a critical parameter in designing and selecting springs for various applications. The stiffness of a spring is determined by its material, geometry, and loading conditions. This article provides an overview of the constant equations used to calculate the stiffness of axial tension compression springs, along with a calculator to simplify the process. Understanding these equations and using the calculator can help engineers and designers optimize spring performance and ensure reliable operation in their systems. The calculator and equations are based on established mechanical principles.

- Axial Tension Compression Spring Stiffness Constant Equations and Calculator

- What is the formula for axial spring stiffness?

- How to calculate spring constant for compression spring?

- What is the formula for the stiffness constant of a spring?

- How to calculate k constant of a spring?

-

Frequently Asked Questions (FAQs)

- What is Axial Tension Compression Spring Stiffness Constant and its significance in engineering applications?

- How do Axial Tension Compression Spring Stiffness Constant Equations and Calculators help in spring design and analysis?

- What are the key factors that influence the Axial Tension Compression Spring Stiffness Constant, and how do they impact spring behavior?

- How can engineers use Axial Tension Compression Spring Stiffness Constant Equations and Calculators to optimize spring design for specific applications, such as aerospace or automotive engineering?

Axial Tension Compression Spring Stiffness Constant Equations and Calculator

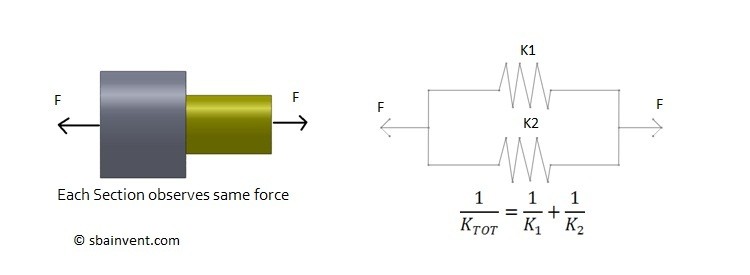

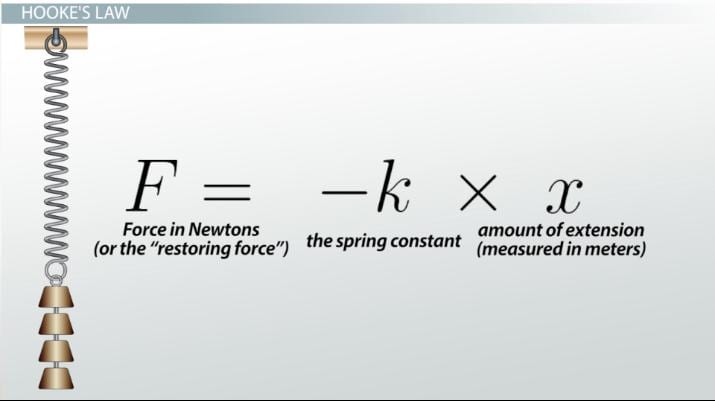

The Axial Tension Compression Spring Stiffness Constant Equations and Calculator is a tool used to calculate the stiffness constant of a spring under axial tension or compression. The stiffness constant is a measure of the spring's resistance to deformation under an applied force. The calculator uses various equations to determine the stiffness constant, including the Hooke's Law, which states that the force required to compress or extend a spring by a certain distance is proportional to that distance.

Introduction to Spring Stiffness Constant

The spring stiffness constant is a critical parameter in the design and analysis of mechanical systems that involve springs. It is defined as the ratio of the applied force to the resulting deformation of the spring. The stiffness constant is typically denoted by the symbol k and is measured in units of force per unit distance, such as Newtons per meter. The stiffness constant is a measure of the spring's ability to resist deformation under an applied force, and it is an important factor in determining the overall performance of a mechanical system.

Equations for Calculating Spring Stiffness Constant

There are several equations that can be used to calculate the spring stiffness constant, including:

| Equation | Description |

|---|---|

| k = F / x | Hooke's Law, where k is the stiffness constant, F is the applied force, and x is the resulting deformation |

| k = G d^4 / (8 n D^3) | Torsional stiffness equation, where k is the stiffness constant, G is the shear modulus, d is the wire diameter, n is the number of coils, and D is the coil diameter |

These equations can be used to calculate the stiffness constant of a spring under various loading conditions, including axial tension and compression.

Factors Affecting Spring Stiffness Constant

Several factors can affect the stiffness constant of a spring, including the material properties, such as the Young's modulus and Poisson's ratio, the wire diameter, the coil diameter, and the number of coils. Additionally, the loading conditions, such as the axial tension or compression, can also affect the stiffness constant. Understanding these factors is critical in designing and analyzing mechanical systems that involve springs.

Calculator for Spring Stiffness Constant

A calculator can be used to calculate the stiffness constant of a spring based on the input parameters, such as the wire diameter, coil diameter, number of coils, and loading conditions. The calculator can use various equations, including the Hooke's Law, to determine the stiffness constant. The calculator can also take into account the material properties and loading conditions to provide a more accurate calculation of the stiffness constant.

Applications of Spring Stiffness Constant

The spring stiffness constant has numerous applications in various fields, including mechanical engineering, aerospace engineering, and automotive engineering. It is used to design and analyze mechanical systems, such as suspension systems, engine mounts, and vibration isolators. The stiffness constant is also used to predict the dynamic behavior of mechanical systems and to optimize their performance. Understanding the spring stiffness constant is critical in designing and developing efficient and reliable mechanical systems.

What is the formula for axial spring stiffness?

The formula for axial spring stiffness is given by k = (G d^4) / (8 n D^3), where k is the spring constant, G is the shear modulus of the material, d is the wire diameter, n is the number of active coils, and D is the mean coil diameter.

Understanding the Variables

The variables in the formula are crucial in determining the axial spring stiffness. The shear modulus (G) is a measure of the material's resistance to shear stress. The wire diameter (d) and mean coil diameter (D) are dimensions of the spring that affect its stiffness. The number of active coils (n) also plays a significant role in determining the spring's stiffness. Consider the following factors:

- The material properties of the spring, such as its shear modulus and Young's modulus, affect its stiffness.

- The geometry of the spring, including its wire diameter and mean coil diameter, also impacts its stiffness.

- The number of active coils can be adjusted to achieve the desired spring stiffness.

Applications of Axial Spring Stiffness

The axial spring stiffness formula has various applications in engineering and design. It is used to calculate the spring constant of compression springs, extension springs, and torsion springs. This knowledge is essential in designing mechanical systems that rely on springs for load bearing and vibration damping. Consider the following applications:

- Aerospace engineering uses axial spring stiffness to design landing gear and shock absorption systems.

- Automotive engineering applies axial spring stiffness in the design of suspension systems and engine mounts.

- Industrial machinery uses axial spring stiffness to design conveyor systems and vibration isolation systems.

Calculating Axial Spring Stiffness

To calculate the axial spring stiffness, it is essential to have accurate values for the variables in the formula. The shear modulus (G) can be found in material property tables or calculated using experimental methods. The wire diameter (d) and mean coil diameter (D) can be measured directly from the spring. The number of active coils (n) can be determined by counting the coils or using a spring design calculator. Consider the following steps:

- Measure the wire diameter and mean coil diameter of the spring using a caliper or micrometer.

- Count the number of active coils in the spring to determine the value of n.

- Look up the shear modulus (G) of the material in a material property table or calculate it using experimental methods.

Factors Affecting Axial Spring Stiffness

Several factors can affect the axial spring stiffness of a spring, including material properties, geometry, and operating conditions. The spring's temperature and environmental conditions can also impact its stiffness. Consider the following factors:

- The temperature of the spring can affect its material properties and subsequently its stiffness.

- The corrosion resistance of the spring material can impact its stiffness over time.

- The spring's geometry and design can be optimized to achieve the desired axial spring stiffness.

Design Considerations for Axial Spring Stiffness

When designing a spring with a specific axial spring stiffness, it is essential to consider the application requirements and operating conditions. The spring's material, geometry, and design should be carefully selected to achieve the desired stiffness. Consider the following design considerations:

- The spring's material should be chosen based on its material properties and environmental resistance.

- The spring's geometry should be optimized to achieve the desired axial spring stiffness and load bearing capacity.

- The spring's design should be validated using finite element analysis or experimental testing to ensure it meets the application requirements.

How to calculate spring constant for compression spring?

To calculate the spring constant for a compression spring, you need to understand the relationship between the force applied to the spring and the resulting displacement. The spring constant (k) is a measure of the stiffness of the spring, and it can be calculated using the formula: k = F / x, where F is the force applied to the spring and x is the resulting displacement.

Understanding Spring Constant Formula

The spring constant formula is derived from Hooke's Law, which states that the force required to stretch or compress a spring by a certain distance is proportional to that distance. To calculate the spring constant, you need to know the force applied to the spring and the resulting displacement. The formula can be expressed in terms of the spring's physical properties, such as its wire diameter, coils, and material.

- Measure the force applied to the spring using a force gauge or other measurement device.

- Measure the resulting displacement of the spring using a displacement sensor or other measurement device.

- Use the formula k = F / x to calculate the spring constant, where k is the spring constant, F is the force, and x is the displacement.

Factors Affecting Spring Constant

The spring constant of a compression spring can be affected by several factors, including the wire diameter, coils, and material. The wire diameter affects the spring's stiffness, with smaller diameters resulting in a softer spring and larger diameters resulting in a stiffer spring. The number of coils also affects the spring constant, with more coils resulting in a softer spring and fewer coils resulting in a stiffer spring.

- The wire diameter affects the spring's stiffness, with smaller diameters resulting in a softer spring.

- The number of coils affects the spring constant, with more coils resulting in a softer spring.

- The material used to make the spring affects its strength and durability.

Importance of Spring Constant

The spring constant is an important factor in the design and operation of compression springs. It determines the amount of force required to compress the spring by a certain distance, and it affects the spring's ability to store energy. A spring with a high spring constant will require more force to compress than a spring with a low spring constant.

- A high spring constant indicates a stiff spring that requires more force to compress.

- A low spring constant indicates a soft spring that requires less force to compress.

- The spring constant affects the spring's ability to store energy and release it as the spring expands or contracts.

Methods for Measuring Spring Constant

There are several methods for measuring the spring constant of a compression spring, including the use of force gauges and displacement sensors. The most common method involves applying a known force to the spring and measuring the resulting displacement. The spring constant can then be calculated using the formula: k = F / x.

- Use a force gauge to measure the force applied to the spring.

- Use a displacement sensor to measure the resulting displacement of the spring.

- Calculate the spring constant using the formula k = F / x.

Applications of Spring Constant

The spring constant has numerous applications in various fields, including engineering, physics, and materials science. It is used to design and optimize compression springs for use in a wide range of applications, from automotive and aerospace to medical and consumer products. The spring constant is also used to predict the behavior of springs under different loads and conditions.

- The spring constant is used to design and optimize compression springs for use in automotive and aerospace applications.

- The spring constant is used to predict the behavior of springs under different loads and conditions.

- The spring constant is an important factor in the design and operation of medical and consumer products.

What is the formula for the stiffness constant of a spring?

The formula for the stiffness constant of a spring is given by k = F / x, where k is the stiffness constant, F is the force applied to the spring, and x is the displacement of the spring from its equilibrium position. This formula is a fundamental concept in physics and engineering, and is used to describe the behavior of springs and other elastic systems.

Understanding the Stiffness Constant Formula

The stiffness constant formula is derived from Hooke's Law, which states that the force required to stretch or compress a spring is proportional to the displacement of the spring. The formula k = F / x shows that the stiffness constant is a measure of the spring's resistance to deformation. Some key points to consider when using this formula are:

- The stiffness constant is typically measured in units of Newtons per meter (N/m)

- The force applied to the spring is typically measured in units of Newtons (N)

- The displacement of the spring is typically measured in units of meters (m)

Factors Affecting the Stiffness Constant

The stiffness constant of a spring can be affected by several factors, including the material the spring is made of, the shape and size of the spring, and the temperature of the spring. For example, a spring made of a stiff material like steel will have a higher stiffness constant than a spring made of a soft material like copper. Some other factors that can affect the stiffness constant are:

- The spring's cross-sectional area and length

- The type of spring, such as a compression or tension spring

- The environmental conditions, such as temperature and humidity

Calculating the Stiffness Constant

To calculate the stiffness constant of a spring, you can use the formula k = F / x, where F is the force applied to the spring and x is the displacement of the spring. For example, if you apply a force of 10 N to a spring and it displaces by 0.1 m, the stiffness constant would be k = 10 N / 0.1 m = 100 N/m. Some steps to follow when calculating the stiffness constant are:

- Measure the force applied to the spring using a force sensor or scale

- Measure the displacement of the spring using a ruler or caliper

- Use the formula k = F / x to calculate the stiffness constant

Applications of the Stiffness Constant Formula

The stiffness constant formula has many practical applications in engineering and physics, including the design of springs and other elastic systems. For example, the stiffness constant is used to calculate the natural frequency of a spring-mass system, which is an important consideration in the design of vibrating systems. Some other applications of the stiffness constant formula are:

- Designing springs for automotive and aerospace applications

- Calculating the natural frequency of a spring-mass system

- Analyzing the behavior of elastic systems under static and dynamic loads

Limitations of the Stiffness Constant Formula

The stiffness constant formula is a simplified model that assumes a linear relationship between the force applied to a spring and its displacement. However, in real-world applications, the stiffness constant can vary depending on the material and geometry of the spring, as well as the environmental conditions. Some limitations of the stiffness constant formula are:

- The formula assumes a linear relationship between force and displacement

- The formula does not account for friction or other dissipative forces

- The formula is only applicable to small displacements and low forces

How to calculate k constant of a spring?

To calculate the k constant of a spring, also known as the spring constant, you need to understand the relationship between the force applied to the spring and the resulting displacement. The k constant is a measure of the spring's stiffness, and it can be calculated using Hooke's Law. According to Hooke's Law, the force (F) required to stretch or compress a spring by a certain distance (x) is proportional to the spring constant (k) and the displacement (x). The formula to calculate the k constant is k = F / x.

Understanding Hooke's Law

To calculate the k constant, you need to understand Hooke's Law, which states that the force required to stretch or compress a spring is proportional to the displacement. This can be expressed mathematically as F = kx, where F is the force, k is the spring constant, and x is the displacement. The key points to consider when applying Hooke's Law are:

- The force and displacement must be measured in the same direction.

- The spring constant (k) is a measure of the spring's stiffness.

- The k constant is typically measured in units of Newtons per meter (N/m).

Measuring Force and Displacement

To calculate the k constant, you need to measure the force and displacement of the spring. This can be done using a variety of techniques, including using a force sensor and a displacement sensor. The key points to consider when measuring force and displacement are:

- The force and displacement must be measured simultaneously.

- The force and displacement must be measured in the same direction.

- The force and displacement must be measured using calibrated instruments.

Calculating the Spring Constant

Once you have measured the force and displacement of the spring, you can calculate the k constant using the formula k = F / x. The key points to consider when calculating the k constant are:

- The force and displacement must be measured in the same units.

- The k constant must be calculated using a linear regression analysis.

- The k constant must be reported in units of Newtons per meter (N/m).

Factors Affecting the Spring Constant

The k constant of a spring can be affected by a variety of factors, including the material the spring is made of, the diameter of the spring, and the number of coils. The key points to consider when evaluating the factors that affect the k constant are:

- The material the spring is made of can affect its stiffness.

- The diameter of the spring can affect its stiffness.

- The number of coils can affect the stiffness of the spring.

Applications of the Spring Constant

The k constant has a variety of applications in physics and engineering, including the design of mechanical systems, vibration analysis, and stress analysis. The key points to consider when evaluating the applications of the k constant are:

- The k constant is used to design mechanical systems that require specific stiffness.

- The k constant is used to analyze vibrations in mechanical systems.

- The k constant is used to analyze stress in mechanical systems.

Frequently Asked Questions (FAQs)

What is Axial Tension Compression Spring Stiffness Constant and its significance in engineering applications?

The Axial Tension Compression Spring Stiffness Constant is a crucial parameter in the design and analysis of springs, particularly in mechanical engineering and aerospace engineering. It represents the ratio of force to displacement in a spring, indicating how much force is required to compress or extend the spring by a certain amount. This constant is essential in determining the behavior of springs under various loading conditions, such as tension, compression, and torsion. By understanding the Axial Tension Compression Spring Stiffness Constant, engineers can design and optimize springs for specific applications, ensuring that they can withstand the required loads and stresses while maintaining their structural integrity.

How do Axial Tension Compression Spring Stiffness Constant Equations and Calculators help in spring design and analysis?

The Axial Tension Compression Spring Stiffness Constant Equations provide a mathematical framework for calculating the stiffness constant of a spring, taking into account its geometric parameters, such as wire diameter, coil diameter, and number of coils. These equations enable engineers to predict the behavior of springs under different loading conditions, allowing for the optimization of spring design and performance. Calculators and software tools that implement these equations can significantly simplify the design process, reducing the need for trial and error and enabling the rapid evaluation of different design scenarios. By using these equations and calculators, engineers can ensure that their spring designs meet the required performance specifications and safety standards.

What are the key factors that influence the Axial Tension Compression Spring Stiffness Constant, and how do they impact spring behavior?

Several key factors influence the Axial Tension Compression Spring Stiffness Constant, including the material properties of the spring, such as its elastic modulus and Poisson's ratio. The geometric parameters of the spring, such as its wire diameter, coil diameter, and number of coils, also play a significant role in determining the stiffness constant. Additionally, the loading conditions, including the type of load (e.g., tension or compression) and the magnitude of the load, can affect the behavior of the spring. Understanding how these factors interact and influence the Axial Tension Compression Spring Stiffness Constant is crucial for designing and optimizing springs for specific applications, ensuring that they can withstand the required loads and stresses while maintaining their structural integrity.

How can engineers use Axial Tension Compression Spring Stiffness Constant Equations and Calculators to optimize spring design for specific applications, such as aerospace or automotive engineering?

Engineers can use the Axial Tension Compression Spring Stiffness Constant Equations and Calculators to optimize spring design for specific applications by iteratively analyzing and refining their designs. By inputting the geometric parameters and material properties of the spring, engineers can calculate the stiffness constant and predict the behavior of the spring under different loading conditions. This allows them to evaluate and compare [...) and optimize their designs to meet the required performance specifications and safety standards. In aerospace engineering, for example, engineers can use these equations and calculators to design springs that can withstand the extreme temperatures and loads encountered in space exploration. Similarly, in automotive engineering, engineers can use these tools to design springs that can optimize the suspension system of vehicles, improving their handling and stability.

Deja una respuesta

Entradas Relacionadas