Two Gears Sprocket Speed and Gear Ratio Equation and Calculator

The Two Gears Sprocket Speed and Gear Ratio Equation and Calculator is a valuable tool for engineers and mechanics. Understanding gear ratios is crucial in designing and optimizing mechanical systems. This equation and calculator enable users to calculate the output speed of a gear system, given the input speed and gear ratio. By inputting the number of teeth on each gear, users can determine the gear ratio and output speed, making it an essential resource for designing and troubleshooting gear systems in various industries, including automotive, aerospace, and manufacturing. The calculator simplifies complex calculations, saving time and effort.

- Understanding Two Gears Sprocket Speed and Gear Ratio Equation and Calculator

- How do you calculate gear ratio with two gears?

- What is the formula for gear ratio and speed?

- What is the formula for the sprocket gear ratio?

- What is the gear ratio and the speed ratio of two gears?

-

Frequently Asked Questions (FAQs)

- What is the Two Gears Sprocket Speed and Gear Ratio Equation and Calculator?

- How does the Two Gears Sprocket Speed and Gear Ratio Equation and Calculator work?

- What are the advantages of using the Two Gears Sprocket Speed and Gear Ratio Equation and Calculator?

- What are the limitations of the Two Gears Sprocket Speed and Gear Ratio Equation and Calculator?

Understanding Two Gears Sprocket Speed and Gear Ratio Equation and Calculator

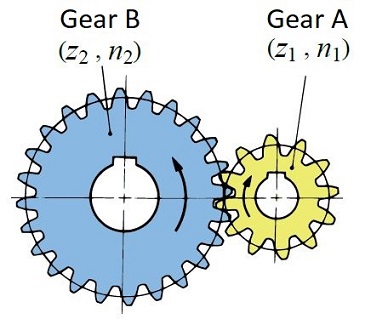

The concept of two gears sprocket speed and gear ratio is crucial in understanding the mechanics of gearboxes and transmissions. In simple terms, the gear ratio is the ratio of the speed of the input gear to the speed of the output gear. This ratio determines the torque and speed of the output shaft. The equation for calculating the gear ratio is: Gear Ratio = (Number of teeth on output gear) / (Number of teeth on input gear).

What is Gear Ratio and Its Importance

The gear ratio is a critical factor in determining the performance of a vehicle or a machine. A higher gear ratio means that the output shaft will rotate slower, but with more torque. This is useful for applications where high torque is required, such as in heavy-duty vehicles or machines. On the other hand, a lower gear ratio means that the output shaft will rotate faster, but with less torque. This is useful for applications where high speed is required, such as in racing cars or high-speed machines.

How to Calculate Gear Ratio

Calculating the gear ratio is a straightforward process. The formula for calculating the gear ratio is: Gear Ratio = (Number of teeth on output gear) / (Number of teeth on input gear). For example, if the input gear has 20 teeth and the output gear has 40 teeth, the gear ratio would be 2:1. This means that for every one rotation of the input gear, the output gear will rotate twice.

Understanding Sprocket Speed

Sprocket speed is the speed at which the sprocket rotates. The sprocket speed is determined by the gear ratio and the input speed. The equation for calculating the sprocket speed is: Sprocket Speed = (Input Speed) / (Gear Ratio). For example, if the input speed is 1000 rpm and the gear ratio is 2:1, the sprocket speed would be 500 rpm.

Applications of Two Gears Sprocket Speed and Gear Ratio

The concept of two gears sprocket speed and gear ratio has numerous applications in various fields, including automotive, aerospace, and industrial. In the automotive industry, the gear ratio is used to determine the performance and efficiency of a vehicle. In the aerospace industry, the gear ratio is used to determine the thrust and efficiency of an aircraft. In the industrial sector, the gear ratio is used to determine the productivity and efficiency of a machine.

Advantages and Limitations of Two Gears Sprocket Speed and Gear Ratio Equation and Calculator

The two gears sprocket speed and gear ratio equation and calculator have several advantages, including accuracy, convenience, and ease of use. However, they also have some limitations, including complexity and limited applicability. The calculator is only applicable to simple gear systems and may not be accurate for more complex systems. Additionally, the calculator assumes that the gear ratio is constant, which may not be the case in real-world applications.

| Parameter!strong> | Description!strong> | Unit!strong> |

|---|---|---|

| Input Speed!strong> | The speed at which the input gear rotates | rpm!strong> |

| Output Speed!strong> | The speed at which the output gear rotates | rpm!strong> |

| Gear Ratio!strong> | The ratio of the output speed to the input speed | -!strong> |

| Torque!strong> | The rotational force exerted by the output gear | Nm!strong> |

| Number of Teeth!strong> | The number of teeth on the input and output gears | -!strong> |

How do you calculate gear ratio with two gears?

To calculate the gear ratio with two gears, you need to understand the relationship between the number of teeth on each gear and the resulting ratio. The gear ratio is calculated by dividing the number of teeth on the output gear by the number of teeth on the input gear. This ratio determines how much the torque and speed of the input gear are modified as they are transmitted to the output gear.

Understanding Gear Ratio Basics

The gear ratio is a critical factor in determining the performance of a mechanical system. To calculate the gear ratio, you need to know the number of teeth on each gear. The formula for calculating the gear ratio is: Gear Ratio = Number of teeth on output gear / Number of teeth on input gear. This can be represented as follows:

- Identify the number of teeth on the input gear and the output gear

- Divide the number of teeth on the output gear by the number of teeth on the input gear

- Use the resulting ratio to determine the torque and speed multiplication or division

Calculating Gear Ratio with Two Gears

When working with two gears, the gear ratio calculation is straightforward. For example, if the input gear has 20 teeth and the output gear has 40 teeth, the gear ratio would be 40/20 = 2:1. This means that for every one rotation of the input gear, the output gear rotates twice, resulting in a speed reduction and torque increase. The calculation can be represented as follows:

- Determine the number of teeth on the input and output gears

- Apply the gear ratio formula: Gear Ratio = Number of teeth on output gear / Number of teeth on input gear

- Use the resulting ratio to determine the mechanical advantage of the gear system

Importance of Gear Ratio in Mechanical Systems

The gear ratio plays a crucial role in determining the performance of mechanical systems, including machinery, vehicles, and industrial equipment. A well-designed gear system can provide a mechanical advantage, increasing torque and reducing speed, or vice versa, depending on the application. The gear ratio can be used to:

- Increase torque and reduce speed for applications requiring high force and low speed

- Decrease torque and increase speed for applications requiring high speed and low torque

- Optimize the efficiency and performance of mechanical systems

Gear Ratio and Mechanical Advantage

The gear ratio is closely related to the mechanical advantage of a gear system. The mechanical advantage is the ratio of the output force to the input force, and it is directly related to the gear ratio. A higher gear ratio results in a greater mechanical advantage, allowing for increased torque and reduced speed. The relationship between gear ratio and mechanical advantage can be represented as follows:

- Determine the gear ratio of the system

- Calculate the mechanical advantage using the gear ratio

- Use the mechanical advantage to determine the output force and speed of the system

Applications of Gear Ratio in Real-World Systems

The gear ratio has numerous applications in real-world systems, including automotive transmissions, industrial machinery, and aerospace engineering. In these applications, the gear ratio is used to:

- Optimize the performance and efficiency of mechanical systems

- Provide a mechanical advantage for applications requiring high torque and low speed

- Enable the use of motors and engines with varying power and speed characteristics

What is the formula for gear ratio and speed?

The formula for gear ratio and speed is a fundamental concept in mechanics and engineering. The gear ratio is calculated by dividing the number of teeth on the output gear by the number of teeth on the input gear. This ratio determines the speed and torque of the output shaft. The formula for gear ratio is: Gear Ratio = Number of Teeth on Output Gear / Number of Teeth on Input Gear. The speed of the output shaft is calculated using the formula: Speed = (Input Speed x Number of Teeth on Input Gear) / Number of Teeth on Output Gear.

Understanding Gear Ratio and Speed

The gear ratio and speed are crucial in determining the performance of a machine or vehicle. A higher gear ratio results in a lower speed but higher torque, while a lower gear ratio results in a higher speed but lower torque. The following are key points to consider:

- The gear ratio determines the speed and torque of the output shaft.

- The speed of the output shaft is affected by the gear ratio and the input speed.

- The torque of the output shaft is affected by the gear ratio and the input torque.

Calculating Gear Ratio and Speed

To calculate the gear ratio and speed, you need to know the number of teeth on the input and output gears, as well as the input speed. The following steps can be used to calculate the gear ratio and speed:

- Determine the number of teeth on the input and output gears.

- Calculate the gear ratio using the formula: Gear Ratio = Number of Teeth on Output Gear / Number of Teeth on Input Gear.

- Calculate the speed of the output shaft using the formula: Speed = (Input Speed x Number of Teeth on Input Gear) / Number of Teeth on Output Gear.

Factors Affecting Gear Ratio and Speed

Several factors can affect the gear ratio and speed, including the gear material, gear design, and operating conditions. The following are key factors to consider:

- The gear material can affect the efficiency and durability of the gears.

- The gear design can affect the gear ratio and speed of the output shaft.

- The operating conditions, such as temperature and load, can affect the gear ratio and speed.

Applications of Gear Ratio and Speed

The gear ratio and speed have numerous applications in various fields, including automotive, aerospace, and industrial. The following are key applications:

- Automotive: The gear ratio and speed are used to optimize the performance of vehicles.

- Aerospace: The gear ratio and speed are used to optimize the performance of aircraft and spacecraft.

- Industrial: The gear ratio and speed are used to optimize the performance of machines and equipment.

Importance of Gear Ratio and Speed

The gear ratio and speed are critical in determining the performance and efficiency of machines and vehicles. A properly designed gear system can result in improved speed, torque, and efficiency, while a poorly designed gear system can result in reduced performance and efficiency. The following are key points to consider:

- A properly designed gear system can result in improved speed and torque.

- A poorly designed gear system can result in reduced performance and efficiency.

- The gear ratio and speed must be carefully selected to optimize the performance of the machine or vehicle.

What is the formula for the sprocket gear ratio?

The formula for the sprocket gear ratio is calculated by dividing the number of teeth on the output sprocket by the number of teeth on the input sprocket. This can be expressed as: Gear Ratio = (Number of teeth on output sprocket) / (Number of teeth on input sprocket).

Understanding Sprocket Gear Ratio

The sprocket gear ratio is a critical parameter in determining the performance and efficiency of a system. To understand this concept, it is essential to know the definition of gear ratio and its impact on the overall system. The gear ratio is calculated by dividing the number of teeth on the output sprocket by the number of teeth on the input sprocket. Some key points to consider when calculating the gear ratio include:

- Number of teeth: The number of teeth on both the input and output sprockets must be considered when calculating the gear ratio.

- Sprocket size: The size of the sprockets can also impact the gear ratio, as larger sprockets may have more teeth.

- System requirements: The gear ratio must be chosen based on the specific requirements of the system, including the desired speed and torque.

Calculating Sprocket Gear Ratio

To calculate the sprocket gear ratio, you need to know the number of teeth on both the input and output sprockets. The formula is simple: Gear Ratio = (Number of teeth on output sprocket) / (Number of teeth on input sprocket). For example, if the input sprocket has 20 teeth and the output sprocket has 40 teeth, the gear ratio would be 2:1. Some key steps to follow when calculating the gear ratio include:

- Identify the number of teeth: Determine the number of teeth on both the input and output sprockets.

- Apply the formula: Use the formula to calculate the gear ratio.

- Consider the system requirements: Ensure the calculated gear ratio meets the speed and torque requirements of the system.

Importance of Sprocket Gear Ratio

The sprocket gear ratio is crucial in determining the performance and efficiency of a system. A properly chosen gear ratio can help achieve the desired speed and torque, while an incorrect gear ratio can lead to inefficiency and reduced performance. Some key benefits of a well-chosen gear ratio include:

- Increased efficiency: A properly chosen gear ratio can help reduce energy losses and increase system efficiency.

- Improved performance: The correct gear ratio can help achieve the desired speed and torque, resulting in improved system performance.

- Reduced wear and tear: A well-chosen gear ratio can help reduce wear and tear on system components, resulting in increased lifespan.

Applications of Sprocket Gear Ratio

The sprocket gear ratio has numerous applications in various fields, including industrial machinery, automotive systems, and bicycle transmissions. In each of these applications, the gear ratio plays a critical role in determining the performance and efficiency of the system. Some key applications of the gear ratio include:

- Industrial machinery: The gear ratio is used to determine the speed and torque of industrial machinery, such as conveyors and pumps.

- Automotive systems: The gear ratio is used to determine the speed and torque of automotive systems, such as transmissions and differentials.

- Bicycle transmissions: The gear ratio is used to determine the speed and torque of bicycle transmissions, allowing riders to optimize their performance.

Common Mistakes in Sprocket Gear Ratio Calculation

When calculating the sprocket gear ratio, there are several common mistakes that can be made. These mistakes can result in an incorrect gear ratio, leading to inefficiency and reduced performance. Some key mistakes to avoid include:

- Incorrect tooth count: Failing to accurately count the number of teeth on the input and output sprockets can result in an incorrect gear ratio.

- Failure to consider system requirements: Failing to consider the speed and torque requirements of the system can result in a suboptimal gear ratio.

- Ignoring sprocket size: Ignoring the size of the sprockets can result in an incorrect gear ratio, as larger sprockets may have more teeth.

What is the gear ratio and the speed ratio of two gears?

The gear ratio and speed ratio of two gears are fundamental concepts in mechanics, particularly in the context of transmissions and gearboxes. The gear ratio is defined as the ratio of the angular velocity of the input gear to the angular velocity of the output gear. This ratio determines the torque and speed of the output gear relative to the input gear. On the other hand, the speed ratio is the ratio of the linear speed of the input gear to the linear speed of the output gear.

Definition of Gear Ratio

The gear ratio is a measure of the mechanical advantage provided by a gear system. It is calculated as the ratio of the number of teeth on the output gear to the number of teeth on the input gear. A higher gear ratio indicates that the output gear has more teeth than the input gear, resulting in a torque increase and a speed decrease. The gear ratio can be expressed as a fraction or a decimal value, where a gear ratio of 2:1 or 2.0 means that the output gear has twice the number of teeth as the input gear.

- The gear ratio is a dimensionless quantity that represents the ratio of the angular velocities of the input and output gears.

- It is used to determine the mechanical advantage of a gear system, which is the ratio of the output torque to the input torque.

- The gear ratio can be adjusted by changing the number of teeth on the input or output gear, allowing for different speed ratios and torque ratios.

Speed Ratio Calculation

The speed ratio is calculated as the ratio of the linear speed of the input gear to the linear speed of the output gear. This ratio can be expressed as a fraction or a decimal value, where a speed ratio of 2:1 or 2.0 means that the output gear has half the linear speed of the input gear. The speed ratio is inversely proportional to the gear ratio, meaning that a higher gear ratio results in a lower speed ratio.

- The speed ratio is a measure of the linear speed of the output gear relative to the input gear.

- It is used to determine the efficiency of a gear system, which is the ratio of the output power to the input power.

- The speed ratio can be affected by the friction and energy losses in the gear system.

Types of Gear Ratios

There are several types of gear ratios, including simple gear ratios, compound gear ratios, and differential gear ratios. Simple gear ratios involve a single gear pair, while compound gear ratios involve multiple gear pairs. Differential gear ratios involve a gear pair with a differential output, allowing for variable speed ratios.

- Simple gear ratios are used in single-stage transmissions, where a single gear pair provides the required speed ratio.

- Compound gear ratios are used in multi-stage transmissions, where multiple gear pairs provide a range of speed ratios.

- Differential gear ratios are used in differential gearboxes, where a differential output allows for variable speed ratios.

Applications of Gear Ratios

Gear ratios have numerous applications in mechanical engineering, including transmissions, gearboxes, and speed reducers. They are used to increase torque, decrease speed, and improve efficiency in a wide range of mechanical systems.

- Gear ratios are used in automotive transmissions to provide a range of speed ratios for vehicles.

- They are used in industrial gearboxes to provide a high torque output for heavy machinery.

- Gear ratios are used in robotic systems to provide a high speed ratio for precise movements.

Importance of Gear Ratios

The gear ratio and speed ratio are critical parameters in the design and operation of gear systems. They determine the mechanical advantage, efficiency, and performance of the system, and are used to optimize the design of gearboxes and transmissions.

- The gear ratio is a key factor in determining the torque output and speed of a gear system.

- The speed ratio is a critical parameter in determining the efficiency and performance of a gear system.

- The gear ratio and speed ratio are used to optimize the design of gearboxes and transmissions for specific applications.

Frequently Asked Questions (FAQs)

What is the Two Gears Sprocket Speed and Gear Ratio Equation and Calculator?

The Two Gears Sprocket Speed and Gear Ratio Equation and Calculator is a mathematical tool used to calculate the speed and gear ratio of two interconnected gears or sprockets. This equation and calculator are essential in mechanical engineering and industrial design, where understanding the relationships between gears and their speeds is crucial for designing and optimizing mechanical systems. The equation takes into account the number of teeth on each gear, the input speed of one gear, and the desired output speed of the other gear. By using this equation and calculator, engineers and designers can determine the optimal gear ratio for their system, ensuring efficient power transmission and minimizing wear on the gears.

How does the Two Gears Sprocket Speed and Gear Ratio Equation and Calculator work?

The Two Gears Sprocket Speed and Gear Ratio Equation and Calculator works by using a simple mathematical formula that relates the speed of one gear to the speed of the other gear, based on the number of teeth on each gear. The formula is: output speed = input speed (number of teeth on input gear / number of teeth on output gear). This formula is then used in conjunction with the calculator to determine the gear ratio, which is the ratio of the output speed to the input speed. The gear ratio is a critical parameter in mechanical design, as it determines the torque and speed of the output shaft. By using the equation and calculator, users can easily determine the gear ratio and optimize their system for maximum efficiency and performance.

What are the advantages of using the Two Gears Sprocket Speed and Gear Ratio Equation and Calculator?

The Two Gears Sprocket Speed and Gear Ratio Equation and Calculator offers several advantages, including quick and easy calculations, accurate results, and increased efficiency in mechanical design. By using this equation and calculator, engineers and designers can save time and reduce errors, as they no longer need to perform complex calculations by hand. Additionally, the calculator can be used to iterate and optimize the design of a mechanical system, allowing users to test different scenarios and refine their design. The equation and calculator are also versatile, and can be applied to a wide range of mechanical systems, from simple gear trains to complex transmissions.

What are the limitations of the Two Gears Sprocket Speed and Gear Ratio Equation and Calculator?

The Two Gears Sprocket Speed and Gear Ratio Equation and Calculator has several limitations, including assuming ideal gear behavior, neglecting friction and energy losses, and only considering two gears. In real-world applications, gears are subject to wear and tear, friction, and energy losses, which can affect their performance and efficiency. Additionally, the equation and calculator are limited to simple gear trains, and may not be applicable to more complex systems with multiple gears and nonlinear relationships. However, despite these limitations, the equation and calculator remain a useful tool for engineers and designers, providing a quick and easy way to estimate gear ratios and output speeds, and informing the design of more complex mechanical systems.

Deja una respuesta

Entradas Relacionadas