Required Flow Velocity in Sewers Formula and Calculator

The required flow velocity in sewers is a critical parameter in ensuring the effective transportation of wastewater and preventing the accumulation of sediment and debris. The flow velocity must be sufficient to prevent the settling of solids and to minimize the risk of blockages and overflows. The formula for calculating the required flow velocity in sewers takes into account the slope, diameter, and roughness of the pipe, as well as the flow rate and viscosity of the fluid. A calculator can be used to simplify the calculation process and ensure accurate results. This is essential for design.

- Required Flow Velocity in Sewers Formula and Calculator

- What is the formula for flow velocity?

- What should the velocity of flow in a sewer be?

- What is the formula for the required flow rate?

- What is the minimum velocity for a sewer pipe?

-

Frequently Asked Questions (FAQs)

- What is the Required Flow Velocity in Sewers Formula and Calculator?

- How does the Required Flow Velocity in Sewers Formula and Calculator work?

- What are the benefits of using the Required Flow Velocity in Sewers Formula and Calculator?

- What are the limitations of the Required Flow Velocity in Sewers Formula and Calculator?

Required Flow Velocity in Sewers Formula and Calculator

The required flow velocity in sewers is a critical parameter in the design and operation of sewer systems. It is essential to ensure that the flow velocity is sufficient to prevent sedimentation and blockages in the sewer pipes. The required flow velocity can be calculated using the Manning's equation, which takes into account the roughness coefficient, slope, and diameter of the pipe. A calculator can be used to simplify the calculation process and provide accurate results.

Introduction to Required Flow Velocity in Sewers

The required flow velocity in sewers is typically in the range of 0.5 to 3.0 meters per second. This range is considered optimal for preventing deposition and erosion in the sewer pipes. The required flow velocity can be affected by various factors, including the type of sewage, pipe material, and flow rate. A higher flow velocity is often required for pipes with a steeper slope or larger diameter.

Manning's Equation for Required Flow Velocity

Manning's equation is a widely used formula for calculating the required flow velocity in sewers. The equation is as follows: V = (1/n) R^2/3 S^1/2, where V is the flow velocity, n is the roughness coefficient, R is the hydraulic radius, and S is the slope of the pipe. The roughness coefficient is a measure of the friction exerted by the pipe wall on the flowing sewage.

Calculator for Required Flow Velocity in Sewers

A calculator can be used to simplify the calculation process and provide accurate results. The calculator can take into account various factors, including the type of sewage, pipe material, and flow rate. The calculator can also be used to determine the required diameter of the pipe based on the desired flow velocity and flow rate.

Factors Affecting Required Flow Velocity in Sewers

Several factors can affect the required flow velocity in sewers, including the type of sewage, pipe material, and flow rate. For example, grease and debris can increase the roughness coefficient and reduce the required flow velocity. On the other hand, steep slopes and large diameters can increase the required flow velocity.

Importance of Required Flow Velocity in Sewers

The required flow velocity in sewers is crucial for preventing blockages and overflows. A sufficient flow velocity can help to prevent sedimentation and deposition in the sewer pipes, reducing the risk of blockages and overflows. A calculator can be used to determine the required flow velocity and ensure that the sewer system is designed and operated safely and efficiently.

| Parameter | Unit | Description |

|---|---|---|

| Flow Velocity | m/s | The velocity of the sewage flowing through the pipe |

| Roughness Coefficient | - | A measure of the friction exerted by the pipe wall on the flowing sewage |

| Hydraulic Radius | m | The ratio of the cross-sectional area of the pipe to the wetted perimeter |

| Slope | - | The angle of the pipe relative to the horizontal |

| Flow Rate | m3/s | The volume of sewage flowing through the pipe per unit time |

What is the formula for flow velocity?

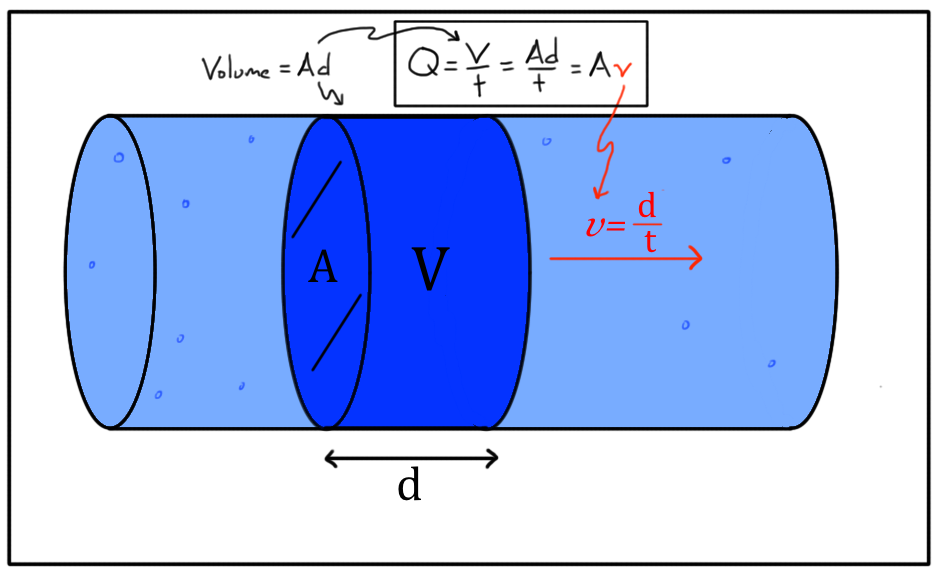

The formula for flow velocity is given by the equation: v = Q/A, where v is the flow velocity, Q is the volumetric flow rate, and A is the cross-sectional area of the flow. This equation is a fundamental concept in fluid dynamics and is used to calculate the velocity of a fluid flowing through a pipe or channel.

Understanding the Components of Flow Velocity

The components of the flow velocity equation are crucial in understanding the concept. The volumetric flow rate (Q) is the volume of fluid that flows through a given area per unit time, typically measured in cubic meters per second (m³/s). The cross-sectional area (A) is the area of the pipe or channel through which the fluid flows, measured in square meters (m²). The flow velocity (v) is the speed at which the fluid flows, measured in meters per second (m/s). Some key points to note are:

- The flow velocity is directly proportional to the volumetric flow rate.

- The flow velocity is inversely proportional to the cross-sectional area.

- The equation assumes a steady flow, where the flow rate and velocity are constant over time.

Applications of Flow Velocity

The concept of flow velocity has numerous applications in various fields, including engineering, physics, and environmental science. It is used to design and optimize pipelines, water treatment systems, and irrigation channels. The flow velocity equation is also used to calculate the pressure drop and energy loss in a flow system. Some key applications are:

- Hydraulic engineering: to design and optimize dams, canals, and water supply systems.

- Chemical engineering: to design and optimize pipelines and process equipment.

- Environmental science: to study and manage water pollution, waste management, and ecosystems.

Measurement of Flow Velocity

Measuring flow velocity is crucial in various applications, and there are several methods to do so. The most common methods include pitot tubes, hot wire anemometers, and ultrasonic flow meters. These methods measure the flow velocity at a specific point or over a range of points, providing valuable data for flow modeling and system optimization. Some key measurement techniques are:

- Pitot tubes: measure the stagnation pressure and static pressure to calculate the flow velocity.

- Hot wire anemometers: measure the heat transfer from a hot wire to the surrounding fluid to calculate the flow velocity.

- Ultrasonic flow meters: measure the time of flight of an ultrasonic signal to calculate the flow velocity.

Factors Affecting Flow Velocity

Several factors can affect the flow velocity, including the viscosity of the fluid, the roughness of the pipe or channel, and the pressure gradient. The viscosity of the fluid can slow down or speed up the flow, depending on its value. The roughness of the pipe or channel can cause turbulence and energy loss, affecting the flow velocity. Some key factors are:

- Viscosity: affects the flow velocity by opposing the motion of the fluid.

- Roughness: affects the flow velocity by causing turbulence and energy loss.

- Pressure gradient: affects the flow velocity by driving the flow through the pipe or channel.

Importance of Flow Velocity in Fluid Dynamics

The concept of flow velocity is fundamental to fluid dynamics, as it describes the motion of fluids and the forces that act upon them. Understanding flow velocity is crucial for designing and optimizing flow systems, such as pipelines, pumps, and turbines. The flow velocity equation provides a basis for calculating the pressure drop, energy loss, and flow rate in a system. Some key importance of flow velocity are:

- Design and optimization: of flow systems to achieve efficient and effective operation.

- Prediction and modeling: of flow behavior to understand and manage complex systems.

- Safety and reliability: of flow systems to prevent accidents and failures.

What should the velocity of flow in a sewer be?

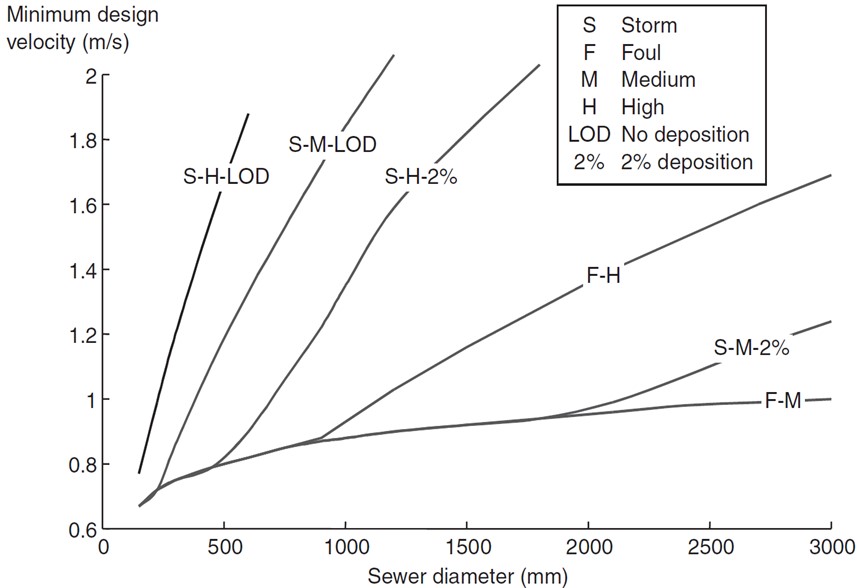

The velocity of flow in a sewer should be sufficient to prevent sedimentation and deposition of solids, while also ensuring that the sewer can handle the maximum flow rate. The ideal velocity of flow in a sewer is typically between 0.6 and 1.2 meters per second, although this can vary depending on the specific sewer design and operating conditions.

Minimum Velocity Requirements

The minimum velocity of flow in a sewer is typically around 0.6! meters per second, which is sufficient to prevent sedimentation and deposition of solids. However, this velocity can be higher or lower depending on the specific sewer design and operating conditions. Some of the key factors that influence the minimum velocity requirements include the sewer slope, sewer diameter, and flow rate.

- The sewer slope should be sufficient to ensure that the flow rate is maintained, even during periods of low flow.

- The sewer diameter should be large enough to handle the maximum flow rate, while also minimizing head loss and energy loss.

- The flow rate should be sufficient to maintain the minimum velocity, even during periods of low flow, to prevent sedimentation and deposition of solids.

Maximum Velocity Limitations

The maximum velocity of flow in a sewer is typically around 1.2! meters per second, which is sufficient to prevent erosion and damage to the sewer. However, this velocity can be higher or lower depending on the specific sewer design and operating conditions. Some of the key factors that influence the maximum velocity limitations include the sewer material, sewer age, and maintenance history.

- The sewer material should be resistant to erosion and corrosion, even at high flow rates.

- The sewer age and maintenance history should be taken into account, as older sewers may be more prone to damage and failure.

- The flow rate should be monitored regularly to ensure that it does not exceed the maximum velocity, to prevent erosion and damage to the sewer.

Design Considerations

When designing a sewer system, there are several key considerations that must be taken into account, including the sewer slope, sewer diameter, and flow rate. The sewer slope should be sufficient to ensure that the flow rate is maintained, even during periods of low flow. The sewer diameter should be large enough to handle the maximum flow rate, while also minimizing head loss and energy loss.

- The sewer slope should be designed to ensure that the flow rate is maintained, even during periods of low flow.

- The sewer diameter should be designed to handle the maximum flow rate, while also minimizing head loss and energy loss.

- The flow rate should be designed to maintain the minimum velocity, even during periods of low flow, to prevent sedimentation and deposition of solids.

Operating Conditions

The operating conditions of a sewer system can have a significant impact on the velocity of flow, including the flow rate, sewer slope, and sewer diameter. The flow rate can vary significantly depending on the time of day, day of the week, and season, which can affect the velocity of flow. The sewer slope and sewer diameter can also affect the velocity of flow, as they can influence the head loss and energy loss.

- The flow rate can vary significantly depending on the time of day, day of the week, and season, which can affect the velocity of flow.

- The sewer slope and sewer diameter can affect the velocity of flow, as they can influence the head loss and energy loss.

- The sewer material and sewer age can also affect the velocity of flow, as they can influence the friction factor and roughness coefficient.

Maintenance and Repair

Regular maintenance and repair are essential to ensure that the velocity of flow in a sewer system is maintained, and that the sewer remains in good condition. This includes inspecting the sewer regularly for signs of damage or deterioration, and making repairs as necessary. The sewer should also be cleaned regularly to prevent sedimentation and deposition of solids.

- The sewer should be inspected regularly for signs of damage or deterioration.

- The sewer should be cleaned regularly to prevent sedimentation and deposition of solids.

- The sewer should be repaired as necessary to maintain the velocity of flow and prevent damage to the sewer.

What is the formula for the required flow rate?

The formula for the required flow rate is given by the equation: Q = V / t, where Q is the flow rate, V is the volume, and t is the time. This equation can be used to calculate the flow rate of a fluid in a pipe or a channel.

Understanding the Variables

To understand the formula for the required flow rate, it is essential to know the variables involved. The variables are volume, time, and flow rate. The volume is the amount of fluid that flows through a pipe or a channel, the time is the duration it takes for the fluid to flow, and the flow rate is the rate at which the fluid flows. Here are some key points to consider:

- The volume of the fluid is typically measured in cubic meters (m³) or liters (L).

- The time is usually measured in seconds (s) or minutes (min).

- The flow rate is typically measured in cubic meters per second (m³/s) or liters per minute (L/min).

Applying the Formula

The formula Q = V / t can be applied in various situations, such as calculating the flow rate of water in a pipe or the flow rate of air in a ventilation system. To apply the formula, we need to know the volume and time of the fluid flow. Here are some steps to follow:

- Determine the volume of the fluid that flows through the pipe or channel.

- Measure the time it takes for the fluid to flow.

- Plug in the values of volume and time into the formula Q = V / t to calculate the flow rate.

Importance of Flow Rate

The flow rate is a critical parameter in many engineering applications, such as designing piping systems, pumps, and valves. A correct flow rate ensures that the fluid flows smoothly and efficiently through the system, while an incorrect flow rate can lead to problems such as pipe damage, pump failure, and energy loss. Here are some reasons why flow rate is important:

- Efficient operation: A correct flow rate ensures that the system operates efficiently and effectively.

- Pipe sizing: The flow rate is used to determine the pipe size required for a particular application.

- Pump selection: The flow rate is used to select the right pump for a particular application.

Common Units of Flow Rate

The flow rate can be measured in various units, depending on the application and the fluid properties. Some common units of flow rate include cubic meters per second (m³/s), liters per minute (L/min), and gallons per minute (gpm). Here are some examples of flow rates in different units:

- Cubic meters per second (m³/s): used for large-scale applications such as water treatment and power generation.

- Liters per minute (L/min): used for small-scale applications such as laboratory equipment and medical devices.

- Gallons per minute (gpm): used for applications such as irrigation and plumbing.

Real-World Applications

The formula Q = V / t has many real-world applications, including water supply systems, wastewater treatment, and chemical processing. In these applications, the flow rate is used to design, operate, and maintain the systems. Here are some examples of real-world applications:

- Water supply systems: the flow rate is used to design and operate water distribution networks.

- Wastewater treatment: the flow rate is used to design and operate wastewater treatment plants.

- Chemical processing: the flow rate is used to design and operate chemical processing plants.

What is the minimum velocity for a sewer pipe?

The minimum velocity for a sewer pipe is typically 2-3 feet per second (fps) to ensure that the wastewater flows smoothly and sediment is carried away. This velocity is crucial in preventing clogging and blockages in the pipe, which can lead to backups and overflows. The minimum velocity required can vary depending on the pipe size, slope, and material, as well as the type of wastewater being transported. In general, a higher velocity is required for larger pipes and steeper slopes to maintain a stable flow.

Design Considerations for Sewer Pipes

The design of sewer pipes must take into account several factors, including the minimum velocity required to prevent clogging and blockages. The following are some key considerations:

- The pipe size and material must be suitable for the flow rate and type of wastewater being transported.

- The slope of the pipe must be sufficient to maintain a minimum velocity of 2-3 fps.

- The roughness of the pipe surface can affect the flow rate and velocity, and must be taken into account in the design.

Factors Affecting Minimum Velocity

Several factors can affect the minimum velocity required for a sewer pipe, including the type of wastewater being transported, the pipe size and slope, and the material of the pipe. The following are some key factors to consider:

- The viscosity of the wastewater can affect the minimum velocity required, with thicker wastewater requiring a higher velocity.

- The density of the wastewater can also affect the minimum velocity, with denser wastewater requiring a higher velocity.

- The roughness of the pipe surface can affect the flow rate and velocity, and must be taken into account in the design.

Consequences of Low Velocity

If the velocity in a sewer pipe is too low, it can lead to clogging and blockages, which can cause backups and overflows. The following are some potential consequences of low velocity:

- Clogging and blockages can occur, causing backups and overflows.

- Sediment can accumulate in the pipe, reducing the flow rate and increasing the risk of clogging.

- Odors and gas buildup can occur, posing a health risk to nearby residents.

Methods for Increasing Velocity

If the velocity in a sewer pipe is too low, there are several methods that can be used to increase it, including increasing the slope of the pipe, using a larger pipe size, or installing a pumping station. The following are some potential methods:

- Increasing the slope of the pipe can increase the velocity, but may require re-grading the surrounding area.

- Using a larger pipe size can increase the velocity, but may require replacing the existing pipe.

- Installing a pumping station can increase the velocity, but may require significant investment.

Best Practices for Maintaining Velocity

To maintain a minimum velocity in a sewer pipe, it is essential to follow best practices for design, installation, and maintenance. The following are some key practices to follow:

- Regular inspections should be performed to identify potential problems and prevent clogging and blockages.

- Maintenance should be performed regularly, including cleaning and repairing the pipe as needed.

- Upgrades should be made as needed to ensure that the pipe is suitable for the flow rate and type of wastewater being transported.

Frequently Asked Questions (FAQs)

What is the Required Flow Velocity in Sewers Formula and Calculator?

The Required Flow Velocity in Sewers Formula is a mathematical equation used to determine the minimum velocity required for wastewater to flow through a sewer system without causing deposition or erosion of the pipe walls. This formula takes into account factors such as the pipe diameter, slope, and roughness of the pipe, as well as the flow rate and viscosity of the wastewater. The calculator is a tool used to simplify the calculation process, allowing users to input the relevant parameters and obtain the required flow velocity. By using this formula and calculator, engineers and designers can ensure that their sewer systems are designed to operate efficiently and effectively, preventing clogging and overflow.

How does the Required Flow Velocity in Sewers Formula and Calculator work?

The Required Flow Velocity in Sewers Formula works by using a combination of empirical and theoretical equations to calculate the minimum velocity required for wastewater to flow through a sewer system. The formula takes into account the hydraulic gradient of the pipe, which is the slope of the pipe divided by the length of the pipe, as well as the friction factor, which is a measure of the roughness of the pipe. The calculator uses these inputs to calculate the required flow velocity, which is typically expressed in units of meters per second or feet per second. By using this formula and calculator, users can determine the minimum velocity required to prevent deposition and erosion of the pipe walls, and design their sewer systems accordingly.

What are the benefits of using the Required Flow Velocity in Sewers Formula and Calculator?

The benefits of using the Required Flow Velocity in Sewers Formula and calculator include improved design and operation of sewer systems, reduced maintenance costs, and increased efficiency. By using this formula and calculator, engineers and designers can ensure that their sewer systems are designed to operate within the optimal flow range, preventing clogging and overflow. This can also help to reduce the risk of environmental pollution and public health risks associated with sewer overflows. Additionally, the calculator can help to streamline the design process, saving time and resources.

What are the limitations of the Required Flow Velocity in Sewers Formula and Calculator?

The limitation of the Required Flow Velocity in Sewers Formula and calculator is that they are based on simplified assumptions and empirical equations, which may not accurately reflect the complexity of real-world sewer systems. Additionally, the formula and calculator may not account for transient flow conditions, such as storm surges or sewer backups, which can affect the hydraulic gradient and friction factor of the pipe. Furthermore, the calculator may not be able to account for non-uniform pipe geometries or irregular flow patterns, which can affect the accuracy of the calculations. Therefore, it is essential to use the formula and calculator in conjunction with other design tools and expert judgment to ensure the optimization of sewer system design.

Deja una respuesta

Entradas Relacionadas