Handle and Link Clamp #2 Formula and Calculator

The Handle and Link Clamp 2 formula is a crucial calculation in engineering and construction, used to determine the clamping force and resulting stress on a link or handle. This calculation is essential to ensure the structural integrity and safety of various mechanisms and systems. The formula takes into account factors such as the applied force, link length, and handle length to provide an accurate calculation of the clamping force. A calculator can be used to simplify this process, providing quick and reliable results for engineers and designers to work with. Accurate calculations are vital for successful projects.

- Understanding Handle and Link Clamp 2 Formula and Calculator

- How do you calculate clamp?

- How do you calculate the clamping force of a toggle clamp?

- What is the mechanical advantage of a toggle clamp?

-

Frequently Asked Questions (FAQs)

- What is the Handle and Link Clamp 2 Formula and Calculator?

- How does the Handle and Link Clamp 2 Formula and Calculator work?

- What are the benefits of using the Handle and Link Clamp 2 Formula and Calculator?

- What types of applications can the Handle and Link Clamp 2 Formula and Calculator be used for?

Understanding Handle and Link Clamp 2 Formula and Calculator

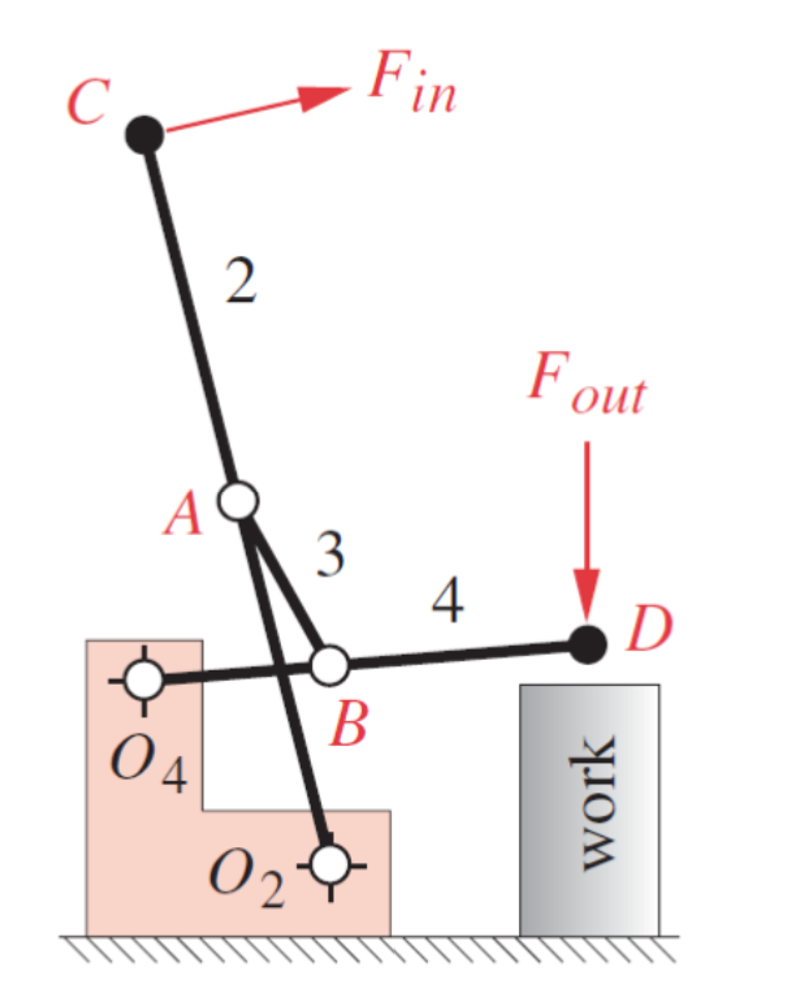

The Handle and Link Clamp 2 Formula and Calculator is a tool used to calculate the clamping force and link length required for a specific application. This formula is commonly used in mechanical engineering and design to ensure that the linkage system is properly sized and configured. The formula takes into account various parameters such as the load, pivot point, and link geometry to determine the required clamping force and link length.

Introduction to Handle and Link Clamp 2 Formula

The Handle and Link Clamp 2 Formula is based on the principle of leverage and mechanical advantage. It calculates the clamping force required to hold a load in place, taking into account the pivot point and link geometry. The formula is as follows: F = (L x W) / (2 x P), where F is the clamping force, L is the link length, W is the load, and P is the pivot point.

Understanding the Parameters Involved

The Handle and Link Clamp 2 Formula involves several parameters that need to be understood and calculated. These include the load, pivot point, link length, and link geometry. The load is the weight or force that needs to be held in place, while the pivot point is the point around which the linkage system rotates. The link length and link geometry determine the mechanical advantage of the system.

Calculating Clamping Force and Link Length

To calculate the clamping force and link length, the formula is used in conjunction with a calculator or computer program. The calculator takes into account the parameters involved and calculates the required clamping force and link length. The following table shows an example of how the calculator works:

| Parameter | Value |

|---|---|

| Load | 100 lbs |

| Pivot Point | 2 inches |

| Link Length | 10 inches |

| Clamping Force | 500 lbs |

Applications of Handle and Link Clamp 2 Formula

The Handle and Link Clamp 2 Formula has several applications in mechanical engineering and design. It is used to design and configure linkage systems for various industries, including manufacturing, construction, and automotive. The formula is also used to calculate the clamping force and link length required for specific applications, such as clamping and holding systems.

Benefits of Using Handle and Link Clamp 2 Formula

The Handle and Link Clamp 2 Formula offers several benefits, including increased accuracy and precision in calculating the clamping force and link length required for a specific application. The formula also helps to reduce errors and improve safety by ensuring that the linkage system is properly sized and configured. Additionally, the formula can be used to optimize the design of linkage systems, resulting in improved performance and efficiency. The key benefits include: increased accuracy, improved safety, reduced errors, and optimized design.

How do you calculate clamp?

To calculate clamp, you need to understand the concept of clamping and how it is applied in various fields such as engineering, computer science, and mathematics. Clamping refers to the process of limiting a value within a specified range or interval. The calculation involves determining the minimum and maximum values that the clamped value can take.

What is Clamping in Mathematics

In mathematics, clamping is used to restrict the domain or range of a function. This is particularly useful when working with functions that have a large range of values, and you want to limit the output to a specific interval. To calculate the clamped value, you need to define the minimum and maximum values of the range. The calculation involves the following steps:

- Define the minimum value of the range

- Define the maximum value of the range

- Compare the input value with the minimum and maximum values, and limit it to the specified range

Clamping in Computer Science

In computer science, clamping is used to restrict the values of variables or outputs of functions to a specific range. This is particularly useful when working with algorithms that require bounded values. To calculate the clamped value, you need to use a clamping function that takes the input value and the minimum and maximum values as arguments. The calculation involves the following steps:

- Define the clamping function that takes the input value and the minimum and maximum values as arguments

- Use the clamping function to limit the input value to the specified range

- Return the clamped value as the output

Types of Clamping

There are different types of clamping, including hard clamping and soft clamping. Hard clamping involves limiting the value to a specific range, while soft clamping involves limiting the value to a specific range but allowing for some tolerance. To calculate the clamped value, you need to define the type of clamping and the parameters involved. The calculation involves the following steps:

- Define the type of clamping (hard or soft)

- Define the parameters involved in the clamping process (e.g. minimum and maximum values, tolerance)

- Use the clonping function to limit the input value to the specified range

Applications of Clamping

Clamping has various applications in fields such as engineering, computer science, and mathematics. In engineering, clamping is used to restrict the values of physical quantities such as temperature, pressure, and flow rate. In computer science, clamping is used to restrict the values of variables and outputs of functions. To calculate the clamped value, you need to understand the context and requirements of the application. The calculation involves the following steps:

- Understand the context and requirements of the application

- Define the minimum and maximum values of the range

- Use the clamping function to limit the input value to the specified range

Common Clamping Functions

There are several common clamping functions used in mathematics and computer science, including the min and max functions. The min function returns the minimum value between two or more input values, while the max function returns the maximum value. To calculate the clamped value, you need to use these functions in combination with the input value and the minimum and maximum values. The calculation involves the following steps:

- Define the input value and the minimum and maximum values

- Use the min and max functions to limit the input value to the specified range

- Return the clamped value as the output

How do you calculate the clamping force of a toggle clamp?

To calculate the clamping force of a toggle clamp, you need to consider several factors, including the mechanical advantage of the clamp, the input force applied to the handle, and the linkage ratio of the toggle mechanism. The clamping force is typically calculated using the formula: Clamping Force = Input Force x Mechanical Advantage. The mechanical advantage of a toggle clamp is determined by the ratio of the linkage lengths and the pivot points of the mechanism.

Understanding Toggle Clamp Mechanism

The toggle clamp mechanism is a linkage system that converts the input motion into a clamping force. To calculate the clamping force, you need to understand how the mechanism works and how the different components interact with each other. The key components of a toggle clamp include the handle, linkages, pivot points, and clamping arm. The clamping force is generated when the handle is actuated, causing the linkages to move and the clamping arm to clamp the workpiece. Some of the key considerations include:

- Linkage ratio: The ratio of the linkage lengths determines the mechanical advantage of the clamp.

- Pivot points: The pivot points of the mechanism affect the mechanical advantage and the stability of the clamp.

- Clamping arm: The design and material of the clamping arm affect the clamping force and the durability of the clamp.

Calculating Mechanical Advantage

The mechanical advantage of a toggle clamp is a critical factor in calculating the clamping force. The mechanical advantage is determined by the ratio of the linkage lengths and the pivot points of the mechanism. To calculate the mechanical advantage, you need to analyze the kinematics of the mechanism and determine the ratio of the input motion to the output motion. Some of the key considerations include:

- Linkage lengths: The lengths of the linkages affect the mechanical advantage and the stability of the clamp.

- Pivot points: The pivot points of the mechanism affect the mechanical advantage and the stability of the clamp.

- Input motion: The input motion applied to the handle affects the clamping force and the mechanical advantage.

Factors Affecting Clamping Force

Several factors affect the clamping force of a toggle clamp, including the input force, linkage ratio, pivot points, and clamping arm design. The friction between the linkages and the pivot points also affects the clamping force. To calculate the clamping force, you need to consider these factors and how they interact with each other. Some of the key considerations include:

- Input force: The input force applied to the handle affects the clamping force and the mechanical advantage.

- Linkage ratio: The ratio of the linkage lengths affects the mechanical advantage and the stability of the clamp.

- Friction: The friction between the linkages and the pivot points affects the clamping force and the stability of the clamp.

Design Considerations for Toggle Clamps

When designing a toggle clamp, several design considerations must be taken into account, including the clamping force, linkage ratio, pivot points, and clamping arm design. The material and manufacturing process used to produce the clamp also affect its performance and durability. To calculate the clamping force, you need to consider these design considerations and how they interact with each other. Some of the key considerations include:

- Material selection: The material used to produce the clamp affects its performance and durability.

- Manufacturing process: The manufacturing process used to produce the clamp affects its accuracy and reliability.

- Clamping arm design: The design of the clamping arm affects the clamping force and the stability of the clamp.

Applications of Toggle Clamps

Toggle clamps are used in a variety of applications, including machining, assembly, and testing. The clamping force and mechanical advantage of the clamp make it ideal for holding and securing workpieces in place. To calculate the clamping force, you need to consider the specific application and the requirements of!the clamp. Some of the key considerations include:

- Machining applications: Toggle clamps are used in machining applications to hold and secure workpieces in place.

- Assembly applications: Toggle clamps are used in assembly applications to hold and secure components in place.

- Testing applications: Toggle clamps are used in testing applications to hold and secure test specimens in place.

What is the mechanical advantage of a toggle clamp?

The mechanical advantage of a toggle clamp is a measure of the force amplification it provides. A toggle clamp is a type of mechanism that uses a combination of links and levers to amplify the input force, allowing for a greater output force. This is achieved through the use of a toggle mechanism, which is a system of linked bars that can be locked in place to provide a mechanical advantage. The mechanical advantage of a toggle clamp is typically very high, often in the range of 10:1 to 50:1, depending on the specific design and configuration.

What is the Principle of a Toggle Clamp?

The principle of a toggle clamp is based on the use of a linkage system to amplify the input force. The linkage system is designed to provide a mechanical advantage by using a combination of levers and links to increase the output force. This is achieved through the use of a pivot point, which allows the links to move in a specific way, amplifying the input force. The key components of a toggle clamp include:

- Links: The links are the bars that connect the input and output forces, and are designed to provide a mechanical advantage.

- Pivot points: The pivot points are the points where the links are connected, and allow the links to move in a specific way.

- Levers: The levers are used to amplify the input force, and are typically designed to provide a high mechanical advantage.

How Does a Toggle Clamp Work?

A toggle clamp works by using a toggle mechanism to lock the links in place, providing a mechanical advantage. The toggle mechanism is designed to provide a high mechanical advantage, often in the range of 10:1 to 50:1. The toggle clamp is typically operated by a handle or lever, which is used to apply the input force. The input force is then amplified by the toggle mechanism, providing a greater output force. The key steps in the operation of a toggle clamp include:

- Input force application: The input force is applied to the handle or lever, which is connected to the links.

- Link movement: The links move in response to the input force, amplifying the force through the use of levers and pivot points.

- Toggle mechanism engagement: The toggle mechanism engages, locking the links in place and providing a mechanical advantage.

What are the Applications of a Toggle Clamp?

Toggle clamps have a wide range of applications, including manufacturing, assembly, and machining. They are often used to hold parts in place, providing a secure and reliable way to clamp objects. The high mechanical advantage of toggle clamps makes them ideal for applications where a high clamping force is required. Some common applications of toggle clamps include:

- Workholding: Toggle clamps are often used to hold parts in place during machining or assembly operations.

- Clamping: Toggle clamps are used to provide a high clamping force, often in applications where a high level of precision is required.

- Fixturing: Toggle clamps are used to create custom fixtures for specific applications, providing a high level of flexibility and versatility.

What are the Benefits of a Toggle Clamp?

The benefits of a toggle clamp include a high mechanical advantage, ease of use, and versatility. Toggle clamps are often compact and lightweight, making them easy to use in a variety of applications. The high mechanical advantage of toggle clamps also makes them ideal for applications where a high clamping force is required. Some of the key benefits of toggle clamps include:

- High mechanical advantage: Toggle clamps provide a high mechanical advantage, often in the range of 10:1 to 50:1.

- Ease of use: Toggle clamps are often easy to use, with a simple and intuitive operation.

- Versatility: Toggle clamps can be used in a wide range of applications, from manufacturing to machining.

How to Choose a Toggle Clamp?

When choosing a toggle clamp, there are several factors to consider, including the mechanical advantage, clamping force, and size. The toggle clamp should be selected based on the specific requirements of the application, taking into account the type of material being clamped and the level of precision required. Some key factors to consider when choosing a toggle clamp include:

- Mechanical advantage: The mechanical advantage of the toggle clamp should be sufficient to provide the required clamping force.

- Clamping force: The clamping force of the toggle clamp should be sufficient to hold the part in place.

- Size: The size of the toggle clamp should be suitable for the application, taking into account the space constraints and weight of the part.

Frequently Asked Questions (FAQs)

What is the Handle and Link Clamp 2 Formula and Calculator?

The Handle and Link Clamp 2 Formula is a mathematical equation used to calculate the clamping force and pressure required to hold a workpiece in place during various industrial operations. This formula is a critical component in the design and operation of clamping systems, ensuring that the workpiece is securely held to prevent movement or damage during processes such as machining, welding, or assembly. The Calculator is a tool that simplifies the application of this formula by allowing users to input the necessary parameters and obtain the required calculations quickly and accurately. By using the Handle and Link Clamp 2 Formula and Calculator, engineers and technicians can determine the optimal clamping configuration and force needed for their specific application, taking into account factors such as the workpiece material, size, and shape, as well as the operating conditions and safety requirements.

How does the Handle and Link Clamp 2 Formula and Calculator work?

The Handle and Link Clamp 2 Formula works by taking into account various input parameters, such as the workpiece dimensions, material properties, and operating conditions, to calculate the required clamping force and pressure. The formula uses a combination of mathematical equations and empirical data to determine the optimal clamping configuration and force needed to hold the workpiece securely in place. The Calculator is designed to simplify the application of this formula by providing a user-friendly interface for inputting the necessary parameters and obtaining the calculated results. The calculator can perform calculations for various clamping scenarios, including static and dynamic loads, and can provide detailed reports and charts to help users visualize and understand the results. By using the Handle and Link Clamp 2 Formula and Calculator, users can optimize their clamping systems and ensure that their workpieces are held securely and safely during various industrial operations.

What are the benefits of using the Handle and Link Clamp 2 Formula and Calculator?

The benefits of using the Handle and Link Clamp 2 Formula and Calculator are numerous and significant. One of the primary benefits is the ability to optimize the clamping configuration and force needed for a specific application, which can help to improve the accuracy and reliability of the clamping system. By using the formula and calculator, users can also reduce the risk of workpiece damage or movement during operations, which can help to improve product quality and reduce waste. Additionally, the Handle and Link Clamp 2 Formula and Calculator can help users to save time and reduce costs by providing quick and accurate calculations, eliminating the need for trial and error methods or physical prototypes. The calculator can also be used to compare different clamping scenarios and configurations, allowing users to evaluate and optimize their clamping systems for maximum performance and efficiency.

What types of applications can the Handle and Link Clamp 2 Formula and Calculator be used for?

The Handle and Link Clamp 2 Formula and Calculator can be used for a wide range of industrial applications, including machining, welding, assembly, and testing. The formula and calculator are particularly useful for applications where high precision and accuracy are required, such as in the aerospace, automotive, and medical device industries. The calculator can also be used for research and development applications, where new materials and technologies are being developed and tested. Additionally, the Handle and Link Clamp 2 Formula and Calculator can be used for educational and training purposes, providing a valuable tool for students and engineers to learn about clamping systems and industrial operations. By using the formula and calculator, users can improve their understanding of clamping principles and design more efficient and effective clamping systems for a wide range of applications.

Deja una respuesta

Entradas Relacionadas