Floating Bearing Shaft Length Design and Calculator

The design of a floating bearing shaft length is crucial in various mechanical applications, including gearboxes, turbines, and generators. A well-designed shaft length ensures optimal performance, reduces vibration, and minimizes the risk of bearing failure. The calculation of the ideal shaft length involves considering factors such as bearing type, load, and operating conditions. This article provides an overview of the key considerations and a calculator tool to help engineers and designers determine the optimal floating bearing shaft length for their specific applications, ensuring reliable and efficient operation of their machinery. Proper design is essential for longevity.

https://youtube.com/watch?v=GjrWfV2EN7Q

- Floating Bearing Shaft Length Design and Calculator: A Comprehensive Guide

- What is the spacing between bearings on a shaft?

- How to support a rotating shaft?

- Where is the fixed bearing located?

- How does the bearing flat attach to the design?

-

Frequently Asked Questions (FAQs)

- What is the importance of considering the shaft length in the design of a floating bearing?

- How does the calculator for floating bearing shaft length design work?

- What are the key factors to consider when designing a floating bearing shaft length?

- How can a calculator for floating bearing shaft length design help optimize bearing performance?

Floating Bearing Shaft Length Design and Calculator: A Comprehensive Guide

The design of a floating bearing shaft length is a critical aspect of mechanical engineering, as it directly affects the performance and efficiency of rotating machinery. A floating bearing is a type of bearing that allows for axial movement of the shaft, which can help to reduce stress and increase the lifespan of the bearing. The calculator used to design the shaft length takes into account various factors such as the diameter of the shaft, the length of the bearing, and the axial load applied to the shaft.

Introduction to Floating Bearing Shaft Length Design

The design of a floating bearing shaft length involves calculating the optimal length of the shaft to ensure that it can withstand the axial loads and bending moments applied to it. The floating bearing is designed to allow for axial movement of the shaft, which can help to reduce stress and increase the lifespan of the bearing. The design process involves using a calculator to determine the optimal shaft length based on various input parameters such as the diameter of the shaft, the length of the bearing, and the axial load applied to the shaft.

Floating Bearing Types and Applications

There are several types of floating bearings available, each with its own unique characteristics and applications. The most common types!of floating bearings include sleeve bearings, ovial bearings, and cylindrical bearings. Each type of bearing has its own advantages and disadvantages, and the choice of bearing type depends on the specific application and operating conditions. The calculator used to design the shaft length must take into account the specific type of bearing being used.

Factors Affecting Shaft Length Design

Several factors affect the design of the shaft length, including the diameter of the shaft, the length of the bearing, and the axial load applied to the shaft. The calculator used to design the shaft length must take into account these factors to ensure that the shaft can withstand the stresses and loads applied to it. Other factors that can affect the design of the shaft length include the material used to make the shaft, the operating temperature, and the environmental conditions.

Calculator Inputs and Outputs

The calculator used to design the shaft length requires several input parameters, including the diameter of the shaft, the length of the bearing, and the axial load applied to the shaft. The calculator then uses these input parameters to calculate the optimal shaft length and other output parameters such as the stress and deflection of the shaft. The output parameters can be used to evaluate the performance of the shaft and make any necessary adjustments to the design.

Design Example and Results

The following table shows an example of how to use the calculator to design a shaft length:

| Input Parameter | Value |

|---|---|

| Diameter | 50 mm |

| Length | 200 mm |

| Axial Load | 1000 N |

| Output Parameter | Value |

| Optimal Shaft Length | 250 mm |

| Stress | 50 MPa |

| Deflection | 0.1 mm |

The results show that the optimal shaft length is 250 mm, and the stress and deflection of the shaft are within acceptable limits. The calculator can be used to evaluate the performance of the shaft and make any necessary adjustments to the design. The floating bearing and shaft length design are critical components of rotating machinery, and the calculator is an essential tool for ensuring that these components are designed to meet the required specifications and performance criteria. Design and calculation of the shaft length are crucial to ensure the reliability and efficiency of the machinery.

What is the spacing between bearings on a shaft?

The spacing between bearings on a shaft is a critical factor in the design and functionality of rotating equipment. The distance between bearings can affect the stability, vibration, and overall performance of the shaft. Proper spacing is essential to ensure the bearings can operate efficiently and effectively, reducing the risk of premature wear and failure.

Importance of Bearing Spacing

The spacing between bearings is crucial because it can impact the dynamic behavior of the shaft. When bearings are too close together, it can lead to overconstraint, causing the shaft to become stiff and rigid, which can result in increased stress and vibration. On the other hand, when bearings are too far apart, it can lead to underconstraint, causing the shaft to become flexible and prone to deflection, which can result in reduced stability and increased wear. Key considerations for bearing spacing include:

- Shaft diameter and length to determine the optimal bearing spacing

- Bearing type and size to ensure proper fit and function

- Load capacity and operating conditions to determine the required bearing spacing

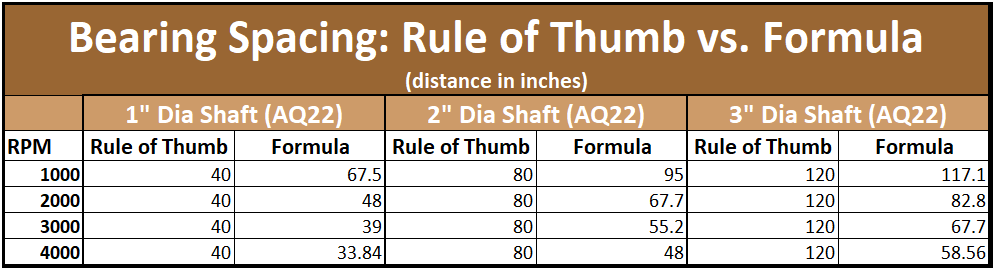

Bearing Spacing Calculations

To determine the optimal bearing spacing, engineers use various calculations and formulas. These calculations take into account the shaft geometry, bearing characteristics, and operating conditions. The L10 life of the bearings, which is the life at which 90% of the bearings are expected to survive, is also an important factor in determining the bearing spacing. Key calculations for bearing spacing include:

- Shaft deflection and slope to determine the bending moment and stress

- Bearing load and capacity to determine the required bearing spacing

- Shaft critical speed to determine the whirling and vibration characteristics

Types of Bearing Spacing

There are various types of bearing spacing, including overhung, between, and face-to-face configurations. Each type of spacing has its own advantages and disadvantages, and the choice of spacing depends on the specific application and requirements. Key considerations for bearing spacing types include:

- Overhung bearings are used in applications where the shaft is cantilevered or overhung

- Between bearings are used in applications where the shaft is supported at both ends

- Face-to-face bearings are used in applications where the bearings are mounted in a back-to-back configuration

Effects of Bearing Spacing on Shaft Performance

The spacing between bearings can significantly impact the performance of the shaft. Proper bearing spacing can reduce vibration, improve stability, and increase the life of the bearings. On the other hand, improper bearing spacing can lead to premature wear, increased maintenance, and reduced efficiency. Key effects of bearing spacing on shaft performance include:

- Vibration reduction through proper bearing spacing and alignment

- Stability improvement through optimal bearing spacing and shaft design

- Increased bearing life through proper bearing spacing and lubrication

Design Considerations for Bearing Spacing

When designing a shaft with bearings, there are several considerations that must be taken into account. These include the shaft material, bearing type, and operating conditions. The design must also consider the manufacturing and assembly processes to ensure that the bearings are properly aligned and spaced. Key design considerations for bearing spacing include:

- Shaft material selection to ensure strength and durability

- Bearing selection to ensure proper fit and function

- Operating condition consideration to ensure safe and efficient operation

How to support a rotating shaft?

To support a rotating shaft, it is essential to consider the bearings, seals, and lubrication systems that will be used. A well-designed support system can help to reduce vibration, noise, and wear on the shaft, while also increasing its overall efficiency and reliability. The type of support system used will depend on the specific application, including the speed, load, and environment in which the shaft will be operating.

Types of Shaft Supports

The type of shaft support used will depend on the specific application. Some common types of shaft supports include sleeve bearings, ball bearings, and roller bearings. Each type of bearing has its own advantages and disadvantages, and the choice of which one to use will depend on the speed, load, and environment in which the shaft will be operating.

- Sleeve bearings are simple and inexpensive, but they can be prone to wear and tear

- Ball bearings are more efficient and reliable, but they can be more expensive

- Roller bearings are designed for high load applications and can provide a high level of support and stability

Shaft Alignment and Positioning

Proper shaft alignment and positioning are critical to ensuring the smooth operation of a rotating shaft. If the shaft is not properly aligned, it can lead to vibration, noise, and wear on the bearings and other components. To achieve proper alignment, the shaft should be carefully positioned and secured using a combination of bearings, seals, and mounting hardware.

- The shaft should be carefully inspected for any signs of wear or damage

- The bearings and seals should be properly installed and aligned

- The mounting hardware should be securely fastened to prevent any movement or vibration

Bearing Selection and Installation

The selection and installation of bearings is a critical step in supporting a rotating shaft. The type of bearing used will depend on the specific application, including the speed, load, and environment in which the shaft will be operating. Proper installation of the bearings is also essential to ensure smooth operation and to prevent vibration, noise, and wear.

- The bearings should be carefully selected based on the specific application

- The bearings should be properly installed and aligned

- The bearings should be regularly inspected and maintained to ensure smooth operation

Lubrication and Maintenance

Proper lubrication and maintenance are essential to ensuring the smooth operation of a rotating shaft. The type of lubricant used will depend on the specific application, including the speed, load, and environment in which the shaft will be operating. Regular maintenance is also necessary to prevent vibration, noise, and wear on the bearings and other components.

- The lubricant should be carefully selected based on the specific application

- The lubricant should be regularly applied to ensure smooth operation

- The shaft and bearings should be regularly inspected and maintained to prevent wear and tear

Shaft Materials and Coatings

The materials and coatings used for the shaft can also play a critical role in its performance and reliability. The type of material used will depend on the specific application, including the speed, load, and environment in which the shaft will be operating. Coatings can also be applied to the shaft to provide additional protection and lubrication.

- The material should be carefully selected based on the specific application

- The coating should be carefully applied to ensure smooth operation

- The shaft and bearings should be regularly inspected and maintained to prevent wear and tear

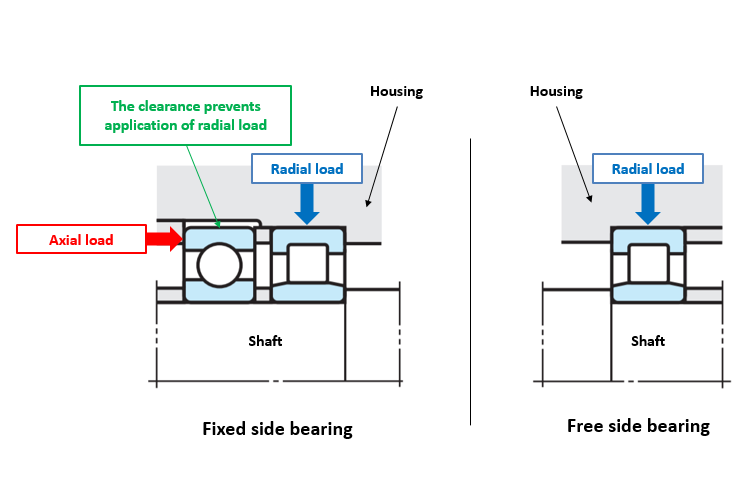

Where is the fixed bearing located?

The fixed bearing is typically located in a position that allows it to provide stable and consistent support to the rotating parts of a machine or mechanism. In most cases, it is situated at a fixed point, such as a housing or a mounting bracket, which provides a rigid base for the bearing to operate.

Location in Mechanical Systems

In mechanical systems, the fixed bearing is usually located at a point where it can provide maximum support and stability to the moving parts. This can be at the base of a shaft or axle, or at a junction where two or more moving parts meet. The location of the fixed bearing is critical to the overall performance and efficiency of the system, as it helps to reduce friction and wear on the moving parts.

- The fixed bearing is typically located at a fixed point, such as a housing or a mounting bracket.

- The location of the fixed bearing is critical to the overall performance and efficiency of the system.

- The fixed bearing helps to reduce friction and wear on the moving parts.

Types of Fixed Bearings

There are several types of fixed bearings, each with its own unique characteristics and applications. Some common types of fixed bearings include ball bearings, roller bearings, and sleeve bearings. Each type of fixed bearing is designed to provide specific benefits, such as high load capacity, low friction, or high speed capability.

- Ball bearings are commonly used in high-speed applications.

- roller bearings are often used in heavy-duty applications.

- Sleeve bearings are typically used in low-speed applications.

Design Considerations

When designing a fixed bearing, there are several factors to consider, including the type of load that the bearing will support, the speed at which the bearing will operate, and the environment in which the bearing will be used. The design of the fixed bearing must also take into account the materials and manufacturing processes that will be used to produce the bearing.

- The design of the fixed bearing must consider the type of load that the bearing will support.

- The design of the fixed bearing must also consider the speed at which the bearing will operate.

- The design of the fixed bearing must take into account the environment in which the bearing will be used.

Installation and Maintenance

The installation and maintenance of a fixed bearing are critical to its performance and longevity. The bearing must be properly aligned and secured to the shaft or housing, and it must be regularly inspected and maintained to ensure that it continues to function smoothly and efficiently.

- The fixed bearing must be properly aligned and secured to the shaft or housing.

- The fixed bearing must be regularly inspected and maintained to ensure that it continues to function smoothly and efficiently.

- The fixed bearing must be replaced periodically to prevent wear and damage to the surrounding components.

Common Applications

Fixed bearings are commonly used in a wide range of applications, including industrial machinery, automotive systems, and aerospace engineering. They are also used in consumer products, such as appliances and power tools. The fixed bearing is an essential component in many machines and mechanisms, and it plays a critical role in ensuring their smooth and efficient operation.

- Fixed bearings are commonly used in industrial machinery.

- Fixed bearings are often used in automotive systems.

- Fixed bearings are typically used in aerospace engineering.

How does the bearing flat attach to the design?

The bearing flat is a crucial component in the design of various mechanical systems, including rotating equipment and linear motion systems. It is a flat surface on a bearing or a shaft that provides a stable and secure attachment point for other components. The bearing flat attaches to the design through various methods, including mechanical fastening, adhesive bonding, and welding. The choice of attachment method depends on the specific requirements of the application, including the load capacity, speed, and environmental conditions.

Design Considerations for Bearing Flat Attachment

The design of the bearing flat attachment requires careful consideration of several factors, including the material properties, surface finish, and dimensional tolerances. The bearing flat must be designed to withstand the stresses and strains imposed by the attached components, as well as any external forces or moments. The attachment method must also be compatible with the operating conditions, including temperature, humidity, and vibration. Some key considerations for bearing flat attachment include:

- Material selection: The bearing flat and attached components must be made from materials that are compatible with each other and the operating conditions.

- Surface preparation: The bearing flat surface must be prepared to ensure a secure attachment, including cleaning, deburring, and surface finishing.

- Dimensional tolerancing: The bearing flat and attached components must be designed to meet strict dimensional tolerances to ensure a secure and precise attachment.

Types of Bearing Flat Attachment Methods

There are several types of bearing flat attachment methods, including mechanical fastening, adhesive bonding, and welding. Each method has its own advantages and disadvantages, and the choice of method depends on the specific requirements of the application. Mechanical fastening methods include bolting, screwing, and riveting, while adhesive bonding methods include epoxy, acrylic, and cyanoacrylate. Welding methods include arc welding, resistance welding, and laser welding. Some key considerations for bearing flat attachment methods include:

- Load capacity: The attachment method must be able to withstand the loads and stresses imposed by the attached components.

- Speed: The attachment method must be able to withstand the speeds and accelerations of the attached components.

- Environmental conditions: The attachment method must be able to withstand the temperature, humidity, and vibration of the operating environment.

Bearing Flat Attachment in Rotating Equipment

In rotating equipment, the bearing flat attachment is critical to ensuring the smooth operation and long lifespan of the equipment. The bearing flat must be designed to withstand the centrifugal forces and gyroscopic effects imposed by the rotating components. The attachment method must also be compatible with the lubrication and cooling systems used in the equipment. Some key considerations for bearing flat attachment in rotating equipment include:

- Balance: The bearing flat and attached components must be balanced to ensure smooth operation and minimize vibration.

- Alignment: The bearing flat and attached components must be aligned to ensure proper load distribution and minimize wear.

- Lubrication: The bearing flat and attached components must be lubricated to reduce friction and wear.

Bearing Flat Attachment in Linear Motion Systems

In linear motion systems, the bearing flat attachment is critical to ensuring the smooth operation and precise movement of the system. The bearing flat must be designed to withstand the forces and moments imposed by the moving components. The attachment method must also be compatible with the guide systems and actuators used in the system. Some key considerations for bearing flat attachment in linear motion systems include:

- Guide system: The bearing flat and attached components must be guided to ensure precise movement and minimize play.

- Actuator: The bearing flat and attached components must be actuated to ensure smooth operation and precise control.

- Feedback system: The bearing flat and attached components must be monitored to ensure precise movement and smooth operation.

Best Practices for Bearing Flat Attachment

To ensure a secure and reliable bearing flat attachment, several best practices must be followed, including proper material selection, surface preparation, and dimensional tolerancing. The attachment method must also be compatible with the operating conditions and environmental factors. Some key considerations for bearing flat attachment best practices include:

- Material testing: The bearing flat and attached components must be tested to ensure compatibility and reliability.

- Surface inspection: The bearing flat surface must be inspected to ensure cleanliness, flatness, and surface finish.

- Dimensional verification: The bearing flat and attached components must be verified to ensure dimensional accuracy and tolerancing.

Frequently Asked Questions (FAQs)

What is the importance of considering the shaft length in the design of a floating bearing?

The shaft length is a critical factor in the design of a floating bearing as it directly affects the stability and performance of the bearing. A floating bearing is designed to allow for axial movement of the shaft, which can help to reduce stress and wear on the bearing. However, if the shaft length is not properly considered, it can lead to oscillations or vibrations in the shaft, which can negatively impact the overall performance of the system. By carefully considering the shaft length and designing the floating bearing accordingly, engineers can help to ensure smooth operation and longer lifespan of the bearing.

How does the calculator for floating bearing shaft length design work?

The calculator for floating bearing shaft length design is a tool that uses complex algorithms and formulas to determine the optimal shaft length for a given floating bearing design. The calculator takes into account various parameters such as the bearing type, shaft diameter, axial load, and operating speed, and uses this information to calculate the optimal shaft length that will provide the best performance and stability for the bearing. The calculator can also be used to evaluate different design scenarios and optimize the shaft length for specific applications. By using the calculator, engineers can save time and reduce errors in the design process, and ensure that the floating bearing is designed to meet the specific requirements of the application.

What are the key factors to consider when designing a floating bearing shaft length?

When designing a floating bearing shaft length, there are several key factors to consider. One of the most important factors is the type of bearing being used, as different types of bearings have different design requirements. The shaft diameter and material are also critical factors, as they can affect the stiffness and strength of the shaft. Additionally, the axial load and operating speed of the bearing must be considered, as they can impact the performance and life expectancy of the bearing. Other factors to consider include the -clearance between the shaft and the bearing, the surface finish of the shaft, and the environmental conditions in which the bearing will operate. By carefully considering these key factors, engineers can design a floating bearing shaft length that meets the specific requirements of the application and provides optimal performance and reliability.

How can a calculator for floating bearing shaft length design help optimize bearing performance?

A calculator for floating bearing shaft length design can help optimize bearing performance in several ways. First, the calculator can help engineers to determine the optimal shaft length for a given floating bearing design, which can help to reduce stress and wear on the bearing. The calculator can also be used to evaluate different design scenarios and optimize the shaft length for specific applications. Additionally, the calculator can help engineers to identify potential design flaws and make adjustments to the design before prototyping or manufacturing the bearing. By using the calculator to optimize the shaft length, engineers can help to improve the overall performance of the bearing, reduce maintenance costs, and extend the life expectancy of the bearing. Overall, the calculator is a valuable tool for engineers designing floating bearings, and can help to ensure that the bearing is designed to meet the specific requirements of the application.

Deja una respuesta

Entradas Relacionadas